Módulos de diodos Schottky de carburo de silicio para etapas PFC de alta eficiencia y bobinado libre de recuperación rápida

Compartir

Visión general del producto y relevancia para el mercado en 2025

Los módulos de diodos Schottky de carburo de silicio (SiC) ofrecen una carga de recuperación inversa ultrabaja (Qrr ≈ 0) y capacidad de alta temperatura, lo que los convierte en la opción preferida para etapas de corrección del factor de potencia (PFC) y caminos de funcionamiento en rueda libre de recuperación rápida en convertidores de alta eficiencia. Para las industrias textil, cementera y siderúrgica de Pakistán, donde las temperaturas ambiente a menudo superan los 45 °C y la exposición al polvo es habitual, los diodos de SiC reducen las pérdidas de conmutación, mejoran los márgenes térmicos y mejoran la fiabilidad del sistema en los inversores fotovoltaicos conectados a la red y los accionamientos industriales de servicio pesado.

En 2025, las interconexiones de media tensión a 11–33 kV se están ampliando en los parques industriales y las instalaciones comerciales de las regiones del sur. Los módulos de diodos Schottky de SiC mejoran la eficiencia PFC frontal, reducen el calor en las salas de inversores confinadas y permiten frecuencias de conmutación más altas (50–150 kHz) que reducen los componentes magnéticos y el tamaño del filtro. Estas ganancias se traducen en:

- Mejora de la eficiencia del 96,5 % (silicio) a ≥98,5 % a nivel de sistema cuando se implementa con dispositivos SiC y accionamientos de puerta optimizados

- Hasta 2× densidad de potencia y aproximadamente un 40 % de reducción en el volumen de refrigeración

- Extensión MTBF hacia las 200.000 horas en entornos cálidos y polvorientos

Estas características apoyan un menor LCOE para la energía fotovoltaica, una reducción de los OPEX en los accionamientos industriales y una mejora del tiempo de actividad para los procesos críticos en los grupos de fabricación de Pakistán.

