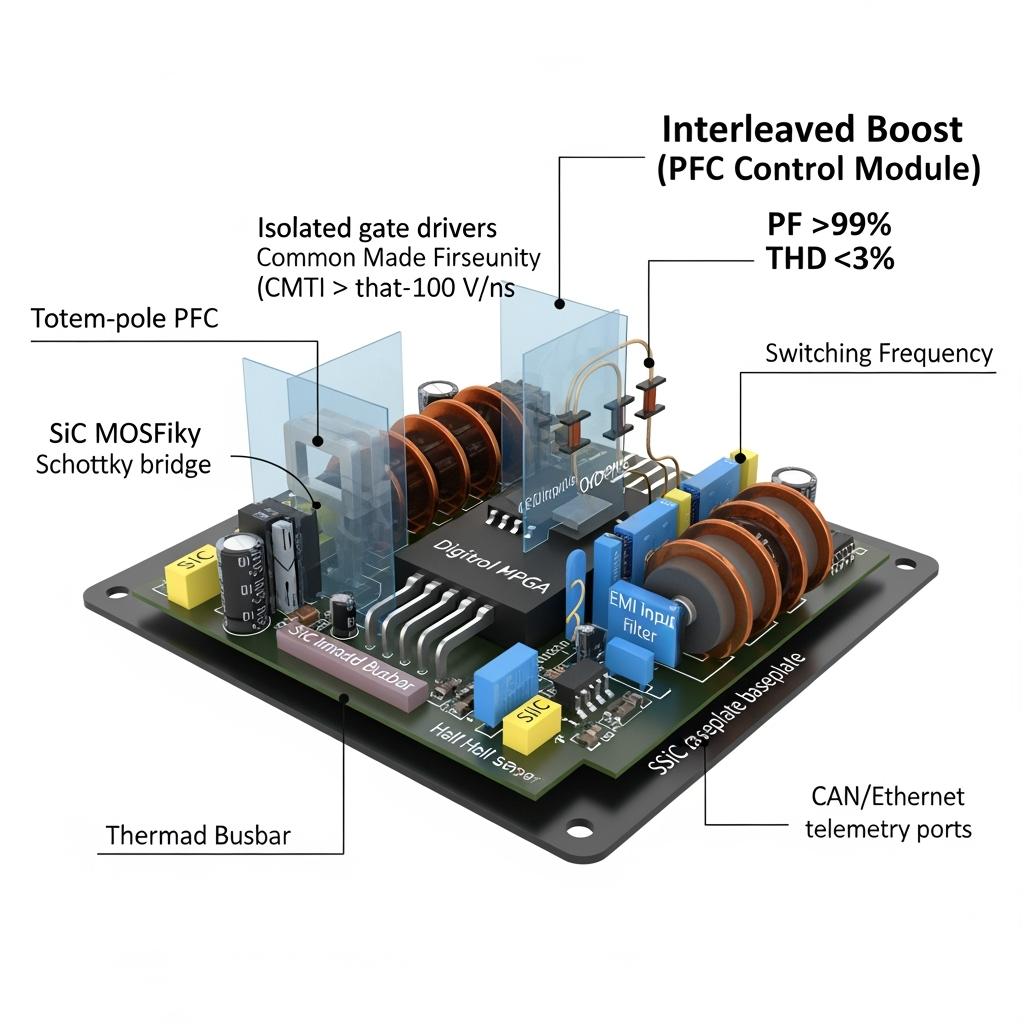

Módulos de control de corrección del factor de potencia de SiC para rectificadores frontales >99% PF y <3% THD

Compartir

Visión general del producto y relevancia para el mercado en 2025

Los módulos de control de corrección del factor de potencia (PFC) SiC son etapas de control y potencia prediseñadas que combinan MOSFET/diodos de carburo de silicio con control digital, detección y protección para ofrecer un factor de potencia (PF) del 99% y una distorsión armónica total (THD) del 3% en amplios rangos de carga. Son la piedra angular de los rectificadores frontales de alta eficiencia en SAI, VFD, SMPS, inversores fotovoltaicos y sistemas industriales de CC. En comparación con las implementaciones de PFC de la era del silicio, los módulos PFC de SiC funcionan más fríos a frecuencias de conmutación más altas, lo que permite un magnetismo más pequeño, un menor ruido acústico y una calidad de energía más ajustada en las difíciles condiciones de la red de Pakistán.

