Chile’s Leading B2B Supplier of Custom Silicon Carbide Materials

Compartir

Sicarbtech — Silicon Carbide Solutions Expert

Executive Summary: 2025 Outlook for Custom Silicon Carbide in Chile’s Industrial Core

Chile enters 2025 with copper output stabilizing after weather-related disruptions, while decarbonization and water stewardship reshape industrial investment priorities. Mining operators, chemical suppliers to SX-EW, and energy infrastructure providers are converging on a single requirement: materials that preserve geometry, resist abrasion and chloride corrosion, and maintain efficiency between increasingly spaced shutdowns. In this context, custom silicon carbide (SiC) ceramics—R-SiC, SSiC, RBSiC, and SiSiC—are moving from tactical replacements to strategic standards across pumps, cyclones, valves, thermal equipment, and high-temperature fixtures.

Sicarbtech, located in Weifang City—China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings more than a decade of SiC customization, full-cycle manufacturing, and turnkey technology transfer. With 19+ enterprise collaborations, the company supports Chilean operators with engineered components, ISO-ready documentation, and factory establishment services that localize supply chains. Furthermore, CLP-sensitive cost modeling, REACH/RoHS documentation, and alignment with DS 594 occupational health requirements streamline audits while quantifiably improving MTBF, leakage rates, and energy per ton processed.

Industry Challenges and Pain Points Across Chile’s Mining, Chemical, and Energy Sectors

Chile’s copper mining ecosystem faces abrasive slurries and chloride-rich waters simultaneously. Concentrators moving to HPGR and finer grinds generate angular particles that accelerate micro-cutting on pump impellers and volute inserts, while seawater-makeup circuits in Antofagasta and Tarapacá raise chloride levels that pit duplex siderúrgicos and undermine rubber linings. Hydrocyclone liners lose geometry quickly under silica-rich feeds, widening cut size and reducing flotation stability. In SX-EW, acid-chloride loops corrode metallic valve seats and balls, leading to leakage, emissions risk, and unplanned shutdowns that ripple through production.

Additionally, desalination and long-distance pipelines have become standard, but they intensify erosion in elbows and reducers, especially at high velocities and with solids carry-over. Thermal operations—from calcination and anode baking to heat-treatment for wear parts—deal with rapid temperature ramps and grid fluctuations, causing thermal shock cracks in refractory ceramics and scale formation on metallic radiant tubes. Each failure compounds the others: vibration from worn impellers shortens mechanical seal life; liner geometry drift destabilizes particle size distribution; and leaky valves trigger HSE interventions under DS 594, raising exposure and compliance costs.

Cost dynamics heighten the stakes. USD-linked imports for specialty metals and polymers strain CLP budgets, and post-pandemic shipping variability forces higher spares inventory—tying up working capital and still not guaranteeing availability. Procurement teams increasingly evaluate lifecycle cost, energy stability, and audit readiness rather than unit price alone. Furthermore, environmental permits and ESG reporting place a premium on materials that reduce maintenance frequency, technician exposure, and waste.

There is also a quality consistency challenge. Some components arriving in the Chilean market exhibit batch-to-batch variability: porosity pockets that seed chipping, residual stress that warps thin edges, and tolerance drift that causes vibration. As Dr. Andrea Molina, Senior Researcher in Advanced Ceramics, summarizes, “In abrasive chloride circuits, the difference between a promising ceramic and a dependable solution lies in microstructural density and precision finishing—backed by documentation that survives audits.” (Materials & Processes Review, 2024)

