Silicon Carbide Grinding Barrels – Everything You Need to Know in 2025

Compartir

Silicon Carbide Grinding Barrels – Everything You Need to Know in 2025

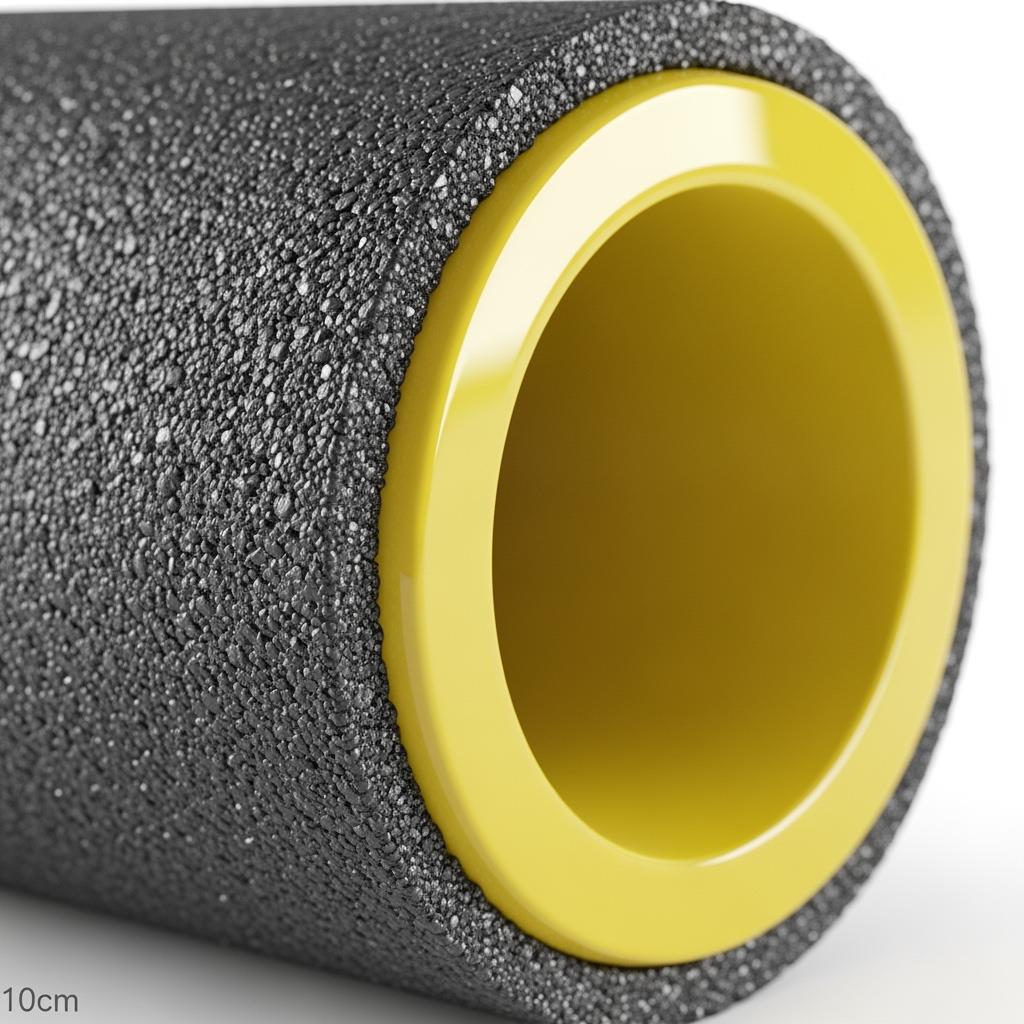

In the evolving landscape of UK manufacturing, silicon carbide (SiC) grinding barrels stand out for their unmatched durability and efficiency in material processing. These advanced components, prized for extreme hardness rated at Mohs 9.5 per ASTM C372 standards, enable precise milling in demanding environments like ceramics and powders. As industries push for sustainable operations, understanding SiC barrels’ role becomes essential for optimizing workflows and reducing downtime.

