Silicon Carbide Bricks: The Cornerstone of High-Temperature Industrial Applications

Share

In the demanding world of high-temperature industrial processes, the reliability and performance of refractory materials are paramount. Among the advanced technical ceramics available, silicon carbide (SiC) bricks stand out for their exceptional properties, making them an indispensable component in a multitude of critical applications. From lining massive industrial furnaces to constructing durable kiln furniture, SiC bricks offer a unique combination of thermal stability, mechanical strength, and resistance to harsh chemical environments. For engineers, procurement managers, and technical buyers in sectors like semiconductors, high-temperature processing, aerospace, energy, and industrial manufacturing, understanding the nuances of silicon carbide bricks is key to optimizing operational efficiency and longevity of equipment. This blog post delves into the world of SiC bricks, exploring their applications, advantages, design considerations, and how to choose the right supplier for your custom needs, with a special focus on the expertise offered by Sicarb Tech.

Introduction to Silicon Carbide Bricks: What Are SiC Bricks and Why Are They Indispensable?

Silicon carbide (SiC) is a synthetic compound of silicon and carbon, renowned for its extreme hardness, high thermal conductivity, and excellent resistance to heat and chemical attack. Silicon carbide bricks are refractory shapes manufactured primarily from SiC grains, bonded together through various methods to create a robust, high-performance ceramic. These bricks are not your ordinary construction bricks; they are engineered materials designed to withstand some of the most extreme conditions found in industrial settings.

The indispensability of SiC bricks stems from their ability to maintain structural integrity and performance at temperatures where many other materials would fail. This makes them essential for applications involving direct exposure to high heat, rapid temperature changes (thermal shock), abrasive materials, and corrosive atmospheres. Industries rely on custom SiC refractory solutions to enhance process efficiency, reduce downtime, and improve the overall quality of their end products. Whether it’s for industrial furnace linings, kiln construction, or specialized thermal processing equipment, SiC bricks provide a reliable barrier against thermal and chemical degradation, ensuring the longevity and safety of these critical assets. The demand for high-performance SiC bricks is consistently driven by the need for materials that can push the boundaries of temperature and durability in modern manufacturing.

Sicarb Tech, situated in Weifang City, the hub of China’s silicon carbide customizable parts manufacturing, has been a pivotal force since 2015. Leveraging the robust scientific and technological capabilities of the Chinese Academy of Sciences , SicSino has been instrumental in advancing SiC production technology, assisting local enterprises in achieving large-scale production and significant technological advancements. This rich heritage and expertise make SicSino a leading authority in the realm of customized silicon carbide components, including high-quality SiC bricks.

Key Industrial Applications of SiC Bricks

The exceptional properties of silicon carbide bricks make them suitable for a wide array of demanding industrial applications. Their ability to withstand extreme temperatures, resist abrasion and corrosion, and maintain high strength at elevated temperatures makes them a preferred choice for engineers and procurement specialists in various sectors.

Here are some of the key industrial applications:

- Iron and Steel Industry:

- Blast Furnace Linings: Used in high-wear areas of blast furnaces due to their excellent abrasion resistance and resistance to molten metal and slag.

- Torpedo Ladles and Steel Ladles: Lining parts that require high thermal shock resistance and chemical inertness.

- Reheating Furnaces: As hearth materials and skid rails due to their high hot strength and resistance to scaling.

- Non-Ferrous Metallurgy:

- Aluminum Smelting: Used in electrolytic cells (Hall-Héroult process) due to their electrical conductivity (in specific grades) and resistance to molten aluminum and cryolite.

- Copper, Zinc, and Lead Smelting: Lining converters, refining furnaces, and launders where high temperatures and corrosive slags are present.

- Ceramics and Glass Industry:

- Kiln Furniture: As shelves, posts, and supports in firing sanitaryware, tiles, and technical ceramics due to their high hot strength, thermal shock resistance, and ability to prevent contamination. SiC refractory bricks are essential here.

- Glass Melting Furnaces: In areas like ports, regenerators, and tank superstructure where resistance to high temperatures and corrosive vapors from molten glass is critical.

- Chemical and Petrochemical Industry:

- Incinerators: Lining waste incinerators (municipal, industrial, hazardous) due to their resistance to high temperatures, thermal cycling, and corrosive flue gases.

- Reactors and Process Vessels: In applications requiring resistance to specific corrosive chemicals at high temperatures.

- Power Generation and Energy:

- Waste-to-Energy Plants: Similar to incinerators, SiC bricks handle aggressive environments.

- Boiler Linings: In certain types of industrial boilers, particularly those burning abrasive fuels or waste materials.

- Cement Industry:

- Rotary Kilns: In specific zones where high abrasion and thermal shock resistance are needed.

