Módulos de supervisión y diagnóstico de sistemas de alimentación de SiC con mantenimiento predictivo y telemetría remota

Compartir

Visión general del producto y relevancia para el mercado en 2025

Los módulos de supervisión y diagnóstico del sistema de alimentación de SiC son complementos inteligentes y unidades integradas que instrumentan rectificadores, inversores, SAI y estantes de alimentación de CC basados en SiC para ofrecer telemetría en tiempo real, mantenimiento predictivo y gestión remota del ciclo de vida. Diseñados específicamente para trenes de potencia de banda ancha que funcionan a mayor frecuencia y temperatura, estos módulos capturan transitorios eléctricos rápidos, gradientes térmicos, estado de la conmutación y parámetros de calidad de la red que los monitores de la era del silicio suelen pasar por alto.

Por qué esto importa en Pakistán en 2025:

- Inestabilidad de la red y calor: las caídas de tensión, las sobretensiones y los armónicos frecuentes combinados con ambientes de 40–45 °C aceleran el envejecimiento de los componentes. Los análisis predictivos evitan el tiempo de inactividad no planificado en las instalaciones textiles, de cemento y siderúrgico y protegen los acuerdos de nivel de servicio de los centros de datos/salas de máquinas financieras.

- OPEX y personal: los análisis automatizados reducen las inspecciones manuales, optimizan los repuestos y acortan el MTTR en sitios de telecomunicaciones e industriales dispersos.

- Cumplimiento y ESG: los informes continuos de PF/THD, el seguimiento de la eficiencia y las auditorías de eventos respaldan la alineación con el Código de red NTDC y los paneles de sostenibilidad.

Sicarb Tech proporciona módulos de supervisión como:

- Placas integradas en sistemas SiC PFC/SAI/CC (integradas en fábrica).

- Kits de adaptación para armarios de alimentación existentes (carril DIN o entrepiso).

- Pila de análisis de nube/borde con acceso remoto seguro, alarmas e integración de API (SNMP/Modbus/CAN/REST).

Especificaciones técnicas y funciones avanzadas

Instrumentación y adquisición de datos:

- Detección eléctrica

- Tensión/corriente de fase de hasta 1 kV rms (red), 1,2 kVcc (bus), con ADC de 16–24 bits, hasta 500 kS/s por canal

- Sondas aisladas de alto CMTI (≥100 V/ns) para nodos de conmutación SiC

- Cálculo de PF/THD conforme a los métodos IEC 61000 (hasta el armónico 50)

- Térmico y mecánico

- Entradas térmicas multipunto: NTC/RTD, sensores de proximidad de matriz, puertos de rejilla de Bragg de fibra opcionales

- RPM del ventilador/bomba, vibración (MEMS), polvo/partículas (opcional), sensores de humedad

- Modelos de mantenimiento predictivo

- Estimación de la deriva de ESR/capacitancia del capacitor y vida útil restante (RUL)

- Modelo de envejecimiento de puntos críticos del inductor y tensión de ciclo de potencia para módulos SiC

- Predicción de la vida útil del cojinete del ventilador/bomba (L10), detección de aumento térmico del conector

- Integración y seguridad del control

- Grifos de solo lectura y salidas a prueba de fallos; no interfiere con los controladores de puerta ni con la protección

- Correlación rápida de fallos: disparos DESAT, eventos de sobrecorriente, registros de sobretemperatura con marcas de tiempo a nivel de ms

- Conectividad y seguridad

- Interfaces: SNMPv3, Modbus-RTU/TCP, CAN, API RESTful; MQTT opcional a la nube segura

- Ethernet dual, RS-485, LTE/4G opcional; TLS 1.2+, firmware firmado, acceso basado en roles

- Software y análisis

- Inferencia perimetral para la detección de anomalías (análisis espectral de corriente/tensión)

- KPI del panel: PF, THD, eficiencia, estimaciones de ΔTj, pérdida de energía por etapa, mapas de calor de eventos

- Actualizaciones de firmware OTA; almacenamiento en búfer local durante >30 días con almacenamiento y reenvío

- Entorno y factor de forma

- Tarjetas de carril DIN o entrepiso; funcionamiento en ambiente de −20 a +70 °C; opciones de revestimiento conforme (recintos IP54+)

- Alineación de cumplimiento: IEC 61000-6-2/6-4 (EMC), IEC 62477-1 (convertidores de potencia), IEC 62368 (equipos de TIC)

Diferenciadores de Sicarb Tech:

- Sincronización de muestreo consciente de SiC para capturar fenómenos de borde rápidos

- Biblioteca de perfiles de perturbación de la red específicos de Pakistán para la sintonización del modelo

- Asistente de puesta en marcha que integra la capacidad del transformador, la impedancia del alimentador y los SPD del sitio

Visibilidad continua de la calidad de la energía y el estado de los sistemas de SiC

| Visibilidad, precisión y salvaguardias del tiempo de actividad para las redes de Pakistán | Módulo de supervisión y diagnóstico de SiC (Sicarb Tech) | Medidores de armario convencionales y grifos SCADA |

|---|---|---|

| Precisión de PF/THD a alta frecuencia | Alta precisión con armónicos hasta el 50, seguro para el borde de SiC | Rango armónico limitado e inmunidad al ruido |

| Información térmica/de unión | Inferencia de proximidad de matriz y detección multipunto | Temperaturas solo del disipador térmico |

| Mantenimiento predictivo | RUL de ESR/inductor/ventilador con alertas | Basado en calendario, no predictivo |

| Correlación de eventos | Registros a nivel de ms en todas las etapas de potencia | Marcas de tiempo aproximadas y contexto faltante |

| Actualizaciones/seguridad remotas | OTA, RBAC, TLS, imágenes firmadas | Básico o ninguno |

Ventajas clave y beneficios probados

- Evite fallos antes de que ocurran: detecte el aumento de ESR, la deriva del punto crítico del inductor o la degradación del ventilador con semanas de anticipación para programar el mantenimiento en torno a la producción.

- Mejore la eficiencia y la calidad de la energía: la telemetría en vivo de PF/THD y la pérdida de conmutación guían la sintonización del filtro y las actualizaciones de control, lo que mejora el cumplimiento del sitio y reduce los OPEX.

- Acorte el MTTR y evite fallos repetidos: el análisis de la causa raíz correlaciona los eventos de la red con las respuestas del convertidor, lo que reduce el tiempo de resolución de problemas.

- Adecuado para entornos hostiles: las placas revestidas, los sensores de polvo y la lógica de presión positiva se adaptan a las condiciones de las plantas de cemento/textiles/acero.

Cita de un experto:

“La integración de diagnósticos con detección de alto ancho de banda es esencial para aprovechar los dispositivos de banda ancha de forma segura a alta frecuencia: el mantenimiento predictivo es ahora una característica principal, no un complemento”. — Revista de electrónica de potencia de IEEE, Fiabilidad de los sistemas de potencia de banda ancha, 2024

Aplicaciones reales e historias de éxito mensurables

- Flota de SAI del centro de datos de Lahore:

- Se agregaron monitores a los módulos SAI de SiC de 200 kW; los análisis habilitaron el seguimiento de ESR y RUL del ventilador.

- Resultados: las interrupciones no planificadas cayeron

- Líneas VFD textiles de Faisalabad:

- Detección de vibraciones y anomalías térmicas en accionamientos de SiC.

- Resultados: reducción del 26% en los disparos intempestivos durante el verano; reemplazos de condensadores planificados de forma proactiva, lo que reduce las horas de mantenimiento en un 18%.

- Molino de cemento MCC de Karachi:

- Recomendaciones para el etiquetado de perturbaciones de la red y la sintonización automática del control.

- Rendimiento: THD reducido del 6,8% al 3,1% después de la reconfiguración del filtro; tiempo de localización de fallas reducido en ~40% mediante mapas de calor de eventos.