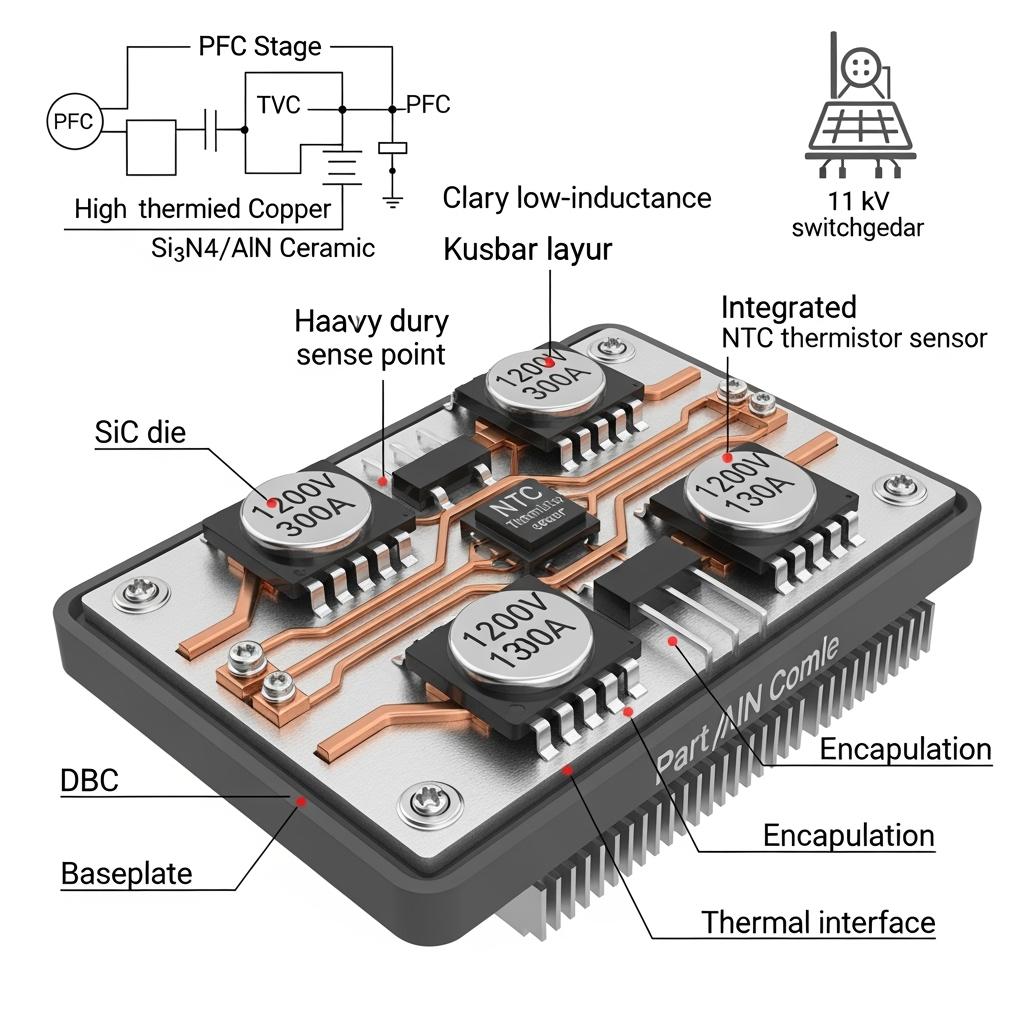

Especificaciones técnicas y funciones avanzadas

- Clasificaciones de tensión: clases de 600 V, 650 V, 1200 V, 1700 V para PFC, impulso y funciones de funcionamiento en rueda libre

- Clasificaciones de corriente: 20–300 A por módulo (se admite el escalado y el paralelismo específicos de la aplicación)

- Recuperación inversa: Qrr casi cero que minimiza las pérdidas de conmutación y las EMI

- Tensión directa (típica): 1,3–1,7 V a la corriente nominal, optimizada para la eficiencia a temperatura elevada

- Temperatura de la unión: funcionamiento de -40 °C a +175 °C con ciclo térmico robusto

- Embalaje: sustratos DBC (Si3N4/AlN) de baja inductancia, conexiones Kelvin para una detección precisa de la corriente

- Rendimiento térmico: bajo Rth(j-c) para reducir el tamaño del disipador de calor; compatible con refrigeración por aire o líquido

- Fiabilidad: Calificado para el ciclo de potencia y el choque térmico; admite el funcionamiento de larga duración en sitios polvorientos y de alta temperatura

- Soporte de cumplimiento: Facilita la reducción de la THD en los extremos frontales de PFC y mejora los márgenes de EMC a frecuencias de conmutación más altas

PFC de alta eficiencia y funcionamiento en rueda libre: diodos de SiC frente a diodos de silicio

Beneficios de rendimiento de los módulos de diodos Schottky de SiC en sistemas industriales y fotovoltaicos

| Criterio | Módulos de diodos Schottky de SiC | Diodos ultrafast/FRD de silicio |

|---|---|---|

| Carga de recuperación inversa (Qrr) | Cerca de cero (recuperación inversa mínima) | Alto Qrr que causa pérdidas e interferencias electromagnéticas |

| Frecuencia de conmutación | 50–150 kHz factibles | Normalmente limitado a kHz más bajos |

| Impacto en la eficiencia en PFC | Reducción significativa de las pérdidas de conmutación/conducción | Mayores pérdidas, funcionamiento más caliente |

| Margen térm | Funciona de forma fiable hasta +175°C | Límites de temperatura más bajos |

| Tamaño del disipador térmico/refrigeración | Posible reducción de aproximadamente el 40% | Se requiere una refrigeración mayor |

| Rendimiento EMI | Menos resonancia inducida por di/dt | Mayor sobreimpulso y ruido |

| Vida útil en condiciones adversas | MTBF extendido hacia las 200.000 horas | Más corto bajo estrés por calor/polvo |

Ventajas clave y beneficios probados con la cita de un experto

- Pérdida de conmutación ultrabaja: la recuperación inversa insignificante del SiC reduce el estrés de encendido del interruptor complementario, lo que reduce el calor y mejora la vida útil del dispositivo.

