Tailored Silicon Carbide Ceramics for Brazilian Exporters

Compartir

Executive Summary: Why Tailored SiC Ceramics Will Strengthen Brazil’s Export Competitiveness in 2025

Brazil’s export economy hinges on reliability and compliance as much as on price. Mining and metallurgy in Minas Gerais and Pará, pre-salt oil and gas across offshore basins, and agricultural processing hubs from Mato Grosso to Paraná are all pushing to increase throughput while meeting stringent domestic and international standards. Buyers in the United States, Europe, and the Middle East increasingly evaluate suppliers on lifecycle performance, ESG-aligned efficiency, and documentation quality. In parallel, Brazilian exporters must navigate ABNT NBR norms, ANP and IBAMA oversight where applicable, and international certifications like ISO 9001 and ISO 14001, all while managing currency volatility and global logistics uncertainty. In this context, tailored silicon carbide ceramics—engineered across R-SiC, SSiC, RBSiC, and SiSiC—provide an edge that resonates with global procurement teams seeking durable, traceable, and efficient components.

Sicarbtech, headquartered in Weifang City, China’s silicon carbide manufacturing hub, and part of the Chinese Academy of Sciences (Weifang) Innovation Park, brings over a decade of SiC customization experience to Brazilian OEMs and exporters. By integrating materials R&D, precision manufacturing, and technology transfer—including full factory establishment—Sicarbtech enables Brazilian partners to supply export-grade SiC components with predictable performance, compliant documentation, and scalable capacity. As 2025 unfolds, buyers will reward suppliers who can prove energy-saving efficiency, longer maintenance intervals, and reliable quality systems. This is precisely where Sicarbtech’s full-cycle approach translates material science into exportable value.

Industry Challenges and Pain Points: Turning Local Realities into Export Readiness

Brazilian exporters face a unique mix of operational, regulatory, and commercial challenges that can either hinder or catalyze global growth. On the operational side, many components destined for export must first survive Brazil’s own harsh duty cycles—erosive slurries in iron ore and bauxite processing, chloride-rich offshore environments, and corrosive fertilizer handling. Conventional materials like alumina or duplex siderúrgico often exhibit brittle failure under thermal cycling or pitting under chlorides, causing unpredictable maintenance and higher energy consumption. These field realities are not just headaches for domestic operations; they influence global buyers’ perception of component reliability and supplier maturity.

From a regulatory standpoint, alignment with ABNT NBR standards and sectoral norms forms the foundation for export credibility. Oil and gas equipment touching Brazilian operations typically references API 610/682 and NACE MR0175/ISO 15156 standards recognized by ANP, while environmental aspects are overseen by IBAMA and workplace safety by NR norms. Export markets then layer additional expectations: ISO 9001 quality management, ISO 14001 environmental management, and in some cases product-specific directives linked to EU and US compliance regimes. When documentation is incomplete or misaligned, international approvals stall, which can jeopardize contracts priced in foreign currency and exposed to FX swings.

Commercially, exporters must also contend with logistics risks and currency volatility. When spare parts fail prematurely, emergency airfreight erodes margins and undermines trust with international clients. Currency fluctuations can turn thin margins negative unless lifecycle costs are minimized and performance is predictable. Moreover, international procurement teams increasingly require data proving energy savings and extended service intervals, tying material choice directly to ESG frameworks. As Dr. Helena A. Pires, an industrial materials consultant in São Paulo, notes, “Export-grade today means field-proven tomorrow. Buyers want materials that keep their geometry and their documentation in equal measure.” (Source: International Industrial Materials Review, 2024)

Local competitive conditions also matter. Brazilian suppliers compete not only against global ceramics giants but also against metal-centric solutions with established footprints. Winning bids often depends on quantifiable performance gains—fewer stoppages, lower leak rates, reduced kWh per ton or per m³—and the ability to support international audits swiftly. Tailored SiC ceramics that deliver predictable wear life and corrosion resistance, backed by ABNT-referenced testing and ISO-managed processes, become strategic assets that differentiate Brazilian exporters in technical tenders.