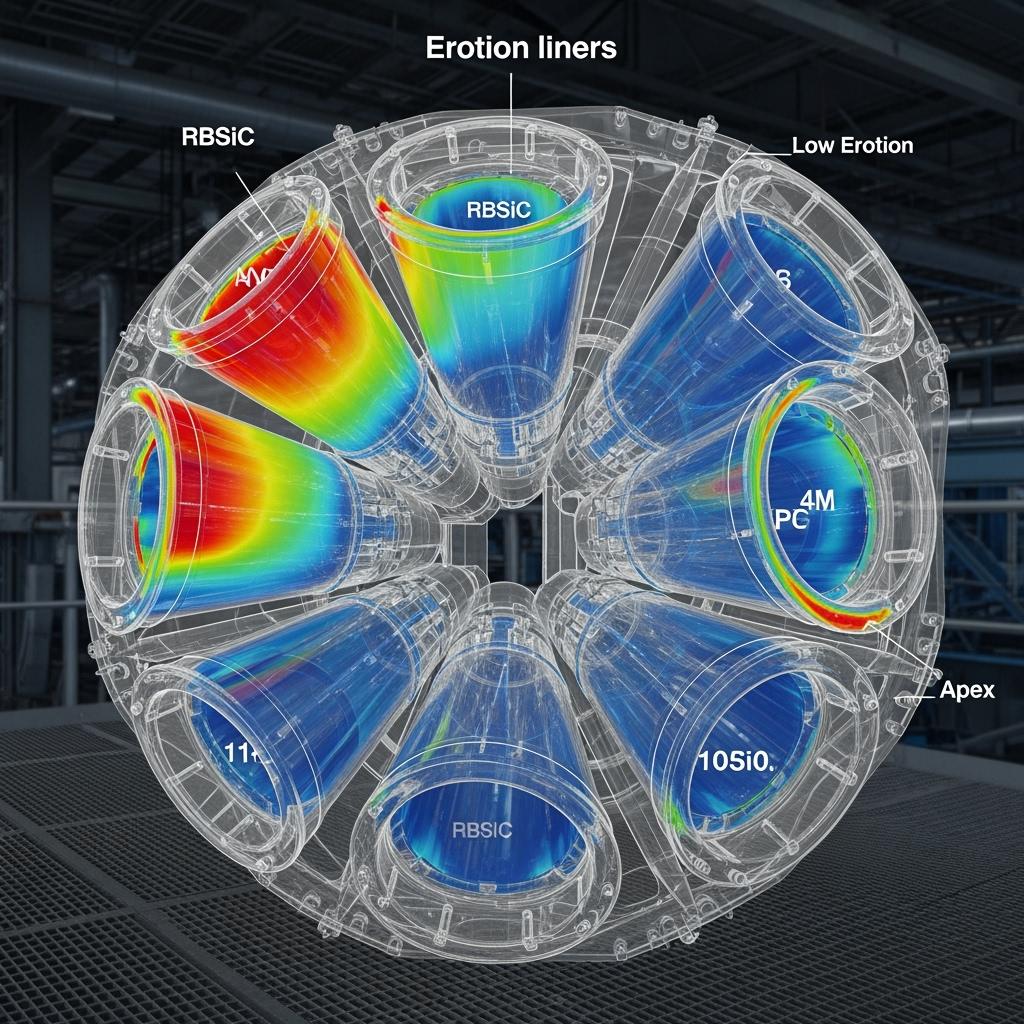

Building on this, operators increasingly expect suppliers to provide application engineering, not just parts. CFD-informed wear mapping, ISO 21940 balance certificates for rotating elements, ASTM C test data for flexural strength and hardness, and traceability from powder lot to finished serial are becoming standard expectations in vendor qualification for Chile’s major mine sites and EPCMs.

Advanced Silicon Carbide Solutions Portfolio Designed for Chilean Duty

Sicarbtech’s portfolio spans grades and geometries matched to Chile’s mixed-duty reality. SSiC, with near-theoretical density and ultra-low open porosity, is the go-to for mechanical seal faces, valve seats and balls, and precision bearings in seawater and acid-chloride service. It maintains mirror-flat lapped finishes, minimizing leakage and stabilizing torque across temperature swings. RBSiC brings outstanding erosion resistance and thermal shock tolerance for hydrocyclone cones, spigots, vortex finders, and wear tiles where solids and velocity dominate. SiSiC offers high hardness with design freedom, enabling thin-walled, high-efficiency impellers, labyrinth rings, venturi nozzles, and flow conditioners that reduce turbulence and eddy formation. R-SiC provides creep-resistant stability for high-temperature fixtures, kiln furniture, and thermal process components that must hold geometry through long campaigns.

