Estructuras apiladas de barra colectora de CC y bastidor de plomo de baja inductancia para la supresión de sobreimpulso y el control de EMI de los módulos SiC

Compartir

In Pakistan’s industrial energy transition, every millisecond matters. Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control have become the unseen architecture behind reliable 50–250 kW string inverters and energy systems that must run through heat, dust, and weak‑grid disturbances. On textile rooftops from Faisalabad to Lahore, in cement corridors across Punjab and KPK, and at siderúrgico facilities stretching from Port Qasim to Site Area, Sicarbtech’s stacked busbar and leadframe engineering stabilizes the fastest switching events so your silicon carbide modules can operate at 40–100 kHz without punishing overshoot or unpredictable emissions. What appears to be a copper sandwich is, in practice, a precision electromagnetic instrument tuned to the realities of 1000/1500 V DC platforms and harsh outdoor enclosures.

Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control product overview and 2025 market relevance

As Pakistan’s commercial and industrial PV scales, system designers face a paradox. Silicon carbide promises higher efficiency and smaller enclosures, yet fast edges produce parasitics that can undermine both EMC and device reliability. Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control resolve this by collapsing loop inductance to single‑digit nanohenry levels, which in turn lowers dv/dt‑induced overshoot, reduces ringing energy, and lets high‑frequency magnetics do their job without oversized filters. In 2025, with tenders leaning toward 1500 V DC platforms and NEPRA‑aligned grid behavior, these structures are no longer a nice‑to‑have; they are the core mechanism that makes high‑density, outdoor‑rated enclosures viable.

Sicarbtech approaches busbars and leadframes as part of an electromechanical stack, co‑designed with module packaging, gate driver paths, and enclosure ground strategy. The result is predictable EMC closure to IEC 61000‑6‑4, stable low‑voltage ride‑through even on feeders with limited short‑circuit capacity, and better thermal margins at 50°C inlet air—conditions that are increasingly common in Pakistan’s industrial parks. By integrating this know‑how with local capability building, Sicarbtech helps Pakistani OEMs shorten lead times, reduce cost per watt, and pass compliance in fewer iterations.

Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control technical specifications and advanced features