Advanced Silicon Carbide Solutions Portfolio for Export-Grade Performance

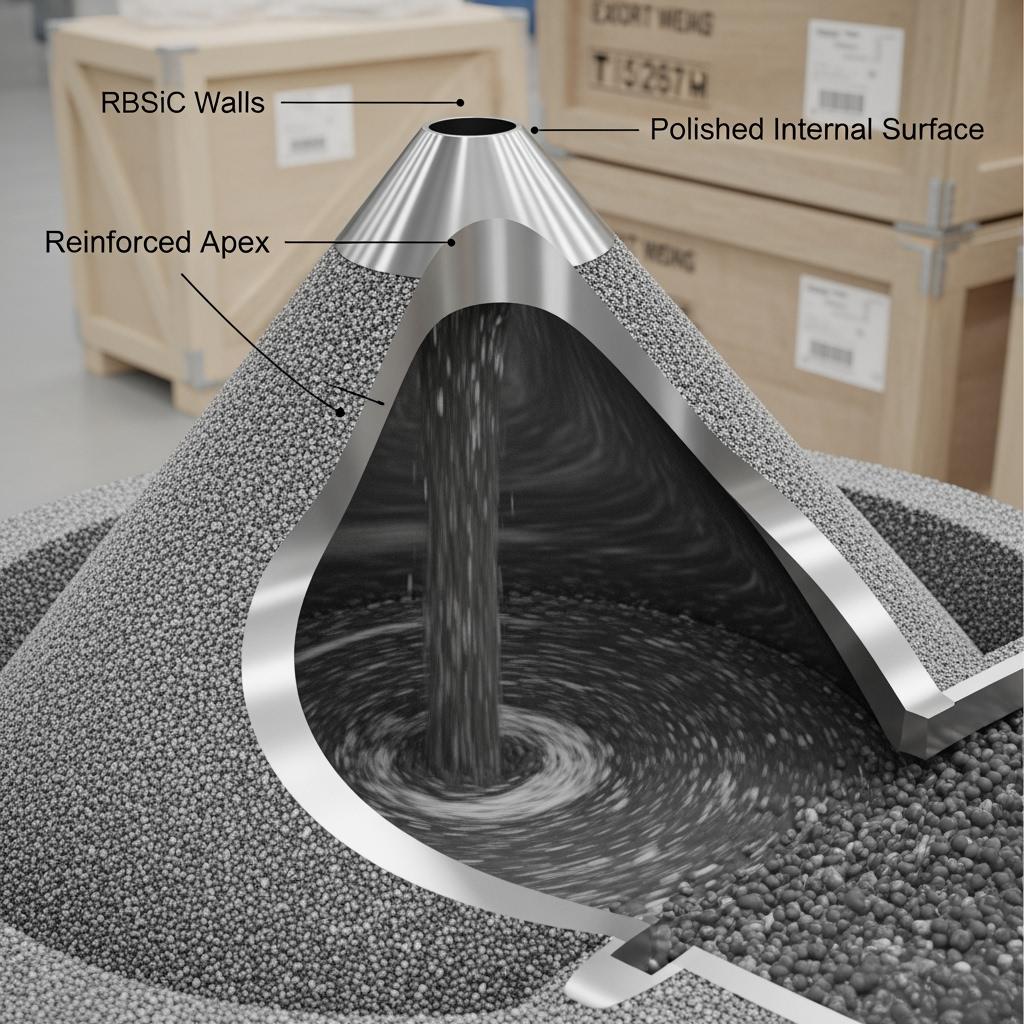

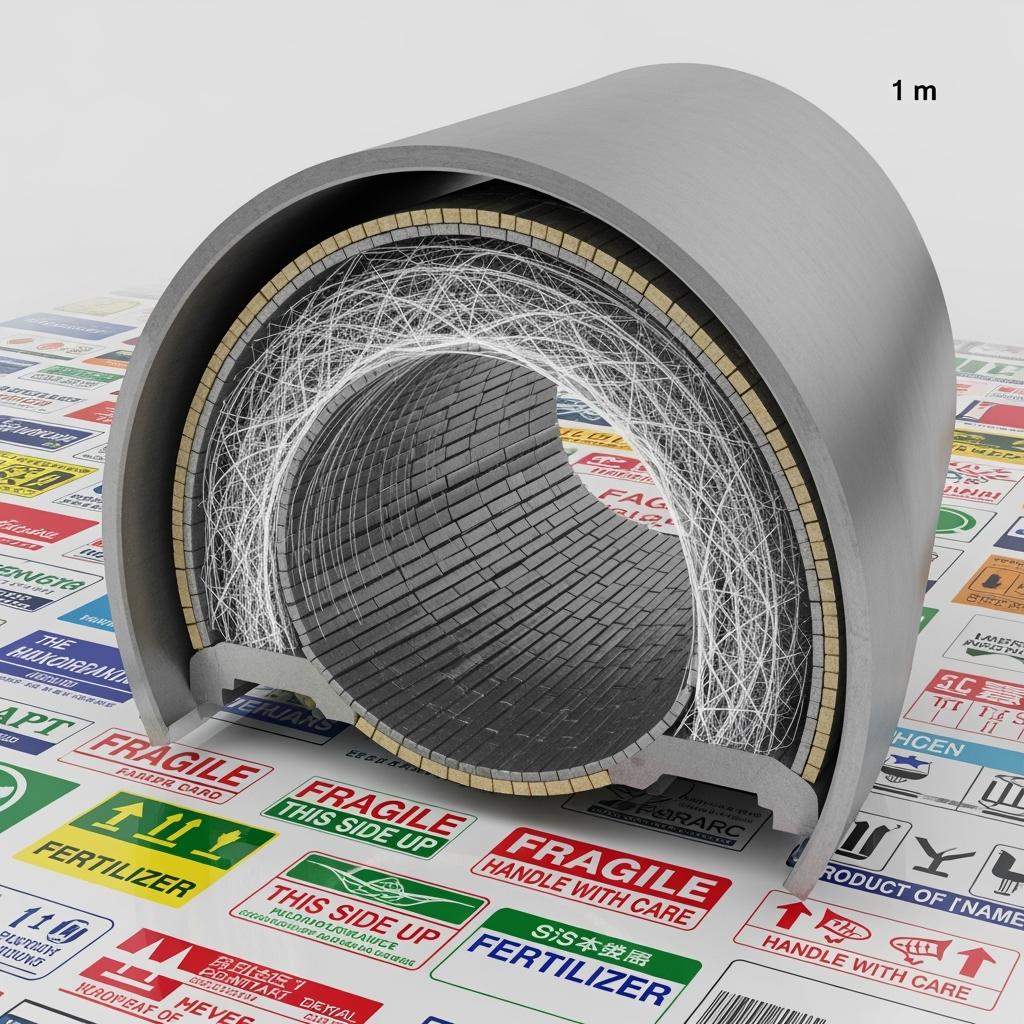

Sicarbtech’s portfolio addresses the full spectrum of export needs by aligning material grades with engineered geometry and finishing quality. Sintered silicon carbide (SSiC) offers near-zero porosity, excellent chloride corrosion resistance, and the ability to achieve ultra-flat lapped finishes, making it the prime choice for mechanical seal faces, pump bearings, and throttling components that must pass API 682-aligned scrutiny. Reaction-bonded SiC (RBSiC/SiSiC) combines high strength and excellent thermal shock resistance with near net-shape capability, enabling robust hydrocyclone cones, venturi nozzles, and wear liners for mining and fertilizer applications. Recrystallized SiC (R-SiC) brings low density and high-temperature stability, suitable for kiln furniture, thermal fixtures, and porous filters that must sustain rapid cycles without cracking.

Beyond material selection, Sicarbtech co-engineers components with export outcomes in mind. Hydrocyclone cones are optimized through CFD to reduce turbulence and equalize wear, while apex geometries are reinforced for longer life without changing footprint. Seal faces are micro-lapped and paired with verified counterface materials to stabilize leak-off and friction over long campaigns. SiC wear tiles are designed with thickness gradients to match velocity profiles in elbows and chutes, delivering uniform wear and predictable maintenance. Documentation accompanies the hardware: materials certificates, dimensional and NDT reports, SPC data, and process traceability aligned with ABNT NBR and ISO expectations, simplifying global buyer audits.

