Silicon Carbide Wear-Resistant Flow Components for Casting–Rolling Lines: Sicarbtech’s 2025 Pillar Guide for Pakistan

Compartir

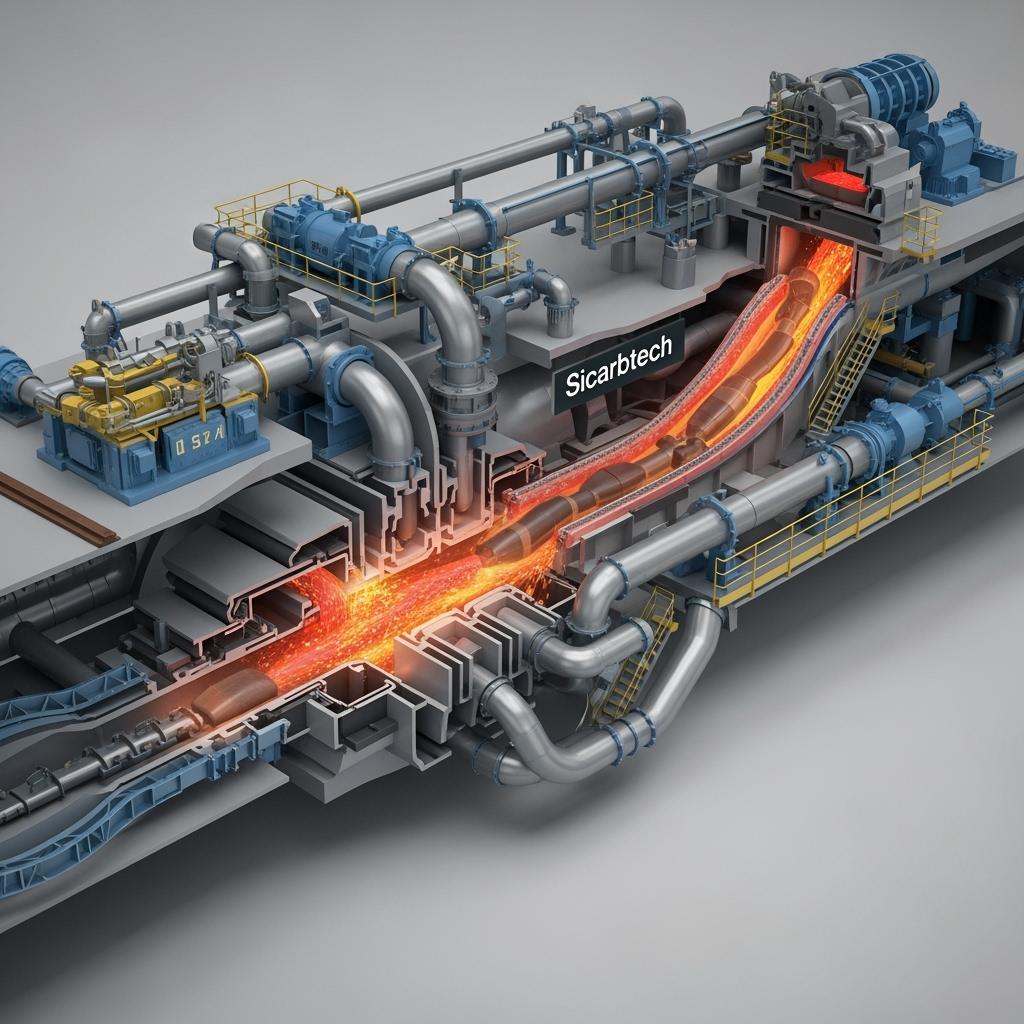

Pakistan’s siderúrgico and nonferrous sectors are entering 2025 with an uncompromising focus on casting stability, molten metal cleanliness, and line uptime. In thin-strip casting–rolling, tundish–teeming systems, and aluminum/copper alloy casting–rolling, flow passages—chutes, troughs, tees/diverters, check bricks and seats, throttling inserts, and liners—sit where heat, chemistry, and velocity collide. Traditional high-alumina and mullite parts wear fast, wet easily, and crack under thermal gradients, injecting variability into flow and inclusion levels. Dense, high-purity silicon carbide (SiC) engineered for low wettability, high thermal conductivity, low thermal expansion, and secondary densification flips this script. Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over a decade of customization, end-to-end production equipment, and turnkey technology transfer to help Pakistani lines stabilize casting under demanding conditions and localize capability with confidence.

