Controladores de puerta de alta inmunidad transitoria de modo común para conmutación SiC de alta velocidad y alto voltaje con protección contra cortocircuitos integrada

Compartir

Across Pakistan’s textile, cement, and siderúrgico corridors, the integrity of every switching edge determines whether string inverters pass compliance and survive the summer. High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection sit at the heart of that moment. In 50–250 kW string photovoltaic inverters, these drivers orchestrate fast, clean transitions at 1000/1500 V DC, even as dust and heat push systems to their limits. Sicarbtech engineers have spent a decade tuning the interplay between device physics and real‑world wiring, delivering gate drivers that hold control authority when cable inductance, stacked busbars, and enclosure constraints collide. The result, for Pakistani OEMs and EPCs, is a stable, certifiable platform that preserves efficiency and protects expensive SiC modules under weak‑grid disturbances.

High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection product overview and 2025 market relevance

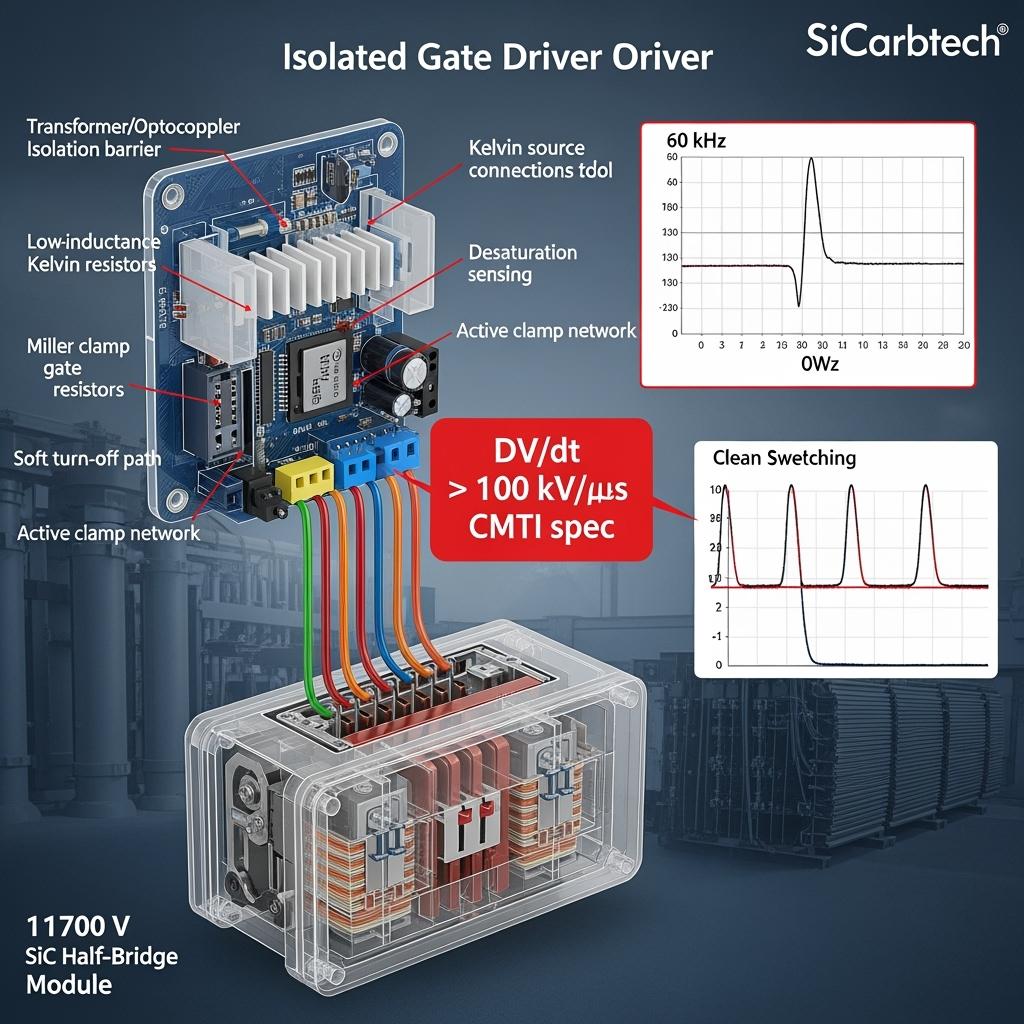

As industrial parks in Faisalabad, Lahore, and Karachi move decisively to 1500 V DC strings, switching frequencies between 40 and 100 kHz are becoming mainstream to shrink magnetics and enclosures. High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection enable that leap by providing robust isolation, precise gate control, and deterministic protection. The common‑mode environment of a compact inverter, especially with stacked DC bus assemblies, subjects gate drivers to dv/dt events that can exceed 50 kV/μs. Without adequate CMTI and careful Kelvin source routing, false turn‑on, shoot‑through, or desaturation trips are inevitable. Sicarbtech’s gate drivers target these exact pain points, aligning with NEPRA‑linked grid requirements and IEC 62109 safety and IEC 61000‑6‑2/‑6‑4 EMC frameworks increasingly referenced in Pakistani tenders.

