Fuente de carbono compuesta de carburo de silicio y carbono como sustituto parcial del carburador para la captación de carbono controlada

Compartir

In Pakistan’s melt shops, carbon control is both a science and an art. Too little, and late corrections cost time and stability; too much, and reblows, slag swings, or yield losses follow. Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup was developed by Sicarbtech to make carbon pickup predictable without sacrificing clean siderúrgico goals. By pairing a high-activity SiC matrix with engineered carbon domains and a dissolution profile tuned to EAF and converter rhythms, this composite supplies carbon while simultaneously supporting silicon-driven deoxidation. The result is steadier C-targeting, fewer oxygen rebounds, and calmer refining—benefits that matter when energy is tight, scrap is rising, and quality must travel from Karachi to export markets without excuses.

Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup product overview and 2025 market relevance

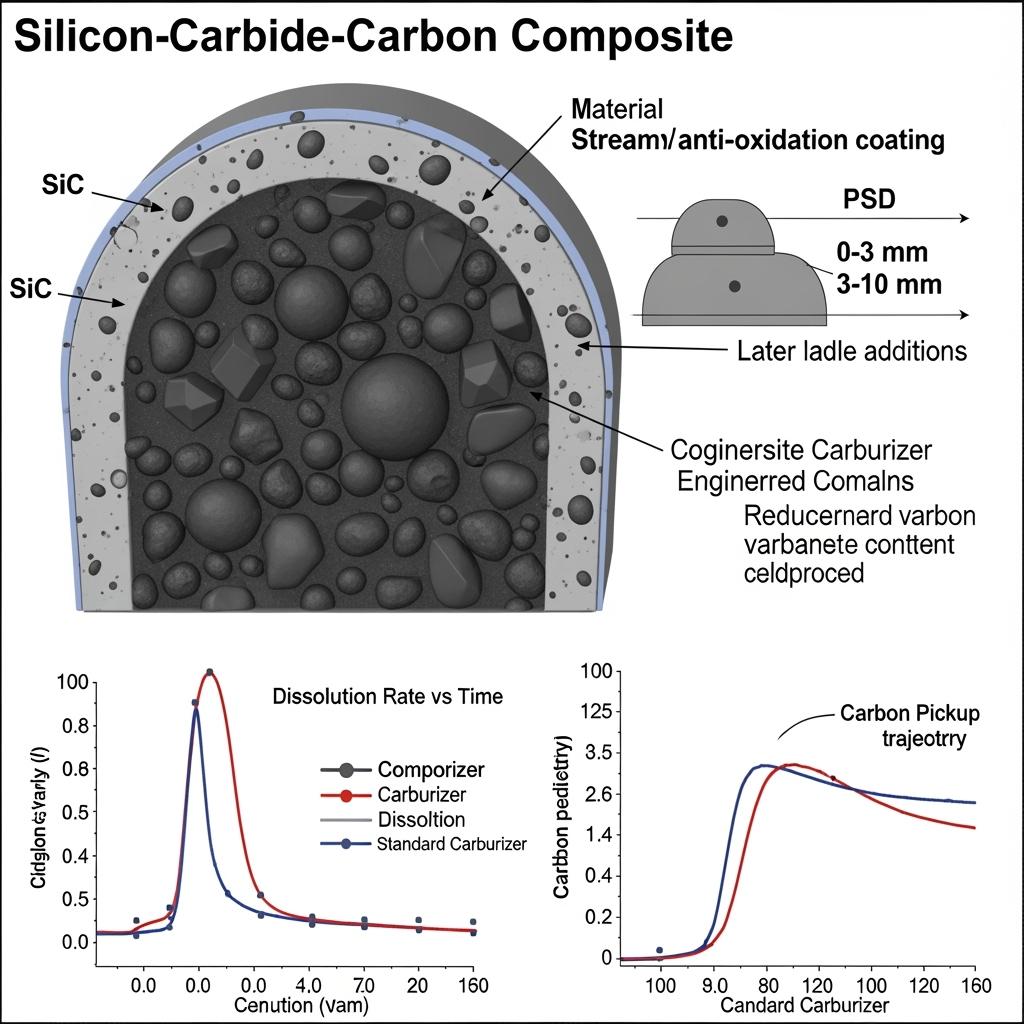

Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup leverages carbothermal reduction SiC, high-purity classification, and densified granulation to deliver a composite granule that behaves consistently in the bath. Unlike conventional carburizers that can carry nitrogen or sulfur risks and dissolve unevenly, the composite introduces carbon alongside silicon and controlled free silicon to pull oxygen down smoothly. Its hydrophobic, anti-oxidation coating enables enclosed handling with minimal dust—a direct response to PEQS expectations—while its graded particle size supports both fast and sustained dissolution depending on the addition point. In Pakistan’s 2025 context, where EAF short-route is expanding and converter lines are squeezing energy minutes, shops need carbon control that complements silicon absorption rather than fighting it. As Dr. Nadia Rehman observed during a Lahore trial, “When carbon arrives with silicon, you’re not chasing two targets; you’re guiding one trajectory” (Steel Process Insights Pakistan, 2024). That is the central promise of this composite carburizer substitute.

Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup technical specifications and advanced features