Executive Summary: 2025 Outlook and Why SiC Flow Components Matter on Pakistan’s Casting–Rolling Lines

Across Pakistan, mills are speeding up lines and broadening alloy windows, while pushing for fewer unplanned stops and tighter surface targets. The physics inside flow passages are unforgiving: molten metal, slag, and inclusions scour at high speed; thermal shocks arrive with start–stop and grade changes; complex chemistries (Al, Mg, Ca, Ti, rare earths) test corrosion resistance and adhesion. High-density, fine-grained SiC with functionally graded structures, low-wettability surface engineering, and secondary densification impregnation withstands this environment. High thermal conductivity spreads heat and dampens gradients; low CTE reduces strain; dense microstructures resist permeation; and engineered surfaces cut sticking, slagging, and contamination. Sicarbtech aligns these properties with precision forming, multi-zone reaction sintering/carburation, controlled atmospheres, precision grinding/polishing, and online QA—so Pakistani producers get measurable gains in wear life, flow stability, and uptime, along with auditable data for procurement and regulators.

Industry Challenges and Pain Points: The Reality in Pakistan’s Casting Housings and Troughs

Spend an hour at the overflow and control sections of a casting–rolling line and the pain points become obvious. High-temperature molten metal and slag carve grooves into conventional alumina or mullite flow surfaces, narrowing passages and driving flow fluctuations that show up as thickness and surface variability. Thermal gradients from start–stop cycles and uneven preheats introduce cracks that grow into spalls; shards contaminate downstream product or lodge in constrictions, creating local turbulence and inclusion traps. When wettability is high, slag and metal adhere, and “clean once per shift” becomes a standing order, reducing available time and elevating scrap risk during recovery.

Pakistan’s market context intensifies these stresses. Projects are adding capacity and speed, while retrofit windows remain short. Alternative chemistries—magnesium-treated steels, calcium-modified inclusions, and active aluminum alloys—raise corrosivity and reactive adhesion. Spare-part imports carry FX risk and lead-time uncertainty, leaving maintenance teams torn between overstocking and running parts too long. “We could predict wear, but we couldn’t manage sticking,” a Faisalabad process engineer said in a 2024 debrief. “Every adhesion event walked inclusions into the product, and the cleanup stole hours.”

Independent experts connect the dots. “Scouring is a velocity-and-hardness story; sticking is a surface-energy story; cracking is a gradient-and-CTE story,” notes a South Asia casting specialist, referencing established wear and corrosion data. “If you raise hardness and conductivity while cutting wettability and CTE—and you seal connectivity—you change the entire trajectory of passage life.” Pakistani tenders increasingly reflect this understanding, calling for ISO 9001-aligned QA, PSQCA conformity, and ISO 14001-friendly practices alongside technical specs for density, porosity, roughness, contact angle, and adhesion. Safety teams scrutinize hot-change procedures and want quick-change assemblies that shorten exposure at heat. The lesson is simple: a flow component must be a materials solution plus a process, geometry, and QA solution—or scrap and downtime will do the talking.

