Sistema de monitoreo y trazabilidad de la calidad del carburo de silicio in situ para la consistencia del lote y la estabilidad del proceso

Compartir

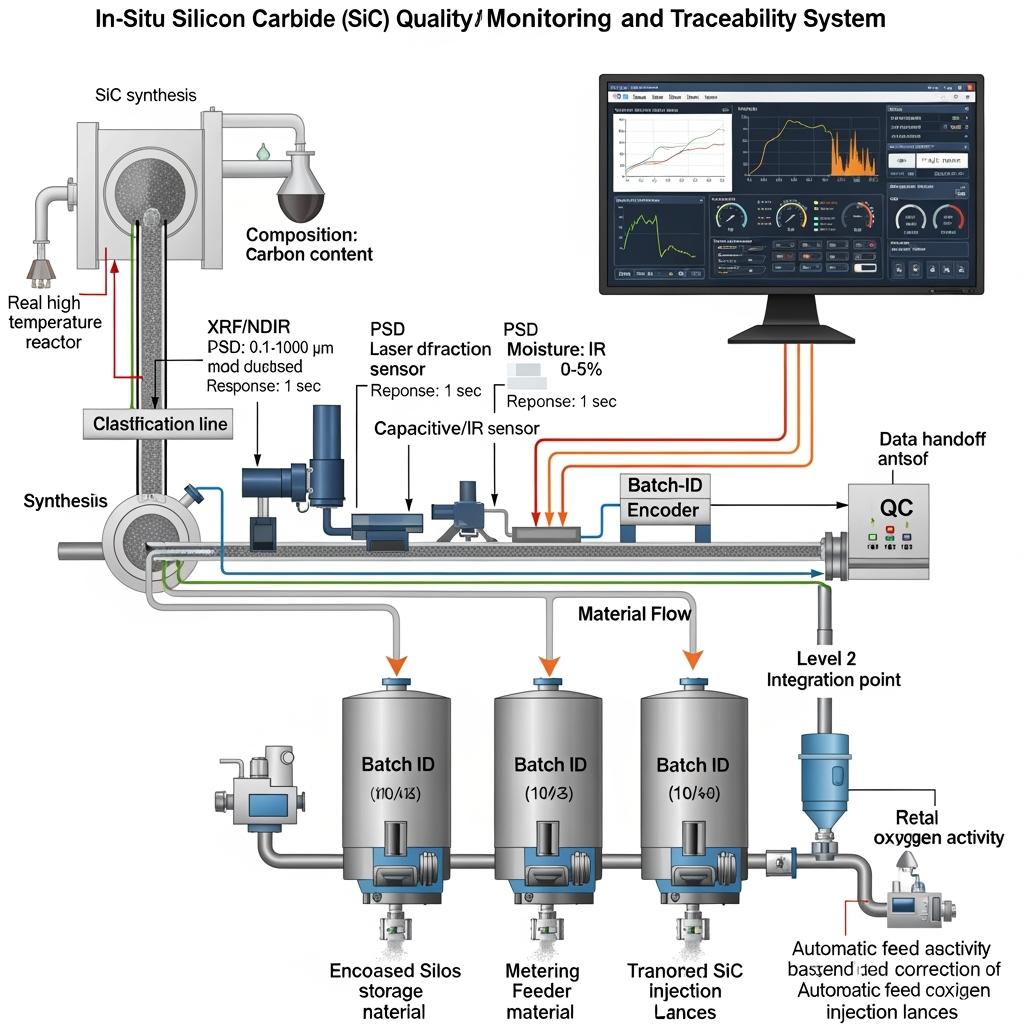

In Pakistan’s increasingly automated melt shops, the alloy room is no longer a black box. In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability transforms SiC from a commodity to a controlled process input. Sicarbtech developed this system so that every kilo of silicon carbide—whether fine powder for pneumatic injection or granules for the teeming stream—carries a verified identity: real-time composition, particle size distribution, moisture, flowability, and reactivity index, all mapped to batch IDs that follow the material from synthesis to the ladle. By linking the quality backbone to feeders, lances, and Level 2 systems, mills in Karachi, Lahore, and beyond stabilize silicon absorption, curb inclusion variability, and reduce the “operator art” hidden in late wire corrections. The outcome is simple but powerful: fewer surprises at casting, shorter heat times, and lower total cost of alloying.

In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability product overview and 2025 market relevance

The business case for the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability is built on Pakistan’s 2025 realities: rising scrap ratios, tight energy budgets, and stricter cleanliness targets for export-grade billets, bars, and flats. Conventional batch certificates tell you what was sampled yesterday; this system tells you what you are dosing now. Inline analyzers monitor SiC content, free carbon, and free silicon while laser diffraction tracks PSD in real time, and low-latency moisture sensors guard against monsoon-driven caking. Each dataset is sealed to a traceable batch code, which downstream feeders read automatically to adjust dosing curves. As Engr. R. Khan, a Lahore-based metallurgist, puts it, “When the material’s digital twin rides with the batch, your feeder setpoints become metallurgy, not guesswork” (Metallurgy Pakistan Review, 2024). With Sicarbtech’s CAS-backed models, the system also predicts reactivity under different tapping temperatures, allowing the shop to keep silicon pickup on target even as operations fluctuate.

