Aditivo de silicio de carburo de silicio de reemplazo de bajo aluminio para aceros con bajo contenido de Al y consumo reducido de alambre de aluminio

Compartir

In Pakistan’s melt shops, a quiet shift is underway. The best operators are discovering that you don’t need heavy aluminum to achieve calm ladles and long sequences. Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption was designed by Sicarbtech to make that shift practical. By delivering silicon addition and carbon-enabled deoxidation in one engineered material, the additive stabilizes oxygen quickly while minimizing alumina spikes, which means fewer nozzle alarms and less emergency wire feeding. In the high-scrap, high-energy-cost reality of 2025, this single decision—moving from Al-heavy routes to a low-Al silicon carbide pathway—often pays back in both cost-per-ton and casting stability.

Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption product overview and 2025 market relevance

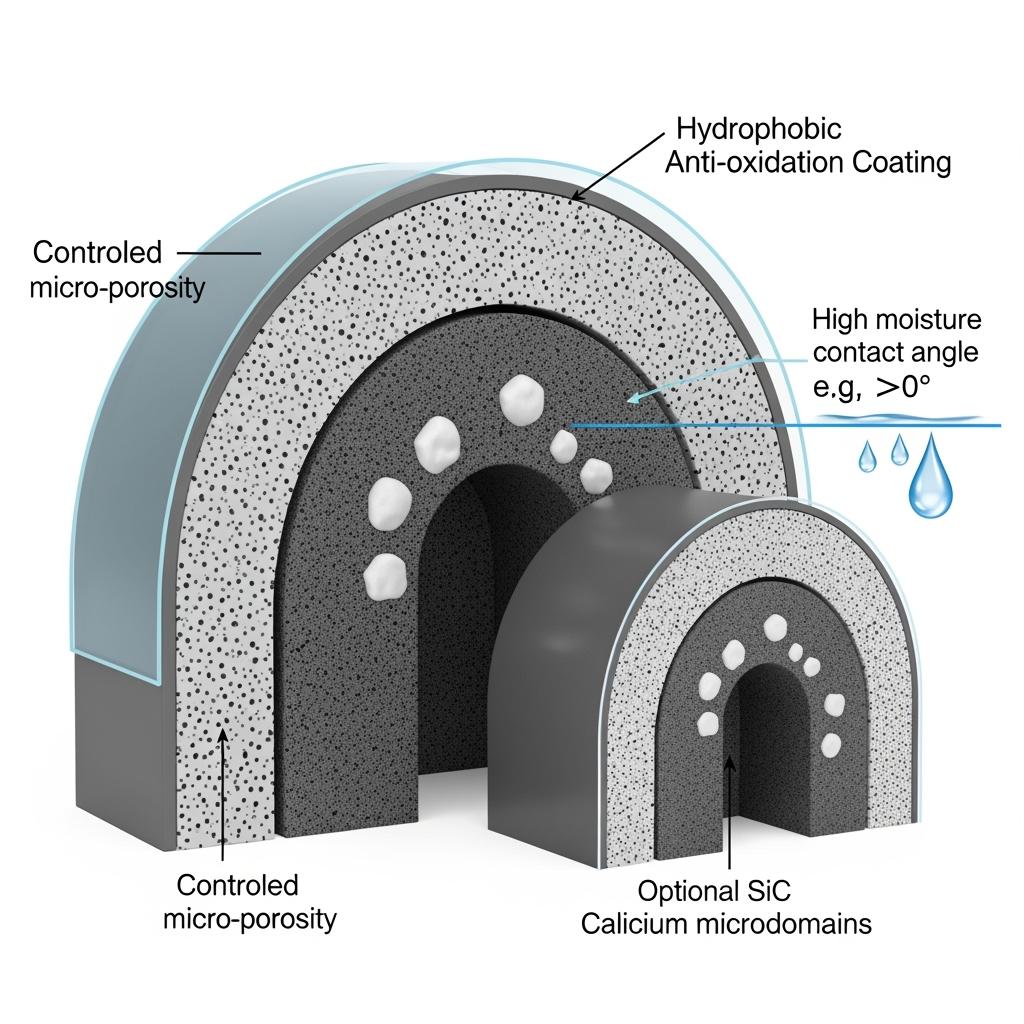

The Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption combines carbothermal reduction SiC with precise classification, hydrophobic coatings, and optional inclusion-modifying microdomains. The result is a high-activity silicon source with built-in carbon synergy that lowers oxygen without flooding the melt with aluminum. For Pakistan’s EAF and converter lines, this matters for three reasons. First, rising scrap ratios introduce variable oxygen loads; the additive’s kinetics allow fast, predictable control. Second, PEQS-aligned dust expectations are pushing enclosed dosing; Sicarbtech’s coated, flow-stable particles support clean automated feeding. Third, currency volatility makes aluminum wire a moving target; replacing a portion with the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption reduces exposure without sacrificing cleanliness. As Dr. Nadia Rehman, a continuous casting specialist in Karachi, often says, “When you aim for cleanliness, don’t create alumina to get there” (Acero Process Insights Pakistan, 2024). This additive helps you avoid that trade-off.

Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption technical specifications and advanced features

Sicarbtech tunes the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption to the realities of Pakistani grade mixes and tapping windows. Typical silicon carbide content sits between eighty-nine and ninety-seven percent. Free carbon is set between one and eight percent to reinforce the dual deoxidation pathway and support exothermic stability, while free silicon stays within 0.5 to 1.5 percent to suppress secondary oxidation during refining. Harmful impurities are tightly controlled, with sulfur and phosphorus each at or below 0.02 percent to protect clean steel objectives. Particle size is aligned to the addition point: 0–3 mm for fast dissolution in the teeming stream or early ladle, and 3–10 mm to stretch dissolution where residence time is generous. A hydrophobic, anti-oxidation coating defends activity through the monsoon season and resists powdering in enclosed feeders, ensuring metering accuracy and minimal dust at addition points. Optional micro-additions of calcium or barium can be incorporated to promote transformation of hard alumina into more deformable calcium aluminates, easing tundish flow and protecting nozzle openness in long sequences.

Clean steel outcomes with Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption

| Deoxidation and casting KPIs | Aditivo de silicio de carburo de silicio de reemplazo de bajo aluminio para aceros con bajo contenido de Al y consumo reducido de alambre de aluminio | Al-heavy deoxidation route (FeSi + high Al wire) | Separate carburizer + FeSi route |

|---|---|---|---|

| Silicon absorption vs baseline | +3-8 puntos porcentuales | Variable; late-wire corrections | +2–5 percentage points |

| Total oxygen after refining (ppm) | -5 to -15 | Lowered but alumina spikes common | -4 to -10 |

| Nozzle clogging incidents per 100 heats | -20–40% | Mayor; riesgo de deposición de Al2O3 | -15–30% |

| Heat time impact | -0,5-2% | Referencia | -0.5–1.5% |

| Dust at addition points | Low; coated and enclosed | Wire dust, open handling | Moderate; open charge dust |

Material and logistics attributes of Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption

| Atributo | Aditivo de silicio de carburo de silicio de reemplazo de bajo aluminio para aceros con bajo contenido de Al y consumo reducido de alambre de aluminio | Importancia operativa en Pakistán |

|---|---|---|

| Contenido de SiC | 89-97% | High-activity silicon with carbon synergy |

| Carbono libre | 1–8% | Dual deoxidation and thermal support |

| Silicio libre | 0,5-1,5% | Limits reoxidation during refining |

| S, P (cada uno) | ≤0.02% | Clean steel and export compliance |

| Tamaño de las partículas | 0-3 mm; 3-10 mm | Stream and ladle flexibility |

| Coating | Hydrophobic, anti-oxidation, anti-powdering | Monsoon-ready, low dust |

| Estabilidad de almacenamiento | ≥6 meses | Karachi-to-upcountry logistics |

| Inclusion modifiers | Optional Ca/Ba | Nozzle openness and sequence length |

Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption performance comparison with alternatives

| Cost, energy, and recipe complexity | Aditivo de silicio de carburo de silicio de reemplazo de bajo aluminio para aceros con bajo contenido de Al y consumo reducido de alambre de aluminio | FeSi + high aluminum wire | Separate carburizer + silicon source |

|---|---|---|---|

| Coste de aleación por tonelada de acero | -1–5% vs Al-heavy | Baseline; FX-sensitive | +0–2% volatility |

| Tapping temperature drop | -2 to -6°C | 0 to -2°C | -1 to -3°C |

| Recipe steps and timing | Simplified; fewer late corrections | Complex; wire timing critical | Multiple feeders and checks |

| Sequence stability | Higher; fewer nozzle events | Lower; alumina deposition | Moderado |

| EHS and housekeeping | Low dust via enclosed feeders | Wire dust; manual handling | Higher open-charge dust |

Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption advantages and proven benefits with expert quote

What sets the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption apart is its ability to lower oxygen decisively without sowing alumina problems that haunt casting later. By front-loading silicon and carbon in a controlled dissolution profile, operators hit silicon targets without resorting to aggressive late-wire fixes. Moreover, the coating and grading strategy keeps dust low and dosing steady, which EHS teams welcome. Prof. Li Wei of the CAS Weifang Innovation Park puts it plainly: “The cheapest ton is the one you don’t rework. Low-Al SiC routes remove oxygen without building the alumina you will later fight” (CAS Materials Review, 2023).

Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption real-world applications and measurable success stories

At a Karachi-area EAF billet producer, introducing the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption during the teeming stream raised silicon absorption by five percentage points and allowed a twelve percent reduction in aluminum wire with no compromise in cleanliness. Over eight weeks, total oxygen fell by seven to nine ppm, and nozzle clogging incidents decreased by thirty percent per hundred heats. Operators reported calmer tundish behavior and fewer mid-sequence interventions. In a Punjab converter shop, early ladle additions of the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption shortened average heat time by about one percent and trimmed tapping temperature losses by roughly three degrees Celsius. SEM analyses showed a shift from dense Al2O3 clusters to mixed calcium aluminates when the Ca-bearing variant was used, matching an observed extension in sequence length.

Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption selection and maintenance considerations

Selecting the right Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption variant begins with grade targets and dosing windows. Long products with moderate silicon requirements and sensitivity to nozzle openness typically benefit from 0–3 mm fractions at the teeming stream, where fast kinetics matter most. Early ladle dosing can use 3–10 mm to sustain release when residence time allows. In low-aluminum strategies, keep free silicon toward the lower bound to minimize secondary oxidation during refining, and specify calcium microdomains if alumina is a chronic issue. Storage and handling must respect Pakistan’s humidity; enclosed silos, dry transfer points, and periodic moisture/flowability checks keep the hydrophobic coating’s advantages intact. Where feeders tie to oxygen activity signals, Sicarbtech’s dosing curves can be mapped directly to the verified PSD and reactivity index of the batch to reduce setpoint hunting.

Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption industry success factors and customer testimonials

The most successful deployments treat the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption as the backbone of a low-Al pathway. Plants align slag basicity and viscosity to promote inclusion floatation, connect feeders to oxygen activity and temperature signals, and coordinate aluminum as a trim tool rather than a primary deoxidant. A QA manager at a North Region billet caster summarized the difference: “We didn’t just feed less wire—we stopped chasing wire. The silicon trajectory flattened, and the caster team finally had quiet shifts.”

Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption future innovations and market trends

As Pakistan’s mills lean harder into low-aluminum pathways through 2025, Sicarbtech is advancing the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption along two fronts. First, coatings are being refined to tune dissolution under variable slag carry-over, giving operators a faster front-end response without overshoot. Second, recipe analytics are linking grade families to microdomain strategies—calcium, barium, and rare-earth traces—so inclusion morphology is not left to chance. On the supply side, localized powder synthesis, classification, and granulation lines—implemented via technology transfer—will cut lead times and let Pakistani mills iterate particle size distributions quickly in response to plant data.

Preguntas frecuentes y respuestas de expertos

How much aluminum wire can the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption typically replace?

In Pakistani trials, mills commonly trim aluminum wire by 8–15 percent while maintaining or improving cleanliness, with exact savings depending on grade, slag practice, and dosing control.

Will the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption change slag volume or chemistry?

When tailored to your flux regime, changes are minimal. Coating and microdomain design are calibrated so that inclusion transformation is favored without destabilizing slag basicity or viscosity.

Which particle size of the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption is best for teeming stream vs ladle?

Use 0–3 mm for fast dissolution in the stream or early ladle. Where residence time is available, 3–10 mm sustains release. Sicarbtech will align PSD to your tapping temperature and flow.

Can the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption support pneumatic injection?

Yes, a companion <200 mesh formulation is available for injection lines, often paired with our matching lances and enclosed silos to preserve low dust and precise metering.

How does Sicarbtech assure batch consistency for the Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption?

Every lot is validated under Sicarbtech’s in-situ monitoring and traceability system for SiC content, free carbon/silicon, PSD, moisture, coating performance, and flowability, with IDs linked to shipment records and ready for Level 2 integration.

Why Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption works for your operations

Because it removes oxygen without creating alumina headaches. Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption gives you silicon where and when you need it, backed by carbon synergy and controlled dissolution. In Pakistan’s mills—where energy pressure, scrap variability, and export quality thresholds converge—this is the most direct route to predictable absorption, calmer casting, and lower total alloy cost with less wire on the reel.

Conecte con especialistas para soluciones a medida

Sicarbtech backs Low-Aluminum Replacement Silicon Carbide Silicon Additive for Low-Al Steels and Reduced Aluminum Wire Consumption with more than ten years of silicon carbide manufacturing expertise and Chinese Academy of Sciences–supported innovation. We develop custom products across R-SiC, SSiC, RBSiC, and SiSiC; deliver technology transfer and factory establishment services for powder synthesis, classification, granulation, and coating; and integrate enclosed storage and online feeding for true closed-loop dosing. With turnkey solutions proven at over nineteen enterprises, our team will structure a no-cost pilot with clear KPIs—lower alloy cost per ton, tighter silicon absorption, reduced total oxygen, and longer sequence stability—so you can scale with confidence now, not later.

Si desea una consulta gratuita y una propuesta rápida basada en datos, póngase en contacto con nosotros:

Email: [email protected]

Teléfono/WhatsApp: +86 133 6536 0038

Metadatos del artículo

Última actualización: 2025-09-15

Próxima revisión programada: 2025-12-15

Autor: Equipo de ingeniería de aplicaciones de Sicarbtech

Enfoque regional: Pakistán (EAF y rutas de convertidores; palanquillas, barras, alambrón, planos)

Timeliness note: Content aligned to 2025 low-aluminum deoxidation strategies, PEQS-aligned dust control, and closed-loop alloy dosing practices

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.