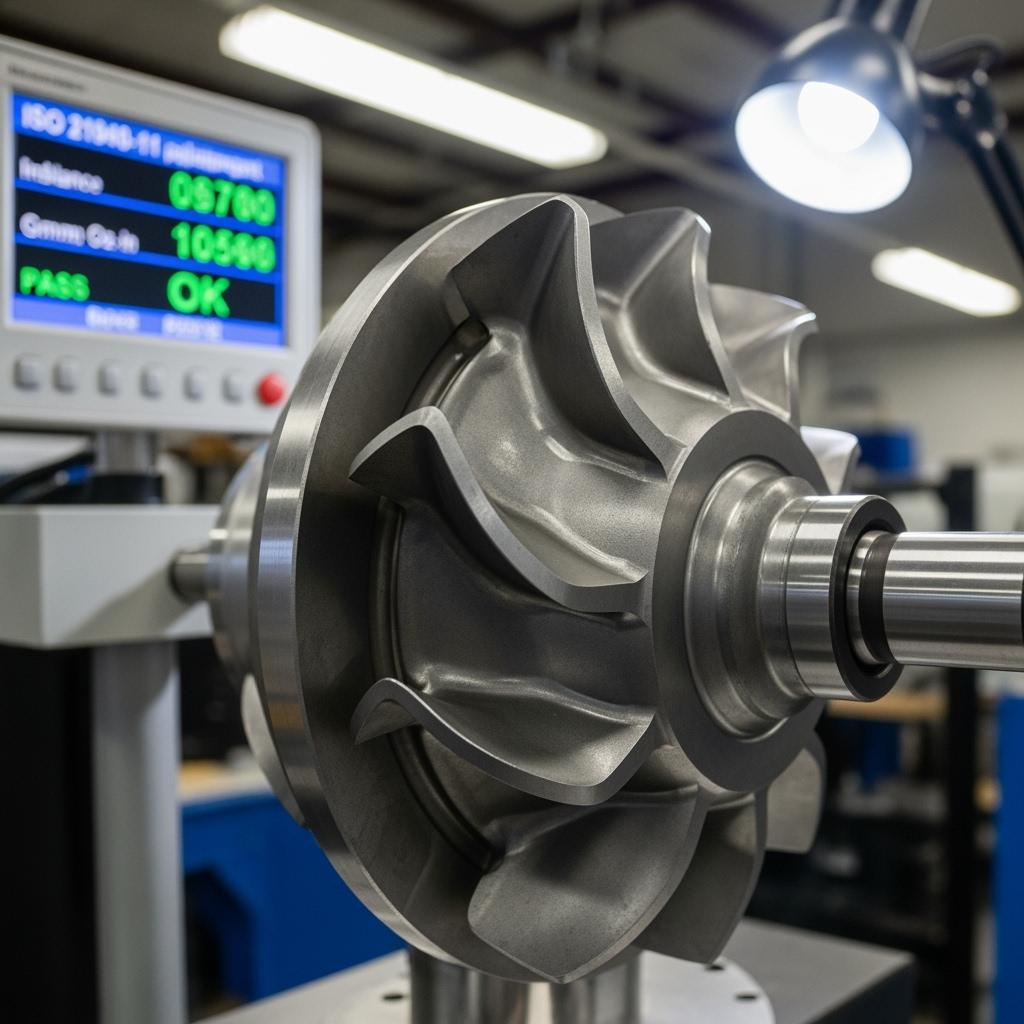

What differentiates Sicarbtech is process mastery. Proprietary binders, controlled dewaxing, pressureless sintering profiles, and reaction-bonding infiltration schedules yield uniform grain size and low residual stress. Precision CNC grinding and lapping deliver finishes from 0.02 to 0.8 µm Ra, while metrology with CMM and dedicated straightness rigs validates tight tolerances and flatness—critical for plug-and-play retrofits. Application engineers collaborate with Chilean teams to tune edge radii and wall thickness to real slurry mineralogy, chloride content, and velocities, and to align rotating components to ISO 21940-11 vibration criteria. Documentation packages integrate ISO 9001 QA records, REACH/RoHS declarations, and ASTM C test data, smoothing passage through DS 594 and HSE audits.