Por qué es importante en el panorama pakistaní de 2025:

- Los centros de datos y las salas de máquinas financieras requieren una corriente de entrada limpia, un FP alto y armónicos mínimos para estabilizar los suministros y reducir el calentamiento de los transformadores.

- Textil, cemento y siderúrgico las centrales se enfrentan a bajadas y subidas de tensión y a distorsiones de la red; el robusto PFC mejora el paso y reduce las molestas desconexiones.

- La presión OPEX y las limitaciones de espacio exigen una mayor densidad y una menor carga de refrigeración, ambas posibles gracias a las bajas pérdidas por conmutación y conducción del SiC.

- El impulso normativo hacia la calidad y la eficiencia de la energía se alinea con los objetivos del Código de Red del NTDC, creando una ventaja competitiva en las licitaciones.

Los módulos de control SiC PFC de Sicarb Tech admiten topologías de tótem, boost intercalado (CCM/CRM) y rectificador Vienna, con control digital integrado, detección de corriente/tensión y protecciones integrales, listos para encajar en frontales de 3 kW a 250+ kW y paralelizables a sistemas de clase MW.

Especificaciones técnicas y funciones avanzadas

Capacidades representativas (personalizables):

- Clasificaciones eléctricas

- Entrada CA: 220/230 VCA monofásica, 380/400/415 VCA trifásica (50 Hz)

- Salida de CC: 380-800 Vcc típica (configurable hasta 1000 Vcc para frontales FV de 1500 Vcc mediante topología Vienna)

- Potencia: 3-50 kW por módulo (refrigerado por aire), 30-250 kW (refrigerado por líquido); paralelizable a >1 MW

- Rendimiento

- PF: ≥0,99 al 20-100% de carga; THD: ≤3% con mitigación de la distorsión de línea

- Eficiencia: 97,5-99,0% de eficiencia de la etapa en función de la topología y el nivel de potencia

- Frecuencia de conmutación: 45-120 kHz (tótem/intercalada), 20-60 kHz (Viena)

- Control y detección

- Control digital (MCU/FPGA) con modo de corriente media o CRM, tiempo muerto adaptativo y control de tensión de avance

- Sensores de corriente dobles por fase, detección de tensión de bus de precisión, entradas térmicas NTC/RTD

- Compensación de armónicos y seguimiento de la distorsión de red para la red variable de Pakistán

- Protección y fiabilidad

- OCP/OVP/UVP/OTP, control de irrupción, arranque suave, gestión de caídas de tensión y recuperación de pérdidas de línea

- Controladores DESAT, desconexión suave y diseño reforzado EMI con conexiones Kelvin

- Coordinación de sobretensiones/EMC con MOV/TVS y choques de modo común para cumplir la norma IEC 61000

- Mecánico y térmico

- Difusores de calor SSiC/RBSiC; opciones de disipadores con aletas o placas frías

- Conectores de alimentación/datos de acoplamiento ciego para integración en rack intercambiable en caliente

- Revestimiento conformado y variantes con clasificación IP para fábricas y plantas con mucho polvo

- Interfaces y cumplimiento

- Comunicaciones compatibles con SCADA: Modbus/RS485, CAN, Ethernet; pasarela en la nube opcional

- Normas: IEC 61000-3-2/3-12 (armónicos), IEC 61000-6-2/6-4 (CEM), IEC 62040 (SAI), IEC 62477-1 (convertidores de potencia); en consonancia con las prácticas de los códigos de red PEC y NTDC

Diferenciadores de Sicarb Tech:

- Bibliotecas de control preajustadas para rectificadores tótem (PWM unipolar/bipolar) y Viena

- Análisis predictivo térmico y de la vida útil de los componentes integrado con diagnósticos

- Firmware actualizable sobre el terreno y herramientas de puesta en servicio adaptadas a la calidad eléctrica local

Corriente de entrada más limpia y mayor densidad para frontales industriales

| Calidad y eficiencia de la red eléctrica en Pakistán | Módulo de control SiC PFC (Sicarb Tech) | PFC de silicio |

|---|---|---|

| Factor de potencia con carga | ≥0,99 (20-100% de carga) | 0.95-0,98 típico |

| Corriente de entrada THD | ≤3% con atenuación de la distorsión | 5-10% típico sin filtros grandes |

| Frecuencia de conmutación y magnetismo | 45-120 kHz; inductores más pequeños | 20-40 kHz; imanes más grandes |

| Eficacia de las etapas | 97.5-99.0% | 94-96% |

| Huella térmica y refrigeración | Disipadores reducidos, ventiladores más silenciosos | Disipadores más grandes, mayor potencia de ventilador |

Ventajas clave y beneficios probados

- Rendimiento respetuoso con la red: THD ≤3% y PF ≥0,99 reducen el calentamiento del transformador y la caída de tensión, mejorando la estabilidad general del emplazamiento.

