Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar for Billet Induction Heating and Furnace Boosting Power Supply

Compartir

Executive Summary: 2025 Outlook for High-Frequency, High-Efficiency Induction Power in Pakistan’s Steel Corridors

Pakistan’s steel value chain is tightening takt from continuous casting to reheating and rolling. Every minute saved in billet heat-up and every degree held within tighter uniformity translates directly into yield, throughput, and energy intensity improvements. In 2025, the strongest lever is upgrading induction heating and furnace boosting power supplies with silicon carbide (SiC): high-voltage, high-current devices operating at higher switching frequencies, packaged in low-inductance, double-sided-cooled modules, and paired with interleaved or multilevel topologies. When integrated with active front ends, soft switching, and coordinated snubbing, SiC platforms deliver cleaner DC buses, faster control response, and compact cabinets that stand up to dust, oil mist, and heat.

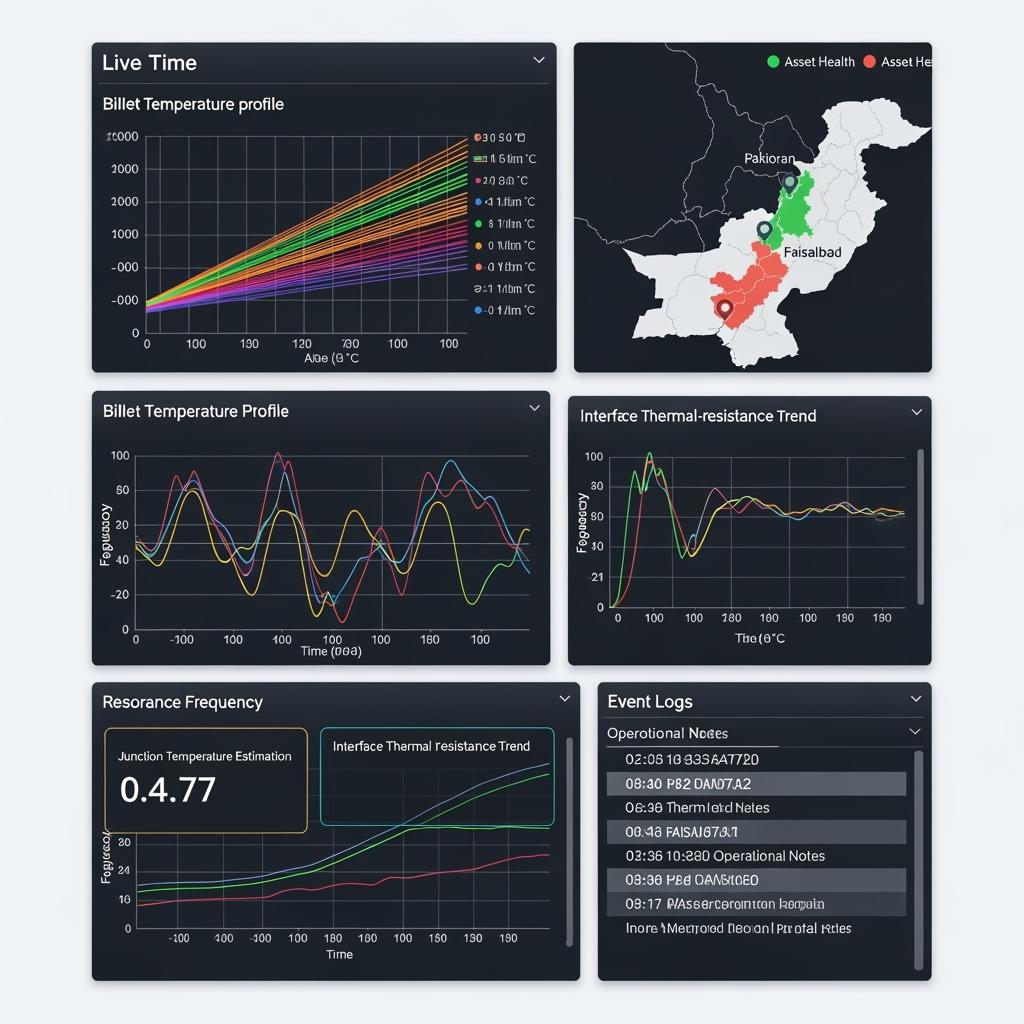

Sicarbtech—Silicon Carbide Solutions Expert—based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings 10+ years of customization supporting 19+ enterprises. From R‑SiC, SSiC, RBSiC, and SiSiC materials through automotive-grade devices, double-sided-cooled modules, layered busbars, resonance-matched topologies, and online health monitoring, Sicarbtech delivers turnkey technology transfer and factory establishment. For Pakistan’s steel clusters in Karachi, Lahore, and Faisalabad, this means faster pilot-to-scale trajectories, consistent local screening, and data-backed compliance—converting better electro-thermal conversion efficiency into reliable PKR economics.

Industry Challenges and Pain Points: Heating Speed, Uniformity, and Power Quality Under Real Plant Conditions

Industrial induction power is where physics meets harsh reality. Conventional silicon limits switching frequency, forcing larger magnetics and slower control, which in turn constrains heating rate and uniformity across billet grades and sections. On production lines where continuous casting, heating, and rolling must be synchronized, even small delays propagate into waiting time, surface scaling, and rework. Moreover, low-frequency switching raises harmonic injection and depresses power factor, prompting utility complaints, penalties, or costly, bulky filtering that crowds already-tight cabinets.

