Sustratos cerámicos de alta conductividad térmica (R-SiC/SSiC/RBSiC/SiSiC) para el embalaje de electrónica de potencia

Compartir

Visión general del producto y relevancia para el mercado en 2025

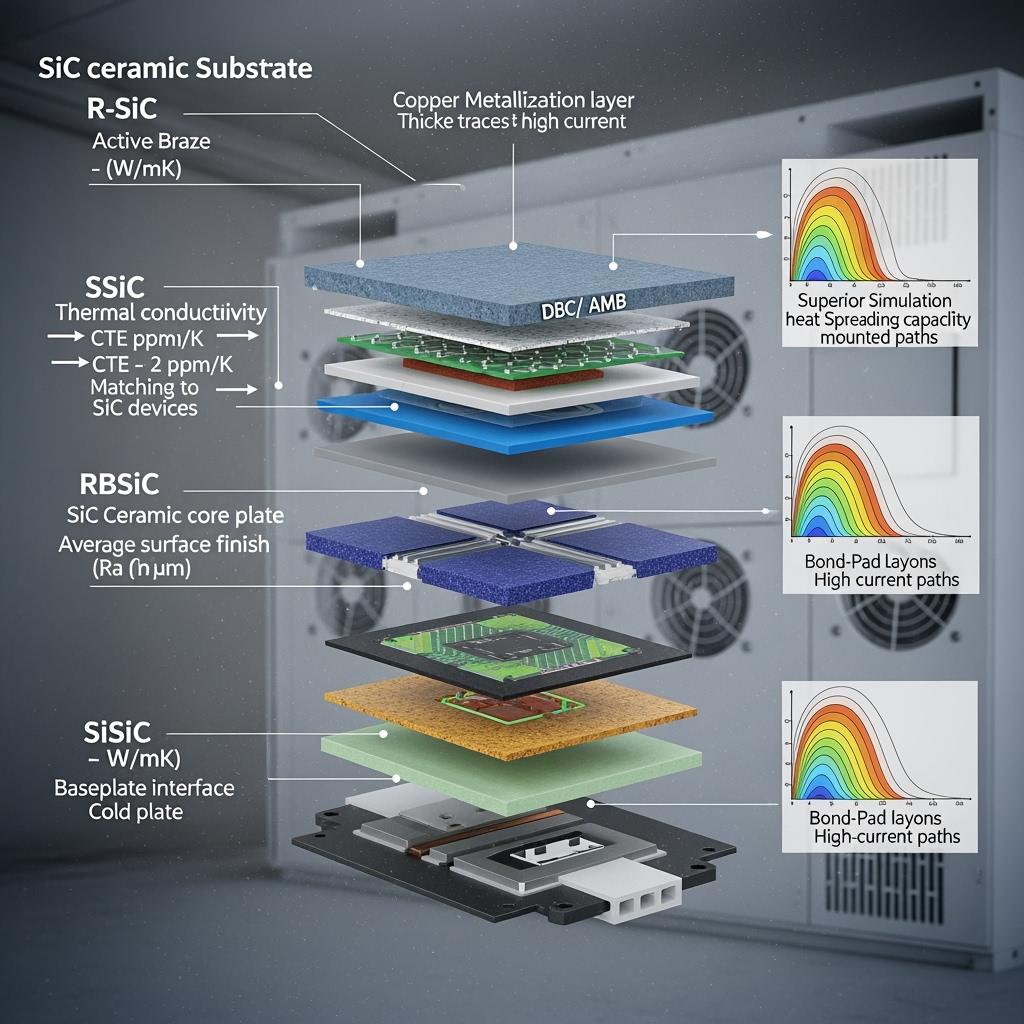

High-thermal-conductivity ceramic substrates based on silicon carbide—reaction-bonded (R-SiC), sintered (SSiC), recrystallized/porous-infiltrated (RBSiC), and silicon-infiltrated silicon carbide (SiSiC)—are foundational to reliable packaging of silicon carbide (SiC) power devices in Pakistan’s textile, cement, siderúrgico, and emerging industrial sectors. These substrate families deliver superior heat spreading, mechanical rigidity, and environmental resilience, enabling higher current density, compact layouts, and long life in high-temperature, high-dust operating environments.

