Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar for DC Bus and Inverter Upgrades in Steel Continuous Casting and Rolling

Compartir

Executive Summary: 2025 Outlook for High-Reliability SiC Drive Upgrades in Pakistan’s Steel, Cement, and Process Industries

Pakistan’s steelmakers and high-energy industries are under simultaneous pressure to raise throughput, stabilize product quality, and cut energy intensity. Continuous casters and hot/cold rolling lines run near 24/7, where unplanned trips cascade into yield loss and reheat penalties. In 2025, the most defensible upgrade is at the heart of the powertrain: the DC bus and inverter stages. Silicon carbide (SiC) technologies—high-voltage devices, low-inductance double-sided-cooled modules, active DC bus management, and multilevel/inteleaved inverter topologies—deliver measurable gains in efficiency, current density, four-quadrant stability, and environmental robustness.

Sicarbtech—Silicon Carbide Solutions Expert—operates from Weifang City, China’s silicon carbide manufacturing hub, and is a member of the Chinese Academy of Sciences (Weifang) Innovation Park. With 10+ years of customization across R‑SiC, SSiC, RBSiC, and SiSiC materials and a track record supporting 19+ enterprises, Sicarbtech brings a full-cycle approach, from device and packaging to validation, online monitoring, and MES traceability. For Pakistan’s steel corridors around Karachi, Lahore, and Faisalabad, Sicarbtech’s turnkey technology transfer and local line establishment compress lead times, stabilize PKR-denominated O&M, and improve line availability.

Industry Challenges and Pain Points: Harsh Loads, Regeneration, and Power Quality Realities

Steel continuous casting and rolling impose punishing duty cycles. Straightening and segment drives handle intermittent impacts and low-speed, high-torque operation; roughing, intermediate, and finishing stands see frequent torque reversals, synchronized speed changes, and large bursts of regenerative energy. Conventional silicon power stages, typically with single-sided cooling and higher parasitics, accumulate switching and conduction losses precisely where load spectra are harshest. Overshoot and ringing can spike during current steps, thick-gauge transitions, or regeneration handovers, stressing devices and aging insulation.