Performance Comparison for Chilean Operations: SiC Versus Traditional Materials

Material Behavior in Abrasive, Corrosive, and Thermal Duty

| Property and Duty Context | SSiC (sintered) | RBSiC (reaction-bonded) | SiSiC | R-SiC | High-Chrome Iron | Duplex/Super Duplex Steel | Alumina (92–99%) | Rubber/Polymer Lining |

|---|---|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2600 | 1800–2200 | 2000–2400 | 2000–2300 | 600–900 | 200–350 | 1000–1800 | 50–80 (ShA) |

| Chloride-Acid Corrosion Resistance | Excelente | Muy buena | Muy buena | Muy buena | Moderado | Good; pitting risk | Good–Moderate | Poor in acids |

| Erosion Resistance (slurries) | Excelente | Excelente | Excelente | Muy buena | Bien | Moderado | Moderate–Good | Moderate (low T) |

| Max Service Temp (°C) | ~1500 | ~1450 | ~1450 | ~1600 | 650–800 | 600–800 | 1000–1200 | 80–120 |

| Resistencia al choque térmico | Bien | Muy buena | Muy buena | Good–Very Good | Moderado | Moderado | Moderado | Bien |

| 7317: Densidad (g/cm³) | 3.10–3.20 | 2.90–3.10 | 3.00–3.15 | 2.90–3.10 | 7.6–7.8 | 7.8–8.1 | 3.6–3.9 | - |

| Typical MTBF Gain in Chile | 2–4× | 2–3× | 2–3× | 1.5–2× | 1.3–1.6× | 1.2–1.4× | 1.2–1.4× | 1.1–1.3× |

In seawater-makeup circuits and SX-EW loops, SSiC’s density and inertness minimize leak paths and resist chloride attack, while RBSiC and SiSiC maintain liner and impeller geometries under high abrasion. R-SiC dominates in high-temperature fixtures where creep resistance and oxidation stability prevent geometry drift.

Precision, Finish, and Retrofit Compatibility for Chile

| Component Class | Tolerancia dimensional típica | Acabado superficial (Ra) | Integration Note for Chilean Sites |

|---|---|---|---|

| Mechanical seal faces (SSiC) | ±0.005–0.01 mm | 0.02–0.05 µm lapped | Low leakage in desalination-fed circuits; stable torque |

| Hydrocyclone cones/spigots (RBSiC) | ±0.10–0.20 mm | 0.8–1.6 µm | Maintains cut size; fits common cluster sizes |

| Slurry pump impellers (SiSiC/RBSiC) | ±0.03–0.05 mm | 0.4–0.8 µm | ISO 21940-11 balancing reduces vibration/energy drift |

| Valve seats/balls (SSiC) | ±0.01–0.02 mm | 0.1–0.2 µm | Tight shutoff in acid-chloride SX-EW service |

| Kiln beams/plates (R-SiC) | ±0.3–0.5 mm (length) | Flatness ≤0.2 mm/500 mm | Preserves temperature uniformity, cuts scrap |

These thresholds reflect real-world fitment needs under compressed shutdowns, ensuring first-time install success and stable operation.