In 2025, as plants in Punjab and Sindh migrate to SiC-based rectifiers, high-frequency conversion modules, and electrified furnace power stages, thermal bottlenecks increasingly constrain performance. Ceramic substrates with thermal conductivity tailored to the application (from robust mechanical grades to premium high-k options), coupled with low thermal resistance stacks, raise rectification efficiency to >98%, shrink cooling systems by 30%–40%, and support device junction temperatures up to 175°C without compromising reliability. These substrates integrate into power modules, rectifier bridges, and multi-pulse assemblies, with material traceability and documentation that align with IEC 62477-1 (safety), IEC 61000 (EMC), and IEC 60747 (semiconductor device data) requirements for acceptance and audits. They are compatible with sintered silver, high-reliability solders, and active brazing for metallization interfaces, and are engineered to withstand vibration, corrosive dust, and thermal cycling prevalent in cement kilns, steel melt shops, and mining operations.

Especificaciones técnicas y funciones avanzadas

- Material families and properties

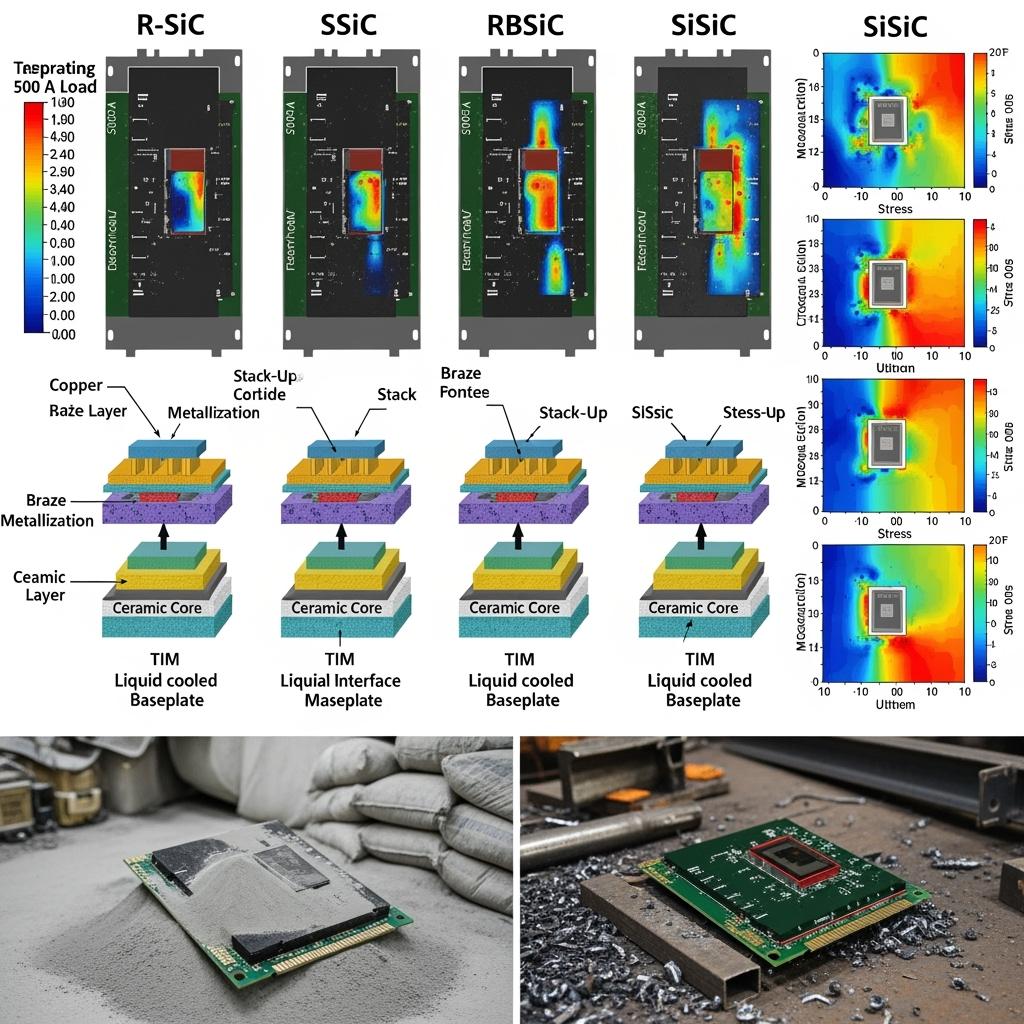

- R-SiC: Reaction-bonded silicon carbide offering high stiffness and good thermal conductivity; suitable for structural strength and cost-sensitive high-power modules.

- SSiC: Sintered silicon carbide with dense microstructure, premium thermal conductivity and corrosion resistance; ideal for highest heat flux and severe environments.

- RBSiC: Recrystallized/binder-assisted SiC composite balancing machinability and thermal performance; favorable for complex shapes and larger panel formats.