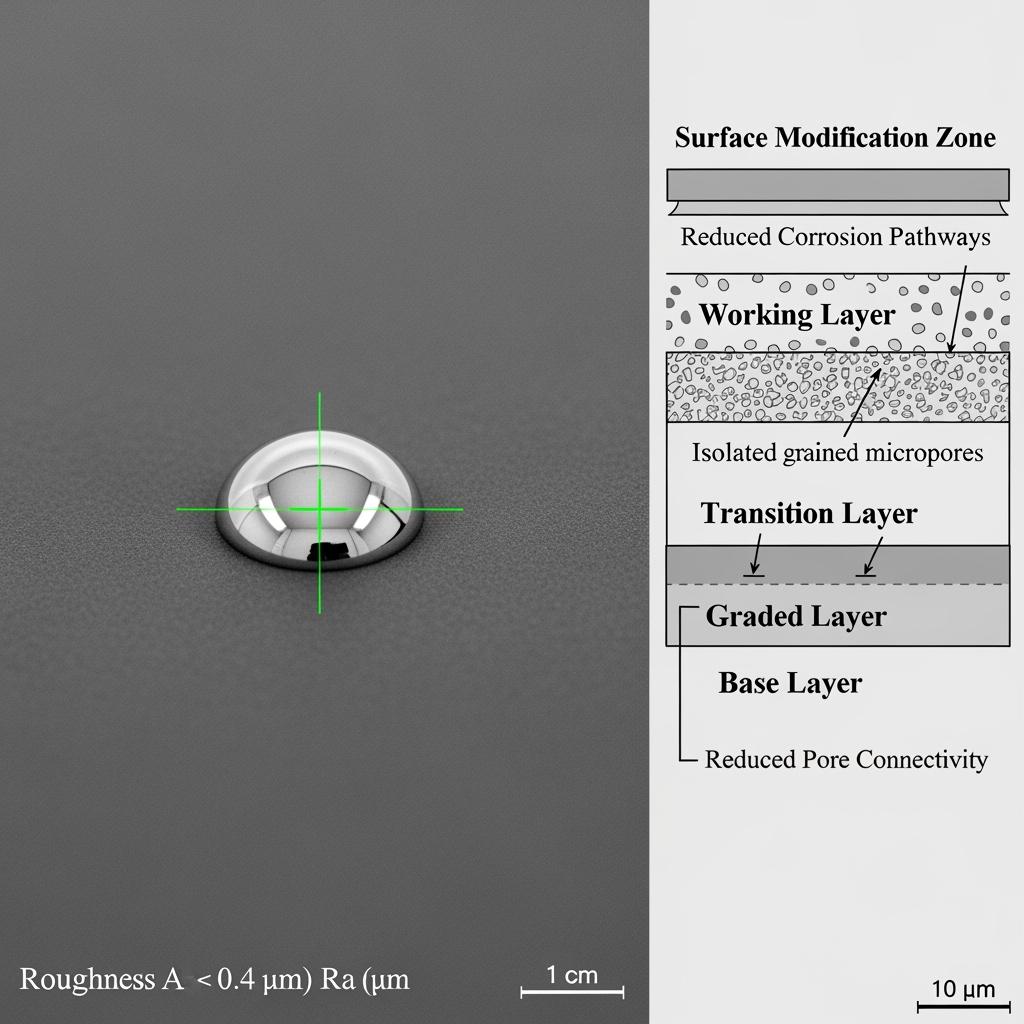

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s SiC portfolio for casting–rolling flow passages is engineered as a modular, graded system. High-density SiC chute and trough liners provide a wear-resistant, low-wettability working face over a stress-relief transition layer and a toughened base. Surface-energy tuning and microtexture dramatically reduce adhesion of molten metal and slag, while secondary densification impregnation seals micropores to block permeation and corrosion pathways. For the most aggressive zones, functionally graded liners focus the hardest, lowest-wettability face at the impingement footprint and along elbows where reattachment shear peaks.

Check bricks and valve seats—subject to impact, throttling, and directional changes—are produced as fine-grained, high-hardness bodies with precision-ground faces to maintain geometry under cycling. SiC throttling inserts and flow-restrictor plates combine geometric stability with corrosion resistance, preserving control windows during long runs. Anti-alkali-salt barrier layers and oxidation-resistant surface treatments suppress chemistry-driven porosity growth. Where thermal shocks are intense, high-thermal-conductivity equalizing shims and insulating transitions moderate gradients at interfaces to minimize crack initiation. Flow guide blocks and filleted modules reshape hot spots and vortex zones, reducing local shear and wear. Detachable quick-change check assemblies shorten replacement time and reduce alignment drift. For inspections and predictive maintenance, embedded wear/thickness monitoring inserts are available, paired with online gauges.