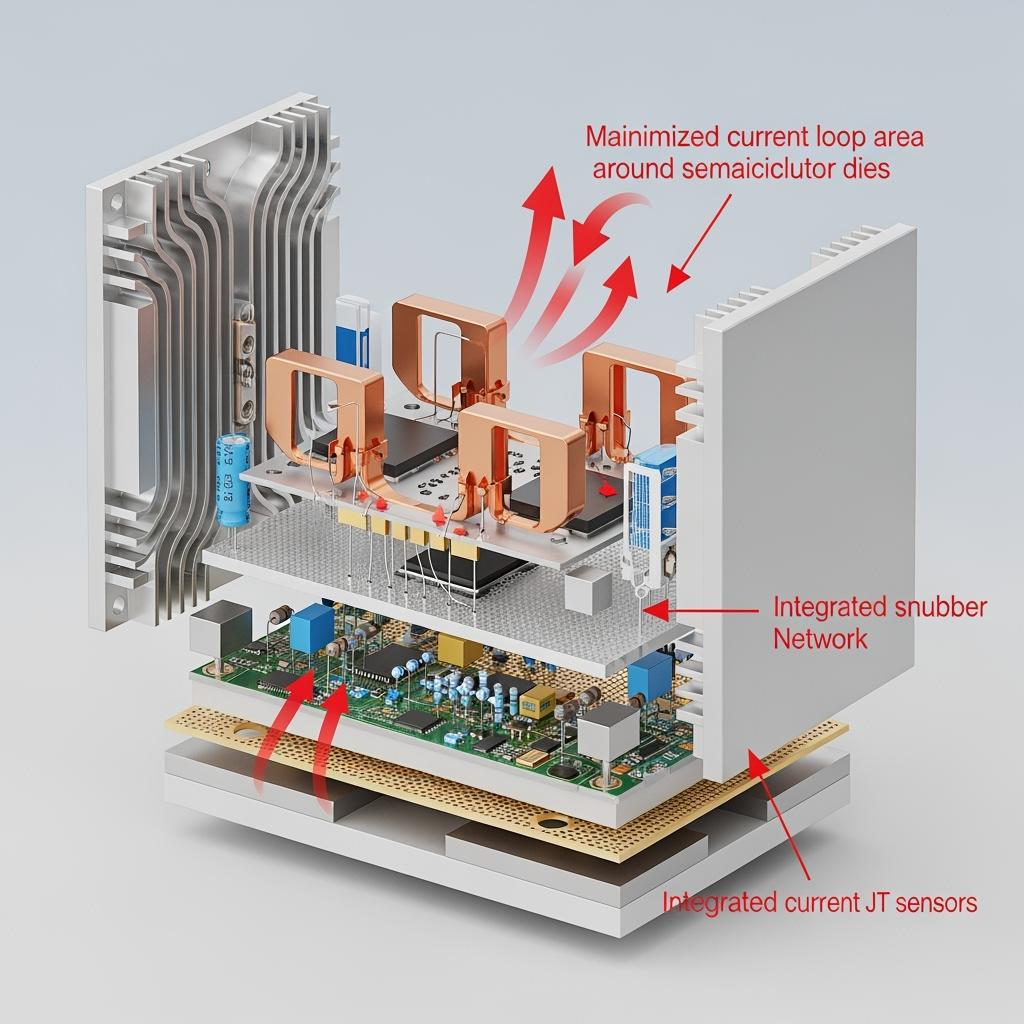

The DC bus is a frequent culprit. Long cables and parallel loads invite oscillations if loop area and damping are not controlled. During power changes, coil-coupling shifts, or furnace boosting transitions, overshoot and ringing can surge, stressing devices and capacitors. Passive snubbers provide limited relief at higher frequencies, and the result is nuisance trips that break takt stability. Without active measures, operators often detune control, sacrificing dynamic response and heating precision.

Thermal and environmental stress compound these issues. Dust, oil mist, and variable cooling-water quality are the daily reality in steel plants. Single-sided-cooled power stages with commodity interface materials can suffer pump-out and voiding under thermal cycling, increasing junction-to-case resistance and creating hotspots. Cold-plate scaling and corrosion degrade heat transfer, forcing derating in the very weeks when demand peaks. Cabinet interiors collect conductive dust; coatings and seals not specified for oil mist or salt-laden air lose integrity, allowing leakage paths and accelerating failure.

O&M frustrations follow. Failures discovered mid-shift become costly stops when spare modules are weeks away and lot-to-lot consistency is uncertain. Lacking online health monitoring and MES traceability, root-cause analysis is slow and inconclusive. Financing and tenders increasingly ask for evidence aligned with IEC 60747 (device characteristics), IEC 60068 (damp heat, salt spray, dust, vibration, shock), and EMC expectations similar to IEC 61800‑3. Power factor near unity and current THD within typical ≤5% bands are not just good practice; they are now key acceptance criteria. As Dr. H. Rehman, an industrial power electronics advisor, observes, “In billet heating, every percentage point of efficiency is worth less than the minutes you save and the uniformity you lock in. In 2025, the bid that wins proves speed, uniformity, and power quality—with data.” [Source: Regional Power Electronics Workshop, 2024]

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech’s High-Frequency Induction and Furnace Boosting Stack