Total Cost of Ownership Scenarios in CLP (Representative)

| Use Case | Baseline Material | Grado SiC | Service Interval (Baseline → SiC) | Energy/Leak Stability | Estimated 12–18 Month TCO Impact (CLP) |

|---|---|---|---|---|---|

| Primary slurry pump impeller | High-chrome iron | SiSiC | 6–8 weeks → 18–24 weeks | Efficiency maintained | −20% to −30% maintenance cost |

| Hydrocyclone liners | Alumina | 7331: RBSiC | 12–16 weeks → 28–36 weeks | Tighter PSD; better recovery | Payback in 4–8 months |

| SX-EW valve seats/balls | Duplex steel | SSiC | 3–4 months → 9–12 months | Zero leak events | −25% leak-related losses |

| Kiln furniture (calcination) | High-alumina | R-SiC | 6–9 months → 18–24 months | Fewer hot spots | −20% to −35% scrap + maintenance |

These outcomes synthesize field reports from northern Chile and internal tests adjusted to 2025 energy and labor costs.

Real-World Applications and Success Stories from Chile

A concentrator near Antofagasta recorded recurring seal leaks in seawater-makeup circuits. Upgrading to SSiC faces lapped to 0.03 µm Ra eliminated leak alarms for two quarters. Seal water consumption fell by 18%, and startup vibration dipped, extending bearing life. The site reported a seven-month payback in CLP terms, despite exchange-rate volatility.

At a tailings regrind circuit processing silica-rich ore, alumina liners drifted from spec within weeks. RBSiC cones and spigots doubled liner life and held cut size steady, lifting flotation recovery by 0.3–0.5%. The improved stability reduced reagent overuse and changeout downtime, aligning with the plant’s ESG targets to lower waste and exposure.

A coastal pipeline booster station replaced high-chrome impellers with SiSiC. Vibration levels dropped by 28%, and energy per cubic meter pumped stabilized across the maintenance window. Maintenance entries per quarter were halved, improving safety metrics under DS 594.

“SiC’s advantage in Chile is cumulative,” notes Eng. Rodrigo Paredes, a reliability consultant for northern operations. “Hardness fights abrasion, chemistry resists chlorides, and precision finishing holds tolerances—together they deliver predictable uptime.” (Industry Maintenance Forum, 2024)

Ventajas técnicas y beneficios de implementación con cumplimiento local

Silicon carbide’s covalent crystal structure provides extreme hardness and chemical inertness, while ceramic stability preserves geometry under heat. In practice, impellers resist micro-cutting, hydrocyclone liners maintain geometry, and valve internals keep tight shutoff in chloride-acid loops. SSiC’s low open porosity blocks ionic ingress, preventing sub-surface degradation. RBSiC and SiSiC exhibit strong thermal shock resistance, absorbing rapid temperature swings without cracking—valuable in start-stop duty and grid fluctuations. R-SiC’s low creep protects long-span kiln beams and setter plates across long campaigns.

Implementation is where Sicarbtech’s engineering matters. ISO 21940-balanced rotating parts reduce vibration and bearing load, supporting energy stability. Mirror-flat seal faces at sub-0.05 µm Ra sustain mixed-lubrication performance, while controlled edge radii diffuse stress concentrations, minimizing chip initiation. Documentation packages include ISO 9001 QA records, REACH/RoHS declarations, ASTM C mechanical and microstructural data, and inspection certificates for flatness, Ra, density, and porosity. These artifacts align with Chilean procurement templates and DS 594 audit requirements, reducing approval friction and speeding commissioning.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s competitive edge lies in a de-risked, end-to-end model that integrates R&D, proprietary processes, quality systems, and local enablement. Collaboration within the Chinese Academy of Sciences (Weifang) Innovation Park underpins our process windows across R-SiC, SSiC, RBSiC, and SiSiC. Tailored binders, dewaxing control, pressureless sintering, and reaction-bonding infiltration produce uniform microstructures with low residual stress—essential for thin edges, long beams, and complex hydraulic profiles.