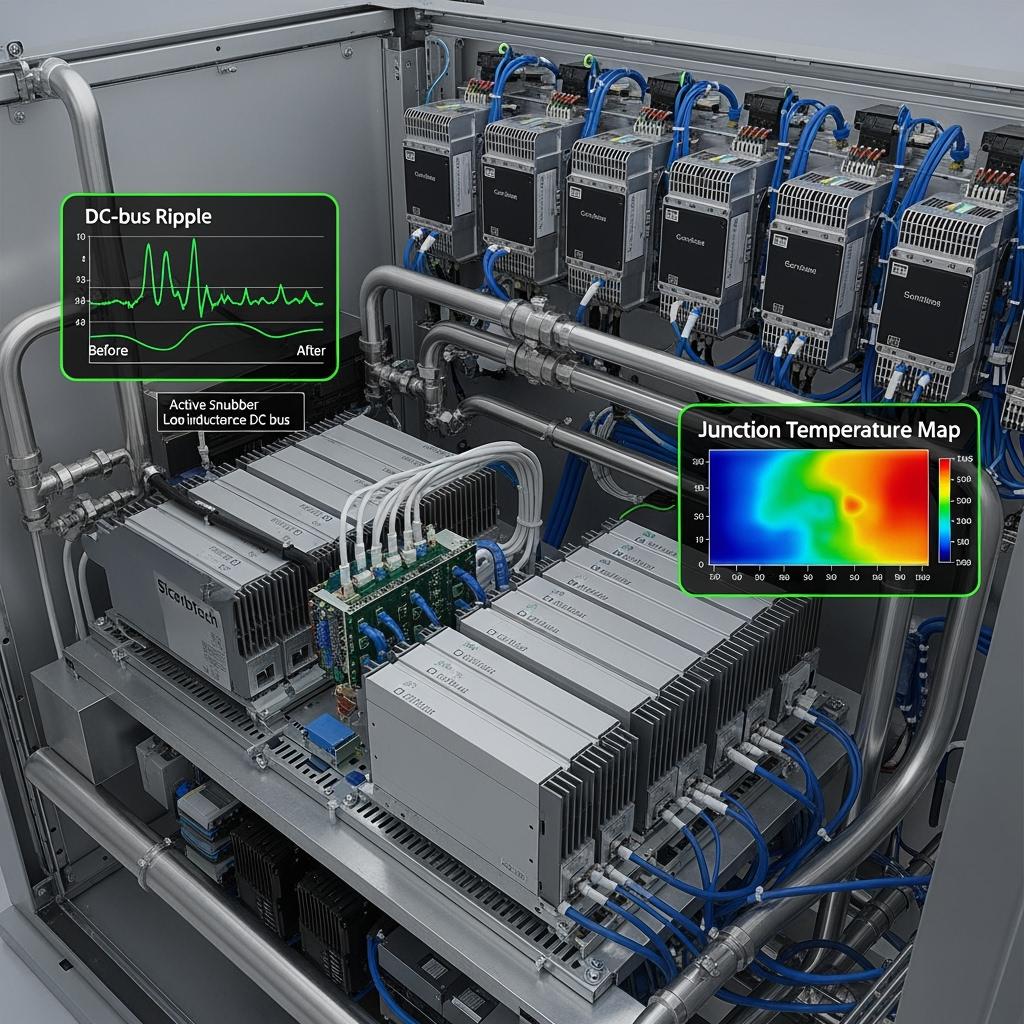

The DC bus is often the weakest link. Parallel drives feeding and drawing from a common bus excite oscillations if bus inductance and damping are not tightly controlled. Long cable runs across mill floors aggravate loop areas, and passive snubbers fail to contain high-frequency energy. The result is DC-bus ripple, overvoltage trips, and control loops that must be detuned, sacrificing line responsiveness and thickness/tension control. Under four-quadrant operation, unstable regeneration can shock the grid, increase harmonic content, and trigger upstream protections—inviting production breaks and penalties.

Environmental factors compound the issue. High ambient temperatures, dust, oil mist, and humidity degrade cooling performance and insulation. Finned exchangers clog and cold plates scale or corrode, especially with inconsistent coolant quality, raising junction temperatures and derating margins. Maintenance windows are narrow, and retrofit tasks that stretch beyond planned outages push recovery out of sequence with heats and campaign schedules. When failures occur, weak traceability from device lot to process parameters slows root-cause analysis and repeats mistakes across batches.

Procurement and financing are moving toward evidence-backed reliability. Tenders and audits increasingly ask for data aligned with IEC 60747 (device characteristics), IEC 60068 (damp heat, salt spray, dust, vibration, shock), and EMC expectations similar to IEC 61800‑3 for adjustable speed systems. Power quality—PF and current THD—matters for interconnection, and ISO 9001/IATF 16949 quality governance helps assure batch consistency. As Dr. H. Rehman, an industrial power electronics advisor, notes, “In a caster or mill, energy losses and ripple don’t just waste kWh; they show up as thickness variation, yield loss, and unplanned cobbles. In 2025, proof of stability is the cheapest capacity increase.” [Source: Regional Power Electronics Workshop, 2024]

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech’s DC Bus and Inverter Upgrade Stack