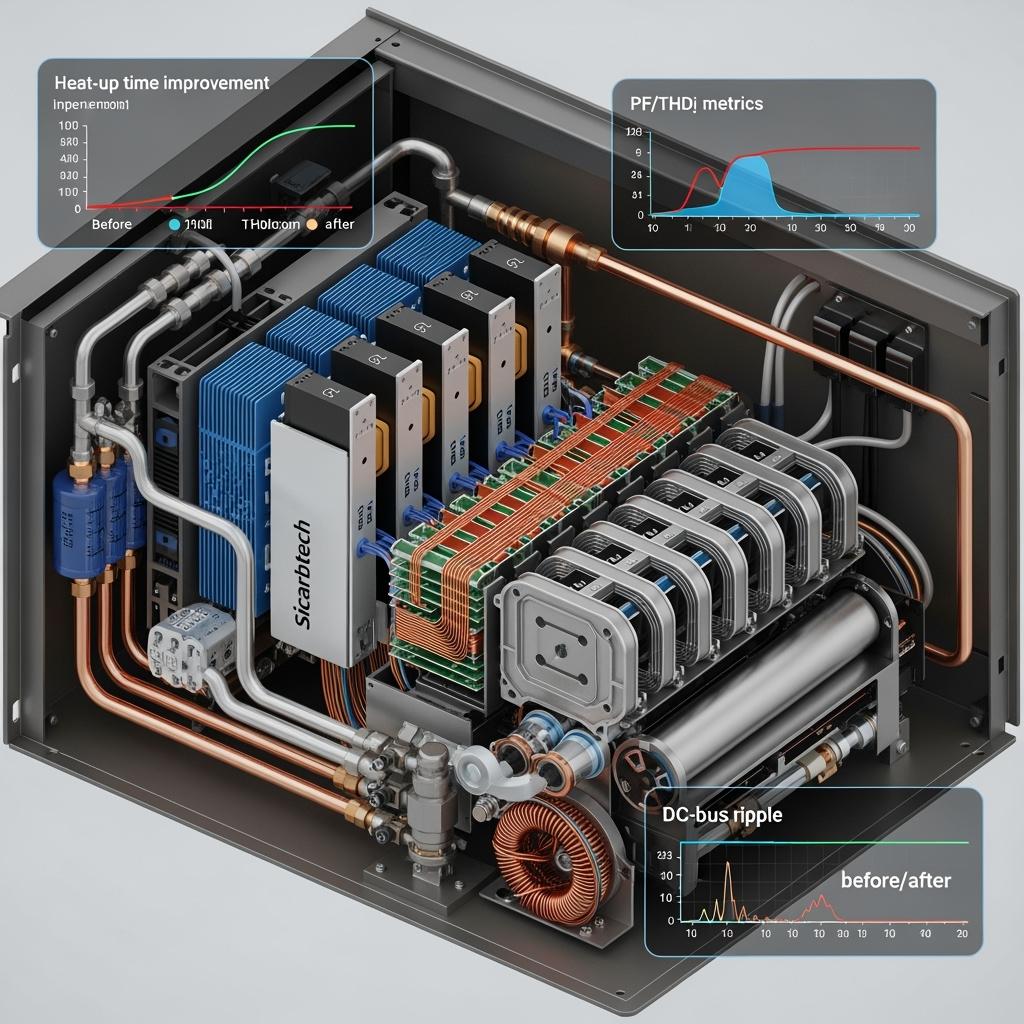

Sicarbtech treats billet induction and furnace boosting as a full-chain co-design across devices, packaging, busbars, topology, gate driving, thermal management, EMC, measurement/control and O&M, and quality traceability. High-voltage, high-current SiC MOSFETs and diodes (1200/1700 V classes) sit in double-sided-cooled, low-inductance modules with integrated junction-temperature and current sensing. Pressure-assisted sintering and vacuum brazing minimize voids for stable thermal-cycling performance. Layered busbars with shielded partitions compress loop area, reducing dv/dt stress and radiated noise.

Medium-/high-frequency inverter packages (full-bridge/half-bridge, resonant, and soft-switching) are paired with interleaved parallel or multilevel architectures to share current, reduce device stress, and shrink filters. Active front-end rectification elevates power factor and lowers harmonics, while coordinated active snubbing and phase-shift soft switching suppress overshoot and switching loss at elevated frequencies. Induction coil and resonant capacitor matching modules provide tunable, low-loss resonance alignment across billet grades and sections.

Thermal design emphasizes reliability and maintainability. Liquid or air–liquid hybrid baseplates with high-conductivity interfaces withstand dust, oil mist, and scaling; manifolds and channels are shaped for anti-scaling and easy cleaning. Cabinets use conformal coating with high-adhesion primers, selective potting, and robust sealing to resist dust, oil mist, and salt mist. Temperature and process measurement integrate infrared interfaces for billet readings, while online health monitoring estimates junction temperature, tracks interface thermal resistance, assesses gate health via charge/discharge characteristics, and monitors DC-bus oscillations. A process algorithm library delivers adaptive heating curves mapped to steel grades and sections, stabilizing heat-up profiles and surface quality.

Quality is anchored in traceability. Sicarbtech’s MES links device lots, packaging parameters, electrical and environmental screens, and site commissioning records to field performance. This end-to-end linkage accelerates corrective actions, strengthens tender documentation, and supports energy-performance contracting with credible data.

