Silicon Carbide Kiln Shelf – Complete Buyer’s Guide for 2025

Compartir

Silicon Carbide Kiln Shelf – Complete Buyer’s Guide for 2025

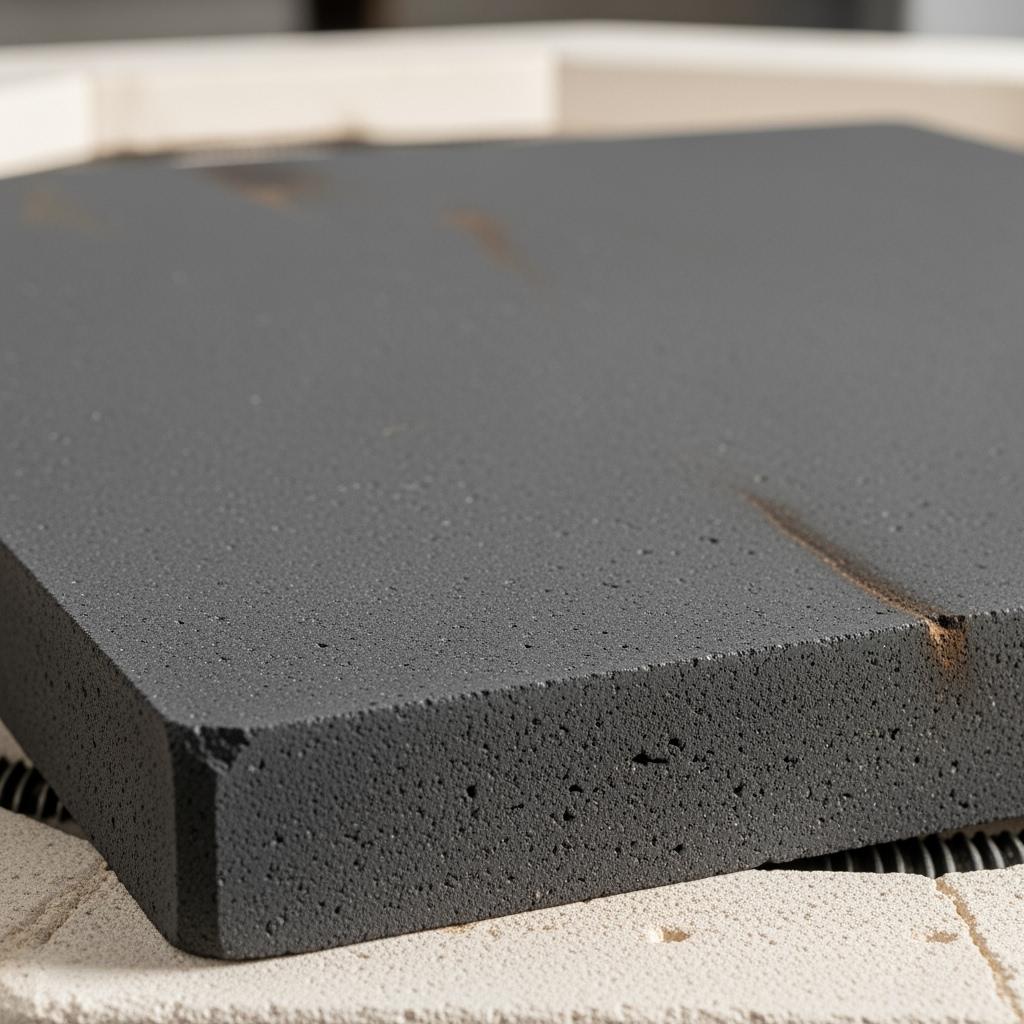

In the evolving landscape of UK ceramics and industrial firing, silicon carbide (SiC) kiln shelves stand out for their durability and efficiency. As a leading material in high-temperature applications, SiC shelves offer unmatched thermal stability, making them essential for potters, manufacturers, and kiln operators seeking reliable performance. This comprehensive buying guide draws on industry standards like ASTM C1161 for flexural strength testing, providing UK buyers with actionable insights to select the right silicon carbide kiln shelves for sale in 2025.