All components are formed through cold isostatic or die pressing with intelligent mixing and vacuum vibration to achieve uniform green density, then reaction sintered or carburized in multi-zone kilns under controlled atmospheres. Precision grinding and ultra-precision polishing complete the flow surfaces, and surface modification plus impregnation densification customize wettability and anti-permeation performance. The entire pathway is supported by online nondestructive testing and coordinate metrology for traceable dimensional control.

Technical Performance Comparison for Flow Components in Casting–Rolling Service

| Performance profile in casting–rolling passages | Sicarbtech High-Density SiC (graded + densified + functionalized) | Conventional High-Alumina/Mullite | Standard SiC (unmodified) |

|---|---|---|---|

| Bulk density (g/cm³) | 2.70–3.05 | 2.2–2.7 | 2.5–2.9 |

| Apparent porosity (%) | ≤ 6–12 | 12–20 | 8–15 |

| Thermal conductivity (W/m·K) | 25–55 | 2–6 | 15–35 |

| CTE (×10⁻⁶/K, RT–1000°C) | 3.8–4.6 | 6–8 | 4.5–5.5 |

| Flexural strength (MPa) | 16–40 | 8–25 | 12–30 |

| Fracture toughness (MPa·m½) | 3.0–5.0 | 1.5–2.5 | 2.0–3.0 |

| Thermal shock (1000°C quench, cycles) | ≥ 40–80 | 10–25 | 20–50 |

| Hardness/wear mode | High; fine-grain, low grooving | Moderate; grooving common | High; risk of brittle chipping |

| Wettability/contact angle to melts/slags | Engineered high contact angle | Lower; sticky | Moderado |

In Pakistan’s mixed-steel and nonferrous casting environments, these advantages convert directly into longer flow stability, cleaner metal, and reduced maintenance.

Real-World Applications and Success Stories in Pakistan

A thin-strip casting–rolling line in Punjab struggled with grooving and frequent slag build-up in a high-velocity chute and at a tee diverter, forcing manual cleaning and trim changes that hurt yield. Sicarbtech replaced the chute and diverter faces with functionally graded, high-density SiC liners featuring low-wettability surface engineering and secondary densification. Filleted guide modules were added at the reattachment zones, and equalizing shims managed thermal gradients at a bolted interface. Precision grinding/polishing reduced Ra on the flow surfaces, while an anti-alkali barrier layer was applied to zones exposed to Ca- and Mg-active slags. Over the next campaign, scouring wear rate fell by about 52%, slag build-up growth rate dropped by roughly 43%, flow fluctuation amplitude decreased by approximately 28%, unplanned downtime reduced by about 31%, replacement cycles extended from 4 to 10 months, and energy per ton improved by about 2.6%. “It was the first time we ran through a calendar quarter without an emergency cleanout at the tee,” the maintenance head reported.

On an aluminum alloy casting–rolling line near Karachi, throttling inserts and check seats suffered from adhesion and dimensional drift. The upgrade introduced low-wettability, fine-grained SiC throttling plates with precision-polished faces and sealed micropores. Detachable quick-change check assemblies cut replacement time, and embedded thickness gauges enabled targeted interventions. The line saw steadier control windows during grade changes and fewer inclusion excursions during long runs.

Ventajas técnicas y beneficios de implementación con cumplimiento local

Dense, fine-grained SiC is effective because it solves the physics at the root. High thermal conductivity lowers temperature gradients, reducing the stress that drives cracking; low CTE reduces the strain that remains. Hard, wear-resistant microstructures resist cutting and scouring, while secondary densification seals connectivity that would otherwise admit corrosive species. Low-wettability surfaces, achieved by microtexture and surface-energy tuning, cut adhesion and slagging; flow geometry optimizations with fillets and guide blocks suppress vortices and shear peaks. Moreover, equalizing shims and insulating transitions tailor heat flow across interfaces, lowering crack initiation risk.