- Foundries:

- Lining induction furnaces and crucibles for melting various metals.

The versatility of industrial SiC bricks means they are often custom-designed to meet the specific operational conditions of each application. This includes variations in brick shape, size, chemical composition, and bonding system. Sicarb Tech excels in providing such custom SiC solutions, drawing upon their deep understanding of material science and the specific challenges faced by these industries. Their support has enabled numerous enterprises in Weifang, a region accounting for over 80% of China’s SiC output, to upgrade their processes and product quality.

| Industry Vertical | Common Applications of SiC Bricks | Key SiC Properties Utilized |

|---|---|---|

| Iron & Steel | Blast furnaces, torpedo ladles, reheating furnaces | Abrasion resistance, hot strength, chemical inertness |

| Non-Ferrous Metallurgy | Aluminum electrolytic cells, copper converters, zinc roasters | Chemical resistance, thermal shock resistance |

| Ceramics & Glass | Kiln furniture, glass tank linings, regenerators | High hot strength, thermal shock, non-contaminating |

| Chemical & Petrochemical | Incinerators, chemical reactors | Corrosion resistance, high-temperature stability |

| Power Generation | Waste-to-energy plants, boiler components | Abrasion resistance, thermal cycling resistance |

| Cement | Rotary kiln sections | Abrasion resistance, thermal shock resistance |

This table highlights the diverse utility of SiC refractory shapes across major industrial segments, underscoring their importance as a critical technical ceramic for high-temperature environments.

Advantages of Custom Silicon Carbide Bricks

Choosing custom silicon carbide bricks over standard refractory options or even other advanced ceramics offers a range of compelling advantages, particularly for applications with unique or severe operating conditions. Customization allows for the optimization of material properties and brick design to precisely match the demands of the industrial process, leading to improved performance, longer service life, and reduced operational costs.

Key benefits of opting for custom SiC bricks include:

- Optimized Thermal Performance:

- Superior Thermal Shock Resistance: SiC has a relatively low coefficient of thermal expansion and high thermal conductivity, which combine to give it excellent resistance to cracking or spalling during rapid temperature changes. Custom grades can further enhance this property based on the expected thermal cycling.

- High Hot Strength and Creep Resistance: Silicon carbide maintains significant mechanical strength even at very high temperatures (up to 1400−1650∘C or higher, depending on the grade). Customization can ensure the brick composition is designed to bear specific loads at operating temperatures without deforming.

- Tailored Thermal Conductivity: While generally high, the thermal conductivity can be influenced by the SiC grade and porosity. Custom bricks can be designed for optimal heat transfer or insulation depending on the application’s needs, crucial for furnace thermal management.

- Exceptional Wear and Abrasion Resistance:

- Silicon carbide is one of the hardest commercially available materials, second only to diamond and boron carbide. This makes wear-resistant SiC bricks ideal for applications involving the movement of abrasive solids, such as in chutes, hoppers, cyclone liners, and certain areas of kilns and furnaces. Customization can focus on maximizing hardness and density for these demanding environments.

- Excellent Chemical Stability and Corrosion Resistance:

- SiC is highly resistant to a wide range of acids, alkalis, and molten salts. Corrosion-resistant SiC components are vital in chemical processing, non-ferrous metal production, and waste incineration. Custom formulations can target resistance to specific corrosive agents present in an industrial process.

- Resistance to Oxidation: While SiC can oxidize at very high temperatures to form a protective silica (SiO2) layer, custom grades can be engineered with additives or specific microstructures to enhance oxidation resistance for prolonged high-temperature exposure in oxidizing atmospheres.