- Estabilidad a alta temperatura: Mantiene el rendimiento a temperaturas de unión elevadas comunes en los sitios industriales de Pakistán.

- Diseño térmico compacto: Las pérdidas más bajas permiten disipadores de calor más pequeños o placas refrigeradas por líquido, lo que reduce el volumen y el peso del armario.

- Mejor comportamiento EMC: La corriente de recuperación inversa reducida limita el sobreimpulso y la resonancia, lo que facilita el diseño y el cumplimiento del filtro.

Perspectiva experta:

“Los dispositivos de banda prohibida ancha como el carburo de silicio alteran fundamentalmente el diseño del convertidor al minimizar las pérdidas de recuperación, lo que permite frecuencias de conmutación más altas y componentes pasivos más pequeños”. — Publicaciones y actas de congresos de IEEE Power Electronics (ieee.org)

Aplicaciones reales e historias de éxito mensurables

- Etapas PFC front-end de PV (parques industriales, sur de Pakistán): La sustitución de los diodos FRD de silicio por módulos Schottky de SiC de 1200 V aumentó la eficiencia de la etapa PFC en 1,0–1,5 puntos porcentuales y permitió una reducción del 30–40% en la masa del disipador térmico. Resultado: eficiencia general del inversor ≥98,5% y estabilidad térmica mejorada durante los picos de verano.

- Rectificadores VFD textiles (Punjab y Sindh): Las trayectorias de rueda libre de SiC en las etapas de rectificador activo reducen los picos de conmutación y los puntos críticos térmicos, lo que reduce los disparos térmicos en los telares de alta velocidad y mejora el tiempo de actividad durante las horas pico.

- Accionamientos auxiliares de plantas cementeras: Los diodos SiC en funciones de refuerzo y rueda libre dentro de las salas eléctricas propensas al polvo mantuvieron bajas temperaturas de unión y prolongaron los intervalos de mantenimiento para la limpieza de los filtros.

Selección y mantenimiento

- Selección de tensión y corriente: Elija la clase de 1200 V para buses de CC de 600–800 V comunes en los accionamientos industriales y fotovoltaicos; 1700 V para mayores márgenes de enlace de CC o topologías multinivel.

- Diseño térmico: Calcule Rth(j-a) con factores de carga ambiental (45–50 °C) y de polvo realistas. Considere placas frías refrigeradas por líquido en armarios sellados para mitigar la obstrucción.

- Puesta en paralelo y diseño: Utilice módulos coincidentes y barras colectoras de baja inductancia; implemente diseños simétricos para el reparto de corriente.

- EMI y filtrado: Aproveche la mayor frecuencia de conmutación para reducir los tamaños de L y C en los filtros PFC y de salida. Valide frente a los objetivos locales de THD para la interconexión MV.

- Mantenimiento preventivo: Supervise las temperaturas NTC y los gradientes de la carcasa al ambiente; programe la mitigación del polvo del armario para preservar el rendimiento del flujo de aire.

Factores de éxito del sector y testimonios de clientes

- Los módulos listos para la integración y los sustratos DBC simplifican las actualizaciones de FRD a SiC sin rediseñar por completo los armarios.

- Las mejoras en el controlador de puerta combinadas con los diodos SiC alivian la tensión en los interruptores, lo que prolonga la vida útil del sistema.