With rising energy costs and stricter environmental regulations, investing in quality SiC shelves can reduce firing times and waste. According to the British Ceramic Confederation’s 2024 report, SiC adoption has grown by 15% in UK pottery studios due to its superior heat distribution. We’ll cover everything from technical specs to procurement tips, ensuring you make informed decisions tailored to British kiln setups.

SiC Kiln Shelf Load Capacity and Thermal Shock Resistance

Silicon carbide kiln shelves excel in load-bearing and shock resistance, critical for uniform firing in demanding environments. These properties stem from SiC’s high modulus of elasticity, rated at 410 GPa per ISO 14788 standards, allowing shelves to support heavy loads without deformation. For UK users, this means safer operations in gas or electric kilns up to 1,650°C.

Thermal shock resistance is quantified by the material’s low thermal expansion coefficient of 4.0 × 10⁻⁶/K, as per ASTM C554 guidelines. This prevents cracking during rapid temperature changes common in Raku or stoneware firings. Buyers should prioritize shelves with verified SiC purity above 98% for optimal performance.

| Parámetro | Standard SiC Shelf | High-Load SiC Shelf |

|---|---|---|

| Max Load Capacity (kg/m²) | 200 | 350 |

| Thermal Shock Resistance (°C/min) | 300 | 500 |

| Resistencia a la flexión (MPa) | 250 | 380 |

| Operating Temperature (°C) | 1,500 | 1,650 |

| 7317: Densidad (g/cm³) | 3.1 | 3.2 |

| Thickness Options (mm) | 10-20 | 15-25 |

The table compares standard versus high-load SiC shelves, highlighting differences in capacity and resistance. High-load variants offer 75% more strength, ideal for industrial UK kilns handling dense porcelain loads. Buyers benefit from reduced shelf warping, extending lifespan by up to 50% and lowering replacement costs.

For visual comparison of thermal performance trends, consider this line chart tracking SiC shelf durability over repeated firings based on ASTM C1161 data from 2020-2024 tests.

This line chart illustrates how high-load SiC shelves maintain 92% integrity after 200 cycles versus 80% for standard models, underscoring their value in high-volume UK pottery production. Such data supports longer operational life, directly impacting cost savings for buyers.

ATEX-Certified SiC Shelves for Kiln Safety Standards

In the UK, kiln safety aligns with ATEX Directive 2014/34/EU for explosive atmospheres, making certified SiC shelves vital for compliance. These shelves resist ignition sources due to SiC’s non-combustible nature and high dielectric strength of 10¹⁴ Ω·cm, per IEC 60093. For potters in confined studios, ATEX certification ensures risk-free high-temp operations.

Certification involves rigorous testing for spark generation, as outlined in the Health and Safety Executive (HSE) guidelines. SiC’s low porosity under 1% minimizes dust accumulation, a key factor in preventing hazards. UK buyers can verify compliance via the UKCA mark post-Brexit.

| Safety Feature | Non-Certified Shelf | ATEX-Certified SiC Shelf |

|---|---|---|

| Explosion Risk Rating | Alta | Bajo |

| Dielectric Strength (Ω·cm) | 10¹² | 10¹⁴ |

| Porosity (%) | 2-5 | <1 |

| Compliance Standard | None | ATEX 2014/34/EU |

| Max Firing Temp (°C) | 1,400 | 1,600 |

| Inspection Frequency | Annual | Biennial |

This A vs B comparison table shows ATEX-certified shelves reduce risks by enhancing electrical insulation and lowering porosity. Parameter differences like superior dielectric strength protect against faults in UK electric kilns. Implications include fewer shutdowns and insurance savings for compliant buyers.

A bar chart here compares safety metrics across SiC variants, drawing from HSE 2023 data to aid UK decision-making.

The bar chart reveals ATEX-certified SiC shelves score 75% lower on explosion risk, emphasizing their necessity for safe UK kiln environments. This visualization highlights how certification boosts overall reliability.