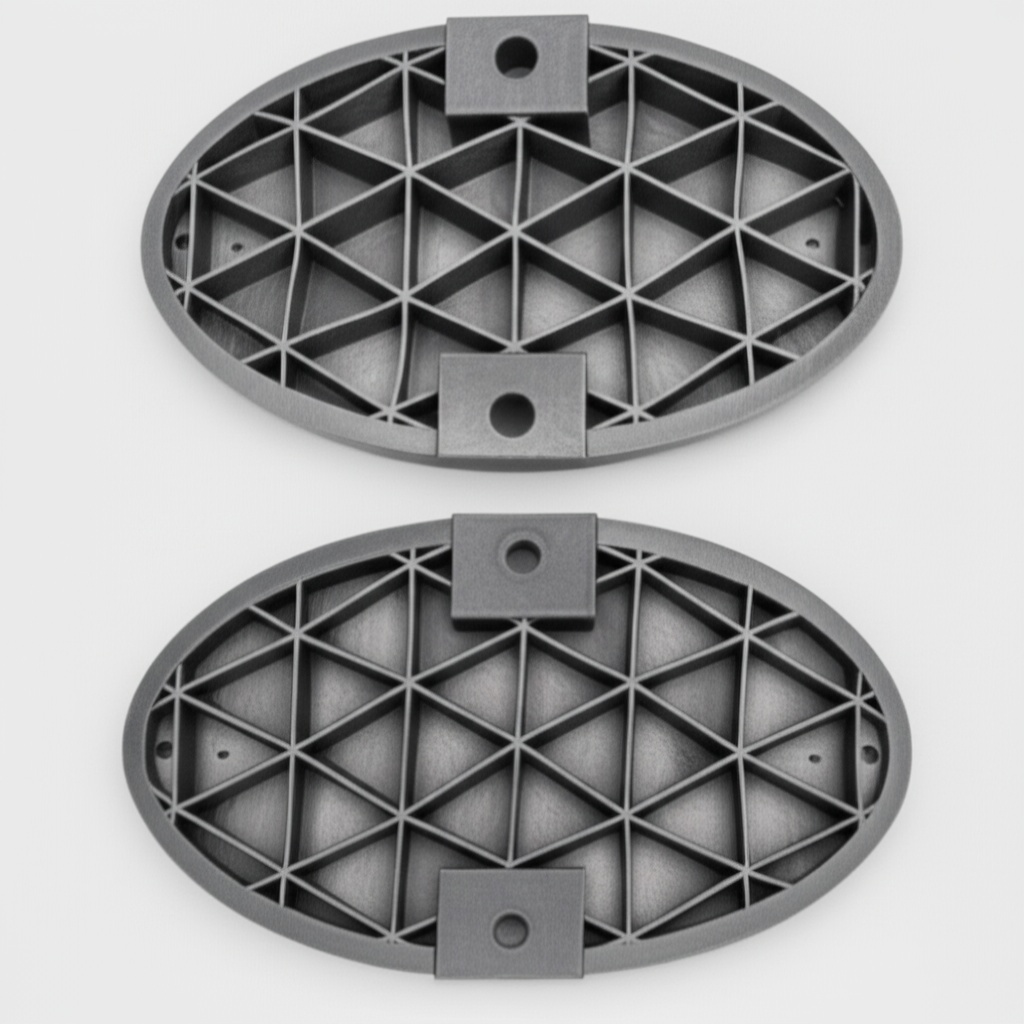

- Design Flexibility for Complex Geometries:

- Custom manufacturing allows for the production of SiC bricks in complex shapes, sizes, and interlocking designs. This is crucial for creating stable and efficient furnace linings, intricate kiln furniture setups, or specialized components that standard brick shapes cannot accommodate. This leads to precision SiC refractory installations.

- Improved Energy Efficiency:

- The high thermal conductivity of some SiC grades can lead to more uniform temperature distribution and faster heat-up times in furnaces, potentially reducing energy consumption. Custom designs can optimize this aspect.

- Longer Service Life and Reduced Downtime:

- By tailoring the brick properties to the specific application, custom SiC bricks generally offer a longer service life compared to generic refractories. This translates to less frequent relining or replacement, significantly reducing maintenance costs and production downtime. This is a key driver for wholesale SiC refractory procurement.

- Cost-Effectiveness in the Long Run:

- While the initial investment for custom SiC bricks might be higher than for conventional refractories, their extended lifespan, reduced maintenance needs, and potential energy savings often result in a lower total cost of ownership.

Sicarb Tech, with its robust backing from the Chinese Academy of Sciences National Technology Transfer Center and a top-tier professional team, specializes in customized production of silicon carbide products. They possess a wide array of technologies encompassing material science, process engineering, design, and metrology, enabling them to meet diverse customization needs for SiC bricks, ensuring optimal performance and reliability for their clients. Their expertise helps businesses select or design the ideal engineered SiC solutions for their specific industrial challenges.

Recommended SiC Grades and Types for Brick Manufacturing

Silicon carbide bricks are not a one-size-fits-all solution. They are manufactured using different types of SiC grains and bonding systems, resulting in various grades with distinct properties tailored for specific applications. Understanding these grades is crucial for selecting the most appropriate SiC refractory material for your needs.

Here are some common types of SiC bricks and their characteristics:

- Clay-Bonded Silicon Carbide Bricks:

- Description: These bricks are made by bonding SiC grains with refractory clays (like kaolin or ball clay) and then firing them at high temperatures. They typically contain 75-85% SiC.

- Properties: Good thermal shock resistance, moderate hot strength, and good abrasion resistance. They are generally more economical than other SiC brick types.

- Applications: Muffle furnaces, general-purpose kiln linings, incinerator linings where conditions are not overly severe.