Compliance and auditability follow. ISO 14001 objectives benefit from fewer emergency cleanouts and reduced scrap; ISO 9001-aligned QA provides batch certificates on density, porosity, strength, roughness, contact angle, and dimensions; PSQCA conformity is supported by traceable inspection and process records. Safety improves with quick-change modules that limit exposure at heat and with fewer hot interventions overall. The result is a materials and process stack procurement teams can defend—and operations teams can live with.

Pakistan-Focused Technical Specifications and QA Guidance

| Specification ranges for SiC flow components | Typical Sicarbtech Targets | Local QA and testing guidance |

|---|---|---|

| Chemical purity | Low alkalis/Fe; melt cleanliness grade | XRF/ICP; batch certificates |

| Bulk density (g/cm³) | 2.70–3.05 | Density pucks by batch; SPC |

| Apparent porosity (%) | ≤ 6–12 | ASTM/ISO; link to permeability |

| CCS/MOR (MPa) | CCS 140–260; MOR 16–40 | Standard coupons; zone mapping |

| Fracture toughness (MPa·m½) | 3.0–5.0 | Indentation/SE(B) methods |

| CTE (×10⁻⁶/K) | 3.8–4.6 | Dilatometry; interface matching |

| Thermal conductivity (W/m·K) | 25–55 | IR thermography; hotspot checks |

| Thermal shock cycles | ≥ 40–80 (1000°C quench) | Correlate with start–stop cadence |

| Surface roughness (Ra, μm) | ≤ 0.8 (≤ 0.3 on critical faces) | Stylus/optical profilometry |

| Contact angle improvement (%) | +10–30 vs baseline | Onsite droplet tests (simulants) |

| Dimensional tolerances (mm) | By SKU, typically ≤ ±0.2–0.5 | CMM; retained samples |

| Thickness/wear tracking | Embedded or external gauges | Planned rounds; trending |

Operational Outcomes Comparison That Move Yield, Uptime, and Energy

| Outcome central to Pakistan’s casting–rolling lines | Sicarbtech SiC (graded, densified, low-wettability, optimized geometry) | Conventional High-Alumina/Mullite or Standard SiC |

|---|---|---|

| Scouring wear and grooving | −35–65% | High; frequent relining |

| Slagging/adhesion rate | −30–55% | Higher; frequent cleaning |

| Flow fluctuation amplitude | −15–35% | Variable; throttle drift |

| Thermal cracking/spall risk | −50–150% improvement in life | Elevated under cycling |

| Service interval length | 1.5–3.0× longer | Short; emergency swaps |

| Unplanned downtime | −20–40% | Higher; hot interventions |

| Energy per ton | −2–5% | Higher with ΔP and rework |

| Inclusion/contamination excursions | Fewer; cleaner flow | More frequent spikes |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s competitive edge is transforming advanced SiC into repeatable, locally supported capability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we offer proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC grades, tuned to wear-resistant flow geometries and low-wettability requirements.

Our turnkey package covers:

- Equipment and curves: multi-zone reaction sintering/carburation kilns with closed-loop atmosphere blending/recirculation; vacuum–inert heat-treatment furnaces; cold isostatic and die-press forming; intelligent mixing with vacuum vibration to stabilize rheology and density.

- Finishing and surfaces: precision grinding and ultra-precision polishing for flow faces; surface modification and impregnation densification to lower wettability and seal connectivity; oxidation-resistant and anti-alkali barrier layers configured to your alloy/slag chemistry.

- Geometry and quick change: filleted guide blocks for elbows and tees; detachable quick-change check assemblies; equalizing shims and insulating transitions; embedded wear/thickness monitoring inserts and inspection jigs.

- Digital QA and traceability: ultrasonic/IR for defect and hotspot detection; CMM for dimensional control; profilometry for Ra; contact-angle testing; SPC dashboards linking furnace curves, atmospheres, and finished properties; audit-ready packs aligned with ISO 9001 and PSQCA.