In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability technical specifications and advanced features

Sicarbtech’s In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability anchors control on four measurement pillars. Composition modules quantify SiC content to within tight tolerances and track free carbon from one to eight percent while keeping free silicon between 0.5 and three percent depending on the grade—numbers that align with low-inclusion deoxidation strategies in EAF and BOF routes. Particle size analysis runs continuously, locking in <200 mesh profiles for injection or 0–3 mm/3–10 mm bands post-granulation. Moisture is measured at transfer points so hydrophobic treatments can be verified before material enters sealed silos. Finally, a reactivity index, calibrated with lab and on-site curves, forecasts the dissolution behavior against bath temperature and oxygen activity. The traceability layer glues it together, assigning cryptographic batch IDs and writing QC tags that feeders and Level 2 read, enabling automatic correction of dosing rates in response to the verified material state.

Shop-floor stability improvements with In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability

| KPI and control dimension | Sistema de monitoreo y trazabilidad de la calidad del carburo de silicio in situ para la consistencia del lote y la estabilidad del proceso | Conventional COA-based acceptance | Periodic offline checks |

|---|---|---|---|

| Real-time composition and PSD visibility | Continuous; inline, batch-linked | None; prior-lot paperwork | Intermittent; lagging |

| Moisture/flowability assurance | Inline sensors at transfer | Visual/manual tests | Occasional lab tests |

| Automatic feeder/lance correction | Yes; QC tags drive setpoints | No; manual tuning | Limited; delayed |

| Silicon absorption variability (σ) | Low; closed-loop dosing | Moderate–high | Moderado |

| Inclusion behavior predictability | High; stable inputs | Variable | Variable |

Measurement and integration attributes of In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability

| Atributo | Sistema de monitoreo y trazabilidad de la calidad del carburo de silicio in situ para la consistencia del lote y la estabilidad del proceso | Importancia operativa en Pakistán |

|---|---|---|

| SiC content tracking | Live, tolerance-banded | Aligns dosing to actual assay |

| Free carbon and free silicon | 1–8% C; 0.5–3% Si range | Tunes dual deoxidation vs reoxidation risk |

| PSD coverage | <200 mesh to 10 mm | Matches injection, stream, ladle |

| Moisture sensing | Inline; humidity compensation | Monsoon resilience; anti-caking validation |

| Reactivity index | Lab-on-site calibrated | Dissolution predictability across taps |

| Batch traceability | Cryptographic IDs | Auditability; supplier accountability |

| Level 2 interface | OPC/REST connectors | Fast deployment into existing MES |

| Alarm logic | Out-of-band QC alerts | Prevents off-spec dosing events |

In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability performance comparison with alternatives

| Cost, risk, and casting outcomes | Sistema de monitoreo y trazabilidad de la calidad del carburo de silicio in situ para la consistencia del lote y la estabilidad del proceso | No in-situ QC; supplier COA only | Manual sampling and operator tuning |

|---|---|---|---|

| Alloy cost per ton of siderúrgico | -1–4% via right-first-time dosing | Baseline; overfeeds common | Baseline; variability losses |

| Heat time impact | -0.5–1.5% from fewer corrections | Referencia | Variable; operator dependent |

| Incidentes de obstrucción de boquillas | -20–35% with stable inclusions | Higher; alumina spikes | Moderate; inconsistent |

| Rework/downgrades | Reduced via stable oxygen | Higher risk | Moderado |

| Medio ambiente, salud y seguridad | Lower dust via fewer recharges | Variable | Variable |

In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability advantages and proven benefits with expert quote

The distinguishing benefit of the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability is that it collapses uncertainty at the source. When feeders receive live QC tags, dosing becomes proactive. Silicon targets are met without late wire, inclusions trend smaller and more floatable, and the tundish team stops firefighting. Moreover, batch traceability enforces supplier discipline and accelerates root-cause analysis when anomalies arise. Prof. Li Wei of the CAS Weifang Innovation Park notes, “Stability is a data problem as much as a chemistry problem. Put sensors at the material gates and you tame both” (CAS Materials Review, 2023). In Pakistani mills, this approach pays back in quieter radios and cleaner cast surfaces.

In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability real-world applications and measurable success stories

At an EAF billet producer near Karachi, deploying the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability cut silicon absorption variability by forty percent within six weeks. With PSD and moisture stabilized in-line and QC tags linked to feeders, aluminum wire usage dropped by twelve percent, total oxygen fell by about eight ppm, and the average heat time reduced by approximately one percent. In Punjab, a converter shop integrated the system with a pneumatic injection line. By letting oxygen activity signals and QC tags jointly govern powder feed, nozzle clogging incidents per hundred heats declined by thirty-three percent and tapping temperature drop narrowed by three degrees Celsius. The plant’s QA logs showed faster investigations when off-nominal heats occurred because the batch ID stitched composition, PSD, and moisture data to specific strands and times.