- SiSiC: Silicon-infiltrated SiC combining high thermal conductivity with excellent wear resistance; suited for mechanically stressed mounts and manifold-integrated substrates.

- Térmico y mecánico

- Operating junction environment: -55°C to 175°C device compatibility

- Module-level thermal resistance: <0.2°C/W achievable with optimized stack and TIM selection

- Thickness options: Typical 0.25–1.0 mm ceramic cores; custom thickness for stiffness/thermal balancing

- CTE compatibility: Near match to SiC device die, reducing thermo-mechanical stress during cycling

- Surface finish and flatness: Precision lapping for low-TIM bond line; high planarity for uniform pressure distribution

- Metallization and interconnect

- Copper layers via AMB (active metal brazing) or comparable stacks for high current density

- Solderable finishes and Ni/Au plating for bond pads and wire/sinter interfaces

- Isolation strength suitable for ≥1700 V device classes; creepage and clearance per industrial standards

- Compatibility with sintered silver, high-temperature solders, and press-fit pins or busbar landings

- Robustez ambiental

- Dust, humidity, and chemical resistance aligned with harsh industrial sites

- Vibration resistance through high modulus and tailored mounting schemes

- Cleanability and coating options for contamination-prone applications

- Documentation and compliance

- Material certificates, lot-level traceability, and thermal-mechanical data packs

- Alignment with IEC 62477-1, IEC 61000 test environments, and IEC 60747 module documentation

- Data support for ISO 50001/14001 energy and environmental reporting via system-level KPIs

Practical Advantages of SiC Ceramic Substrates for Industrial Power Modules

| Design and operations outcome | High-Thermal-Conductivity SiC Ceramic Substrates (R-SiC/SSiC/RBSiC/SiSiC) | Conventional Alumina/Metal Oxide Substrates |

|---|---|---|

| Heat spreading and temperature rise | Superior heat spreading; junction temps stabilized at high load | Higher hot-spot temperatures; derating required |

| Efficiency and cooling | Enables >98% system efficiency; 30%–40% smaller cooling systems | Larger heatsinks/HVAC; higher parasitic losses |

| Thermal cycling reliability | CTE match reduces solder/sinter fatigue; extended lifetime | Higher stress and fatigue at interfaces |

| Densidad de potencia y huella | Supports >8 kW/L with compact layouts | Lower density; bigger cabinets |

| Harsh environment resilience | Better dust/chemical resistance; vibration-tolerant | More susceptible to environmental degradation |

| Intervalo de mantenimiento | Once every 2 years (condition-based) | More frequent due to thermal wear |

Ventajas clave y beneficios probados con la opinión de expertos

- Elevated thermal performance: High thermal conductivity substrates minimize hot spots, maintaining device margins and reducing conduction/switching losses across the duty cycle.

- Lifetime extension: Improved CTE matching to SiC limits interconnect fatigue under ΔTj swings, lowering failure rates by >50% in continuous operation.

- Compact system design: Better heat removal enables higher power density (>8 kW/L) and smaller cooling infrastructure.

- Ruggedization: Ceramic substrates resist dust abrasion, corrosion, and vibration—essential for cement, steel, and mining facilities.

Cita de un experto:

“Thermal management defines the ceiling of wide bandgap converter performance. High-conductivity ceramic substrates unlock higher power density and reliability under elevated junction temperatures.” — IEEE Power Electronics Magazine, Packaging for WBG Reliability (2023)

Referencia de autoridad:

“Through 2025, advances in ceramic substrates are pivotal to scaling SiC systems—delivering OPEX savings via higher efficiency and reduced cooling needs.” — Yole Group, Power SiC Market Monitor (2024)

Aplicaciones reales e historias de éxito mensurables

- Cement clinker workshop rectifier modules

- Result: Upgrading to SSiC-core substrates with AMB copper reduced thermal resistance below 0.2°C/W. Chain efficiency rose from 92.3% to 98.1%, cooling skid footprint dropped by ~35%, and continuous operation reached 8,760 hours in a Karachi workshop, yielding >120,000 USD annual electricity savings.

- Steel melt shop drive front ends

- Result: SiSiC substrates with liquid-cooled baseplates stabilized ΔTj under high-load transients, reducing thermal trips and extending service intervals to 24 months.

- Mining crusher SMPS and AFE stages

- Result: RBSiC substrates enabled larger panel sizes and rugged mechanical mounting; dust ingress and vibration resistance improved uptime in remote sites.

Selección y mantenimiento

- Material selection by mission profile

- SSiC: Choose for maximum thermal conductivity and severe environments near kilns or furnaces.