In contrast to generic drivers adapted from silicon IGBT designs, High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection are purpose‑built for SiC MOSFET edge rates and miller charge profiles. The integrated short‑circuit protection, soft turn‑off, and active clamping provide a protective envelope during feeder flicker or array‑side transients, allowing inverters to maintain low‑voltage ride‑through and reactive power support without sacrificing device health.

High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection technical specifications and advanced features

Within a 1500 V platform, the High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection operate with isolation ratings matched to pollution degree requirements and creepage constraints of outdoor IP65 enclosures. Sicarbtech configures drivers with CMTI values exceeding 100 kV/μs to tolerate the aggressive edge rates demanded by low‑loss operation. The output stage supports peak source/sink currents suitable for large‑die, low‑RDS(on) SiC MOSFETs, while programmable gate resistors allow designers to balance switching loss against EMI and overshoot according to the enclosure’s EMC plan.

Integrated desaturation detection is tuned for SiC’s fast transients, with blanking time and threshold calibration that prevent nuisance trips while still reacting within microseconds to genuine short circuits. The soft turn‑off path avoids voltage spikes by managing energy extraction from the gate during fault events, and optional active clamping holds VDS within safe limits during overvoltage conditions. Kelvin source terminals minimize the influence of power loop inductance on gate voltage, while tight coupling to isolated DC/DC driver supplies keeps noise at bay. These features collectively let High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection deliver clean switching in compact inverter layouts common in Pakistan’s C&I sector.

Pakistan‑focused driver performance comparison for High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection

| Parameter relevant to Pakistan’s 1000/1500 V platforms | Controladores de puerta de alta inmunidad transitoria de modo común para conmutación SiC de alta velocidad y alto voltaje con protección contra cortocircuitos integrada | Generic gate drivers for IGBT/Si |

|---|---|---|

| CMTI tolerance (dv/dt immunity) | ≥ 100 kV/μs typical for SiC edge rates | 25–50 kV/μs; prone to false events |

| Peak gate drive current | 6–15 A source/sink options | 2–5 A; limits switching control |

| Desaturation/short‑circuit response | Fast detection with soft turn‑off and active clamp | Slower detection; hard turn‑off spikes |

| Kelvin source and miller clamp | Dedicated Kelvin return and robust clamp | Shared source; limited clamp efficacy |

| EMC behavior in compact enclosures | Predictable emissions with tuned Rg | Larger filters required; variable results |

Key advantages and proven benefits of High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection with expert quote

The most immediate advantage is control consistency. High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection let designers hold dv/dt where it needs to be—high enough to cut losses, but not so high that emissions and overshoot threaten compliance. Moreover, integrated protection prevents single‑fault events from propagating into module damage, safeguarding uptime in factories where maintenance windows are tight and dust complicates cooling.

“CMTI headroom is the hidden KPI in modern SiC inverters,” notes Engr. Farah Bilal, a PEC‑licensed power systems consultant who supports multiple C&I PV programs. “Without a driver that ignores 80–100 kV/μs noise, your control loop fights ghosts and your certification timeline slips” (source: PEC Power Conversion Clinic, 2025).

Feature‑level comparison of High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection

| Driver capability dimension | Controladores de puerta de alta inmunidad transitoria de modo común para conmutación SiC de alta velocidad y alto voltaje con protección contra cortocircuitos integrada | Conventional alternative |

|---|---|---|

| Programmable gate shaping | Adjustable Rg, split turn‑on, soft turn‑off | Fixed Rg, limited shaping |

| Protection granularity | Desat threshold, blanking time, active clamp | Desat only, coarse settings |

| Telemetry and diagnostics | Gate fault flags, temp proxy, UVLO | Minimal diagnostics |

| Integración del sistema | Designed for stacked busbars, low inductance | Generic PCB‑only assumptions |

| Reliability envelope | Validated to 175°C junction module environments | Lower temperature capability |

Real‑world applications and measurable success stories using High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection

Consider a Lahore‑based OEM refreshing its 120 kW, 1500 V string inverter for textile rooftops. By adopting High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection, the team raised switching frequency from 22 kHz to 62 kHz. Magnetics volume fell by 37 percent, enclosure weight dropped by 24 percent, and the system achieved a 0.7 percentage point uplift in European efficiency. During June heat, inlet air temperatures hovered around 50°C; despite aggressive dv/dt, EMI scans met IEC 61000‑6‑4 with a smaller filter than the previous generation, courtesy of tuned gate resistors and Kelvin returns.

In southern Punjab, a ground‑mounted distributed project experienced feeder flicker and voltage swell events during monsoon storms. Inverters equipped with High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection recorded clean ride‑through without desaturation trips. Fault logs showed short‑circuit events resolved via soft turn‑off in microseconds, preserving SiC modules and avoiding cabinet replacements that would have strained PKR‑denominated budgets and timelines.