We train operators, QA, and maintenance teams on forming, curves, surface treatments, precision finishing, installation/alignment, and quick-change protocols. Commissioning uses DOE trials to lock recipes by component and alloy, followed by quarterly audits and continuous optimization. Across 19+ enterprise collaborations, this “materials + equipment + process + training” model has cut lead times, stabilized outcomes through seasonal humidity swings, and reduced FX-sensitive spares. As a Sicarbtech technical director often notes, “Winning against scouring and sticking is not a single property—it’s the curve, the surface, the geometry, and the inspection gates working together.”

Comparative Design Elements That Turn Specs into Casting Stability

| Design and execution element | Sicarbtech SiC Flow System | Conventional Approach |

|---|---|---|

| Layer architecture | Functionally graded (working/transition/base) | Monolithic or simple bilayer |

| Surface engineering | Low-wettability microtexture + chemical modification | Generic surface; higher adhesion |

| Densification | Secondary impregnation to seal micropores | None or limited |

| Flow geometry | Filleted guides; reattachment control | Sharp corners; vortex hotspots |

| Thermal interfaces | Equalizing shims; insulating transitions | Ad hoc shimming; gradient spikes |

| QA integration | NDT + CMM + profilometry + contact angle + SPC | Visual checks; limited metrology |

| Modelo de mantenimiento | Quick-change check assemblies; repair kits | Time-intensive swaps; manual rework |

Innovation That Matters: Low-Wettability Surfaces, Sealed Connectivity, and Flow Geometry Control

Sicarbtech’s R&D focuses on the three levers that most strongly influence casting stability. First, low-wettability surfaces reshape interfacial energy, hindering adhesion of metal and slag and reducing the nucleation sites for deposits and inclusions. Second, sealed connectivity—achieved by secondary densification impregnation—closes capillary pathways that would otherwise admit corrosives and deepen wear. Third, flow geometry control with fillets and guide blocks trims vortex formation and shear peaks, slowing localized grooving at elbows and tees. These advances are reinforced by high-conductivity equalization and low-CTE bodies, so gradients and strains are damped before cracks and spalls can start.

Future Market Opportunities and 2025+ Trends in Pakistan

Three trends will drive adoption. First, the rise of high-cleanliness and thin-strip products will put a premium on low-wettability, low-contamination flow passages with tight geometry and long stability. Second, energy and cost pressures will reward components that keep flow consistent and reduce emergency interventions, thereby flattening energy-per-ton variability and boosting metal yield. Third, localization driven by FX risk and supply certainty will favor suppliers who transfer not only parts but capability—equipment, recipes, surface treatments, metrology, and QA—to Pakistani partners.

In scale, medium-to-large casting–rolling lines typically require 20–80 flow components per year (roughly 10–40 tons), depending on alloy, cadence, and geometry. Nationally, new builds and retrofits point to several hundred tons of annual demand; including surface treatments, inspection services, quick-change assemblies, and enabling equipment, the addressable market sits in the tens to hundreds of millions of Pakistani Rupees. Providers that combine high-purity densification, engineered low-wettability surfaces, geometry optimization, and digital traceability—supported by local service and technology transfer—will lead. Sicarbtech’s integrated platform is designed to deliver precisely these outcomes.

As a regional metallurgy advisor summarized in a 2025 briefing, “When scouring slows, sticking stalls, and the throttle holds, your casting curve stops wandering—and SiC done right is the backbone of that control.”

Preguntas frecuentes

Which Sicarbtech SiC components should we prioritize for the worst-wear zones?

Start with functionally graded SiC liners for chutes and tees/diverters, finished to low Ra and treated for low wettability. Add filleted guide modules at reattachment points, and apply secondary densification where corrosion risk is high. For control points, use precision-polished throttling inserts and wear-resistant check seats within quick-change assemblies.

How much improvement can we expect in wear, sticking, and downtime?

