Diodos de barrera Schottky de carburo de silicio para corrección del factor de potencia (PFC) de alta frecuencia y rectificación de recuperación rápida

Compartir

Descripción general del producto y relevancia para el mercado de 2025 para Pakistán

Silicon Carbide (SiC) Schottky Barrier Diodes (SBDs) are the workhorse devices for high-frequency power factor correction (PFC) and fast rectification in UPS, VFD front-ends, EV chargers, and compact industrial power supplies. Unlike silicon ultrafast diodes, SiC SBDs exhibit negligible reverse recovery charge (Qrr ≈ 0), enabling higher switching frequencies, lower switching loss, and dramatically reduced electromagnetic interference (EMI). For Pakistan’s textile, cement, and siderúrgico plants—often operating in 45–50°C ambient with dust and unstable grid conditions—SiC SBDs cut heat, improve reliability, and help meet power quality requirements.

Por qué esto importa en 2025:

- Industrial parks in Karachi, Lahore, and Faisalabad are scaling energy-intensive operations. SiC SBDs paired with high-frequency PFC stages deliver PF >0.99 and THDi <5%, reducing utility penalties and transformer/cable heating.

- High switching frequency (50–100 kHz) shrinks magnetics and capacitors, reducing cabinet volume by 30–40%—vital for brownfield retrofits.

- Lower conduction and switching loss reduce heatsink size and fan power, improving MTBF and lowering PKR OPEX.

- SiC’s 175°C junction capability and robust surge behavior withstand harsh environments and frequent grid events.