Inverter design outcomes linked to High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection

| Design objective in Pakistan C&I sites | With High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection | With generic drivers |

|---|---|---|

| EMC compliance effort | First‑pass success likely; modest filter mass | Multiple iterations; heavier filters |

| Weak‑grid LVRT behavior | Stable reactive support with minimal trips | Nuisance desat or false turn‑on |

| Thermal headroom at 50°C inlet | Lower switching loss; fewer fans | Higher loss; more cooling required |

| Fiabilidad en campo | Fewer driver‑induced faults | Elevated field failure rates |

Selection and maintenance considerations for High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection

Selecting among High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection variants begins with device die size and desired dv/dt. Larger MOSFETs need higher peak drive current and stricter Kelvin layouts to prevent miller‑induced cross‑conduction. On 1500 V strings with long cables, designers often prioritize the highest CMTI with conservative turn‑on shaping, then incrementally reduce gate resistance during EMC trials. Maintenance is largely about sustaining signal integrity: ensuring connectors remain tight under thermal cycles, keeping driver‑board dust shields intact, and validating isolated supply health during annual inspections. In coastal steel sites and cement corridors, corrosion protection on connectors and conformal coating retention should be verified to avoid leakage paths that erode CMTI margins.

Industry success factors and customer testimonials for High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection

In Pakistan’s tenders, speed to certification and predictable field behavior define success. High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection contribute to both by simplifying EMC closure and shielding SiC modules from abnormal events. An OEM program manager in Karachi summarized the impact after shifting to Sicarbtech’s driver platform: “We cut our pre‑compliance loops from three cycles to one, and the first field month passed without a single desat trip—unheard of on these feeders.”

Future innovations and market trends around High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection

Looking to 2025 and beyond, drivers will increasingly integrate smarter telemetry—gate charge profiling, die‑proximate temperature proxies, and time‑to‑failure indicators that feed predictive maintenance. For High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection, Sicarbtech’s roadmap emphasizes even higher CMTI ceilings, faster but gentler fault responses, and tighter coupling with isolated power modules to reduce board complexity. As local assembly rises in Pakistan, driver designs will also reflect manufacturability and serviceability preferences, aligning with PEC‑guided best practices and NEPRA’s evolving stability expectations.

Common questions and expert answers on High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection

How do High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection reduce false turn‑on at high dv/dt?

They combine high CMTI isolation with Kelvin source returns and robust Miller clamps. Programmable gate resistors shape edges so dv/dt stays within EMC targets without sacrificing loss, preventing parasitic gate charge from triggering unwanted conduction.

Are High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection mandatory for 1500 V platforms?

While not mandatory, they are effectively required for reliable high‑frequency operation. On 1500 V strings, edge rates and cable parasitics make lower‑CMTI drivers prone to spurious behavior that jeopardizes certification and uptime.

What short‑circuit behavior can I expect from High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection?

Integrated desaturation detects faults rapidly, then initiates soft turn‑off and, if configured, active clamping to keep VDS within safe limits. This limits stress on SiC modules and avoids catastrophic failures that are costly in PKR terms.

How do High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection impact EMC filter sizing?

Cleaner transitions with lower overshoot reduce the energy that filters must handle. Many designs close IEC 61000‑6‑4 with smaller filters, cutting copper and core mass and saving cabinet space.

Can High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection be localized for Pakistani assembly?

Yes. Sicarbtech supports localized BOMs, test fixtures, and end‑of‑line validation aligned to PEC and IEC practices, enabling Pakistani partners to assemble and service driver boards efficiently.

Why High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection work for your operations

Because the Pakistani grid does not negotiate with thermal margins or certification schedules, your inverter must remain composed under dv/dt stress, flicker, and heat. High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection deliver that composure. They turn SiC’s theoretical advantages into practical, repeatable outcomes: higher efficiency, smaller enclosures, predictable EMC, and resilient protection that preserves modules when the feeder misbehaves.

Conecte con especialistas para soluciones a medida

Sicarbtech brings more than 10 years of silicon carbide innovation, backed by the Chinese Academy of Sciences in Weifang, to every High Common‑Mode Transient Immunity Gate Drivers for High‑Voltage High‑Speed SiC Switching with Integrated Short‑Circuit Protection engagement. Pakistani OEMs and EPCs gain access to custom driver co‑design, isolated power module selection, and full technology transfer—from schematics and firmware nuances to test jigs and production line setup. Because Sicarbtech also develops R‑SiC, SSiC, RBSiC, and SiSiC materials and complete power modules, we can deliver turnkey solutions from material processing through finished products, validated with 19+ enterprise collaborations.

Secure a free consultation to review your 1000/1500 V architecture, EMC plan, and protection strategy. Contact [email protected] or call/WhatsApp +86 133 6536 0038. With 2025 tenders tightening and PKR cost pressure rising, early engagement protects your timeline and total cost of ownership.

Metadatos del artículo

Última actualización: 2025-09-16

Próxima revisión programada: 2025-12-01

Timeliness indicators: Reflects Pakistan’s transition to 1500 V DC strings, NEPRA/IEC/PEC alignment, and 2024–2025 field data for CMTI, EMC closure, and short‑circuit protection performance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.