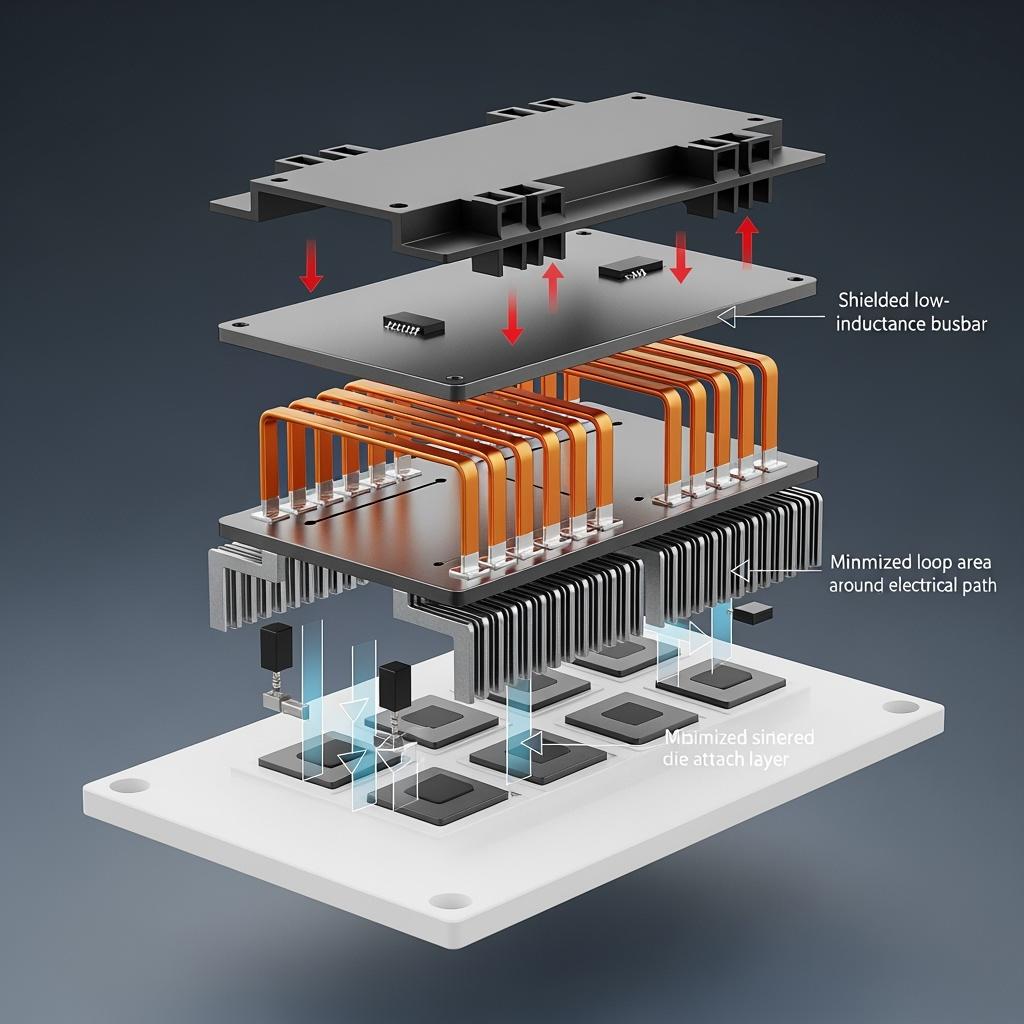

Sicarbtech designs upgrades as a coordinated program across “devices—packaging—busbar—topology—gate driving—thermal management—EMC—online monitoring—production testing and traceability.” High-voltage, high-current SiC MOSFETs and diodes in 1200/1700 V classes populate double-sided-cooled modules with integrated junction-temperature and current-sensing interfaces. Pressure-assisted sintering and vacuum brazing deliver low-void die attach and stable thermal cycling life. Low-inductance busbars and shielded partitions minimize loop area, reduce dv/dt stress, and tame radiated noise.

For topology, interleaved or multilevel inverter packages cut device stress and shrink filtering needs. An active front end (AFE) improves PF, lowers THD, and feeds a low-impedance DC bus augmented with active snubbing/damping to suppress ripple and overshoot under coupled multi-axis regeneration. Gate drivers implement fast soft turn-off, active clamping, and short-circuit protection with microsecond-level response. Cooling options include high-conductivity interfaces and liquid or hybrid air–liquid bases engineered for anti-clogging and ease of maintenance, with coatings and sealing for dust, oil mist, and salt mist.

Online health monitoring closes the loop with junction-temperature estimation, interface thermal-resistance trending, and gate health analytics derived from charge/discharge behavior. A regeneration and DC feedback control library stabilizes four-quadrant behavior, smoothing bus fluctuations. Production to field traceability is anchored by an MES that records device lots, process parameters, electrical/thermal screens, and on-site events, enabling fast corrective actions and confident audits.