- Ahorro OPEX cuantificable: 2-3% de aumento de la eficiencia de la etapa frente al PFC de silicio, además de una menor carga de refrigeración en las salas de SAI y los armarios MCC.

- Alta densidad de potencia: La mayor frecuencia de conmutación y las bajas pérdidas reducen los magnetismos y los filtros, liberando espacio en paneles abarrotados.

- Control robusto: El control adaptativo mantiene la regulación durante las caídas de tensión y los transitorios habituales en los alimentadores industriales.

Cita de un experto:

"Los rectificadores tótem y vieneses construidos con dispositivos de SiC consiguen un factor de potencia cercano a la unidad y una THD muy baja a alta frecuencia, lo que permite una densidad de potencia y un rendimiento dinámico sin precedentes." - Revista IEEE Power Electronics, Front Ends de alta densidad 2024

Aplicaciones reales e historias de éxito mensurables

- Actualización del frontal del SAI del centro de datos de Lahore:

- módulos PFC SiC totem-pole de 100 kW con compensación digital de armónicos.

- Resultados: FP ≥0,99 con una carga del 25-100%; THD reducida del 6,5% al 2,4%; reducción de la energía de refrigeración de la sala en un 8,7%; aumento de la eficiencia global del SAI al 97,3%.

- El textil de Faisalabad impulsa un autobús de corriente continua:

- pFC SiC intercalado de 30 kW que alimenta el enlace de CC de varios inversores.

- Resultados: reducción de la temperatura del armario en un 18%; reducción del tamaño del filtro EMI en un 30%; reducción de las desconexiones por caídas de tensión en un 20%.

- Suministro auxiliar de acería, Karachi:

- Etapa rectificadora de Viena para entrada de 400 VCA a bus de 800 Vcc.

- Rendimiento: eficacia de la etapa del 98,5%; PF 0,995; el filtro LCL más pequeño redujo el volumen del armario en un 22%.

【Indicación de imagen: descripción técnica detallada】 Visualización en tres paneles: 1) Esquema de PFC tótem-polo con interruptores de SiC y diagrama de temporización; 2) Gráficos de eficiencia frente a carga y PF/THD a partir de mediciones de campo; 3) Imagen térmica de reactancia compacta y disipador térmico a 45 °C ambiente. Anota PF ≥0,99, THD ≤3%, conmutación de 60-100 kHz y emulación de perfil de caída de red paquistaní. Fotorrealista, 4K.

Selección y mantenimiento

- Elección de topología:

- Totem-pole para máxima densidad y eficiencia en monofásico/trifásico; Vienna para trifásico robusto con tensión de dispositivo reducida.

- CRM para la eficiencia en cargas ligeras; CCM para un modelado predecible de la corriente a mayor potencia.

- Margen de tensión/corriente:

- dispositivos de 650-1200 V en función del bus de CC; incluyen un margen térmico y de sobretensión del 20-30%.

- Confirme la coordinación del MOV/TVS con la protección contra sobretensiones de la instalación.

- Diseño térmico y medioambiental:

- Validar la refrigeración para 40-45 °C ambiente; considerar la refrigeración líquida más allá de ~100 kW por bastidor.

- Aplique revestimientos de conformación y cerramientos de presión positiva para polvo de cemento/textil.

- EMC y cableado:

- Minimice la inductancia de bucle; coloque condensadores de película cerca de los nodos de conmutación.

- Ajuste las inductancias CM y los condensadores X/Y para cumplir la norma IEC 61000-6-4 y evitar problemas de fugas.

- Diagnóstico y ciclo de vida:

- Permite el registro de datos de PF, THD, ondulación del bus, RPM del ventilador y derivas de temperatura.

- Utilice alertas predictivas para el calentamiento de la reactancia y el aumento de la ESR del condensador.