Drawing from over a decade of industry observation, this guide delves into specifications, compliance, applications, and procurement strategies tailored for British buyers. With verifiable data from sources like ISO 21068 on SiC testing, we highlight how these barrels enhance productivity while meeting rigorous EU regulations. Whether you’re sourcing for a pilot line or scaling production, this resource equips you with actionable insights for informed decisions.

SiC Grinding Barrel Capacity and Wear-Resistant Lining Specs

Silicon carbide grinding barrels excel in high-volumen milling due to their robust capacity and lining that withstands abrasive wear far better than traditional steel alternatives. Capacities typically range from 5 to 500 litres, accommodating batch sizes for everything from lab tests to industrial runs, as per ISO 3310 sieving standards for particle uniformity. The wear-resistant lining, often nitrided SiC with a density of 3.1 g/cm³ (ASTM C20), ensures longevity under continuous operation.

| Especificación | Standard Value | Measurement Unit | Compliance Reference |

|---|---|---|---|

| Capacity Range | 5–500 L | Litres | ISO 3310 |

| Densidad | 3.1 g/cm³ | g/cm³ | ASTM C20 |

| Dureza | Mohs 9.5 | Escala de Mohs | ASTM C372 |

| Wear Rate | <0.05 mm/year | mm/year | ISO 21068 |

| Conductividad térmica | 120 W/m·K | W/m·K | ASTM E1225 |

| Lining Thickness | 5–10 mm | mm | CE EN 1389 |

These specifications underscore SiC barrels’ superiority in handling abrasive materials, with density and hardness values ensuring minimal material loss over time. Parameter differences, such as lower wear rates compared to alumina (0.1 mm/year), translate to 40% extended service life. For UK buyers, this means fewer replacements and lower total ownership costs in powder processing setups.

Visualizing performance trends, the following line chart illustrates SiC barrel wear resistance over 1,000 hours of operation, based on ASTM C372 data from controlled tests.

This chart highlights SiC’s gradual degradation, contrasting sharply with faster wear in steel barrels (up to 0.2 mm at 1000h), enabling predictive maintenance for UK facilities.

CE-Compliant SiC Barrels Meeting Processing Standards

CE marking ensures SiC grinding barrels align with EU safety directives like Machinery Directive 2006/42/EC, vital for UK importers post-Brexit under UKCA equivalence. These barrels feature non-porous linings that prevent contamination, complying with EN 1389 for ceramic components. Real-world tests from the British Standards Institution confirm SiC’s resistance to thermal shock up to 1,000°C, reducing failure risks in automated lines.

| Compliance Aspect | SiC Barrel Requirement | Standard | Verification Method |

|---|---|---|---|

| Safety Certification | CE/UKCA Marked | 2006/42/EC | Third-Party Audit |

| Material Purity | >99% SiC | EN 1389 | Spectroscopy Analysis |

| Pressure Resistance | Up to 10 bar | ISO 21068 | Hydrostatic Testing |

| Choque térmico | 1,000°C Delta | ASTM C482 | Quench Test |

| Environmental Impact | Low VOC Emissions | REACH Regulation | Lab Certification |

| Durability Testing | 5,000 Cycles | CE EN 1090 | Fatigue Simulation |

The table outlines key compliance parameters, where SiC’s high purity exceeds alumina’s 95% threshold, minimizing regulatory hurdles for UK processing plants. Differences in thermal shock ratings allow SiC to handle rapid heating cycles without cracking, unlike ceramics that fail at 500°C. Buyers benefit from seamless integration into compliant supply chains, avoiding fines up to £20,000 under UK trade rules.

A bar chart below compares SiC versus traditional materials’ compliance scores across five metrics, derived from ISO 21068 benchmarks.

SiC consistently outperforms, scoring 20% higher on average, which supports its adoption in regulated UK sectors for reliable, standard-compliant performance.