Performance Comparison: SiC Upgrade Versus Conventional Silicon in Steel Drives

Energy, Stability, and Robustness Under Heavy Load and Regeneration

| Atributo | Sicarbtech SiC DC Bus + Inverter Upgrade | Conventional Silicon, Single-Sided Cooling | Mixed Silicon with Passive DC Bus Control | Impacto operativo en Pakistán |

|---|---|---|---|---|

| System efficiency (typical) | +2%–4% higher | Línea de base | +0%–1% | Lower electricity cost, less heat |

| DC-bus ripple (p‑p) under regen | −30% to −50% | Alta | Moderado | Fewer trips, smoother control |

| Overshoot/ringing (HF transients) | −15% to −30% amplitude | Más alto | Moderado | Larger device margin, fewer faults |

| Junction-to-case thermal resistance | −10% to −25% | Más alto | Moderado | Lower hot-spot temperature |

| Availability metrics | Downtime −20% to −40% | Línea de base | Slight improvement | More stable takt, higher yield |

By combining low-parasitic packaging with active DC-bus management and multilevel/interleaved stages, Sicarbtech’s stack improves four-quadrant stability and reduces the chronic failure modes seen in mills.

Real-World Applications and Success Stories in Pakistan

A continuous casting straightening drive upgrade cut DC-bus ripple peak-to-peak by around 40% and reduced overvoltage trips by roughly 35%. Energy consumption dropped about 3% annually, with fewer cobbles and smoother segment transitions.

A hot-rolling finishing stand adopted a multilevel SiC inverter with an active DC-bus management unit. Thickness variation standard deviation fell by double digits, and availability rose toward full-capacity targets. Operators noted tighter tension control during gauge changes and reduced nuisance trips.

A steel plant integrating online health monitoring and gate health analytics identified at-risk modules 2–4 weeks early. Planned replacements during scheduled stops cut unplanned downtime by about 30%, with warranty claims declining as MES traceability streamlined root-cause analysis.

Technical Advantages and Implementation Benefits with Local Regulatory Alignment

SiC’s lower switching and conduction losses at 3–20 kHz enable tighter current loops and improved torque and tension control at low speed and high torque. Double-sided cooling with high-thermal-conductivity substrates lowers junction-to-case resistance and mitigates hotspot-driven aging. Low-inductance, symmetric busbars reduce dv/dt stress, easing EMC burdens and enhancing device survival during fast transitions and grid disturbances. Active DC-bus damping and snubbing contain oscillations across long cable runs and parallel axes, preserving stability in four quadrants.

Compliance is designed into the upgrade path. Device characteristics align with IEC 60747, environmental endurance with IEC 60068 for damp heat, salt spray, dust, vibration, and shock, and EMC design follows expectations similar to IEC 61800‑3 for industrial adjustable speed systems. Power-factor and harmonic targets (PF ≥ 0.99, THDi ≤ 5% subject to interconnection conditions) support plant power quality. Quality governance follows ISO 9001 and IATF 16949 principles, with MES serialization enabling auditable records for tenders and insurance. As Engr. S. Khan remarks, “When the bid includes PF/THD evidence, ripple logs, and thermal histories, the conversation shifts from risk to schedule.” [Source: EV and Industrial Drives Roundtable, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge for Heavy Industry

Sicarbtech’s advantage is capability transfer underpinned by advanced R&D. As a member of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech leverages proprietary processes across R‑SiC, SSiC, RBSiC, and SiSiC to craft thermally and mechanically resilient substrates and assemblies suitable for dust, oil mist, and corrosion-prone environments.

The technology transfer package covers full process know-how—pressure-assisted sintering profiles, vacuum brazing atmospheres and flux control, metallization/passivation stacks, low-inductance busbar/bond geometries, and gate-drive tuning for soft turn-off, active clamping, and rapid desaturation detection. Equipment specifications include sintering presses, vacuum furnaces, wire/ribbon bonders, inline electrical testers, power-cycling rigs with junction temperature estimation, HTRB/HTGB setups, EMC pre-compliance stations, and IEC 60068 environmental chambers. Each station ships with acceptance tests, calibration procedures, and vetted vendor lists.