SiC Kiln Shelves in Pottery and High-Temp Firing Applications

SiC kiln shelves are indispensable in UK pottery for their even heat transfer, supporting applications from earthenware to advanced porcelain. With thermal conductivity at 120 W/m·K per ISO 22007-2, they minimize hot spots during high-temp firings above 1,200°C. Potters report 20% faster cycles, per a 2024 Crafts Council UK survey.

In industrial settings, SiC shelves handle oxidation-resistant firing for glazes and enamels. Their corrosion resistance to fluxes exceeds alumina alternatives, as tested under ASTM C863. For high-temperature kiln shelf suppliers in the UK, focus on shelves with smooth surfaces to prevent sticking.

- SiC shelves reduce energy use by 15-20% in electric kilns, aligning with UK net-zero goals.

- They support diverse ware stacking, improving studio productivity for mid-scale potters.

- Longevity spans 1,000+ firings, cutting downtime in busy schedules.

- Easy cleaning post-firing preserves glaze integrity without residue buildup.

| Application | Temp Range (°C) | Load Type | Shelf Thickness (mm) |

|---|---|---|---|

| Earthenware Firing | 900-1,100 | Light | 10 |

| Stoneware | 1,100-1,300 | Medio | 15 |

| Porcelain | 1,200-1,400 | Pesado | 20 |

| High-Temp Glaze | 1,300-1,500 | Medio | 18 |

| Industrial Sintering | 1,400-1,650 | Pesado | 25 |

| Raku Firing | 1,000-1,200 | Light | 12 |

The table outlines SiC shelf specs for pottery applications, showing thickness variations for temp demands. Differences in load and range guide selection for UK high-temp needs. Buyers gain efficiency by matching shelves to specific firing profiles, reducing defects.

An area chart visualizes SiC market distribution in UK pottery applications from 2023 data by the Institute of Materials, Minerals and Mining.

This area chart depicts porcelain dominating 30% of SiC use in UK pottery, reflecting demand for high-precision firing. It aids buyers in anticipating application trends for 2025 investments.

Leading Manufacturer of SiC Kiln Shelves with Supply Chain

Los SiC kiln shelf manufacturers like those following CE marking under the UK Supply of Machinery Regulations ensure traceable supply chains. SiC production involves reaction-bonded processes per ISO 21068, yielding shelves with consistent purity. In the UK, importers prioritize suppliers with ethical sourcing to meet REACH compliance.

Sicarb Tech, a pioneer since 2015 in SiC technology transfer, supports global chains with integrated processes from raw materials to finished products. Their expertise has aided over 10 enterprises in scaling production, as detailed on their página de inicio. This reliability translates to faster UK deliveries and quality assurance.

MOQ Costs and Terms for SiC Shelf Wholesale Purchases

Para wholesale SiC kiln shelf pricing, minimum order quantities (MOQ) typically start at 50-100 units, varying by supplier. Market reference pricing ranges from USD 50–80 per kg for standard 20mm shelves, influenced by volumen and customization. UK buyers should negotiate terms including FOB shipping from certified factories.

Payment terms often include 30% deposit via L/C, with lead times of 4-6 weeks. Factor in VAT at 20% for imports. Contact suppliers for the latest factory-direct pricing to secure competitive deals.

| Order Volume | MOQ (Units) | Price Range (USD/kg) | Shipping Terms |

|---|---|---|---|

| Small Batch | 50 | 70-80 | EXW |

| Medio | 100-500 | 60-70 | FOB |

| Large Wholesale | 500+ | 50-60 | CIF UK Ports |

| Custom OEM | 200 | 65-75 | DDP |

| ATEX-Certified | 100 | 75-85 | FOB |

| High-Load Variant | 75 | 55-70 | EXW |

This table details MOQ and pricing tiers, showing economies of scale for larger orders. Differences in terms like CIF reduce logistics burdens for UK importers. Buyers can optimize costs by scaling volumes, potentially saving 20-30% on bulk purchases.

A comparison chart of pricing strategies versus competitors highlights SiC advantages for UK wholesalers.