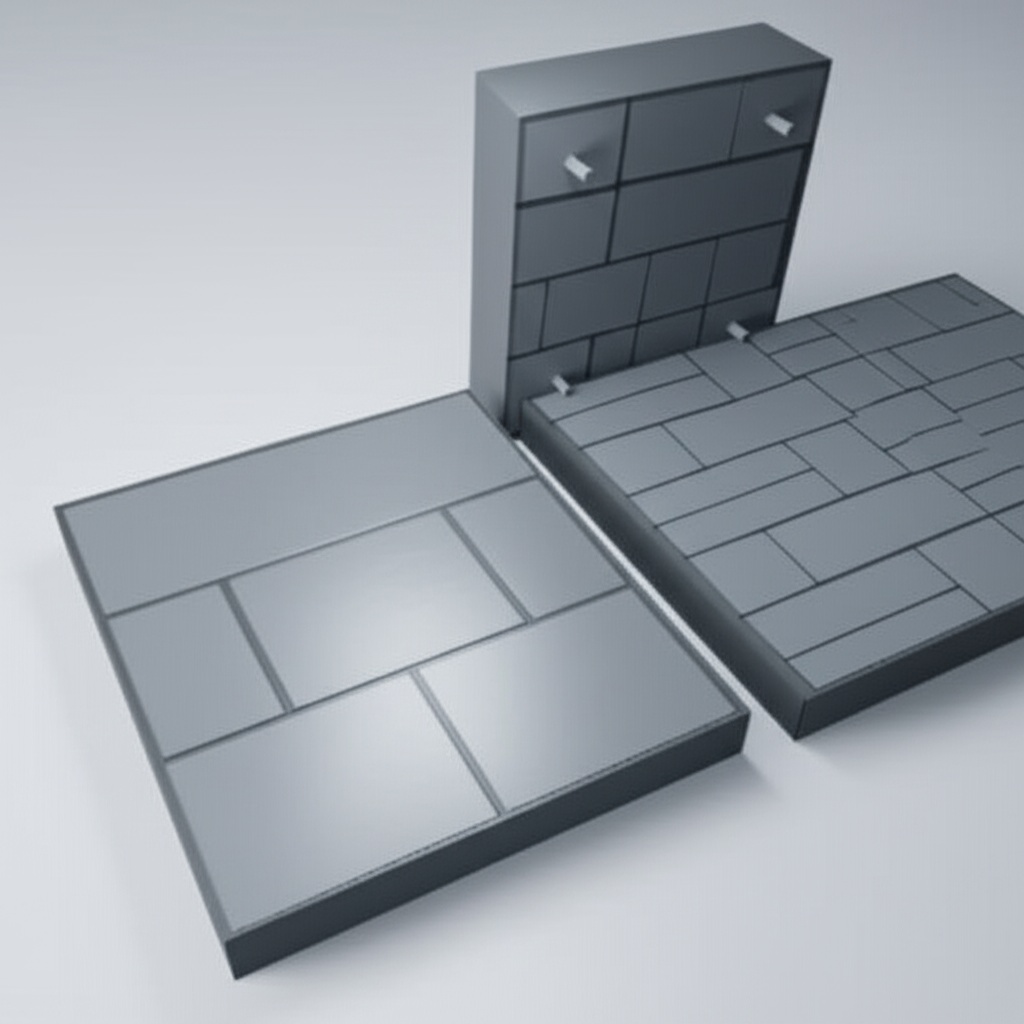

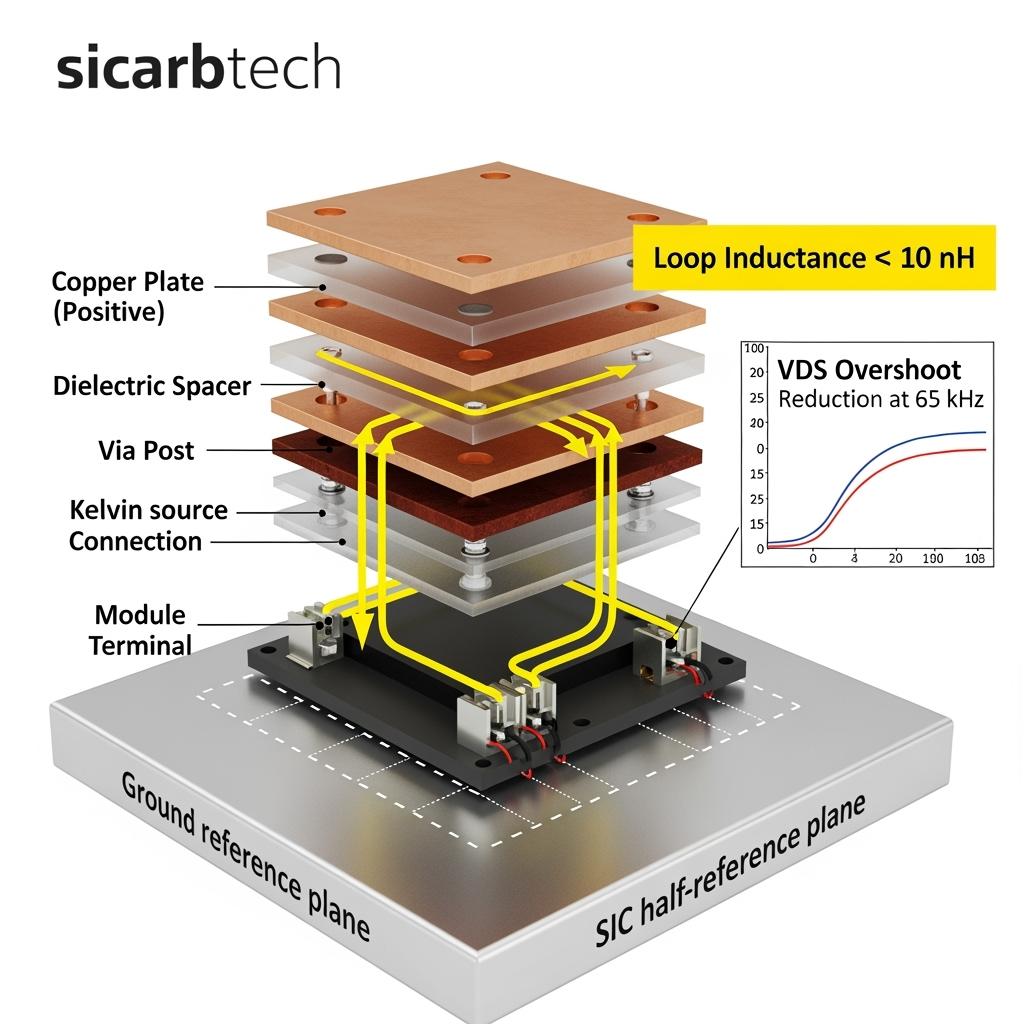

At the heart of Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control is a tightly coupled positive‑negative conductor pair separated by controlled‑thickness dielectrics. By superimposing opposing current paths in laminated or stacked planes, the magnetic fields cancel, dragging loop inductance down to levels—often below 10 nH—that materially change switching behavior. Sicarbtech couples these planes directly to module DC terminals with short, wide connections, while reserving separate Kelvin source paths for the gate driver to prevent power current dynamics from contaminating gate signals.

