Disipadores modulares de refrigeración líquida de alta densidad de potencia para módulos de potencia de SiC con gestión térmica tolerante al polvo

Compartir

Visión general del producto y relevancia para el mercado en 2025

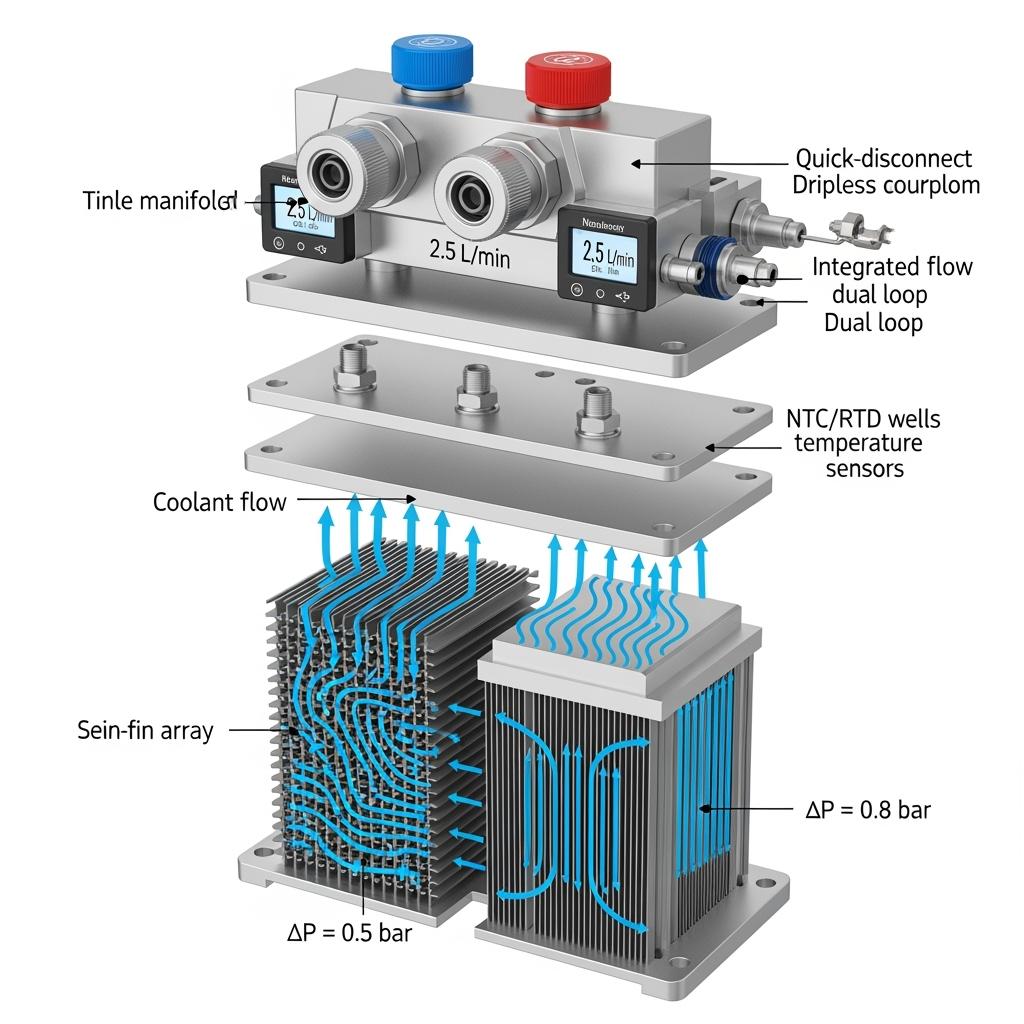

Los disipadores de calor modulares de refrigeración líquida de alta densidad de potencia están diseñados para extraer el calor de forma eficiente de los módulos de potencia SiC que funcionan a altas frecuencias de conmutación (50–200 kHz) en los sistemas de conversión de potencia (PCS) de los sistemas de almacenamiento de energía de baterías (BESS) y los inversores MV. Para los sectores textil, cementero, siderúrgico, y los sectores industriales emergentes de Pakistán, las temperaturas ambiente pueden alcanzar los 45–50 °C, y el aire de fábrica cargado de polvo limita el flujo de aire efectivo, condiciones que castigan los diseños convencionales refrigerados por aire. Las placas frías refrigeradas por líquido con arquitecturas tolerantes al polvo proporcionan un rendimiento térmico estable, lo que permite una eficiencia de PCS ≥98 %, una densidad de potencia de 1,8–2,2× y una alta fiabilidad, incluso cuando los filtros de aire están parcialmente obstruidos o se amplían los intervalos de servicio.