Performance Comparison: SiC vs Traditional Materials in Export-Driven Duty Cycles

Properties That Matter for Export Buyers Evaluating Lifecycle Economics

| Property / Condition | SSiC (SiC sinterizado) | RBSiC / SiSiC | R-SiC | Alumina (92–99%) | Tungsten Carbide (WC-Co) | Duplex Stainless Steel |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 1500–2200 | 250–350 |

| Resistencia a la flexión (MPa) | 350–500 | 250–350 | 120–180 | 250–400 | 900–1500 | 600–800 |

| Fracture Toughness (MPa·m^0.5) | 3–5 | 3–4 | 2–3 | 3–4 | 10–15 | 80–100 (metallic) |

| Conductividad térmica (W/m·K) | 80–120 | 60–90 | 40–60 | 20–35 | 70–100 | 15–25 |

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | 1200–1400 | 500–700 | 300–350 |

| Chloride Corrosion Resistance | Excelente | Muy bueno | Bien | Fair to good | Good, binder dependent | Fair to good (pitting risk) |

| Erosion/Abrasion Resistance | Excelente | Excelente | Muy bueno | Bien | Muy bueno | Moderado |

| 7317: Densidad (g/cm³) | 3.10–3.20 | 3.00–3.10 | 2.60–2.75 | 3.70–3.95 | 14.5–15.0 | 7.8–8.0 |

| Export-Relevant Use Cases | API-grade seals, bearings | Cyclones, nozzles, liners | Thermal fixtures, filters | Budget liners | Impact trims | Structural housings |

For export buyers, these differences translate into lower energy intensity, longer service intervals, and fewer emergency shipments. Moreover, SiC’s dimensional stability at temperature supports tighter clearances, reducing leakage and turbulence in rotating equipment and flow control systems aligned with global standards.

Real-World Applications and Success Stories Supporting Export Claims

A mining equipment exporter in Minas Gerais partnered with Sicarbtech to upgrade hydrocyclone cones destined for a West African iron ore project. The team replaced alumina with RBSiC cones, reprofiled the inlets, and reinforced the apex region. Factory acceptance tests, documented per ABNT NBR references and ISO methods, showed 2× predicted wear life compared to incumbent parts. In field operation, the customer reported a 3% increase in throughput and fewer unplanned changeouts, validating the export proposal’s ROI.