Dielectric materials are chosen for both partial discharge performance and thermal stability, with creepage and clearance tailored to 1000/1500 V platforms and outdoor IP65 enclosures. In high‑humidity or salt‑mist areas such as coastal Karachi, conformal coatings and corrosion‑resistant platings maintain surface integrity and keep leakage currents predictable. The leadframe extensions inside the module are equally critical; they shape the internal loop geometry so that the external stacked busbar can complete the low‑inductance circuit rather than fighting parasitics embedded in the package. Together, the Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control become an integrated system element rather than a bolt‑on fix.

Pakistan‑relevant electrical‑mechanical comparison for Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control

| Engineering dimension in C&I PV/UPS | Estructuras apiladas de barra colectora de CC y bastidor de plomo de baja inductancia para la supresión de sobreimpulso y el control de EMI de los módulos SiC | Conventional cable or plate bus |

|---|---|---|

| Loop inductance (module DC loop) | 5–10 nH typical with stacked planes | 20–60 nH with spaced bars/cables |

| VDS overshoot at 65 kHz | 20–40% reduction vs. conventional | High overshoot, dv/dt stress |

| EMI filter size to pass IEC 61000‑6‑4 | Reduced by 15–30% in mass | Se requieren filtros más grandes |

| Thermal and current density | High due to wide planes, low loss | Lower due to hotspots and constrictions |

| Assembly repeatability | High; fixture‑guided stack alignment | Variable; torque‑dependent outcomes |

Key advantages and proven benefits of Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control with expert quote

The immediate benefit of Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control is calmer switching. With less stored energy in the loop, voltage overshoot and ringing diminish, device stress falls, and the gate driver can run edge rates that preserve efficiency without tripping EMC limits. Moreover, smaller filters and magnetics reduce copper and core mass, shaving cabinet weight—critical for rooftop installations on lightweight purlins in textile facilities. Reliability also improves, because overshoot events are a hidden accelerant for module aging and random trips that disrupt production.

“Stacked busbars are the fastest path to real SiC density,” says Prof. Sadia Rehman, an IEEE senior member who advises PEC on inverter qualification (source: PEC Inverter Engineering Notes, 2025). “When the loop is below ten nanohenries, your control code stops firefighting, and certification becomes a scheduling exercise—not a science experiment.”

Construction and reliability comparison for Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control

| Atributo | Estructuras apiladas de barra colectora de CC y bastidor de plomo de baja inductancia para la supresión de sobreimpulso y el control de EMI de los módulos SiC | Traditional bus/cable harness |

|---|---|---|

| Plane coupling and dielectric | Laminated or stacked planes with controlled dielectric | Separated plates/cables with air gaps |

| Kelvin source accommodation | Dedicated return path integrated | Often absent; shared return path |

| Corrosion and dust countermeasures | Coatings, sealed interfaces, plated copper | Exposed surfaces; variable sealing |

| Power cycling impact on joints | Lower stress with short, wide interconnects | Higher stress at lugs/bolts |

| Repeatable inductance across units | Tight process control and jigs | Assembly‑dependent variability |

Real‑world applications and measurable success stories using Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control

On a 10 MW portfolio of textile rooftops around Faisalabad, a local OEM redesigned the DC link using Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control. The shift dropped measured loop inductance from roughly 32 nH to under 9 nH. At 62 kHz, oscilloscope captures showed VDS overshoot reduced by about 35 percent, and the inverters passed IEC 61000‑6‑4 emissions with a 20 percent lighter filter. Cabinet weight fell by 25 kilograms per unit, leading to faster installation and fewer structural reinforcements.

A ground‑mounted project in southern Punjab operating at 1500 V saw a different gain. When the Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control were introduced, fault logs showed a sharp decline in nuisance trips during feeder flicker. Drive waveforms became stable enough that the LVRT and reactive power functions could be tightened, improving grid support during evening ramps. Maintenance crews, accustomed to dust‑laden enclosures, appreciated the sealed stack interfaces and reduced hot spots around bolted lugs.

Topology outcomes enabled by Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control

| Use case | With Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control | Without low‑inductance stack |

|---|---|---|

| 1500 V string, 100–150 kW | 60–70 kHz stable switching; smaller LCL | 12–20 kHz limits; heavy filtering |

| Weak‑grid LVRT in industrial estates | Fewer trips; tighter VAR control | Frequent desat or anti‑islanding trips |

| Thermal management at 50°C inlet | Cooler interconnects; fewer fans | Hot spots near lugs; higher airflow needed |

Selection and maintenance considerations for Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control

Selecting the right Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control begins with the module footprint and the DC link geometry. On 1500 V designs with long strings, the dielectric thickness and creepage strategy must match pollution degree and altitude considerations common in Pakistan’s plains and hill regions. Sicarbtech typically starts with a laminated stack whose plane widths match module pad spacing, then iterates via placement to minimize current crowding at joints. Kelvin source routing is non‑negotiable—it must bypass high current loops and land as a controlled impedance path to the gate driver.