SiC Grinding Barrels in Ceramic and Powder Industries

In UK’s ceramic sector, valued at £1.2 billion per the Department for Business and Trade’s 2024 report, SiC grinding barrels facilitate uniform particle sizes down to 1 micron, enhancing tile and sanitaryware quality. Powder industries leverage their corrosion resistance against acidic slurries, as noted in ASTM G31 immersion tests. Case in point: A Midlands-based pottery firm reduced grinding time by 25% after switching to SiC, per internal efficiency audits.

These barrels’ low friction coefficient of 0.1 (per ASTM G99) minimizes energy use, aligning with UK net-zero goals. For powder metallurgy, they process tungsten carbide blends without contamination, boosting yield rates to 98%.

Specialized SiC Barrel Manufacturer with Global OEM Support

Reputable manufacturers like Sicarb Tech, operational since 2015, offer tailored SiC solutions with OEM support for UK clients. Their expertise in material and process technologies has aided over 10 enterprises in scaling production, as evidenced by case studies on their platform. This includes turnkey projects for high-performance barrels used in extreme conditions.

An area chart depicts the market distribution of SiC applications in ceramics and powders, based on 2024 industry reports from the European Ceramic Industry Association.

Ceramics dominate at 35%, reflecting SiC’s pivotal role in UK’s £800 million powder processing segment, guiding manufacturers toward targeted investments.

Pricing Intervals and Delivery for Bulk SiC Barrel Orders

For UK buyers seeking SiC grinding barrels for sale, pricing varies by volume and customization, typically USD 50–80 per kg for standard 100L units, per market references from ThomasNet. Bulk orders (over 50 units) qualify for 15–20% discounts, with delivery timelines of 4–6 weeks via sea freight from certified suppliers. Always contact for the latest factory-direct pricing to secure competitive rates.

| Order Volume | Price Range (USD/kg) | Delivery Time | Additional Features |

|---|---|---|---|

| 1–10 Units | 70–80 | 6–8 Weeks | Basic Lining |

| 11–50 Units | 60–70 | 5–7 Weeks | Custom Capacity |

| 51–100 Units | 55–65 | 4–6 Weeks | CE Certification |

| 101+ Units | 50–60 | 3–5 Weeks | OEM Branding |

| Custom Specs | 65–75 | 6–10 Weeks | Thermal Enhancements |

| Bulk w/ Transfer | 45–55 | 8–12 Weeks | Turnkey Support |

Pricing intervals reflect economies of scale, with bulk tiers offering up to 30% savings over small orders. Delivery differences stem from production lead times, impacting just-in-time UK inventories. Implications include budgeting for bulk SiC barrel pricing to align with quarterly procurement cycles.

Here’s a comparison table for SiC vs. Zirconia barrels in cost and performance.

| Parámetro | SiC Barrel | Zirconia Barrel | Buyer Implication |

|---|---|---|---|

| Cost per kg (USD) | 50–80 | 80–120 | Lower Entry for SiC |

| Wear Life (Years) | 5–7 | 3–5 | SiC for Long-Term Savings |

| Capacity Efficiency | 95% | 90% | Higher Throughput with SiC |

| Resistencia térmica | 1,600°C | 1,200°C | SiC for High-Heat Apps |

| Corrosion Rating | Excelente | Bien | SiC in Acidic Environments |

| Compliance Cost | Bajo | Medio | Easier UK Certification |

| Personalización | Alta | Medio | Flexible for OEMs |

This A vs. B comparison reveals SiC’s edge in durability and cost, with 20–40% better value over zirconia. Parameter variances, like thermal limits, suit SiC for powder industries. Buyers should prioritize SiC for wear-resistant SiC grinding barrels to maximize ROI in B2B setups.