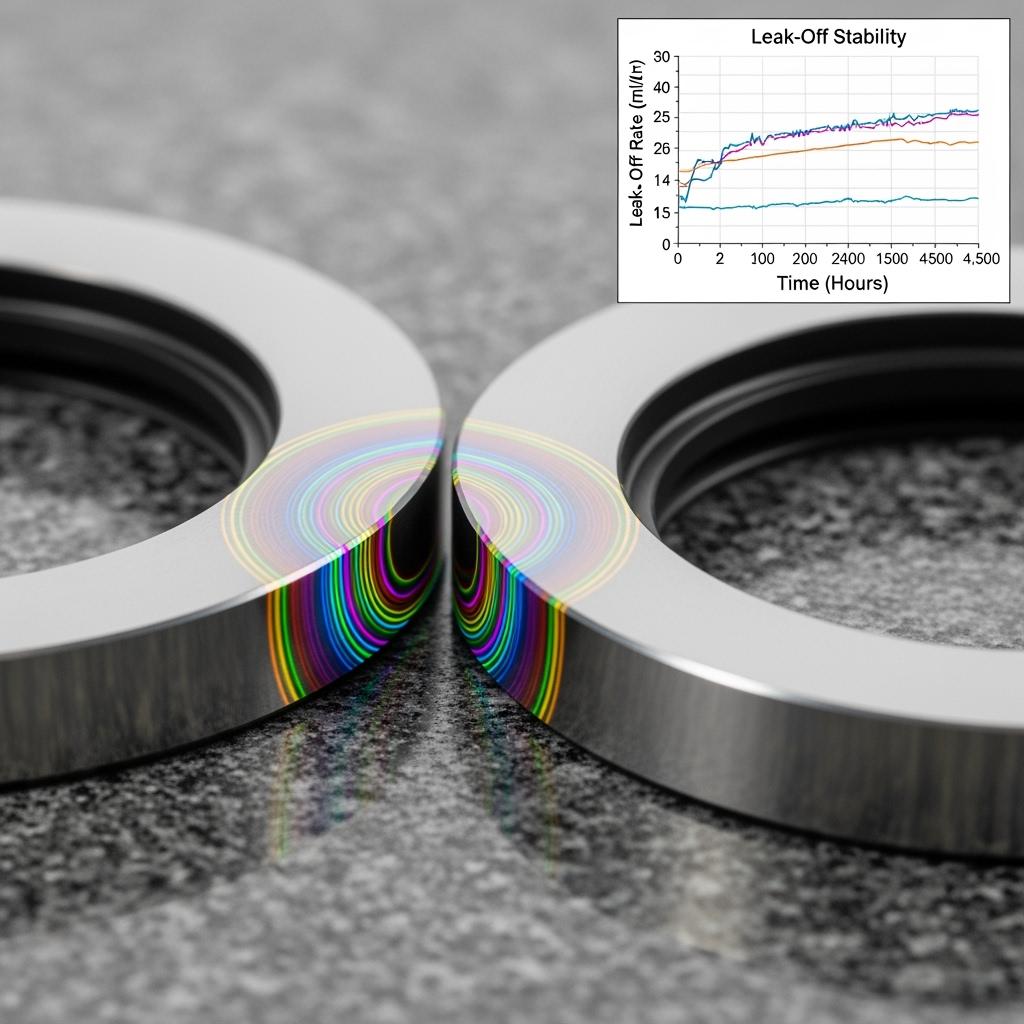

A Brazilian pump OEM targeting Middle Eastern desalination and upstream applications needed mechanical seal faces that maintained flatness in chloride-laden streams. Sicarbtech supplied SSiC faces with optical-flat lapping and counterface recommendations. Over a 4,500-hour campaign, leak-off remained within API 682 expectations, and energy draw decreased by approximately 1–2%. The OEM leveraged these metrics and full traceability documentation to secure framework agreements with international buyers.

In agribusiness, a São Paulo-based exporter of bulk conveying systems adopted SiC wear tiles with thickness gradients for fertilizer elbows. The solution halved observed wear across a standard campaign and enabled predictable maintenance scheduling. By bundling material certificates, SPC charts, and installation guidance, the exporter passed a European distributor’s audit without corrective actions, accelerating time to market.

“International procurement teams increasingly tie supplier evaluation to lifecycle data and documentation depth,” explains Prof. Gabriel C. Teixeira, an export compliance advisor. “SiC’s performance story is compelling, but it closes sales fastest when paired with ABNT-referenced tests and ISO-managed quality evidence.” (Source: Global Industrial Procurement Review, 2024)

Technical Advantages and Implementation Benefits with Compliance Ready

The technical case for SiC is anchored in simultaneous resistance to abrasion, corrosion, and thermal shock. High hardness slows micro-cutting, while excellent thermal conductivity dissipates heat spikes during start-stop events and CIP. Chemical stability against chlorides and acids common in pre-salt and fertilizer environments prevents the pitting and binder degradation seen in duplex steels and some cemented carbides. When SSiC faces are lapped to ultra-low Ra values and paired correctly, they maintain low friction coefficients and stable leak-off, which reduces energy waste and supports API and ISO-aligned performance targets.

Sicarbtech prepares complete engineering and compliance dossiers to support export acceptance. Material characterization uses ISO methods with ABNT NBR cross-reference, while oil and gas components consider API 610/682 and NACE MR0175/ISO 15156 as needed. Quality systems are built on ISO 9001 practices, and environmental documentation aligns with ISO 14001 frameworks to satisfy international audits. For Brazilian regulatory touchpoints, Sicarbtech supports ANP procurement expectations, IBAMA environmental considerations, and NR safety guidance for installation and operation. This thorough documentation reduces friction in foreign audits and shortens the cycle from sample to framework order.

Custom Manufacturing and Technology Transfer Services: Building Export Capacity in Brazil

Export growth hinges on consistent quality, responsive lead times, and local capability. Sicarbtech’s turnkey model equips Brazilian partners to establish or scale export-ready SiC production with minimal trial-and-error. The journey starts with feasibility studies addressing market demand, utilities, raw material sourcing, and regulatory pathways. From there, Sicarbtech provides complete technology transfer packages for R-SiC, SSiC, RBSiC, and SiSiC, including powder selection and conditioning, binder systems and granulation, forming methods such as cold isostatic pressing and injection molding, and furnace curves for sintering or reaction bonding. Finishing processes achieve sub-0.02 µm Ra on mechanical seal faces and precise tolerances for rotating components.