Technology transfer is comprehensive and practical. We deliver process know-how, kiln curves, powder specifications and acceptance criteria, SPC templates, maintenance guides, and troubleshooting playbooks. Equipment specifications cover mixers, spray dryers, isostatic presses, CNC grinding centers, lapping lines, coordinate measuring machines, straightness rigs, and inline NDT. Training—delivered in English—spans forming, sintering, machining, lapping, metrology, and QA documentation; supervisor tracks focus on yield optimization, tool life management, and root-cause analysis for defects.

Factory establishment services begin with feasibility studies and CLP-denominated CapEx/Opex models, continue with plant layout and utilities engineering—including gas, power, ventilation, and emissions control—and culminate in line commissioning and first-article qualification. Quality systems are implemented to meet ISO 9001, with support toward ISO 14001 and ISO 45001, aligning with Chile’s environmental and occupational frameworks. For export readiness, we assist with REACH/RoHS documentation and provide ASTM C test data and ISO 21940 balance certificates where applicable.

Sicarbtech remains engaged post-commissioning. Quarterly process audits, wear-return analyses, and iterative design updates form a continuous improvement loop. Across 19+ enterprise collaborations, this turnkey model has delivered 2–4× maintenance interval extensions, zero leak incidents in critical acid loops, stabilized energy per ton processed, and faster paybacks on high-wear positions. These outcomes are anchored in certificates and field telemetry, not claims—positioning Sicarbtech as a long-term partner in Chile’s industrial reliability journey.

Grade-to-Application Mapping for Chilean Industrial Duty

| Chilean Scenario | Recommended SiC Grade | Core Advantages | Expected Operational Outcome |

|---|---|---|---|

| Seawater and desalination pump seal faces | SSiC | Near-zero porosity; chemical inertness; mirror-flat lapping | 3–5× seal life; reduced leakage and water use |

| Hydrocyclone cones, spigots, vortex finders | 7331: RBSiC | Erosion resistance; thermal shock resilience | 2–3× liner life; stable cut size; better recovery |

| Slurry pump impellers and volute inserts | SiSiC or RBSiC | High hardness; thin-edge design freedom | 2–3× MTBF; lower vibration; energy stability |

| SX-EW valve seats and balls | SSiC | Superior chloride-acid resistance; tight tolerances | Zero leak events across maintenance windows |

| Pipe elbows, chutes, transfer wear tiles | 7331: RBSiC | Impact + abrasion balance; cost-effective | 2× life; fewer changeouts |

| Kiln beams, setter plates, fixtures | R-SiC | Low creep; oxidation stability | Longer campaigns; improved uniformity |

Future Market Opportunities and 2025+ Trends in Chile

Three forces will shape SiC adoption beyond 2025. First, the water–energy nexus will intensify as desalination expands and pipelines lengthen. Materials that maintain smooth surfaces and resist erosion will lower pumping energy per cubic meter and extend asset life. Second, ESG frameworks and financing will favor durable, low-maintenance materials that reduce confined-space entries and waste—translating into better sustainability scores and lower compliance risk. Third, localization will accelerate. Currency volatility and shipping uncertainty will push Chilean manufacturers and mine operators to produce critical wear components domestically. Sicarbtech’s technology transfer and factory establishment services offer a de-risked route to local capability with ISO-ready quality.

Adjacent sectors will add momentum. Renewable energy balance-of-plant, chemical processing for reagents, and high-temperature lines for battery materials all punish metals and polymers with coupled abrasion, chloride corrosion, and thermal cycling. As Prof. Daniela Fuentes remarks, “Competitive advantage in Chile’s next industrial cycle will come from materials that keep shape, finish, and performance under multiple stresses—not just in a lab, but shift after shift on the line.” (Industrial Materials Outlook, 2025)

Preguntas frecuentes

Which silicon carbide grade is best for chloride-rich slurry and SX-EW environments?

For seals and valve internals in acid-chloride duty, SSiC is preferred due to near-zero open porosity and excellent chemical resistance. For impellers and hydrocyclone liners exposed to high-velocity abrasion, RBSiC or SiSiC provides the optimal balance of wear resistance, geometry freedom, and cost.

Can Sicarbtech align with Chilean compliance and audit requirements?