- Considerations: The presence of clay can limit their maximum service temperature and resistance to certain chemical attacks compared to purer SiC grades.

- Nitride-Bonded Silicon Carbide (NBSC) Bricks:

- Description: These bricks utilize a silicon nitride (Si3N4) bond, formed in-situ by nitriding silicon metal powder mixed with SiC grains in a nitrogen atmosphere at high temperatures.

- Properties: Excellent thermal shock resistance, very good hot strength and creep resistance, high thermal conductivity, and good resistance to molten metals like aluminum and cryolite.

- Applications: Aluminum industry (electrolytic cells, cast houses), blast furnace linings, kiln furniture, and applications requiring high strength at elevated temperatures. High-strength SiC bricks often fall into this category.

- Oxide-Bonded Silicon Carbide Bricks:

- Description: Similar to clay-bonded but may use other oxide bonding agents for improved properties.

- Properties: Good thermal shock resistance, reasonable strength. Performance can vary widely based on the specific oxide system used.

- Applications: General furnace construction, areas with moderate wear and thermal loads.

- Reaction-Bonded Silicon Carbide (RBSiC or SiSiC) Bricks:

- Description: Also known as Silicon Infiltrated Silicon Carbide (SiSiC). These are produced by infiltrating a porous preform of SiC grains and carbon with molten silicon. The silicon reacts with the carbon to form new SiC, which bonds the original grains. They typically contain 8-15% free silicon.

- Properties: Very high strength (maintained up to the melting point of silicon, around 1410∘C), excellent abrasion and wear resistance, high thermal conductivity, and good thermal shock resistance. They are nearly impervious.

- Applications: High-wear applications such as cyclone liners, burner nozzles, kiln furniture, pump components, and applications requiring intricate shapes with tight tolerances. RBSiC refractory components are highly sought after for such uses.

- Sintered Silicon Carbide (SSiC) Bricks:

- Description: Made from very fine, high-purity SiC powder with sintering aids. They are fired at very high temperatures (over 2000∘C) in an inert atmosphere to achieve densification without a secondary bonding phase.

- Properties: Highest purity SiC, excellent corrosion resistance (even to strong acids and alkalis), superior hot strength, very good wear resistance, and good thermal shock resistance. They maintain strength at very high temperatures (up to 1650∘C or higher).

- Applications: The most demanding applications, including chemical processing, semiconductor manufacturing components, advanced kiln furniture, heat exchangers, and where extreme corrosion or temperature resistance is needed. Sintered SiC refractories represent the premium end of the market.

- Recrystallized Silicon Carbide (RSiC) Bricks:

- Description: Made by firing high-purity SiC grains at very high temperatures, causing the grains to bond directly to each other without any secondary phase. They are typically porous.

- Properties: Excellent thermal shock resistance due to porosity, very high service temperature (can exceed 1650∘C), and good chemical stability. Lower mechanical strength than SSiC or RBSiC at room temperature but retains strength well at high temperatures.

- Applications: Kiln furniture (beams, setters, plates) where thermal shock is a major concern, high-temperature furnace components.

The selection of the appropriate grade depends on a thorough analysis of the operating environment, including maximum temperature, thermal cycling conditions, chemical atmosphere, and mechanical stresses.

| SiC Brick Type | Typical SiC Content | Key Characteristics | Common Uses | Max Service Temp (approx.) |

|---|---|---|---|---|

| Clay-Bonded SiC | 75-85% | Economical, good thermal shock resistance, moderate strength | Muffle furnaces, general kiln linings | 1300−1450∘C |

| Nitride-Bonded SiC (NBSC) | 70-90% | Excellent thermal shock, good hot strength, molten metal resistance | Aluminum industry, blast furnaces, kiln furniture | 1400−1550∘C |

| Reaction-Bonded SiC (RBSiC/SiSiC) | 85-92% SiC + Free Si | Very high strength, excellent wear resistance, high thermal conductivity, impervious | High-wear areas, burner nozzles, complex shapes | 1350−1380∘C |

| Sintered SiC (SSiC) | >98% | Highest purity, excellent corrosion & wear resistance, superior hot strength | Extreme environments, chemical processing, semiconductor, advanced kiln furniture | 1600−1700∘C |

| Recrystallized SiC (RSiC) | >99% | Excellent thermal shock, very high service temp, porous | Kiln furniture (beams, plates), high-temp furnace parts | 1650−1750∘C |

Sicarb Tech offers a comprehensive range of these SiC grades and works closely with clients to identify the optimal SiC material specification for their brick applications. Their connection to the Chinese Academy of Sciences (Weifang) Innovation Park ensures access to cutting-edge material science and manufacturing processes, delivering high-quality SiC bricks that meet stringent performance requirements.