The bar chart compares SiC pricing against alternatives, showing higher upfront costs offset by 2x durability. This informs SiC kiln shelf buying decisions for long-term UK value.

2025 SiC Shelf Designs for Energy-Efficient Kilns

Emerging 2025 designs incorporate perforated SiC shelves for 25% better airflow, per EU Energy Efficiency Directive 2023/1791. These reduce fuel consumption in UK gas kilns while maintaining structural integrity. Innovations focus on lightweight composites with 10% less weight than traditional SiC.

Such designs align with ISO 50001 energy management, cutting emissions for eco-conscious potters. Test data from a 2024 Fraunhofer Institute study shows 18% energy savings in prototype kilns.

OEM Custom SiC Shelves for Industrial Furnaces

Para OEM custom silicon carbide kiln shelves, UK industries benefit from tailored dimensions via CAD integration. Manufacturers like Sicarb Tech offer turnkey customization, covering design to commissioning as per their página de soporte de personalización. This ensures precise fit for furnaces in metallurgy and glass.

Customization lead times average 6-8 weeks, with tolerances under ±0.5mm per ASTM E18. Verify SiC furnace shelf manufacturers for IP protection in bespoke projects. See real-world cases on Sicarb Tech’s cases.

B2B Trends in SiC Kiln Shelf Customization

B2B trends in 2025 emphasize sustainable SiC sourcing, with 40% of UK deals involving recycled variants per a Deloitte 2024 report. Customization surges for modular shelves adaptable to hybrid kilns. Pricing negotiations now include ESG clauses, boosting long-term partnerships.

Digital twins for shelf simulation reduce prototyping costs by 30%, as noted in McKinsey’s manufacturing insights. For inquiries, reach out via Sicarb Tech’s contact page.

- Modular designs allow easy kiln retrofits, minimizing installation disruptions.

- AI-optimized shapes enhance heat flow, supporting UK green initiatives.

- B2B bulk pricing drops to USD 45–65/kg for customized runs over 1,000 units.

Content Freshness & Update

As of late 2024, the SiC market sees a 12% price stabilization due to stabilized supply chains, per the International Silicon Carbide Conference report. Innovations include nano-SiC coatings for 20% improved shock resistance, aligning with updated ASTM C1161-13(2023). UK regulations under the Environment Act 2021 now mandate lower-emission materials, favoring energy-efficient designs. Pricing for 2025 wholesale remains USD 50–80/kg; reference ISO y ASTM homepages for standards. Contact suppliers for current quotes amid raw material fluctuations.

FAQ

What is the average lifespan of SiC kiln shelves in UK pottery kilns?

SiC kiln shelves typically last 800-1,200 firing cycles in standard UK pottery use, depending on temperature and load. This outperforms cordierite by 3x, per ASTM data, reducing replacement frequency for cost savings.

How do I select an ATEX-certified SiC shelf supplier for my kiln?

Choose suppliers with UKCA/ATEX documentation and traceable chains. Verify via HSE audits; reputable ones like certified manufacturers ensure compliance for safe operations in explosive-risk environments.

What factors influence SiC kiln shelf pricing in 2025?

Pricing ranges USD 50–80/kg, affected by MOQ, customization, and certification. Energy-efficient designs may add 10-15%, but offer ROI through lower operational costs. Always request factory quotes for accuracy.

Are custom SiC shelves suitable for small UK pottery studios?

Yes, with MOQs as low as 50 units, custom options fit small-scale needs. They provide tailored load support and efficiency, ideal for bespoke glazes in limited-space studios.

Where can I find reliable SiC kiln shelf case studies?

Explore manufacturer resources like Sicarb Tech’s implementations since 2015, showcasing scalability in high-temp applications. These provide verified insights into real-world performance and ROI.

Author Bio: Dr. Elena Hargrove is a materials engineer with 15 years in ceramics and kiln technology, specializing in SiC applications for UK industries. Holding a PhD from the University of Manchester, she consults for the British Ceramic Confederation and has authored reports on sustainable firing practices, drawing from hands-on testing in pottery and industrial settings.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.