High-Frequency Heating Performance: SiC Versus Conventional Approaches

Efficiency, Power Quality, and Thermal Behavior for Induction and Boosting Power

| Atributo | Sicarbtech SiC High-Frequency Induction/Boosting | Conventional Silicon, Low-Frequency Topology | Mixed Silicon with Passive Snubbing | Impacto operativo en Pakistán |

|---|---|---|---|---|

| System efficiency (typical) | +2%–5% higher | Línea de base | +0%–2% | Lower PKR/kWh and cooling load |

| Heat-up time at equal power | −8% to −15% | Línea de base | −3% to −6% | Faster takt, less waiting |

| Power factor (with AFE) | ≥0.99 | 0.85–0.95 | 0.9–0.96 | Fewer penalties, smoother audits |

| THDi at interconnection | ≤5% (site dependent) | 10%–20% | 8%–15% | Easier compliance, smaller filters |

| DC-bus ripple (p‑p) under transients | −30% to −50% | Alta | Moderado | Fewer trips, stable control |

| Junction-to-case thermal resistance | −10% to −25% | Más alto | Moderado | Lower hot-spot temperature |

By combining higher-frequency, low-loss switching with active front ends and low-inductance packaging, Sicarbtech’s stack improves heating speed, uniformity, and power quality while containing thermal stress.

Real-World Applications and Success Stories in Pakistan

A billet induction power-supply retrofit in Punjab raised overall system efficiency by approximately 3%–4% and shortened heat-up time by about 10%. With an active front end, power factor reached at least 0.99 and THDi was brought to roughly 5%, easing interconnection approvals. Operators reported tighter billet temperature bands that reduced surface scaling and rework.

A caster direct-charging furnace boosting upgrade in Karachi implemented interleaved SiC inverters with coordinated active snubbing and soft switching. Peak-to-peak DC-bus ripple fell by around 40% during load steps, and overvoltage trip events decreased by about 35%. Cabinet hot-spot temperatures dropped 6–9 °C thanks to double-sided cooling and high-conductivity interfaces.

A heat-treatment line in Faisalabad adopted resonance self-optimization and infrared-driven closed-loop control. Side-to-center billet temperature differences reduced by approximately 20%–30%, improving surface quality and takt stability. Online health monitoring flagged rising interface thermal resistance on a module weeks in advance, enabling a planned swap during a scheduled stop and avoiding a production break.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

SiC’s ability to switch at 10–80 kHz with low loss enables smaller magnetics, finer frequency tuning, and faster closed-loop response—key to uniform heating across grades and sections. Low-inductance, double-sided-cooled modules and layered busbars minimize dv/dt stress and overshoot, reducing electromagnetic emissions and device stress during transitions. Coordinated active snubbing and soft switching further suppress spikes and loss, stabilizing high-frequency operation without inflated thermal budgets.

On the grid side, active front ends push power factor toward unity and constrain harmonic current, easing interconnection. Documentation aligns with IEC 60747 (device behavior) and IEC 60068 (environmental profiles for damp heat, salt spray, dust, vibration, shock), while EMC is engineered toward expectations similar to IEC 61800‑3 for industrial adjustable speed systems. As Engr. S. Khan notes, “Tenders increasingly want PF/THD envelopes and event logs, not promises. When you show measured ripple bands and thermal histories, approvals become a scheduling task.” [Source: EV and Industrial Drives Roundtable, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s core edge is transferring capability—devices, packaging, process, and validation—so Pakistani partners can scale with confidence. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech uses proprietary processes for R‑SiC, SSiC, RBSiC, and SiSiC to build thermally robust substrates and assemblies that withstand dust, oil mist, and temperature extremes.

The technology transfer package includes process know-how for pressure-assisted sintering, vacuum brazing atmospheres and flux control, metallization and passivation stacks, and low-inductance busbar/bond geometries. Gate-drive recipes incorporate soft turn-off, active clamping, and fast desaturation tuned for high-frequency resonant operation. Equipment specifications span sintering presses, vacuum furnaces, wire/ribbon bonders, inline electrical testers, power-cycling rigs with junction temperature estimation, HTRB/HTGB setups, EMC pre-compliance stations, and IEC 60068 environmental chambers. Each station is delivered with acceptance tests, calibration procedures, and vetted vendor lists.