Design and Engineering Considerations for SiC Brick Installations

The successful application of silicon carbide bricks goes beyond just selecting the right material grade; it heavily relies on proper design and engineering of the installation. Whether it’s a furnace lining, a kiln car superstructure, or a complex refractory structure, careful consideration of various factors is essential to maximize performance and lifespan.

Key design and engineering aspects include:

- Brick Shapes and Sizes:

- Standard brick shapes (straights, arches, wedges, keys) are commonly used, but custom SiC shapes are often required for optimal fit-up, especially in complex geometries or to minimize joints.

- The size of the bricks can influence thermal stability and installation efficiency. Larger bricks can reduce the number of joints but may be more susceptible to thermal stress if not properly designed.

- Interlocking Designs:

- For enhanced structural stability, especially in furnace roofs, arches, and walls subjected to mechanical stress, interlocking brick designs (e.g., tongue-and-groove) are highly beneficial. These designs help to keep bricks in place, prevent joint opening, and maintain a tighter seal. Engineered SiC refractory linings often incorporate such features.

- Mortar Selection:

- The choice of mortar is critical. It must be chemically compatible with the SiC bricks and the operating environment.

- The mortar should have thermal expansion characteristics similar to the SiC bricks to prevent stress concentrations at the joints.

- High-purity SiC mortars or specialized refractory cements are often used. The mortar joint thickness should be minimized while ensuring complete bonding.

- Thermal Expansion Management:

- Silicon carbide, like all materials, expands upon heating. Proper provision for thermal expansion is crucial to prevent compressive stresses that could lead to cracking or structural failure.

- Expansion joints, filled with compressible ceramic fiber or other suitable materials, must be strategically placed within the brickwork. The size and spacing of these joints depend on the overall dimensions of the structure, the SiC grade, and the maximum operating temperature.

- Expert SiC installation services will always factor in detailed expansion calculations.

- Structural Support and Anchoring:

- Larger SiC brick structures, such as walls or roofs, may require metallic or ceramic anchoring systems to provide support and ensure stability, especially during heat-up and cool-down cycles.

- The design of these anchors must accommodate differential thermal expansion between the SiC bricks and the support structure.

- Thermal Gradient and Heat Flow Analysis:

- Understanding the thermal profile across the SiC brick lining is important. In some cases, backup insulation layers may be used behind the SiC hot face lining to reduce heat loss and protect the outer shell of the equipment.

- Finite Element Analysis (FEA) can be employed to model temperature distributions and stress concentrations in complex SiC brick assemblies, optimizing the design for thermal efficiency and structural integrity.

- Atmosphere Control and Gas Tightness:

- In applications involving controlled atmospheres or where gas leakage is a concern, the brick lining must be designed for maximum gas tightness. This often involves using impervious SiC grades like RBSiC or SSiC and ensuring well-sealed joints.

- Installation Quality:

- Even the best materials and design can fail if the installation is subpar. Skilled and experienced refractory masons are essential for proper bricklaying, jointing, and installation of expansion joints and anchors.

- Heat-Up and Cool-Down Schedules:

- Controlled heat-up and cool-down rates are critical, especially for new installations or after repairs. SiC bricks, despite their good thermal shock resistance, can be damaged by excessively rapid temperature changes. The equipment supplier or SiC brick manufacturer should provide recommended schedules.

Sicarb Tech, with its integrated process from materials to products and extensive design capabilities, provides invaluable support in these areas. They can assist clients in designing custom SiC brick solutions that consider all these engineering principles, ensuring optimal performance and durability. Their experience in diverse industrial applications allows them to anticipate potential challenges and incorporate design features that mitigate risks. For companies seeking turnkey SiC furnace solutions, SicSino’s expertise extends to the entire system design and implementation.

Achievable Tolerances, Surface Finish, and Quality Control in SiC Brick Production

The performance and ease of installation of silicon carbide bricks are significantly influenced by their dimensional accuracy, surface finish, and overall quality. Manufacturers of high-quality SiC refractories adhere to stringent quality control measures throughout the production process, from raw material selection to final inspection.

Dimensional Tolerances:

- The achievable dimensional tolerances for SiC bricks depend on the manufacturing method (e.g., pressing, casting, extrusion), the SiC grade, the size and complexity of the brick, and the level of post-firing machining.

- Pressed and fired bricks without machining typically have wider tolerances. Standard refractory brick tolerances might be in the range of ±1% to ±2% of the dimension, or a few millimeters.