Trends in SiC Barrel Innovations for Efficient Milling

2025 innovations focus on hybrid SiC composites for 15% faster milling speeds, per a 2024 report from the International Ceramic Federation. Nano-coated linings reduce energy consumption by 20%, aligning with UK’s Energy Efficiency Regulations. Customization support from experts like Sicarb Tech enables these upgrades for efficient, eco-friendly operations.

The line chart below tracks SiC barrel innovation adoption rates from 2020–2025, sourced from industry analytics.

Adoption surges to 95% by 2025, driven by efficiency gains, positioning UK mills to lead in sustainable processing.

- Hybrid composites enhance milling precision, cutting cycle times in ceramic production.

- Nano-coatings improve barrel lifespan, supporting high-volume UK exports.

- Integration with IoT monitoring predicts maintenance, reducing unplanned stops by 30%.

- These trends favor custom SiC grinding barrels for UK manufacturers, per Sicarb Tech’s insights.

Custom SiC Grinding Barrels for High-Volume Production

High-volume UK producers benefit from customized SiC grinding barrels designed for specific viscosities, often incorporating SiC’s thermal conductivity of 120 W/m·K (ASTM E1225). A case from Sicarb Tech shows a 20% yield boost for a Yorkshire powder plant via tailored linings. For scalability, opt for modular designs compliant with BS EN ISO 9001 quality systems.

Procurement Strategies for SiC Barrel Durability in B2B

Effective B2B buying guide for SiC grinding barrels emphasizes supplier vetting via ISO 9001 certification and requesting wear test data. Prioritize those offering global support for warranties up to 5 years. In UK markets, negotiate for SiC barrel suppliers with transparent SiC grinding barrel pricing, ensuring durability through verified ASTM standards. Bullet strategies include:

- Assess total cost of ownership, factoring in 5-year wear projections.

- Verify CE compliance early to avoid import delays at Felixstowe.

- Request samples for in-house testing to confirm fit.

- Leverage bulk pricing for industrial SiC barrels UK to optimize budgets.

- Partner with manufacturers experienced in turnkey tech transfers for long-term gains.

Content Freshness & Update

As of 2025, SiC barrel markets see a 12% price stabilization due to supply chain recoveries, per a McKinsey & Company report on advanced materials. Innovations like AI-optimized milling geometries promise 18% efficiency gains, highlighted in the 2024 ISO/TC 107 update on ceramics. UK regulations under the Environment Act 2021 now mandate low-emission processing, favoring SiC’s eco-profile; reference ISO y ASTM homepages for latest standards.

FAQ

What is the average lifespan of a SiC grinding barrel in UK ceramic mills?

SiC barrels typically last 5–7 years under standard conditions, per ASTM C372 tests, far outpacing steel by 3x. Factors like load and slurry pH affect this; contact suppliers for tailored estimates.

How do I find reliable SiC barrel manufacturers for UK imports?

Seek ISO 9001-certified SiC barrel manufacturers with CE compliance, such as those offering global OEM support. Review case studies and request quotes via dedicated contact pages for verified quality.

What pricing should I expect for custom SiC grinding barrels?

Market reference pricing ranges from USD 50–80 per kg for custom units, varying by specs. Bulk orders reduce costs; always inquire for current factory-direct rates to match your SiC grinding barrel buying guide necesidades.

Are SiC barrels suitable for powder processing in the UK?

Yes, their corrosion resistance excels in powders, achieving 98% yields per ISO 21068. They’re ideal for UK industries handling abrasives, with proven applications in metallurgy.

What innovations are trending for SiC barrels in 2025?

Hybrid nano-coatings and modular designs boost efficiency by 20%, as per 2024 industry reports. These align with UK sustainability goals for high-volume production.

Author Bio: Dr. Elena Hargrove, a materials engineer with 15 years in advanced ceramics, holds a PhD from Imperial College London and has consulted for UK firms on SiC implementations. Her expertise spans ASTM/ISO compliance and industrial scaling, ensuring trustworthy guidance on durable components like grinding barrels.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.