Training programs build in-country capability: operator certification, failure analysis and cross-section techniques, SPC-driven yield improvement, and PPAP-like control plans aligned with ISO 9001 and IATF 16949. Factory establishment spans feasibility studies, utilities and layout, line installation and commissioning, pilot runs, parameter locking, and capability validation. Post-SOP, Sicarbtech sustains quarterly audits, yield sprints, and roadmap co-development to adapt packaging, busbars, and control strategies to Pakistan’s load spectra and ambient profiles.

Across 19+ enterprise collaborations, operators have accelerated time-to-value, raised first-pass yields, reduced field failure rates, and secured domestic spares within days or weeks. For steel and cement retrofits, this translates to shorter outages, reliable replication, and O&M models aligned with local maintenance rhythms and budget cycles.

Comparative Engineering Choices and Lifecycle Economics

DC Bus, Topology, and Protection Choices that Stabilize Four-Quadrant Operation

| Design Area | Sicarbtech SiC Best Practice | Conventional Alternative | Practical Outcome in Pakistan |

|---|---|---|---|

| DC front end | Active front end (PF≥0.99, THDi ≤5%) | Diode/thyristor front end | Better power quality, fewer grid trips |

| Inverter topology | Multilevel or interleaved parallel | Two-level, low kHz | Lower device stress, smaller filters |

| Bus architecture | Low-impedance bus with active snubber/damping | Passive RC snubbers | Ripple and overshoot suppression |

| Gate strategy | Fast soft turn-off + active clamp + desat | Single-path protection | 2–5 µs shutdown, fewer ruptures |

| Packaging & cooling | Double-sided cooling, low‑L busbars | Single-sided, long leads | Lower Tj, improved EMC margins |

Localization and Total Cost of Ownership for Steel/Cement Retrofits

| Business Factor | With Sicarbtech Localization & Traceability | Import-Only, Conventional Drives | Outcome for Plant Operators |

|---|---|---|---|

| Retrofit outage duration | Modular hot-swap, parameterized commissioning | Custom onsite rework | Faster restart, less lost output |

| Energy and cooling OPEX | +2%–4% efficiency, cooler cabinets | Higher losses, larger cooling | Lower PKR/ton, longer component life |

| Availability and spares | Local screening, days–weeks delivery | Weeks–months | Higher uptime, smaller inventory |

| Power quality compliance | AFE + harmonic control | Variable | Fewer interconnection issues |

| Audit and warranty | MES-backed evidence and RCA | Fragmented records | Lower claims, faster approvals |

Future Market Opportunities and 2025+ Trends: Measurable Stability as a Competitive Weapon

In 2025 and beyond, Pakistani mills and heavy-process plants will differentiate on stability and energy intensity as much as on raw capacity. Expect tenders to ask for DC-bus ripple envelopes under parallel regeneration, microsecond-level protection timing, and thermal histories under mill-representative load profiles. ESG-linked financing will weigh kWh/ton improvements and documented reductions in trip-induced scrap and reheat. Technologically, multilevel SiC inverters, active front ends, and low-inductance, double-sided-cooled packaging will become standard in major axes, while online health models will inform planned stops and spares.

Sicarbtech’s integrated stack—devices, packaging, bus engineering, control libraries, validation, and factory establishment—positions Pakistani partners to move quickly from pilot to replicated rollouts. The payoff is higher availability, tighter gauge/tension control, better PKR economics, and a data trail that converts reliability into bankable value.

Extended Technical Specifications and Local Standards Alignment

DC bus voltage platforms typically span 750–1100 V, with field expansion as needed. Inverter power ranges from 0.5–8 MW per axis with multi-axis synchronization. Switching frequencies of 3–20 kHz are tuned to motor characteristics and filter strategies to balance loss, acoustics, and EMC. Device junction temperature capability reaches up to 175 °C with online junction-temperature estimation. Short-circuit withstand targets 3–10 µs at the device level, and system detect-to-soft-turn-off aims for 2–5 µs.