- For applications requiring tighter fits, such as intricate kiln furniture assemblies or precision-lined reactors, machined SiC bricks can achieve much tighter tolerances, often in the range of ±0.5mm or even better for critical dimensions. RBSiC (SiSiC) and SSiC components, due to their manufacturing processes, can often be produced to net shape or near-net shape with good accuracy, or subsequently diamond ground for high precision.

- It’s important for buyers to clearly specify the required tolerances based on their application needs. Tighter tolerances generally increase manufacturing costs.

Surface Finish:

- The as-fired surface finish of SiC bricks can vary. Clay-bonded bricks might have a relatively rougher surface compared to the denser, finer-grained surfaces of SSiC or RBSiC.

- For most refractory lining applications, the as-fired surface is acceptable.

- However, in applications where smooth surfaces are critical (e.g., to prevent material hang-up, ensure cleanability, or for specific aerodynamic/fluid dynamic reasons), SiC bricks can be ground or lapped. This is more common for engineered SiC components than for bulk refractory bricks, but it is an available option.

- A typical surface roughness (Ra) for as-fired SiC might range from 3.2μm to 12.5μm. Ground surfaces can be much smoother, potentially below Ra=0.8μm.

Quality Control (QC) in Manufacturing:

A comprehensive QC program is essential for producing reliable SiC bricks. This typically involves:

- Raw Material Inspection: Verifying the purity, particle size distribution, and chemistry of incoming SiC grains, bonding agents, and other additives.

- Process Control: Monitoring and controlling critical manufacturing parameters such as mixing, forming pressures, drying conditions, and firing temperatures and atmospheres.

- Dimensional Checks: Measuring brick dimensions at various stages (green, after firing, after machining if applicable) using calipers, gauges, CMMs (Coordinate Measuring Machines) for complex shapes.

- Physical Property Testing:

- Density and Porosity: Important for assessing densification and predicting performance.

- Strength Testing: Cold Crushing Strength (CCS), Modulus of Rupture (MOR) at room and elevated temperatures.

- Thermal Shock Resistance: Testing via water quench or air quench cycles.

- Abrasion Resistance: Testing using standard methods.

- Chemical Analysis: Verifying the final chemical composition, especially the SiC content and the nature of the bond phase.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing can sometimes be used to detect internal flaws or cracks in high-value or critically stressed components, although this is less common for standard bricks.

- Visual Inspection: Checking for cracks, chips, warping, or other surface defects.

Sicarb Tech, as a company deeply rooted in the technological advancements fostered by the Chinese Academy of Sciences, places a strong emphasis on quality. Their integrated process, from materials science through to product design, measurement, and evaluation technologies, ensures that their customized silicon carbide components, including bricks, meet high standards of quality and consistency. This commitment is crucial for industrial buyers and OEMs requiring reliable SiC solutions. Their support of over 10 local enterprises in Weifang to upgrade their production capabilities also underscores their commitment to a quality-driven SiC industry.

Procurement managers should always inquire about a supplier’s QC procedures and request test certificates or compliance reports for their SiC brick orders.

Addressing Common Challenges in SiC Brick Applications

While silicon carbide bricks offer exceptional performance in many high-temperature applications, users may encounter certain challenges. Understanding these potential issues and how to mitigate them is crucial for ensuring the longevity and efficiency of SiC refractory linings and structures.

- Brittleness and Susceptibility to Mechanical Impact:

- Challenge: SiC is a hard but brittle material, meaning it has low fracture toughness. This makes SiC bricks susceptible to chipping or cracking from mechanical impact during installation, maintenance, or due to operational upsets (e.g., falling charge material).

- Mitigation:

- Careful handling during transport and installation.

- Designing structures to minimize direct impact.

- Using tougher SiC grades (e.g., some NBSC or RBSiC formulations can offer slightly better impact resistance than highly pure SSiC).

- Incorporating protective layers or sacrificial elements in high-impact zones.

- Thermal Shock Failure (Spalling/Cracking):

- Challenge: Although SiC generally has excellent thermal shock resistance, extreme or improperly managed temperature changes can still lead to spalling (surface flaking) or cracking.

- Mitigation:

- Adhering to recommended heat-up and cool-down schedules provided by the equipment or brick manufacturer.

- Ensuring proper design of expansion joints.

- Selecting SiC grades with optimized thermal shock resistance for the specific application (e.g., RSiC or certain NBSC grades are particularly good).

- Avoiding direct impingement of cold air or water on hot SiC surfaces.

- Chemical Attack in Specific Environments:

- Challenge: While highly resistant, SiC can be attacked by certain aggressive chemicals under specific conditions:

- Strongly oxidizing atmospheres at very high temperatures: Can lead to accelerated formation of silica (SiO2), which can then react with other compounds.