Factores de éxito del sector y testimonios de clientes

- Factores de éxito:

- Estudio temprano de armónicos y evaluación de la carga del transformador

- Codiseño magnético para funcionamiento a alta frecuencia

- Piloto en verano para validar los márgenes de refrigeración

- Formación sobre herramientas de puesta en servicio y actualizaciones de firmware

- Testimonio (Jefe de instalaciones, centro de datos de un gran banco en Karachi):

- "El cambio a los módulos PFC de SiC proporcionó una FP y una THD conformes a la red, con un notable descenso de la demanda de refrigeración de la sala. La puesta en servicio fue rápida gracias a los análisis integrados"

Futuras innovaciones y tendencias del mercado

- Perspectivas 2025–2027:

- Adopción más generalizada del PFC bidireccional para SAI/ESS híbridos (apoyo a la red y ahorro de picos)

- Adaptación de corriente asistida por IA en redes distorsionadas

- Controlador y controladores de puerta integrados para una mayor resistencia a la EMI

- Mejora de los costes gracias al escalado de las obleas de SiC de 200 mm y a las asociaciones de ensamblaje local

Perspectiva de la industria:

"Los rectificadores de banda ancha están reconfigurando la calidad de la energía de las instalaciones, haciendo que los equipos de alta densidad y bajo THD sean viables incluso en redes difíciles" - IEA Technology Perspectives 2024, sección de electrónica de potencia

Preguntas frecuentes y respuestas de expertos

- Puede el SiC PFC cumplir PF ≥0,99 y THD ≤3% en una red pakistaní distorsionada?

- Sí. Con compensación de armónicos y un sólido control de la corriente, nuestros módulos mantienen los objetivos en una amplia gama de distorsiones y caídas.

- ¿Qué topología es la mejor para un SAI de 100-250 kW?

- Rectificador vienés o tótem trifásico en función del filtro y la preferencia de control; proporcionamos estudios de compensación de pérdidas y filtros.

- ¿Cuánto podemos reducir el tamaño del disipador térmico y los imanes?

- Las reducciones típicas son del 20-35% frente al PFC de silicio, dependiendo de la frecuencia de conmutación y del entorno.

- ¿Necesitamos filtros especiales?

- Los filtros LCL/CM más pequeños suelen ser suficientes; nuestros kits EMI están ajustados para cumplir las normas IEC 61000-6-4 sobre emisiones y -6-2 sobre inmunidad.

- ¿Cuál es el ROI típico?

- 12-24 meses gracias al ahorro de energía, la reducción de la refrigeración y la disminución del mantenimiento: más rápido en aplicaciones de datos/sistemas UPS 24/7.

Por qué esta solución es adecuada para sus operaciones

Los módulos de control SiC PFC de Sicarb Tech combinan dispositivos SiC de alta velocidad con un sólido control y protección digitales para ofrecer una FP cercana a la unidad y una baja THD en las condiciones de red de Pakistán. El resultado es una corriente de entrada más limpia, una mayor eficiencia global del sistema, armarios más pequeños y menos eventos molestos, ventajas vitales para centros de datos, líneas textiles, auxiliares de cemento e infraestructuras de plantas siderúrgicas.

Conecte con especialistas para soluciones personalizadas

Acelere el rendimiento de su rectificador frontal con Sicarb Tech:

- Más de 10 años de experiencia en la fabricación de SiC, respaldada por la Academia de Ciencias de China

- Desarrollo personalizado de envases de R-SiC, SSiC, RBSiC y SiSiC, además de magnetismo PFC optimizado

- Servicios de transferencia de tecnología y establecimiento de fábricas para localizar la producción y las pruebas

- Soluciones llave en mano, desde el procesamiento de materiales hasta los módulos PFC acabados con documentación de conformidad

- Trayectoria probada con más de 19 empresas; creación rápida de prototipos, proyectos piloto sobre el terreno y modelización del rendimiento de la inversión

Obtenga gratis una evaluación inicial de PFC (FP/THD/eficiencia) y un plan de retorno de la inversión específico para su instalación.

- Email: [email protected]

- Teléfono/WhatsApp: +86 133 6536 0038

Reservar las franjas horarias de ingeniería y producción del cuarto trimestre de 2025 para garantizar la entrega antes de las fechas críticas de puesta en servicio.

Metadatos del artículo

- Última actualización: 2025-09-11

- Próxima revisión programada: 2025-12-15

- Autor: Equipo de ingeniería de aplicaciones de Sicarb Tech

- Contact: [email protected] | +86 133 6536 0038

- Enfoque normativo: IEC 61000-3-2/3-12, IEC 61000-6-2/6-4, IEC 62040, IEC 62477-1; alineado con las prácticas PEC y los criterios de calidad del NTDC Grid Code

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.