En 2025, a medida que Pakistán despliegue 3–5 GWh de almacenamiento C&I y del lado de la red y las empresas de servicios públicos hagan cumplir estrictos requisitos de interconexión y calidad de la energía, el margen térmico determinará el tiempo de actividad. Los módulos SiC combinados con uniones de sinterización de Ag y sustratos Si3N4/AlN pueden funcionar a altas temperaturas de unión, pero solo si la impedancia térmica de la unión al refrigerante está estrechamente controlada. Las placas frías modulares y reparables (de aletas, microcanal o diseños híbridos) ofrecen temperaturas de unión constantes en condiciones polvorientas y calientes, lo que reduce la reducción de potencia, evita los disparos molestos y prolonga la vida útil.

Especificaciones técnicas y funciones avanzadas

- Rendimiento térmico

- Manejo del flujo de calor: ≥150–300 W/cm² puntos calientes locales soportados con híbridos de aletas/microcanales

- Resistencia térmica (base del módulo al refrigerante): tan bajo como 0,02–0,05 K/W por módulo (dependiente de la geometría)

- Objetivos de aumento de temperatura: reducción de ΔTj en 10–15 °C frente a las líneas de base refrigeradas por aire con la misma carga

- Rendimiento hidráulico

- Refrigerante: mezclas de agua-glicol (por ejemplo, 30–40 % de glicol), opciones de agua desionizada; inhibidores de corrosión compatibles con aleaciones de cobre o aluminio

- Caudales: 2–10 L/min por segmento de placa fría; caída de presión 10–60 kPa (dependiente del diseño/ajuste)

- Modularidad del colector: arquitectura de alimentación paralela para igualar el flujo a través de múltiples placas (armarios de 100 kW a varios MW)

- Mecánica y materiales

- Materiales de la placa: cobre (niquelado) para una conductividad máxima; aluminio anodizado para optimizar el peso y el coste

- Planitud de la superficie: ≤20 µm en la huella del módulo; rugosidad Ra ≤ 0,8 µm

- Compatibilidad TIM: cambio de fase o grasa de alta conductividad; control validado del grosor de la línea de unión

- Detección y control

- NTC/RTD integrado para temperaturas de entrada/salida y placa; sensores de flujo y presión opcionales

- Detección de fugas con acopladores QD sin goteo y sensores de bandeja de recogida

- Integración SCADA para alarmas térmicas, disparadores de reducción de potencia y programación de mantenimiento

- Robustez ambiental

- Interfaces de recinto tolerantes al polvo: cartuchos de filtro reemplazables con sensores ΔP

- Recubrimientos resistentes a la corrosión; químicas de refrigerante compatibles con biocidas

- Montaje resistente a las vibraciones para entornos industriales

Comparación de rendimiento: Placas frías modulares refrigeradas por líquido frente a refrigeración por aire de alto rendimiento en PCS de SiC

| Criterio | Disipadores de calor modulares refrigerados por líquido (pin-fin/microcanal) | Refrigeración por aire de alto rendimiento con apilamientos de aletas |

|---|---|---|

| Temperatura de unión a plena carga | Inferior en 10–15 °C, estable en todo el ambiente | Sensible al ambiente y a la obstrucción por polvo |

| Densidad de potencia y huella | 1,8–2,2× superior; volumen del armario >30% menor | Mayor volumen; conductos de flujo de aire y ventiladores |

| Impacto en la eficiencia | Admite una eficiencia de PCS ≥98% a través de un Rth más bajo | Potencia de ventilador adicional; se necesitan mayores márgenes térmicos |

| Tolerancia al polvo | Mantiene el rendimiento; filtros en el aire del armario | Las aletas del disipador de calor se obstruyen; se requiere una limpieza frecuente |

| Ruido y mantenimiento | Menor ruido acústico; cambios de filtro programados | Mayor ruido; limpieza frecuente de aletas y sustitución de ventiladores |

Ventajas clave y beneficios probados con la cita de un experto

- Margen térmico para alta frecuencia: Un Rth más bajo y una eliminación de calor robusta permiten una conmutación de 50–200 kHz, reduciendo los filtros LCL y los componentes magnéticos sin sobrecalentamiento.