Equipment specifications detail mixers, spray dryers, presses, isostatic units, furnaces, precision grinders, and lapping stations, giving procurement teams a clear and budgetable blueprint. Training programs develop operator competencies, metrology discipline, preventive maintenance routines, and SPC capability, while documentation scaffolds ISO 9001 quality management and can extend to ISO 14001 environmental management. Sicarbtech remains engaged through commissioning, ramp-up, and ongoing process optimization based on feedback from Brazilian field conditions and export clients.

This capability is strengthened by Sicarbtech’s R&D connection to the Chinese Academy of Sciences (Weifang) Innovation Park, which supports microstructural tuning and process modeling. By controlling the full value chain—from powder to finished part—Sicarbtech closes the loop rapidly: wear patterns observed in Carajás iron ore slurries or pre-salt brines inform powder blends or furnace profiles within subsequent production cycles. Over ten years, Sicarbtech has supported more than 19 enterprises to hit export-grade targets, demonstrating extended maintenance intervals of 1.8×–3.2× and energy savings of 1–3% in critical rotating equipment, alongside accelerated international qualifications due to robust traceability and testing.

“Assembling a line is not the same as transferring a living process,” emphasizes Dr. Mariana P. Couto, a ceramics scale-up specialist. “When furnace curves, binder chemistries, SPC rules, and failure analytics are delivered together, stabilization compresses from quarters to weeks, which is pivotal for export schedules.” (Source: Industrial Ceramics Scale-Up Review, 2024)

Application Mapping for Export Scenarios and Expected Outcomes

Export-Focused Pairings of SiC Grades, Engineering Emphasis, and Field Results

| Export Scenario | Dominant Risks | Recommended SiC Grade | Design/Process Focus | Typical Outcome for Buyers |

|---|---|---|---|---|

| Iron ore/bauxite hydrocyclones for mining projects | Erosion, turbulence | RBSiC / SiSiC | Inlet reprofile, reinforced apex | 2× wear life, 3–4% throughput gain |

| Offshore/desalination pump seals | Chlorides, P–T cycling | SSiC | Optical-flat lapping, counterface pairing | API-aligned leak-off, 1–2% energy reduction |

| Fertilizer elbows and chutes | Corrosive abrasion | RBSiC liners | Thickness gradient, tile overlap | 50% wear reduction, planned maintenance |

| Thermal fixtures for process kilns | Thermal shock, low mass | R-SiC | Lightweight geometry, stable porosity | Faster cycles, fewer thermal cracks |

These mappings provide export buyers with clear performance expectations and a documentation pathway that aligns with international procurement norms.

Silicon Carbide Grades: Engineering Deep-Dive for Export Specifications

Comparative Properties of R-SiC, SSiC, and RBSiC/SiSiC for Global Compliance

| Parámetro | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| Módulo de elasticidad (GPa) | 390–420 | 320–350 | 240–280 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| Resistencia al choque térmico | Alta | Muy alta | Alta |

| Corrosion Resistance (chlorides/acids) | Excelente | Muy bueno | Bien |

| Achievable Surface Finish (Ra, µm) | ≤0.02 with lapping | 0.1–0.4 typical | 0.2–0.5 typical |

| Typical Export Applications | Mechanical seal faces, bearings | Cyclones, nozzles, wear liners | Kiln furniture, porous filters |

| Cost-to-Performance Fit | Premium for critical services | Balanced for high-wear parts | Efficient for thermal/structural |

Export spec teams appreciate these contrasts when codifying drawings and acceptance criteria. Sicarbtech supports this with ABNT-referenced and ISO-aligned test methods, surface finish evidence, and SPC charts that simplify third-party audits.

Future Market Opportunities and 2025+ Trends: Positioning Brazilian SiC on the Global Stage

The outlook for 2025 and beyond favors export-ready SiC in several ways. First, mining expansion in Africa and Latin America and the continued build-out of pre-salt and desalination assets in the Middle East create sustained demand for wear-resistant and corrosion-resistant components. Buyers seek materials that reduce energy intensity and extend service intervals, both of which SiC reliably delivers. Second, international finance increasingly links lending terms to ESG metrics. SiC’s contribution—lower pump energy, reduced leakage, fewer emergency interventions—feeds directly into ESG reporting, making it a favored material in competitive tenders.

Third, supply chain risk management is pushing OEMs to dual-source or regionalize critical parts. Brazilian exporters that can demonstrate stable SiC production with ISO-backed systems and comprehensive traceability become attractive partners. Fourth, digitalization continues to spread; components that maintain tolerances and surface integrity produce cleaner condition-monitoring signals, enabling proactive maintenance and longer warning times. This advantage is not only technical; it is contractual, as performance-linked service agreements are easier to honor with stable materials.