In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability selection and maintenance considerations

Choosing the right configuration of the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability begins with your dosing routes. Plants relying on pneumatic injection benefit most from high-frequency PSD and moisture control at the silo inlet and near the lance feed, while stream and ladle dosing lines see outsized gains from reactivity indexing that maps dissolution to tapping temperature windows. Integration planning matters: connecting QC tags to Level 2 via standard OPC or REST interfaces simplifies commissioning, and assigning alarm thresholds tied to grade families prevents nuisance trips. Sustaining performance depends on calibration discipline—monthly PSD verifications against reference standards, scheduled moisture sensor drift checks, and periodic correlation between lab assays and inline composition modules. Finally, pairing the system with Sicarbtech’s granulation and coating lines closes the quality loop from synthesis to metering, ensuring batch consistency survives Pakistan’s transport and climate realities.

In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability industry success factors and customer testimonials

Plants that thrive with the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability treat QC data as an operational asset, not a certificate archive. A North Region billet caster’s QA manager described the shift: “Once feeders read the QC tag, arguments ended. We stopped discussing what was in the bag and focused on what the strand needed.” That cultural change—from hindsight to live control—has proven as valuable as the metallurgy itself, aligning procurement, QC, and production around a common dataset.

In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability future innovations and market trends

Through 2025 and beyond, Pakistani mills will knit quality and automation even closer. Sicarbtech is advancing the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability with AI models that correlate reactivity index with furnace profiles and historic oxygen curves, enabling predictive dosing setpoints before the heat begins. Edge computing will push analytics to the silo and feeder, reducing latency and preserving control even during network hiccups. On the supply side, expanded technology transfer will allow local SiC producers to embed the same QC backbone, so mills receive QC-tagged material that synchs instantly with their Level 2—bringing batch consistency from factory gate to ladle mouth.

Preguntas frecuentes y respuestas de expertos

How does the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability connect to our existing feeders and Level 2?

The system publishes QC tags via standard OPC or REST interfaces. Feeders subscribe to these tags and automatically adjust dosing curves based on verified composition, PSD, moisture, and reactivity index, while Level 2 logs everything to the heat record.

Will the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability slow down material flow?

No. Sensors are inline and low-latency, and data handoff occurs in parallel to conveying. In practice, dosing becomes faster to stabilize because feeders start from accurate inputs rather than conservative overfeeds.

Can the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability work with multiple SiC forms?

Yes. The system supports fine powder for pneumatic injection, 0–3 mm for the teeming stream, and 3–10 mm for ladle additions, with PSD sensing and reactivity indexing tailored to each stream.

What level of batch traceability does the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability provide?

Each batch ID binds composition, PSD, moisture, flowability, and time stamps. The ID follows the material into silos and feeders, and the heat record maps specific batches to strands and time intervals for rapid root-cause analysis.

How is calibration maintained in the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability?

Sicarbtech provides calibration schedules and reference standards. Routine checks align inline readings with lab assays, while software flags drift and schedules guided recalibration to keep measurements in tolerance.

Why In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability works for your operations

Because variation is the enemy of both cleanliness and cost. In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability gives your feeders the truth about the material in real time, then turns that truth into stable dosing and inclusion behavior. In Pakistan’s mills—where energy pressure and export quality coexist—live QC and traceability convert alloying from a reactive task into a predictable, low-risk routine that protects yield and schedule.

Conecte con especialistas para soluciones a medida

Sicarbtech brings more than ten years of silicon carbide manufacturing expertise, strengthened by Chinese Academy of Sciences innovation, to deploy the In-Situ Silicon Carbide Quality Monitoring and Traceability System for Batch Consistency and Process Stability. Our team designs custom R-SiC, SSiC, RBSiC, and SiSiC materials; integrates powder synthesis, classification, granulation, coating, enclosed storage, and online feeding; and delivers technology transfer and factory establishment services for localized capability in Pakistan. With turnkey solutions proven across nineteen-plus enterprises, we will structure a no-cost pilot with clear KPIs—reduced alloy cost per ton, tighter silicon absorption bands, lower total oxygen, and longer casting sequence stability—so you can scale with confidence.

Si desea una consulta gratuita y una propuesta rápida basada en datos, póngase en contacto con nosotros:

Email: [email protected]

Teléfono/WhatsApp: +86 133 6536 0038

Metadatos del artículo

Última actualización: 2025-09-15

Próxima revisión programada: 2025-12-15

Autor: Equipo de ingeniería de aplicaciones de Sicarbtech

Region focus: Pakistan (EAF and converter routes; billets, bars, flats)

Timeliness note: Content aligned to 2025 automation trends, PEQS-aligned dust controls, and closed-loop dosing and traceability practices

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.