- Fiabilidad en condiciones adversas: Los diseños de armarios tolerantes al polvo, las placas frías resistentes a la corrosión y el control del flujo/temperatura reducen las interrupciones no planificadas en entornos de 45–50 °C.

- Puesta en marcha más rápida y funcionamiento estable: El rendimiento térmico predecible simplifica las estrategias de reducción de potencia durante las caídas de la red y los eventos FRT, minimizando los disparos molestos.

Perspectiva experta:

“Liquid cooling with engineered cold plates provides the thermal margin necessary to exploit wide bandgap switching speeds while ensuring reliability in high ambient and contaminated environments.” — IEEE Power Electronics Magazine, thermal management for WBG converters (https://ieeexplore.ieee.org)

Aplicaciones reales e historias de éxito mensurables

- Actualización de PCS de 2 MW/4 MWh en Punjab: La sustitución de los apilamientos refrigerados por aire por placas frías modulares de pin-fin redujo la Tj máxima en ~12 °C con una conmutación de 100 kHz. La eficiencia de ida y vuelta mejoró en ~0,7% y la huella del armario se redujo en ~35%. Los incidentes de reducción de potencia relacionados con el polvo se redujeron en >40% durante el verano.

- Reacondicionamiento de accionamientos textiles en Sindh: Las placas de microcanal en inversores compactos permitieron una mayor frecuencia de conmutación sin disparos térmicos a 50 °C de ambiente; el mantenimiento se trasladó a los cambios trimestrales de filtro, reduciendo el tiempo de inactividad en ~25%.

- Piloto de inversor MV (sur de Pakistán): Las placas frías híbridas con colector paralelo mejoraron la uniformidad térmica entre fases, lo que permitió filtros LCL más pequeños y pruebas de utilidad de primera pasada satisfactorias para FRT y potencia reactiva.

Selección y mantenimiento

- Diseño y dimensionamiento térmico

- Adapte la geometría de la placa fría (pin-fin frente a microcanal) al flujo de calor del módulo y a la disponibilidad de refrigerante; verifique el ΔTj en el peor de los casos ambientales (50 °C).

- Asegúrese de la planitud de la base y de la calidad del TIM; valide el grosor de la línea de unión.

- Refrigerante y materiales

- Seleccione las proporciones de agua-glicol para la protección contra la congelación/corrosión; confirme la compatibilidad con el cobre o el aluminio y los materiales de sellado.

- Incluya biocidas y análisis periódico del refrigerante para evitar incrustaciones; planifique la renovación anual del refrigerante en sitios difíciles.

- Hidráulica y colectores

- Diseñe para flujos equilibrados a través de múltiples placas; utilice restrictoras de flujo u orificios calibrados si es necesario.

- Proporcione acopladores QD y bandejas de goteo que se puedan reparar; incluya sensores de presión para la detección temprana de obstrucciones.

- Medio ambiente y servicio

- Aísle el circuito de líquido de las vías de aire polvorientas; mantenga los filtros de polvo del armario con alertas basadas en ΔP.

- Implemente la detección de fugas y la lógica de apagado; conserve repuestos críticos (sellos, acopladores, sensores).

- Validación

- Realice pruebas de calorimetría y cámara térmica; correlacione con los modelos de gemelos digitales. Valide el rendimiento con filtros cargados de polvo para simular las condiciones reales.

Factores de éxito del sector y testimonios de clientes

- El co-diseño de los aspectos térmicos, mecánicos y de control (módulos, accionamientos de puerta, filtro LCL y placas frías) reduce el riesgo residual en la puesta en marcha.

- El mantenimiento predictivo a través de telemetría (temperatura de entrada/salida, flujo, ΔP en los filtros) reduce las llamadas de servicio de emergencia.