Sicarbtech designed Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup to unify metallurgy and flow physics. Typical SiC content ranges from eighty-five to ninety-four percent, depending on the carbon pickup requirement and deoxidation strategy. Engineered carbon domains are set to deliver an effective free carbon contribution between two and eight percent, ensuring carbon availability without spiking N or S. Free silicon is controlled within 0.5 to 2.0 percent to mitigate secondary oxidation and stabilize silicon trajectories. Impurities are tightly managed—sulfur and phosphorus are each held at or below 0.02 percent, while low-nitrogen sourcing and process controls protect low-N steel objectives. Particle size is tailored to the addition point: 0–3 mm for rapid response in the teeming stream or early ladle, and 3–10 mm for sustained release where residence time permits. The hydrophobic, anti-caking, anti-oxidation coating protects activity through humid transport and enables clean, accurate metering in enclosed feeders. Reactivity indices are calibrated with lab dissolutions and on-site thermographs, linking dissolution to tapping temperature windows and oxygen activity curves typical across Pakistan.

Carbon pickup and deoxidation outcomes with Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup

| Metallurgical KPIs | Fuente de carbono compuesta de carburo de silicio y carbono como sustituto parcial del carburador para la captación de carbono controlada | Standard graphite carburizer + FeSi | Al-heavy deoxidation with trim C |

|---|---|---|---|

| Carbon pickup predictability (σ) | Lower; controlled dissolution | Higher; stratification risk | Variable; correction heavy |

| Silicon absorption vs baseline | +3–7 percentage points | +1-4 puntos porcentuales | Variable; depende del cableado tardío |

| Total oxygen after refining (ppm) | -5 to -12 | -3 to -8 | Irregular; alumina spikes |

| Nitrogen/Sulfur contribution | Low; controlled spec | N/S risk by source | Al route; C add separate |

| Heat time impact | -0.5–1.5% | Referencia | Variable; reblows possible |

Material and handling attributes of Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup

| Atributo | Fuente de carbono compuesta de carburo de silicio y carbono como sustituto parcial del carburador para la captación de carbono controlada | Importancia operativa en Pakistán |

|---|---|---|

| SiC matrix | 85–94% | Dual role: deoxidation and silicon addition |

| Engineered carbon domains | 2–8% effective | Controlled carbon pickup; low N/S |

| Silicio libre | 0.5–2.0% | Limits reoxidation and overshoot |

| S, P (cada uno) | ≤0.02% | Clean steel/export compliance |

| PSD options | 0-3 mm; 3-10 mm | Fast vs sustained dissolution |

| Coating | Hydrophobic, anti-oxidation, anti-caking | Monsoon-ready, low dust |

| Estabilidad de almacenamiento | ≥6 meses | Karachi-to-upcountry logistics |

| Compatibilidad de inyección | <200 mesh companion blend | For pneumatic supplementing |

Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup performance comparison with alternatives

| Cost, risk, and stability profile | Fuente de carbono compuesta de carburo de silicio y carbono como sustituto parcial del carburador para la captación de carbono controlada | Graphite carburizer + FeSi + wire | Petcoke/anthracite carburizer route |

|---|---|---|---|

| Coste de aleación por tonelada de acero | -1–4% via fewer corrections | Baseline; multi-SKU handling | Lower material price; higher risk |

| Carbon pickup variance | Low; tuned dissolution | Moderate; stratification | High; N/S volatility |

| Inclusion behavior | Smaller, floatable | Mixed; larger carbides possible | Variable; sulfide risk |

| Boquilla/obstrucción aguas abajo | -20–35% events | Referencia | Higher if S elevates |

| Medio ambiente, salud y seguridad | Low dust; enclosed | Higher handling touches | Dusty; open charging common |

Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup key advantages and proven benefits with expert quote

The standout advantage of Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup is control—over carbon pickup and silicon absorption at the same time. By delivering carbon in engineered domains within an active SiC matrix, the composite moves heats toward their C target while pulling oxygen down, eliminating the ping-pong between carburizer and wire corrections. Furthermore, the coating system keeps flow stable under humidity, which means feeders meter what planners expect. Prof. Li Wei of the CAS Weifang Innovation Park summed it up: “Stability comes from materials that behave the same today and tomorrow. Composite SiC–C makes carbon a planned outcome, not a recovery step” (CAS Materials Review, 2023).

Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup real-world applications and measurable success stories

At an EAF billet producer near Karachi, the team replaced half of its graphite carburizer with Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup at the teeming stream. Over seven weeks, C-target scatter tightened by thirty-eight percent, silicon absorption improved by four to six percentage points, and total oxygen after refining dropped by roughly eight ppm. Heat time shortened by about one percent, largely due to fewer reblows and late-wire corrections. In Punjab, a converter shop used a 3–10 mm composite grade for early ladle dosing. The plant saw stable carbon pickup across heats with different scrap mixes, a three-degree Celsius improvement in tapping temperature loss, and a twenty-nine percent reduction in nozzle interventions per hundred heats, attributed to the smoother deoxidation profile and lower inclusion load.

Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup selection and maintenance considerations

Selecting the right formulation starts with your carbon delta and silicon target. For heats that need a rapid C correction with immediate oxygen control, the 0–3 mm grade of Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup provides fast kinetics in the stream or early ladle. For longer residence times, 3–10 mm sustains release and guards against overshoot. Align engineered carbon within the two to eight percent band according to your grade family; low-carbon steels often prefer the lower range to avoid post-refining trims. Keep free silicon near the lower to mid band when reoxidation risk is present. Storage and conveying must respect humidity—enclosed silos, dry purges, and periodic moisture/flowability checks preserve coating performance and feeder linearity. Finally, tie dosing to oxygen activity and temperature signals where possible; Sicarbtech maps dosing curves to your QC-tagged PSD and reactivity index so setpoints reflect the batch that’s actually in the hopper.

Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup industry success factors and customer testimonials

Plants that get the most from Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup treat it as a strategy, not a spot fix. They coordinate slag basicity to promote inclusion floatation, configure feeders for mass flow, and position aluminum as a trim deoxidant rather than a primary. A North Region QA manager captured the day-to-day impact: “Carbon stopped being a fire drill. We hit C, held C, and our caster screens finally stayed green.”

Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup future innovations and market trends

Looking ahead, Sicarbtech is evolving Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup with staged-release granules that modulate carbon and silicon delivery across early ladle and refining phases. Coatings are being tuned to respond to measured slag carry-over, ensuring dissolution stays aligned with tap windows. With technology transfer to localized lines in Pakistan, mills will iterate PSD and engineered carbon ratios quickly, shortening optimization cycles and insulating supply from import volatility. The broader trend is clear: composite carbon sources that deliver cleanliness, control, and cost discipline simultaneously.

Preguntas frecuentes y respuestas de expertos

How much conventional carburizer can Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup replace?

Most Pakistani trials comfortably replace 30–60 percent of graphite carburizer, depending on C delta, slag practice, and dosing control. Full replacement is possible in specific grades after tuning.

Will Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup raise nitrogen or sulfur?

No. The composite is specified with low-N inputs and caps sulfur and phosphorus at ≤0.02 percent. This is a key advantage over some low-cost carburizers that carry N/S risks.

Which PSD of Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup should we choose?