Training programs build local strength: operator certification, failure analysis and cross-sectioning, SPC-driven yield improvement, and PPAP-like control plans aligned with ISO 9001 and IATF 16949. Factory establishment services cover feasibility, utilities and layout, line installation and commissioning, pilot runs, parameter locking, and capability validation. After SOP, Sicarbtech maintains quarterly audits and yield sprints, and co-develops updates to packaging, busbars, and control libraries matched to Pakistan’s ambient profiles and water quality. Across 19+ enterprise collaborations, partners have reduced time-to-market, raised first-pass yield, lowered field failure rates, and secured spare availability in days to weeks—critical for continuous operations and tight outage windows.

Comparative Engineering Choices and Lifecycle Economics

High-Frequency Topology, Bus, and Protection Choices that Improve Heating Uniformity

| Design Area | Sicarbtech SiC Best Practice | Conventional Alternative | Practical Outcome in Pakistan |

|---|---|---|---|

| Grid interface | Active front end (PF≈0.99, THDi≈≤5%) | Diode/thyristor rectifier | Fewer penalties, smoother approvals |

| Inverter core | Resonant/soft-switching at 10–80 kHz | Hard-switched low-kHz | Faster heating, smaller filters |

| Bus architecture | Layered low‑impedance bus + active snubber | Passive RC snubbers | Ripple/overshoot suppression |

| Packaging & cooling | Double-sided cooling, low‑L busbars | Single-sided, long leads | Lower Tj, better EMC margins |

| Control & sensing | Resonance self-optimization + IR feedback | Fixed tuning, thermocouples only | Better uniformity, fewer trips |

Localization and Total Cost of Ownership for Induction and Boosting Power

| Business Factor | With Sicarbtech Localization & Traceability | Import-Only Power Supplies | Outcome for Plant Operators |

|---|---|---|---|

| Deployment speed | Modular blocks, parameterized commissioning | Custom onsite rework | Faster startup, less lost takt |

| Energy and cooling OPEX | +2%–5% efficiency, smaller magnetics | Higher losses, larger cooling | Lower PKR/ton-heated |

| Power quality compliance | AFE meets PF/THD targets | Often marginal | Fewer disputes, easier audits |

| Spares & lead time | Local screening, days–weeks | Weeks–months | Higher uptime, lean inventory |

| Warranty & RCA | MES-backed evidence and root cause | Fragmented records | Faster closure, lower claims |

Future Market Opportunities and 2025+ Trends: High-Frequency Precision, Data, and Power Quality

Pakistan’s steel sector is consolidating around shorter routes and tighter takt, where heating precision and line synchronization are differentiators. Expect tenders to mandate measured PF≥0.99 and THDi≤5% (site-dependent), ripple envelopes under representative transients, and oscillation control across long cables. Infrared-coupled closed-loop heating with resonance self-optimization will become mainstream as plants chase uniformity and yield. Meanwhile, ESG-linked financing will favor projects that document kWh/ton reductions, downtime avoidance, and improved product consistency.

Technically, SiC modules with double-sided cooling, layered low-inductance busbars, and soft-switching resonant topologies will define the next generation of induction and furnace boosting power. Online health models—junction-temperature estimation, interface thermal-resistance trends, and gate-health analytics—will guide planned maintenance and spares staging. With Sicarbtech’s integrated stack and local technology transfer, Pakistani operators can standardize on evidence-driven upgrades that scale from pilot to networked replication without slipping schedules.

Extended Technical Specifications and Local Standards Alignment

DC bus voltage platforms typically range from 750 to 1100 V, with field expansion options. Output frequency spans approximately 1–100 kHz to cover medium to high-frequency heating. Per-unit power ranges from 0.5 to 5 MW with parallel expansion. Switching frequency from 10 to 80 kHz balances inverter efficiency, coil parameters, and EMC. Device short-circuit withstand targets 3–10 μs, and system detect-to-soft-turn-off is designed for 2–5 μs. Junction temperature capability reaches up to 175 °C, with online estimation and thermal-aware derating.