Comentarios de los clientes:

“Las placas frías modulares estabilizaron las temperaturas de unión durante las olas de calor y la temporada de polvo. Logramos nuestros objetivos de eficiencia sin sobredimensionar la refrigeración”. — Jefe de ingeniería, integrador de ESS con sede en Pakistán

Futuras innovaciones y tendencias del mercado

- Placas frías fabricadas de forma aditiva con canales optimizados por topología para un Rth ultrabajo con una caída de presión reducida

- Refrigerantes dieléctricos sin glicol y conectores rápidos a prueba de fugas integrados para un servicio de campo más fácil

- Microsensores integrados para la detección de incrustaciones en tiempo real y la reducción automática de potencia

- Localización en Pakistán: centros de montaje y servicio para placas frías, preparación de refrigerante y reacondicionamiento rápido en campo

Preguntas frecuentes y respuestas de expertos

- ¿Qué es mejor: placas frías de pin-fin o de microcanal?

Pin-fin ofrece un rendimiento robusto y un menor riesgo de obstrucción; los microcanales ofrecen un Rth más bajo a expensas de una mayor caída de presión y sensibilidad a las incrustaciones. Los híbridos equilibran ambos. - ¿Qué refrigerante debemos utilizar en sitios industriales calientes?

Las mezclas de agua y glicol (30–40% de glicol) con inhibidores de corrosión son comunes; valide la compatibilidad con metales y sellos y establezca un plan de mantenimiento del refrigerante. - ¿Cómo gestionamos las fugas en entornos de fábrica?

Utilice desconexiones rápidas sin goteo, sensores de fugas y bandejas de contención. Integre alarmas con la reducción de potencia de PCS y los procedimientos de apagado seguro. - ¿La refrigeración líquida complicará el mantenimiento?

El servicio es predecible: cambios de filtro, comprobaciones del refrigerante y calibración periódica de los sensores. Los colectores modulares y los QD hacen que la sustitución de la placa sea rápida. - ¿La refrigeración líquida puede ayudar a pasar las pruebas de la red?

Indirectamente. Los márgenes térmicos estables evitan la reducción de potencia durante los eventos FRT/caída, lo que permite mantener el soporte de potencia reactiva y real, lo que a menudo mejora los resultados de las pruebas.

Por qué esta solución es adecuada para sus operaciones

Los entornos industriales de Pakistán exigen a los sistemas refrigerados por aire. Los disipadores de calor modulares refrigerados por líquido proporcionan la estabilidad térmica que los módulos de potencia SiC necesitan para funcionar a alta frecuencia y alta eficiencia en condiciones de 45–50 °C y polvo. El resultado es medible: eficiencia de PCS ≥98%, armarios >30% más pequeños, menos disparos térmicos y una vida útil más larga de los componentes, lo que permite una puesta en marcha más rápida, un mayor tiempo de actividad y un mejor retorno de la inversión en los sectores textil, cementero, siderúrgico y emergentes.

Conecte con especialistas para soluciones personalizadas

Contrate a Sicarb Tech para diseñar, validar y localizar su solución de refrigeración:

- Más de 10 años de experiencia en fabricación de SiC e ingeniería de aplicaciones

- Respaldo de la Academia de Ciencias de China e innovación continua en embalaje y gestión térmica

- Desarrollo personalizado en R-SiC, SSiC, RBSiC, SiSiC, además de apilamientos y placas frías DBC/AMB avanzados

- Servicios de transferencia de tecnología y establecimiento de fábricas para construir capacidad local de montaje, pruebas y servicio en Pakistán

- Entrega llave en mano desde materiales y dispositivos hasta placas frías, módulos, controladores, filtros LCL y documentación de cumplimiento

- Trayectoria probada con más de 19 empresas que logran una mayor eficiencia, densidad y fiabilidad

Solicite su consulta gratuita para el dimensionamiento térmico, el diseño del colector y la planificación del mantenimiento:

- Email: [email protected]

- Teléfono/WhatsApp: +86 133 6536 0038

Asegure las plazas de diseño y producción de 2025–2026 para reducir el riesgo de puesta en marcha, reducir la huella y escalar las implementaciones en los centros industriales de Pakistán.

Metadatos del artículo

Última actualización: 2025-09-10

Próxima actualización programada: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.