- Molten alkali salts or slags: Can corrode SiC.

- Certain reactive gases: Like chlorine or fluorine at high temperatures.

- Mitigation:

- Selecting the appropriate SiC grade (e.g., high-purity SSiC offers the best overall chemical resistance).

- Controlling the process atmosphere where possible.

- Consulting with SiC experts like those at Sicarb Tech to assess chemical compatibility for unique environments.

- Challenge: While highly resistant, SiC can be attacked by certain aggressive chemicals under specific conditions:

- Oxidation of Free Silicon in RBSiC (SiSiC):

- Challenge: RBSiC contains free silicon, which can oxidize at temperatures above approximately 1300∘C if oxygen is present. This oxidation can lead to volumetric changes and strength degradation if not controlled. The maximum service temperature for RBSiC is generally limited by the melting point of silicon ( 1410∘C).

- Mitigation:

- Using RBSiC within its recommended temperature limits and atmospheric conditions.

- Considering SSiC or NBSC for applications with higher temperatures in oxidizing environments.

- Joint Degradation:

- Challenge: Mortar joints can sometimes be a weak point in a refractory lining, degrading faster than the bricks themselves due to chemical attack or thermal stress.

- Mitigation:

- Using high-quality, compatible SiC-based mortars.

- Ensuring proper installation with thin, tight joints.

- Designing with interlocking bricks to reduce reliance on mortar for structural integrity.

- Complexity in Machining and Installation:

- Challenge: Due to its hardness, cutting or modifying SiC bricks on-site can be difficult and requires specialized diamond tooling. Complex installations require skilled labor.

- Mitigation:

- Ordering pre-cut or custom-shaped bricks to minimize on-site modifications.

- Engaging experienced refractory installers familiar with SiC materials. Sicarb Tech can offer design support to ensure manufacturability and ease of assembly.

- Higher Initial Cost:

- Challenge: SiC bricks are generally more expensive than conventional aluminosilicate refractories.

- Mitigation:

- Focusing on the total cost of ownership (TCO). The longer service life, reduced downtime, and improved process efficiency of SiC can offset the higher initial investment.

- Strategic use of SiC only in the most critical areas where its properties are truly needed, potentially in combination with other refractories (zoned linings).

By anticipating these challenges and implementing appropriate mitigation strategies, users can fully leverage the benefits of advanced SiC refractory solutions. Partnering with knowledgeable suppliers like Sicarb Tech can provide valuable insights and technical support to overcome these hurdles, ensuring successful application of SiC bricks in even the most demanding industrial environments. Their expertise, built upon years of research and practical application within China’s SiC manufacturing hub, is a valuable asset for any technical buyer or engineer.

| Common Challenge | Potential Impact | Mitigation Strategies | Recommended SiC Focus |

|---|---|---|---|

| Brittleness/Mechanical Shock | Chipping, cracking, premature failure | Careful handling, design for impact resistance, protective layers | NBSC, some RBSiC variants |

| Thermal Shock | Spalling, cracking | Controlled heat-up/cool-down, proper expansion joints, select high thermal shock resistant grades | RSiC, NBSC |

| Chemical Attack | Corrosion, erosion, material degradation | Select appropriate grade (SSiC for highest resistance), control atmosphere, consult experts | SSiC, high-purity NBSC |

| RBSiC Silicon Oxidation | Strength loss, volumetric change at high temps | Operate within temp/atmosphere limits, consider alternatives for extreme oxidizing conditions above 1300∘C | SSiC for higher temps |

| Joint Degradation | Weak points, premature lining failure | Quality mortar, proper installation, interlocking designs | N/A (Installation focus) |

| Machining/Installation Diff. | Higher installation cost/time, improper fit-up | Order custom shapes, use experienced installers, design for manufacturability | Consult supplier (e.g., SicSino) |

| Higher Initial Cost | Budget constraints | Focus on TCO, strategic/zoned use, optimize grade selection | Value engineering with supplier |

Frequently Asked Questions (FAQ) about Silicon Carbide Bricks

Q1: What is the typical lifespan of silicon carbide bricks in a high-temperature furnace? A1: The lifespan of SiC bricks varies significantly based on several factors, including the specific SiC grade used, the operating temperature and thermal cycling frequency, the chemical environment (corrosive gases, molten materials), mechanical abrasion, furnace design, and installation quality. In well-suited applications with proper design and operation, SiC bricks can last anywhere from 1 to 10 years, and sometimes even longer. For example, NBSC or SSiC bricks in aluminum contact applications or as high-end kiln furniture can offer multi-year service. In contrast, in extremely aggressive environments or if an inappropriate grade is used, the life could be shorter. It’s best to consult with a SiC specialist like Sicarb Tech who can help estimate lifespan based on your specific process conditions.