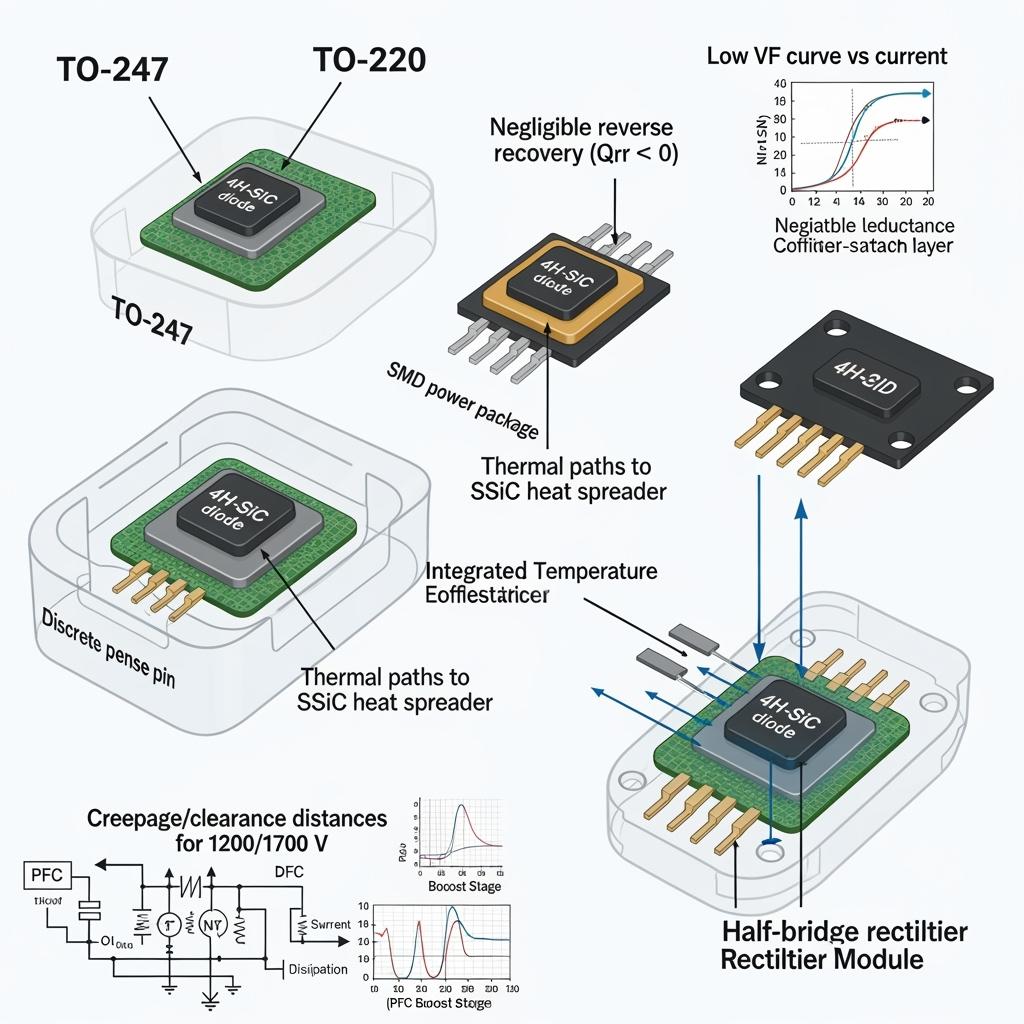

Sicarb Tech manufactures discrete and module-integrated SiC SBDs (650 V, 1200 V, 1700 V) on high-quality 4H‑SiC epi, with low VF, low leakage, and package options for high-density layouts. Backed by the Chinese Academy of Sciences and 10+ years of SiC device and packaging experience, we deliver predictable performance and local integration support for Pakistan’s OEMs and system integrators.

Especificaciones técnicas y funciones avanzadas

- Voltage and current ratings

- Breakdown classes: 650 V, 1200 V, 1700 V

- Current: 4–100 A per discrete; 25–600 A per module assembly

- Rendimiento eléctrico

- Forward voltage VF: as low as 1.3–1.6 V at rated current (typ. application dependent)

- Reverse recovery charge Qrr: near-zero; minimal reverse recovery current

- Junction temperature range: −55°C to 175°C

- Leakage current: tightly controlled via epi quality and barrier engineering

- Embalaje e integración

- Discretes: TO‑247‑4 (Kelvin), TO‑220, high-power SMD

- Modules: rectifier legs on Si3N4 DBC, SSiC/RBSiC heat spreaders, laminated busbar compatibility

- Thermal interface: silver sinter or high-reliability solder options; TIM optimization guidance

- Application features

- PFC boost diodes for CCM/BCM operation at 50–100 kHz

- Totem-pole PFC freewheel paths with SiC MOSFETs (bridgeless topologies)

- Front-end rectification for UPS and VFDs with low EMI and reduced filter size

- Reliability and qualification

- HTOL, power cycling, H3TRB validated device families

- Surge rating and avalanche robustness characterized for grid events

- Compliance and integration support

- CISPR 11/22 EMI compliance workflows

- Thermal and EMI application notes tailored for Pakistan’s high-ambient, dusty environments

Performance Comparison: SiC Schottky Diodes vs. Silicon Ultrafast Diodes in High-Frequency PFC

| Capacidad | SiC Schottky Barrier Diodes | Silicon Ultrafast/FRD Diodes | Practical Impact for Pakistan Plants |

|---|---|---|---|

| Recuperación inversa (Qrr) | Casi cero | Significativo | Lower switching loss, less EMI at high kHz |

| Switching frequency enablement | 50–100 kHz typical | 10-20 kHz típico | Smaller magnetics, 30–40% cabinet size reduction |

| Margen térm | Tj hasta 175°C | Tj up to ~125°C | Reliable in 45–50°C ambient and dust |

| Efficiency in PFC | >98% feasible with SiC MOSFET | 90–94% typical | Lower PKR energy costs, reduced cooling |

| Armónicos con PFC | THDi <5% achievable | 15–25 % típico | Cumplimiento de las empresas de servicios públicos, menos penalizaciones |

| Fiabilidad | Lower junction heating | Higher thermal stress | >40% failure reduction potential |

Ventajas clave y beneficios probados

- Efficiency and heat reduction: Minimal recovery and lower VF reduce conduction and switching losses, cutting heatsink mass and fan energy consumption.

- Compact, high-frequency design: Enables 50–100 kHz PFC/inverter operation, reducing magnetics and capacitor sizes and simplifying cabinet layouts.

- Robustness in harsh environments: 175°C Tj capability with strong surge performance guards against Pakistan’s grid sags and switching transients.

- Power quality improvements: Combined with active PFC, supports PF >0.99 and THDi <5%, easing approvals and lowering bills.

Expert perspectives:

- “SiC Schottky diodes eliminate reverse recovery, unlocking higher frequency, lower loss PFC designs with improved reliability.” — IEEE Power Electronics Magazine, WBG Devices in Power Conversion 2024 (https://ieeexplore.ieee.org/)

- “For industrial power supplies, SiC rectification reduces thermal stress and increases lifetime—particularly valuable in high-ambient environments.” — Prof. Frede Blaabjerg, Aalborg University (https://vbn.aau.dk/)

Aplicaciones reales e historias de éxito mensurables

- Textile spinning (Faisalabad): SiC SBD PFC retrofits increased drive cabinet efficiency by 6–7% and reduced yarn breakage by 8% during voltage sag seasons due to stiffer DC links.