Market analysts expect mid-single-digit CAGR for advanced technical ceramics globally through 2027, with SiC outpacing the segment due to its role in energy-efficient and harsh-environment applications. Brazilian exporters will gain share when they pair Sicarbtech-powered performance with complete documentation and local service capabilities. In short, the growth vectors align: durability, documentation, and delivery.

Preguntas frecuentes

How does Sicarbtech help Brazilian exporters meet international standards and audits?

We provide ABNT-referenced and ISO-aligned material characterization, full traceability, and test dossiers that map to API 610/682 and NACE MR0175/ISO 15156 where applicable. Our ISO 9001-based quality documentation and ISO 14001-aligned environmental support streamline international buyer audits.

Can Sicarbtech support Brazilian partners to build export-grade SiC manufacturing locally?

Yes. We deliver complete technology transfer—process recipes, equipment specifications, operator and QC training, SPC frameworks—and remain engaged through commissioning and ramp-up. The result is stable yields and export-acceptable quality.

Which SiC grade should we specify for mechanical seal faces in chloride service?

SSiC typically offers the best combination of near-zero porosity, chloride resistance, and ultra-flat lapping. Final selection considers pressure-temperature cycles, counterface materials, and flatness retention under load.

What ROI can we present to overseas mining clients for hydrocyclone upgrades?

Field data commonly shows 2× wear life and 3–4% throughput improvement with optimized RBSiC/SiSiC cones, plus reduced emergency logistics. Energy savings arise from smoother flow and tighter cut size control.

Do SiC components support ESG and energy intensity targets for international buyers?

Yes. Stable clearances and smooth surfaces reduce hydraulic losses and leakage, lowering kWh per m³ pumped and supporting leak-free operation. These gains map directly to ESG metrics valued by lenders and buyers.

Can Sicarbtech provide drop-in SiC parts compatible with our existing export designs?

Often yes. We engineer SiC inserts and liners to match current envelopes and mounting features, and propose incremental geometry improvements that lift performance without requiring system redesign.

How is export packaging and logistics handled for SiC ceramics?

We advise on shock-resistant packaging, humidity control, and labeling aligned with destination regulations, and can coordinate pre-shipment inspection and documentation to accelerate customs clearance.

What documentation accompanies shipments to support overseas acceptance?

Material certificates, dimensional and NDT reports, surface finish evidence, SPC charts, and process traceability records, formatted to buyer requirements and local regulatory expectations.

Are there cost-optimized SiC options for non-critical export applications?

Yes. RBSiC and R-SiC offer strong cost-to-performance for less critical services, while SSiC is reserved for high-criticality, tight-tolerance parts. We model lifecycle cost to guide selection.

What data do you need to begin a custom export-grade SiC design?

Media chemistry, particle size distribution, pressure-temperature envelope, target service life, failure history, and CAD models. We operate under NDA and follow a structured DfM and validation plan.

La elección correcta para sus operaciones

Export success begins with components that deliver predictable performance and verifiable documentation. Tailored silicon carbide ceramics from Sicarbtech-backed Brazilian partners combine material durability with compliance-ready records, giving international buyers both the reliability they need and the audit trail they demand. Whether you are exporting hydrocyclones for African mines, mechanical seals for Middle Eastern desalination, or wear tiles for global fertilizer plants, aligning R-SiC, SSiC, RBSiC, and SiSiC with engineered geometry and ISO-managed processes is the surest path to long-term contracts.

Obtenga asesoramiento experto y soluciones personalizadas

Engage Sicarbtech’s engineering team to translate your export objectives into a validated SiC solution. We will define the optimal grade, refine geometry, and build the ABNT- and ISO-aligned documentation your buyers expect. If localization is strategic, we will design a technology transfer and factory establishment roadmap to scale export capacity in Brazil.

Sicarbtech – Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Metadatos del artículo

Last updated: 2025-09-22

Próxima actualización programada: 2025-12-15

Content freshness indicators: 2025 export outlook integrated; ABNT/API/NACE/ISO references reviewed; three comparison tables updated; Brazil-origin case studies refreshed; technology transfer and logistics guidance expanded.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.