From a maintenance standpoint, the stacks should be inspected for torque stability and coating integrity during seasonal service, especially in cement and coastal steel environments where alkaline dust or salt‑mist can creep. However, because Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control eliminate many cable terminations, there are fewer points of failure. Thermal imaging during commissioning and peak summer loads helps verify even current distribution and validates that the design meets the promised low‑loss profile.

Industry success factors and customer testimonials for Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control

Success in Pakistan’s 2025 inverter market is measured by first‑pass EMC, dependable LVRT, and minimal derating at 50°C inlet air. Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control touch each lever. A Lahore EPC technical manager summed up their experience after moving to Sicarbtech’s stacks: “We cut EMC iterations from three to one and shaved almost a week off our average commissioning. The waveform just calmed down.” That calm translates into resilient projects that safeguard PKR‑denominated returns and service schedules.

Future innovations and market trends around Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control

Looking forward, Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control will integrate smarter sensing—embedding Rogowski or shunt‑based current feedback and temperature mapping within the plane to feed predictive controls. Materials will also evolve, with higher thermal conductivity dielectrics and improved coatings for long‑term stability in dusty, hot climates. As Pakistan prioritizes local content, Sicarbtech’s technology transfer packages will help partners laminate and machine stacks domestically, tune creepage profiles to local EHS norms, and validate performance with production‑grade pulse and EMI testing.

Common questions and expert answers on Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control

How do Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control reduce VDS overshoot at high frequency?

By tightly coupling positive and negative planes, the magnetic fields cancel and loop inductance plunges. Less stored energy means less ringing and overshoot when the SiC module switches at 40–100 kHz, even under 1500 V conditions.

Are Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control compatible with my existing module layout?

Often yes. Sicarbtech co‑designs stack geometry to your module pads and enclosure constraints, adding Kelvin source routing and adjusting dielectric thickness to meet creepage and clearance rules for outdoor IP65 cabinets.

What EMC benefits come from Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control?

Cleaner edges reduce high‑frequency content at the source, which allows smaller EMI filters to pass IEC 61000‑6‑4. Many teams see one‑pass compliance and a 15–30 percent reduction in filter mass.

How do Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control perform in dust and salt‑mist?

Protective platings, sealed interfaces, and conformal coatings keep leakage predictable. Periodic inspections maintain coating integrity, and the reduced number of bolted joints lowers corrosion‑driven resistance growth.

Do Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control add cost?

There is an upfront premium versus basic copper, but it is offset by smaller filters, reduced magnetics, lighter enclosures, and faster commissioning. Over the project life, the net effect is a lower PKR cost per watt.

Why Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control work for your operations

Pakistan’s grid volatility and environmental stress punish designs that leave parasitics unmanaged. Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control convert SiC’s theoretical efficiency into dependable field performance. By shrinking the electromagnetic footprint of the DC loop, they tame overshoot, simplify EMC, and let your inverter sustain rated output in 50°C air with fewer fans and smaller filters. The outcome is a lighter, quieter, and more reliable system that installers and operators can trust.

Conecte con especialistas para soluciones a medida

Sicarbtech leads the region in Low‑Inductance Stacked DC Busbar and Leadframe Structures for SiC Module Overshoot Suppression and EMI Control, leveraging over 10 years of silicon carbide manufacturing expertise and the innovation backing of the Chinese Academy of Sciences in Weifang. For Pakistani OEMs and EPCs, we co‑design stacks to your module footprints, validate loop inductance with time‑domain and frequency‑domain measurements, and align creepage/clearance to your enclosure and pollution degree. Beyond design, Sicarbtech offers technology transfer and factory establishment services so you can laminate and machine busbar stacks locally, establish reliability testing, and scale with confidence.

Our turnkey scope spans R‑SiC, SSiC, RBSiC, and SiSiC materials through finished power modules, magnetics, and test equipment, proven with more than 19 enterprise collaborations. Engage our engineers for a free consultation to accelerate certification, cut cabinet weight, and stabilize high‑frequency operation in 1000/1500 V platforms. Email [email protected] or call/WhatsApp +86 133 6536 0038. With 2025 tenders tightening and grid requirements evolving, early engagement protects your schedule and PKR‑based business case.

Metadatos del artículo

Última actualización: 2025-09-16

Próxima revisión programada: 2025-12-01

Timeliness indicators: Reflects Pakistan’s shift to 1500 V DC, NEPRA/IEC alignment, and 2024–2025 field data on loop inductance, EMC closure, and overshoot suppression in SiC inverters.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.