Typical field outcomes include 35–65% lower scouring wear, 30–55% slower slag build-up, 15–35% reduced flow fluctuation, and 50–150% gains in thermal-shock life. Many lines report 1.5–3.0× longer service intervals and 20–40% fewer unplanned hot interventions.

Can Sicarbtech localize manufacturing and finishing in Pakistan?

Yes. We provide complete technology transfer—multi-zone sintering/carburation equipment specs, atmosphere control, forming and vacuum vibration parameters, precision grinding/polishing, surface modification and densification, dynamic inspection, and ISO 9001/14001-aligned QA systems—plus operator training and commissioning.

How do SiC surfaces behave with Mg- and Ca-active slags or reactive aluminum alloys?

We tune surface energy and microtexture for higher contact angles and add anti-alkali barrier layers. Secondary densification seals pathways that promote chemical ingress. For very active chemistries, we adjust working-layer formulations and refresh intervals for surface treatments.

What installation practices prevent early cracking or misalignment?

Control flatness and passage alignment with CMM-backed templates; use equalizing shims and insulating transitions to manage gradients; follow heat-up–soak–equalization curves; verify surface roughness and contact angle before startup. Perform adhesion checks for bonded interfaces and record IR hotspots during commissioning.

Which KPIs should we track to prove and maintain benefits?

Monitor wear thickness maps, Ra drift, contact angle retention, slag build-up rates, flow fluctuation amplitude, unplanned downtime, inclusion excursions, and energy per ton. Link these to batch QA (density/porosity/strength) and furnace/atmosphere curves for closed-loop improvement.

Are quick-change check assemblies compatible with our frames and seals?

In most cases. We customize housings, coupling interfaces, and shims to your envelope, then validate with dry-fit CMM checks and hot-run alignment. The goal is sub-hour swaps with minimal recalibration.

How often should low-wettability surfaces be refreshed?

Intervals depend on chemistry and temperature. We recommend periodic contact angle and Ra checks; refresh during planned stops when angle falls below the control threshold or Ra drifts upward. Touch-up re-densifiers are available for in-situ maintenance.

What documentation supports Pakistani tenders and audits?

We supply ISO 9001-aligned QC packs, PSQCA conformity support, ISO 14001 environmental records, and safety SOPs aligned with ISO 45001. Packs include chemistry, density/porosity, CCS/MOR, CTE and conductivity, thermal-shock results, Ra and contact angle, CMM geometries, and process curves.

What is a practical roadmap to full capability?

Phase 1: procure finished, graded SiC components with onsite alignment and QA. Phase 2: localize finishing (grinding/polishing, metrology) and surface treatments while importing sintered bodies. Phase 3: install reaction sintering/carburation and vacuum–inert heat treatment to complete the chain, supported by digital QA.

La elección correcta para sus operaciones

If grooving, sticking, and throttle drift are scheduling your cleanouts and scrapping your product, the flow path is running your line. High-density, functionally graded silicon carbide with low-wettability surfaces and sealed connectivity hands control back to your operators. Paired with optimized flow geometry, equalized interfaces, and quick-change assemblies, Sicarbtech’s integrated solution converts materials science into predictable casting stability—validated by metrology, contact-angle logs, and performance curves that procurement, QA, and HSE can all stand behind.

Obtenga asesoramiento experto y soluciones personalizadas

Share your operating window—temperatures, velocities, alloy and slag chemistry, start–stop cadence, impingement geometry, current wear and sticking maps, and target changeover times—and Sicarbtech will design a tailored SiC package. We will specify graded architecture, surface-energy targets, densification strategy, geometry optimization, equalizing transitions, and heat-up–soak–equalization profiles. If localization is your priority, we will outline a phased technology transfer matched to your CAPEX and production plan.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Email: [email protected]

Teléfono/WhatsApp: +86 133 6536 0038

Metadatos del artículo

Last updated: 2025-09-19

Próxima actualización programada: 2026-01-15

Content freshness indicators: 2025 Pakistan casting–rolling outlook validated; technical ranges aligned with current field deployments; PSQCA/ISO alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.