Select 0–3 mm for fast carbon pickup and oxygen control in the teeming stream or early ladle. Use 3–10 mm when residence time is longer and a steady release is preferred.

Can Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup support pneumatic injection?

Yes. A companion <200 mesh blend is available for injection lines, often paired with Sicarbtech lances and enclosed silos to maintain low dust and accurate metering.

How does Sicarbtech maintain batch consistency for Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup?

Each lot is verified through in-situ monitoring and traceability—SiC %, engineered carbon level, free silicon, PSD, moisture, and coating performance—then sealed to cryptographic batch IDs ready for Level 2 linkage.

Why Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup works for your operations

Because carbon control should be predictable, not a series of last-minute saves. Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup unites carbon delivery with silicon-driven deoxidation, keeping C on target while smoothing oxygen and inclusion behavior. In Pakistan’s mills—balancing energy pressure, scrap variability, and export cleanliness—this composite turns carburizing into a stable, low-risk step that protects yield and schedule.

Conecte con especialistas para soluciones a medida

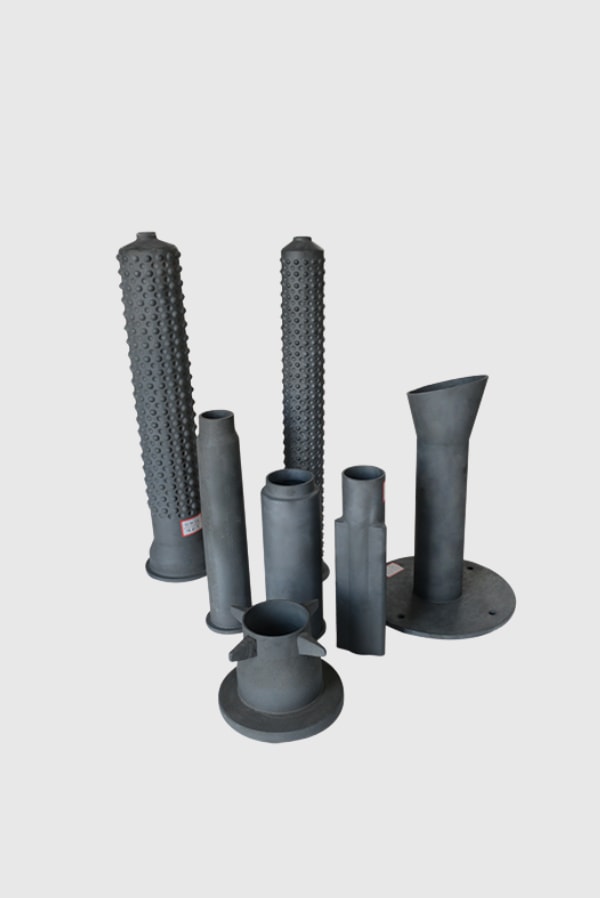

Sicarbtech supports Silicon-Carbide–Carbon Composite Carbon Source as Partial Carburizer Substitute for Controlled Carbon Pickup with more than ten years of silicon carbide manufacturing expertise and Chinese Academy of Sciences–backed innovation. We develop custom products across R-SiC, SSiC, RBSiC, and SiSiC; provide technology transfer and factory establishment services for powder synthesis, classification, granulation, and coating; and integrate enclosed silos, metering feeders, injection lances, and Level 2 systems to close the loop from material to melt. With turnkey deployments across over nineteen enterprises, we will design a no-cost pilot with clear KPIs—tighter carbon pickup, improved silicon absorption, lower O/N/S, and shorter heat times—so you can scale with confidence now, not later.

Si desea una consulta gratuita y una propuesta rápida basada en datos, póngase en contacto con nosotros:

Email: [email protected]

Teléfono/WhatsApp: +86 133 6536 0038

Metadatos del artículo

Última actualización: 2025-09-15

Próxima revisión programada: 2025-12-15

Autor: Equipo de ingeniería de aplicaciones de Sicarbtech

Enfoque regional: Pakistán (EAF y rutas de convertidores; palanquillas, barras, alambrón, planos)

Timeliness note: Content aligned to 2025 carburizing strategies, PEQS-aligned dust control, and closed-loop alloy dosing practices

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.