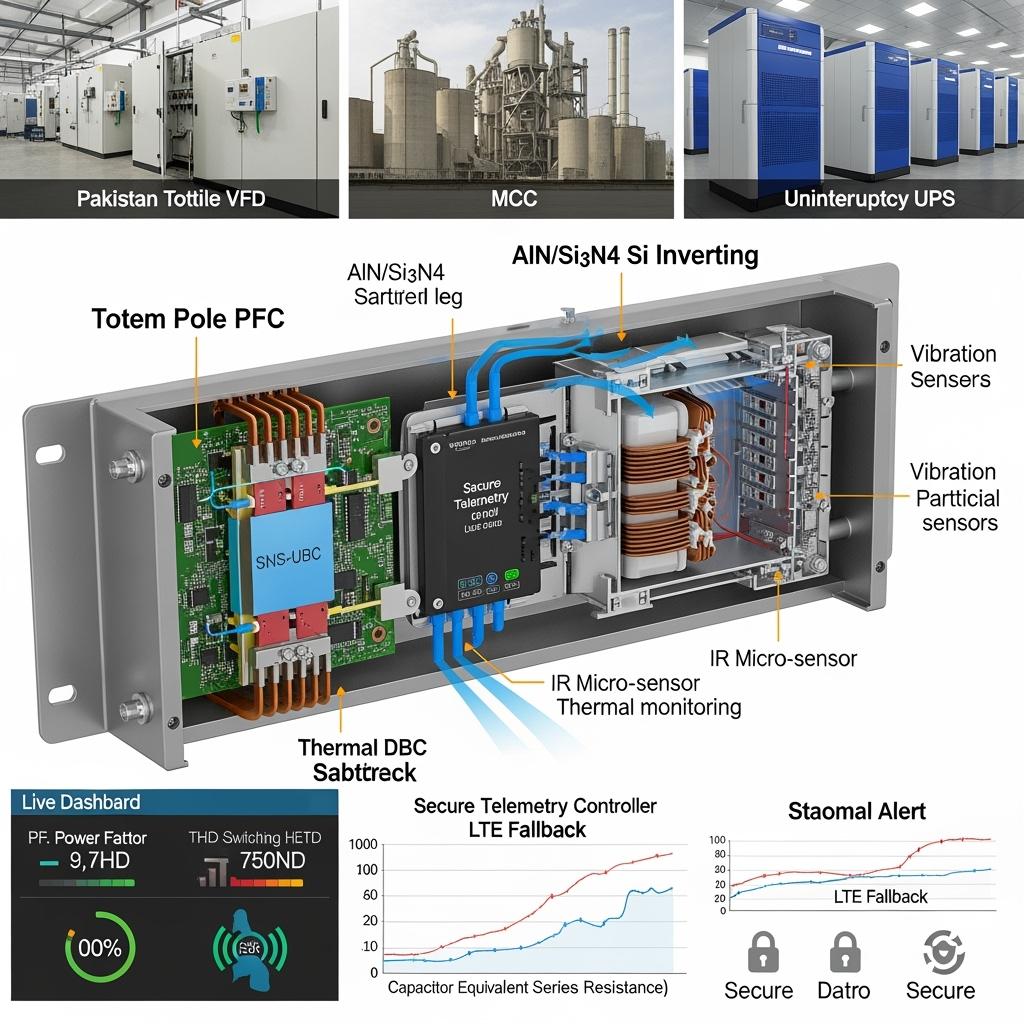

【Indicación de imagen: descripción técnica detallada】 Visualización del panel de control de tres paneles: 1) Espectro PF/THD en vivo con barras armónicas y banderas de cumplimiento; 2) Cronología del estado de los componentes que muestra el aumento de ESR del condensador, la tendencia de los puntos calientes del inductor y el RUL del ventilador; 3) Mapa de correlación de eventos que vincula la caída de la red con el disparo DESAT y el pico térmico con marcas de tiempo en ms. Incluir foto del armario con llamadas de sensor (sondas de corriente, diodos térmicos, MEMS de vibración). Fotorrealista, 4K.

Selección y mantenimiento

- Estrategia de sensores

- Colocar sensores de corriente/tensión cerca de los nodos de conmutación con alto aislamiento CMTI; agregar puntos térmicos cercanos al troquel para una estimación precisa de ΔTj.

- Incluir al menos un sensor de vibración y polvo para molinos y sitios textiles.

- Red y ciberseguridad

- Utilizar VLAN o redes OT segregadas; aplicar RBAC y autenticación basada en certificados; mantener una ruta de exportación de datos fuera de línea para sitios seguros.

- Sintonización de análisis

- Importar perfiles de carga del sitio y registros de perturbaciones de la red; calibrar las líneas de base de ESR después de la puesta en marcha; establecer umbrales de alerta (advertencia/crítico) por clase de dispositivo.

- Protección medioambiental

- Aplicar revestimiento conforme; desplegar envolventes IP54+ y presión positiva donde el polvo sea severo; programar alertas de limpieza de filtros.

- Planificación del ciclo de vida

- Revisión trimestral de los KPI y la deriva de la tendencia; actualizaciones de firmware en ventanas de mantenimiento; mantener kits de sensores de repuesto para una rápida sustitución en campo.