Power quality targets include PF ≥ 0.99 and THDi ≤ 5% subject to interconnection conditions. Environmental protections cover dust, oil mist, humidity, vibration, and shock. Monitoring includes voltage, current, junction temperature estimation, interface thermal resistance trend, insulation, and DC-bus oscillation with event logging. Documentation maps to IEC 60747 and IEC 60068, with EMC designed toward expectations similar to IEC 61800‑3; quality systems align with ISO 9001 and IATF 16949. Sicarbtech coordinates pre-compliance with Karachi and Lahore labs, providing parameter traces and environmental evidence for audits and financing.

Preguntas frecuentes

How much DC-bus ripple and overshoot reduction can we expect during regeneration?

Typical upgrades achieve 30%–50% lower peak-to-peak ripple and 15%–30% lower overshoot amplitude, stabilizing tension/thickness control and cutting trip frequency.

Will multilevel or interleaved topologies complicate maintenance?

No. Modular power stages with hot-swap mechanics and MES-guided service procedures shorten mean time to repair and simplify spares management.

Can the active front end meet power quality requirements at our interconnection point?

Yes. With PF targets near 0.99 and THDi ≤ 5% (subject to site conditions), AFE-based solutions improve compliance and reduce upstream disturbances.

How does double-sided cooling translate into real cabinet temperatures?

Lower junction-to-case resistance (−10%–25%) typically reduces cabinet hot-spot temperatures by 5–10 °C, extending component life and reducing fan duty.

What is the realistic timeline for a pilot retrofit on a single stand?

With standardized SiC modules, busbars, and control libraries, pilots commonly reach commissioning within 8–12 weeks, followed by replication across axes during planned outages.

How do we manage oil mist and dust in cooling systems?

Anti-clog fin geometries, corrosion-resistant cold plates, and cleaning-friendly manifolds maintain flow. Coatings and sealing mitigate ingress; maintenance plans endorse low-pressure wash and filtration checks.

Will faster protection increase nuisance trips?

Properly tuned soft turn-off, active clamping, and desaturation detection reduce nuisance by improving signal integrity and limiting overshoot. False triggers typically decrease after layout and busbar optimization.

Can online monitoring really predict failures early?

Junction-temperature estimation and interface thermal-resistance trending, combined with gate health analytics, have flagged at-risk modules weeks ahead, enabling planned replacements.

How does localization affect warranty and audits?

MES serialization links device lots, process parameters, and test results to field behavior, accelerating root-cause analysis and strengthening warranty and audit positions.

Are there benefits for cement kilns and high-inertia drives beyond steel?

Yes. Low-parasitic SiC inverters and active DC-bus control stabilize long cable runs and high-inertia transients, reducing trips and improving power quality across heavy-process applications.

La elección correcta para sus operaciones

In continuous casting and rolling, stability pays twice: once in kWh saved, and again in tonnage not lost to trips. Sicarbtech’s SiC-based DC-bus and inverter-stage upgrades unite low-inductance packaging, double-sided cooling, multilevel/interleaved topologies, and active DC-bus management with online health monitoring and traceability. The result is verified performance in four quadrants, faster restarts, and better PKR economics—all backed by local validation and support.

Obtenga asesoramiento experto y soluciones personalizadas

Partner with Sicarbtech to scope your retrofit: DC-bus architecture, topology selection, busbar and shielding geometry, gate-driver protection timing, and cooling design. Establish local packaging and screening, pre-compliance workflows, and MES traceability to replicate success across lines and plants with confidence.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Stability is capacity you already own—SiC and active DC control simply unlock it.” — Sicarbtech Applications Team

Metadatos del artículo

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan steel/cement outlook; aligns with IEC 60747, IEC 60068, and EMC expectations similar to IEC 61800‑3; includes AFE/PQ targets, SiC multilevel/interleaved strategies, active DC-bus management, online health monitoring, and localized technology transfer capabilities.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.