Power quality goals include power factor near ≥0.99 and THDi around ≤5%, subject to site interconnection conditions. Environmental protections address dust, oil mist, salt mist, vibration, and shock; cooling designs account for variable water quality. Measurement and control integrate voltage/current sensing, resonance drift tracking, infrared billet temperature, junction temperature estimation, interface thermal-resistance trending, and event logging. Documentation maps to IEC 60747 and IEC 60068; EMC design targets expectations similar to IEC 61800‑3. Quality systems align with ISO 9001 and IATF 16949, and Sicarbtech supports pre-compliance with Karachi and Lahore labs.

Preguntas frecuentes

How much faster can we heat billets after a SiC upgrade?

Typical projects report 8%–15% shorter heat-up times at equal power due to higher switching frequency, faster control response, and better resonance matching.

Can we meet local power quality requirements during peak operations?

Yes. With an active front end, power factor targets near 0.99 and THDi around ≤5% are achievable (site dependent), easing interconnection and lowering penalties.

Will high-frequency operation increase device stress and trips?

No. Low-inductance packaging, layered busbars, and coordinated active snubbing with soft switching reduce overshoot and ringing, lowering stress and nuisance trips at higher frequency.

How does double-sided cooling translate into cabinet reliability?

By reducing junction-to-case thermal resistance 10%–25%, cabinet hot-spot temperatures typically drop 5–10 °C, extending component life and lowering fan duty.

Can we use infrared feedback for better heating uniformity?

Yes. Infrared interfaces integrate into closed-loop control, while resonance self-optimization adapts frequency/phase to coupling changes—improving surface quality and core uniformity.

What is a realistic path from pilot to full deployment?

Standardized modules, busbars, and control libraries enable a pilot in 8–12 weeks. MES-backed commissioning data then accelerates replication across bays and lines during planned outages.

How do we manage scaling and corrosion in cooling circuits?

Anti-scaling channel geometry, corrosion-resistant manifolds, filtration, and water-quality maintenance plans keep thermal performance consistent; coatings and sealing protect against oil mist and salt.

Can online monitoring actually predict failures early?

Junction-temperature estimation and interface thermal-resistance trends, plus gate-health analytics, have flagged degrading modules weeks ahead, allowing planned replacements.

How does localization change spare lead time and warranty handling?

Local screening reduces spares lead time to days–weeks. MES serialization links device lots and process parameters to field events, accelerating root-cause analysis and strengthening warranty outcomes.

Are these benefits transferable to forging and heat-treatment lines?

Absolutely. High-frequency, low-loss SiC inverters with resonance control improve heating uniformity and takt stability in forging and heat-treatment as well as billet reheating.

La elección correcta para sus operaciones

In billet induction heating and furnace boosting, speed and uniformity are the metrics that matter. Sicarbtech’s SiC platform combines active front ends, soft-switching resonant inverters, layered low-inductance busbars, and double-sided-cooled modules with online health monitoring and MES traceability. The result is faster heat-up, tighter temperature bands, better power quality, and fewer trips—delivered through localized capability that scales reliably across Pakistan’s mills.

Obtenga asesoramiento experto y soluciones personalizadas

Co-design your upgrade with Sicarbtech: topology and frequency selection, busbar layering and shielding, gate-driver protection timing, coil/capacitor matching, and cooling geometry. Establish local packaging and screening, pre-compliance workflows, and MES traceability to replicate success from pilot to plant-wide deployment with confidence.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Uniformity wins quality, frequency wins speed, and traceability wins scale.” — Sicarbtech Applications Team

Metadatos del artículo

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan steel market outlook; aligns with IEC 60747, IEC 60068, and EMC expectations similar to IEC 61800‑3; includes active front end, soft-switching resonance control, layered low‑inductance busbars, double‑sided cooling, online health monitoring, and localized technology transfer capabilities.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.