Q2: Can silicon carbide bricks be used in direct contact with molten metals? A2: Yes, certain grades of silicon carbide bricks are well-suited for direct contact with many molten metals, particularly non-ferrous metals. Nitride-Bonded Silicon Carbide (NBSC) and Sintered Silicon Carbide (SSiC) are often preferred due to their excellent chemical inertness and resistance to wetting by molten metals like aluminum, zinc, copper, and their alloys. Reaction-Bonded Silicon Carbide (RBSiC) can also be used, but the free silicon content might be a concern with certain reactive metals. It’s crucial to select a grade that will not contaminate the melt or degrade rapidly. For instance, NBSC is widely used in aluminum melting and holding furnaces. Always verify compatibility with the specific molten metal and its temperature.

Q3: How do SiC bricks compare to other refractory materials like alumina or mullite bricks? A3: SiC bricks generally offer superior performance in several key areas compared to common alumina or mullite bricks: * Thermal Conductivity: SiC has significantly higher thermal conductivity, leading to more uniform temperature distribution and better thermal shock resistance. * Hot Strength: SiC maintains its strength at much higher temperatures. Alumina and mullite bricks tend to soften and creep at temperatures where SiC remains robust. * Abrasion Resistance: SiC is much harder and more abrasion-resistant. * Thermal Shock Resistance: Generally superior in SiC due to high thermal conductivity and moderate thermal expansion. * Cost: SiC bricks are typically more expensive upfront. Alumina and mullite bricks are excellent choices for many applications and are more cost-effective. However, when extreme temperatures, severe abrasion, high hot loads, or excellent thermal shock resistance are primary requirements, engineered SiC bricks often provide a longer service life and better overall value despite the higher initial cost. The choice depends on a careful analysis of the application’s demands and economics. Sicarb Tech can help evaluate whether SiC or another advanced ceramic is the optimal solution for your needs.

Q4: What are the primary cost drivers for custom silicon carbide bricks? A4: The main factors influencing the cost of custom SiC bricks include: * SiC Grade: High-purity grades like SSiC are more expensive than clay-bonded or some NBSC grades due to raw material purity and more complex manufacturing processes. * Complexity of Shape and Size: Intricate shapes, large monolithic pieces, or designs requiring tight tolerances necessitate more complex tooling and potentially post-firing machining (diamond grinding), which adds to the cost. * Order Volume: Larger production runs generally have lower per-unit costs due to economies of scale in tooling and manufacturing. * Tolerances and Finishing: Tighter dimensional tolerances and specialized surface finishes (e.g., grinding, lapping) increase processing time and thus cost. * Raw Material Costs: The price of SiC powder itself can fluctuate based on market conditions and purity. * Manufacturing Process: Different bonding and firing techniques (e.g., reaction bonding vs. sintering) have different energy and equipment requirements. Understanding these drivers can help in discussions with suppliers like Sicarb Tech to optimize designs for cost-effectiveness without compromising essential performance characteristics for your industrial SiC brick procurement.

Conclusion: The Enduring Value of Custom Silicon Carbide Bricks in Demanding Industries

Silicon carbide bricks are far more than mere refractory components; they are engineered solutions critical to the efficiency, reliability, and advancement of high-temperature industrial processes. Their exceptional combination of thermal stability, high hot strength, superior wear resistance, and chemical inertness makes them invaluable in industries ranging from metallurgy and ceramics to chemical processing and energy production. The ability to customize SiC bricks—tailoring their grade, shape, and properties to specific operational challenges—further amplifies their value, allowing engineers and procurement professionals to achieve optimized performance and extended service life for their critical equipment.

Choosing the right SiC brick and, just as importantly, the right supplier is paramount. A partner like Sicarb Tech, with its deep roots in the heart of China’s SiC manufacturing hub in Weifang and its strong affiliation with the Chinese Academy of Sciences, brings unparalleled expertise to the table. Their commitment to technological advancement, comprehensive customization capabilities, and focus on quality assurance make them an ideal choice for businesses seeking high-performance, cost-effective custom silicon carbide brick solutions. Whether you are sourcing components for existing applications or developing new technologies that push thermal and mechanical boundaries, Sicarb Tech offers not only top-tier products but also the technical collaboration needed to succeed. Furthermore, for entities looking to establish their own SiC production, SicSino’s technology transfer and turnkey project services provide a reliable pathway to self-sufficiency and innovation.

By investing in high-quality, custom-designed silicon carbide bricks, industries can look forward to enhanced productivity, reduced downtime, and a superior return on investment, ensuring their operations remain competitive and robust in the face of ever-increasing demands.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.