Factores de éxito del sector y testimonios de clientes

- Factores de éxito:

- Integración temprana con los equipos de control de UPS/accionamiento para alinear los KPI y los umbrales

- Piloto en pleno verano para validar los modelos térmicos

- Manuales de escalada claros y alertas de guardia vinculadas a los flujos de trabajo de las instalaciones

- Formación para el personal de las instalaciones/OT sobre paneles de control y API

- Testimonio (Jefe de Instalaciones, sala de máquinas financieras de Karachi):

- “Las alertas predictivas nos dieron semanas de anticipación para reemplazar un módulo de ventilador defectuoso. Evitamos un evento de derivación y, en el proceso, recortamos la energía de refrigeración”.

Futuras innovaciones y tendencias del mercado

- Perspectivas 2025–2027:

- IA de borde para la clasificación de anomalías de las firmas de conmutación de SiC

- Sensores de fibra de Bragg integrados y proxies de temperatura en el troquel para una estimación de ΔTj más ajustada

- Modelos de gemelos digitales que fusionan la telemetría con los perfiles de misión para la predicción de la vida útil

- Agregación segura en la nube en flotas de múltiples sitios con informes ESG y preparación para el servicio de red

Perspectiva de la industria:

“El liderazgo en fiabilidad en sistemas de banda ancha se basa en la supervisión y el análisis integrados que cierran el ciclo desde la física del dispositivo hasta las operaciones de la flota”. — Perspectivas tecnológicas de la AIE 2024, capítulo de electrónica de potencia

Preguntas frecuentes y respuestas de expertos

- ¿La supervisión interferirá con los bucles de protección o control?

- No. Nuestros módulos utilizan sensores aislados de solo lectura y muestreo sincronizado en el tiempo que no cargan ni alteran las señales de control.

- ¿Qué precisión tiene la estimación de la temperatura de la unión?

- Con sensores cercanos al troquel y modelos térmicos calibrados, la estimación de ΔTj suele estar dentro de ±5–8 K de los puntos de referencia de termografía IR.

- ¿Podemos adaptar armarios existentes basados en silicio?

- Sí. Los kits de riel DIN son compatibles con los sistemas heredados; los análisis aún añaden valor, con modelos compatibles con SiC habilitados selectivamente.

- ¿Qué conectividad se admite para sitios remotos?

- Ethernet dual, RS‑485 y LTE/4G opcional con VPN/TLS. El almacenamiento y reenvío garantiza que no se pierdan datos durante las interrupciones de la red troncal.

- ¿Cuál es el ROI típico?

- 9–24 meses a partir del tiempo de inactividad evitado, la reducción de las llamadas de emergencia y la refrigeración optimizada, más rápido para las líneas críticas para el proceso y de UPS 24/7.

Por qué esta solución es adecuada para sus operaciones

Los módulos de supervisión y diagnóstico de Sicarb Tech traducen el comportamiento del dispositivo SiC de alta velocidad en información práctica: anticipando fallos, optimizando la eficiencia y documentando el cumplimiento en los entornos propensos al calor y al polvo de Pakistán. El resultado es una mayor disponibilidad, un menor OPEX y una ampliación segura de la tecnología SiC en centros de datos, redes de telecomunicaciones e industria pesada.

Conecte con especialistas para soluciones personalizadas

Transforme la fiabilidad con Sicarb Tech:

- Más de 10 años de experiencia en fabricación de SiC con el respaldo de la Academia de Ciencias de China

- Desarrollo personalizado en R‑SiC, SSiC, RBSiC y SiSiC para pilas térmicas robustas

- Servicios de transferencia de tecnología y establecimiento de fábricas para localizar la producción y las pruebas

- Soluciones llave en mano, desde los materiales hasta los sistemas terminados, incluida la supervisión, el análisis y la documentación de cumplimiento

- Historial probado con más de 19 empresas; pilotos rápidos, diseño de KPI y modelado de ROI

Solicite una evaluación gratuita de la preparación para la supervisión y un plan de ROI de mantenimiento predictivo.

- Email: [email protected]

- Teléfono/WhatsApp: +86 133 6536 0038

Reserve las ranuras de integración del cuarto trimestre de 2025 para alinearse con las ventanas de cierre y los objetivos de fiabilidad de temporada alta.

Metadatos del artículo

- Última actualización: 2025-09-11

- Próxima revisión programada: 2025-12-15

- Autor: Equipo de fiabilidad y análisis de Sicarb Tech

- Contact: [email protected] | +86 133 6536 0038

- Enfoque en normas: IEC 62477-1, IEC 61000-6-2/6-4, IEC 62368; alineado con las prácticas de la PEC y los criterios de calidad de la energía del Código de Red NTDC

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.