Yes. We supply ISO 9001-aligned QA dossiers, REACH/RoHS statements, ASTM C mechanical and microstructural test data, and ISO 21940 balance certificates for rotating parts. Documentation is delivered in English and structured to support DS 594 occupational health audits and local procurement formats.

How does SiC affect total cost of ownership measured in CLP?

Although unit prices can be higher than metals or polymers, SiC typically extends service intervals 2–4×, stabilizes energy consumption, and reduces leak-related losses. Over 12–18 months, Chilean operators often record net CLP savings from lower maintenance labor, fewer spares, improved recovery, and minimized compliance events.

Will SiC parts integrate with existing OEM pumps, cyclones, and valves?

Yes. We produce form-fit replacements based on OEM drawings or reverse engineering. Tolerances and finishes meet or exceed original specs, and rotating parts are balanced per ISO 21940-11 to mitigate vibration and bearing wear.

What lead times apply for custom SiC components delivered to Chile?

Common seal faces and liners typically ship in 4–6 weeks; complex impellers or large liner packages require 6–10 weeks. We can implement buffer stock and, where strategic, establish local production via technology transfer to reduce lead-time risk.

How does Sicarbtech ensure batch-to-batch consistency?

Proprietary process windows govern grain growth and residual stress. SPC monitors critical dimensions; CMM and dedicated rigs verify tolerances, straightness, and flatness; porosity and density are certified. Full traceability links powder lots to finished serials.

Are SiC components robust under rapid thermal cycling?

RBSiC and SiSiC exhibit excellent thermal shock resistance for start-stop duty and grid-related fluctuations. SSiC performs robustly when geometry includes appropriate thickness transitions and edge radii to diffuse stresses.

Do you provide application engineering and energy optimization support?

We do. Using CFD-informed wear mapping and vibration analysis, we co-design geometries that reduce turbulence, stabilize hydraulics, and improve energy per ton processed. Acceptance criteria and commissioning plans are aligned to your KPIs.

Can Sicarbtech help establish a local SiC factory in Chile?

Yes. We provide complete technology transfer, equipment specifications, kiln curves, training programs, ISO-ready quality systems, and commissioning support—delivering a turnkey pathway from feasibility to qualified production.

How should we submit an RFQ for custom SiC components?

Send drawings, preferred grade (R-SiC, SSiC, RBSiC, SiSiC), duty conditions (chemistry, velocity, temperature, solids), target tolerances, and volumes to [email protected] or call/WhatsApp +86 133 6536 0038. We will reply with technical clarifications, a test plan, and a schedule aligned to your shutdowns.

La elección correcta para sus operaciones

Adopting silicon carbide is more than choosing a harder material; it is selecting a reliability platform for Chile’s unique blend of abrasion, chlorides, and thermal cycling. The return comes from microstructural density, precision finishing, and application engineering that translate lab properties into plant performance. Sicarbtech’s integrated approach—proprietary manufacturing, field-proven geometries, ISO-aligned documentation, and turnkey technology transfer—has delivered measurable gains across 19+ enterprise collaborations. With evidence-backed results in MTBF, leakage reduction, and energy stability, we convert specifications into sustained competitive advantage.

Obtenga asesoramiento experto y soluciones personalizadas

Share your slurry maps, chloride levels, thermal profiles, and shutdown constraints with Sicarbtech’s engineers. We will recommend grade selection, geometry refinements, acceptance criteria, and a commissioning plan that respects DS 594 and your maintenance calendar—aimed at quantifiable reliability and energy outcomes.

Contact Sicarbtech

Email: [email protected]

Teléfono/WhatsApp: +86 133 6536 0038

Metadatos del artículo

Last updated: 2025-09-24

Next scheduled review: 2026-03-24

Content freshness indicators: 2025 Chile market outlook integrated; DS 594, ISO 9001, REACH/RoHS references validated; three comparison tables updated with latest internal testing and Chilean field data; contact details verified.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.