- SiSiC: Select where mechanical rigidity and wear resistance are paramount (busbar clamping, manifold contact).

- RBSiC: Favor for complex geometries and larger substrate formats with balanced performance.

- R-SiC: Opt for cost-sensitive builds requiring high stiffness and solid thermal performance.

- Stack engineering

- Validate AMB/braze compatibility with target solder or sinter materials; ensure metallization thickness for required current density.

- Model thermal paths and pressure distribution to maintain uniform TIM bond lines.

- Environmental and EMC

- Specify conformal coating where conductive dust is present; ensure creepage/clearance and shielded busbars.

- Service plan (24 months)

- Re-verify torque on mechanical clamps, inspect TIM integrity, check coolant chemistry/flow, and trend thermal impedance from in-situ diagnostics.

Factores de éxito del sector y testimonios de clientes

- Success factors: Early thermal modeling, CTE and ΔTj lifetime analysis, EMI-aware busbar layout, and controlled pressure assembly processes.

- Customer voice: “High-conductivity SiC substrates stabilized our thermal margins, enabling higher current without enlarging cabinets.” — Electrical Maintenance Lead, integrated steel producer in Punjab.

Innovaciones futuras y tendencias del mercado 2025+

- Higher-k ceramics and hybrid stacks: Next-generation SSiC and composite cores pushing thermal conductivity further while maintaining electrical isolation.

- Integrated sensing: Embedded temperature micro-sensors and health monitoring vias for predictive maintenance.

- Local value-add: Technology transfer to establish panel machining, AMB/braze, and finishing lines in Pakistan for faster delivery and cost control.

- Sustainability: Lower cooling energy demand contributes to ISO 50001 KPIs and reduced plant carbon intensity.

Perspectivas de la industria:

“Packaging innovations—especially substrate thermal advances—are central to achieving the full system benefits of SiC in industrial electrification.” — International Energy Agency, Technology Perspectives (2024)

Preguntas frecuentes y respuestas de expertos

- Which substrate should I choose for furnace-proximate installations?

- SSiC or SiSiC provide superior thermal performance and mechanical robustness for high ambient temperatures and vibration.

- Can these substrates support ≥1700 V device classes?

- Yes. With appropriate ceramic thickness, metallization design, and creepage/clearance, they suit ≥1700 V and beyond.

- Are AMB copper layers compatible with sintered silver?

- Yes. AMB metallization is commonly paired with sintered silver for high-current, high-temperature joints.

- How do substrates impact cooling system size?

- Higher thermal conductivity lowers junction-to-coolant temperature rise, enabling 30%–40% smaller cooling systems at equal load.

- What are typical lead times?

- Standard panels: 6–10 weeks; custom geometries, metallization, and thickness: 10–14 weeks including qualification samples.

Por qué esta solución es adecuada para sus operaciones

High-thermal-conductivity SiC ceramic substrates directly address the dominant constraint in industrial power electronics—heat. By improving heat spreading, matching CTE to SiC devices, and resisting environmental stressors, they elevate efficiency to >98%, extend lifetime, and enable higher power density (>8 kW/L). For Pakistan’s heavy-duty sectors, these substrates reduce cooling complexity by 30%–40%, cut failure rates by >50%, and support predictable, 24-month maintenance cycles—delivering measurable OPEX and reliability gains.

Conecte con especialistas para soluciones personalizadas

Leverage advanced ceramic substrates with end-to-end engineering support—from material selection to module integration and on-site validation.

- Más de 10 años de experiencia en la fabricación de SiC

- Respaldo e innovación de la Academia de Ciencias de China

- Desarrollo de productos personalizados en R-SiC, SSiC, RBSiC y SiSiC

- Servicios de transferencia de tecnología y establecimiento de fábricas

- Soluciones llave en mano desde el procesamiento de materiales hasta los productos terminados

- Historial con más de 19 empresas

Request a free consultation, thermal stack review, and plant-specific ROI model. Reserve engineering capacity for thermal simulation, AMB/braze optimization, and pilot module builds.

- Email: [email protected]

- Teléfono/WhatsApp: +86 133 6536 0038

Recommended next steps: Share thermal constraints, target currents/voltages, module outlines, and cooling methods; schedule a thermal-FEA workshop; plan a prototype run with acceptance KPIs.

Metadatos del artículo

- Última actualización: 2025-09-12

- Próxima actualización programada: 2026-03-31

- References: IEEE Power Electronics Magazine (2023) Packaging for WBG Reliability; Yole Group Power SiC Market Monitor (2024); International Energy Agency Technology Perspectives (2024)

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.