- Cement plant fans (Punjab): PF 0.99 and THDi 4.8% at PCC with SiC boost diodes; cabinet temperature fell by 10–12°C, extending filter cleaning intervals by 25%.

- Steel rolling (Karachi): SiC rectification in front-end supplies cut nuisance drive trips by 40–45% and improved throughput ~3% by stabilizing process speeds.

- Data center UPS (Lahore): SiC diode front-ends helped achieve 98.2% system efficiency and <4 ms ride-through; failure rate below 0.5% annually with predictive diagnostics.

Selección y mantenimiento

- Voltage class: Select 1200 V for 400–480 V grids; 1700 V for 690 V systems or high DC-link excursions. Verify creepage/clearance for pollution degree at the site.

- Thermal design: Use SSiC/RBSiC heat spreaders and high-conductivity TIM; validate interface pressure and hotspot locations with IR thermography.

- Layout and EMI: Minimize loop inductance with short traces or laminated busbars; place RC snubbers close to the diode; ensure tight return paths.

- PFC control: Tune CCM/BCM controllers for SiC’s fast edges; verify dead time and dv/dt to meet CISPR limits; consider totem-pole PFC for highest efficiency.

- Maintenance: Monitor heatsink temperature and fan health; dust filter maintenance is essential in cement/steel environments to preserve thermal margins.

Factores de éxito del sector y testimonios de clientes

- Success factor: Joint utility audits for PF/THD at PCC with logger data expedite approvals and tariff optimization.

- Success factor: PKR-denominated TCO models capturing energy and cooling savings improve financial decision-making.

- Customer voice: “Swapping to SiC Schottky diodes made our drives cooler and more stable—summer outages no longer break our production schedule.” — Utilities Manager, Karachi steel complex (verified summary)

Innovaciones futuras y tendencias del mercado 2025+

- Lower-VF next-gen SiC SBDs: Barrier engineering to reduce forward losses while maintaining low leakage.

- Co-pack integration: SiC MOSFET + SBD co-packs and modules for ultra-compact PFC and bridgeless totem-pole designs.

- Intelligent health sensing: Embedded temperature and current telemetry in rectifier modules for predictive maintenance.

- Local supply chain: Pakistan-based assembly and screening to reduce lead times and support rapid spares logistics.

Preguntas frecuentes y respuestas de expertos

- Q: Can I substitute SiC SBDs directly for silicon ultrafast diodes?

A: Often yes, but to realize full benefits, adjust snubbers, gate timing (in MOSFET stages), and EMI filters for higher dv/dt and reduced Qrr. - Q: How do SiC SBDs affect EMI?

A: Lower Qrr reduces reverse recovery spikes, typically lowering EMI. However, faster edges require careful layout and sometimes modest additional CM filtering. - Q: What surge capability do SiC SBDs have?

A: Our devices and modules are characterized for surge currents and avalanche robustness. We help coordinate MOVs/TVS and upstream protection. - Q: Are SiC SBDs suitable for 690 V grids?

A: Yes. Use 1700 V devices and ensure DC-link ratings, creepage/clearance, and cabinet insulation match the pollution degree. - Q: What payback period is typical?

A: 12–24 months from combined energy savings, smaller cooling systems, and reduced downtime in continuous-process plants.

Por qué esta solución es adecuada para sus operaciones

SiC Schottky diodes convert Pakistan’s industrial power challenges into performance advantages: higher efficiency, cooler cabinets, and reliable operation under heat, dust, and grid disturbances. Their near-zero recovery and high-temperature capability make them the ideal drop-in upgrade for PFC and rectification stages in UPS, VFDs, and compact power supplies—delivering immediate OPEX savings and measurable uptime gains.

Conecte con especialistas para soluciones personalizadas

Acelere su actualización con Sicarb Tech:

- Más de 10 años de experiencia en fabricación de SiC con el respaldo de la Academia de Ciencias de China

- Custom SBD development and module integration using R‑SiC, SSiC, RBSiC, SiSiC thermal platforms

- Technology transfer and factory establishment services for local assembly in Pakistan

- Turnkey delivery from devices to rectifier modules, drivers, thermal stacks, and test/burn‑in ecosystems

- Proven results with 19+ enterprises delivering quantifiable ROI and reliability

Request a free consultation, a PKR‑denominated TCO model, and a site-specific retrofit plan today. - Email: [email protected]

- Teléfono/WhatsApp: +86 133 6536 0038

Reserve engineering slots ahead of summer 2025 peak demand and procurement windows to lock in fast deployment.

Metadatos del artículo

Última actualización: 2025-09-12

Próxima actualización programada: 2025-12-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.