Comentarios de los clientes:

“La actualización de nuestros diodos PFC a SiC redujo notablemente el calor del rectificador y estabilizó el funcionamiento durante las olas de calor. Redujimos el tamaño de nuestro hardware de refrigeración y observamos un aumento inmediato de la eficiencia”. — Jefe de electricidad de la planta, instalación textil en el metro de Karachi

Futuras innovaciones y tendencias del mercado

- Módulos de mayor densidad de corriente con mejor fijación de sinterización y conductividad térmica del sustrato

- Soluciones co-empaquetadas que combinan diodos SiC con MOSFET para una inductancia de bucle mínima

- Modelos de gemelos digitales para la temperatura de unión y la predicción de la vida útil para respaldar el mantenimiento predictivo

- Aumento de las capacidades locales de embalaje y prueba para apoyar el crecimiento de los inversores de media tensión en Pakistán

Preguntas frecuentes y respuestas de expertos

- ¿Por qué elegir SiC Schottky sobre silicona FRD en etapas PFC?

La recuperación inversa casi nula reduce drásticamente las pérdidas de conmutación y EMI, lo que permite una mayor frecuencia y componentes pasivos más pequeños, mejorando la eficiencia y el tamaño general del convertidor. - ¿Pueden los diodos SiC soportar entornos industriales de +45 °C?

Sí. Con capacidad de unión a +175 °C y embalaje de baja Rth, los módulos SiC funcionan con una reducción de potencia reducida en condiciones de calor y polvo cuando se combinan con la refrigeración adecuada. - ¿Qué ganancias de eficiencia son típicas a nivel de sistema?

Las mejoras en la etapa PFC de 1,0–1,5 puntos porcentuales son comunes, lo que contribuye a eficiencias del sistema de ≥98,5% cuando se combinan con interruptores SiC y un control optimizado. - ¿Existen clasificaciones específicas para interconexiones de 11–33 kV?

Utilice módulos de diodos SiC de 1200 V o 1700 V dentro de las etapas del convertidor de topologías multinivel. Ayudan a cumplir los requisitos de THD y EMC para la interconexión a nivel de distribución. - ¿Cómo afectan los diodos SiC al mantenimiento?

La menor generación de calor y el mejor comportamiento EMC reducen la tensión de los componentes, lo que extiende los intervalos de servicio y contribuye a las mejoras de MTBF hacia las 200.000 horas.

Por qué esta solución es adecuada para sus operaciones

Los módulos de diodos SiC Schottky abordan las limitaciones principales de Pakistán (alta temperatura ambiente, polvo y salas eléctricas estrechas) al reducir el calor, permitir frecuencias de conmutación más altas y simplificar el cumplimiento de las expectativas de calidad de la energía. El resultado son ganancias de eficiencia medibles, sistemas de refrigeración más pequeños y una vida útil más larga de los equipos en los inversores fotovoltaicos y los accionamientos industriales utilizados en las operaciones textiles, cementeras y siderúrgicas.

Conecte con especialistas para soluciones personalizadas

Acelere su transición a frontales de alta eficiencia y trayectorias de rueda libre robustas con un socio que ofrezca:

- Más de 10 años de experiencia en la fabricación de carburo de silicio y en ingeniería de aplicaciones probada

- Soporte de innovación dentro de un ecosistema de investigación líder

- Desarrollo de productos personalizados en materiales y embalajes R-SiC, SSiC, RBSiC y SiSiC

- Servicios de transferencia de tecnología y establecimiento de fábricas, desde la viabilidad hasta la puesta en marcha

- Soluciones llave en mano que abarcan materiales, dispositivos, embalaje, pruebas e integración

- Un historial de resultados exitosos con más de 19 empresas

Solicite hoy mismo una consulta gratuita y una propuesta técnica personalizada:

- Email: [email protected]

- Teléfono/WhatsApp: +86 133 6536 0038

Metadatos del artículo

Última actualización: 2025-09-10

Próxima actualización programada: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.