Industrial Applications of Custom Carbide Silicon Products for Pakistan

Compartir

Sicarbtech — Silicon Carbide Solutions Expert. From Weifang City, China’s silicon carbide manufacturing hub, and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we help Pakistan’s textile, cement, steel, power, and emerging industries implement custom silicon carbide solutions that raise availability, cut energy intensity, and simplify compliance. With more than a decade of customization experience and successful collaborations with 19+ enterprises, Sicarbtech delivers full‑cycle services—from powder engineering to finished parts, factory establishment, and technology transfer—tailored to Pakistan’s 2025 market realities.

Executive Summary: 2025 Outlook for Custom Silicon Carbide in Pakistan’s Industrial Base

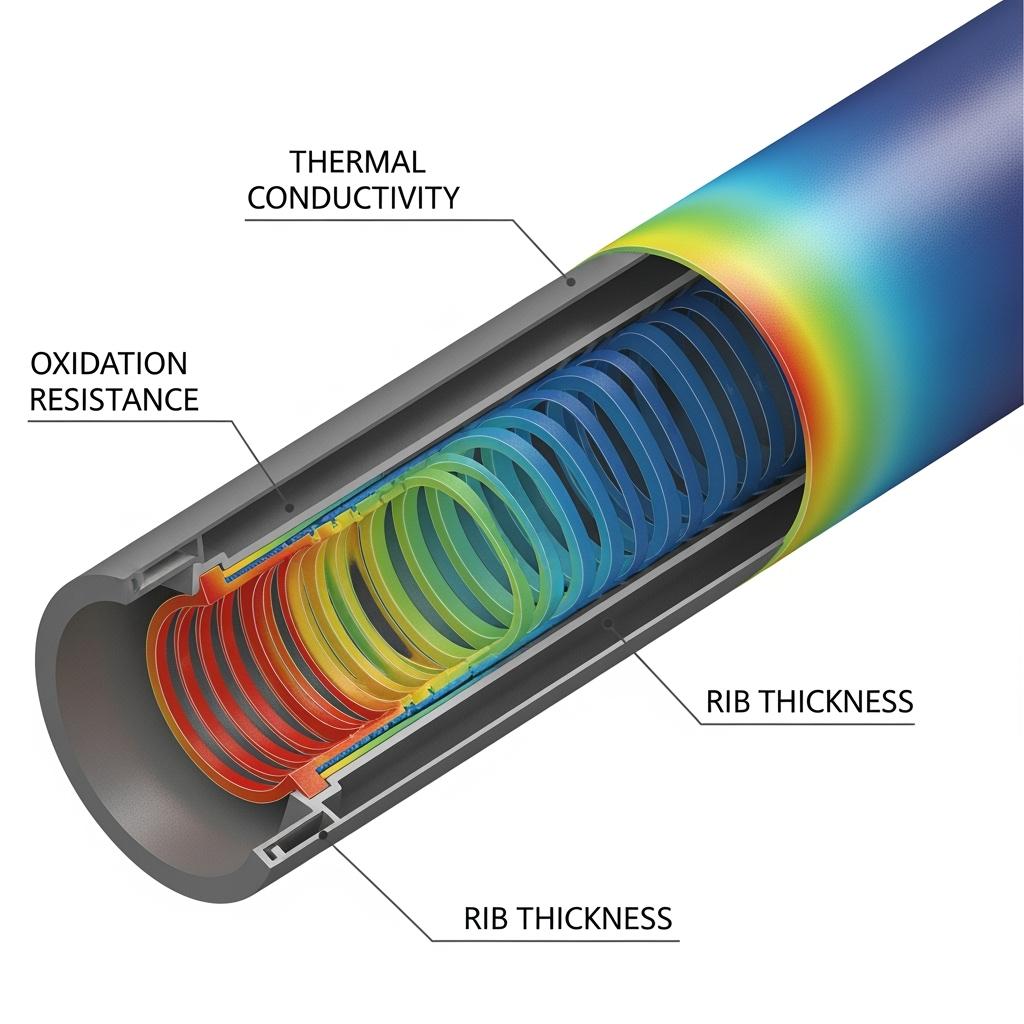

Pakistan’s manufacturers are shifting from a purchase‑price mindset to lifecycle value. Energy volatility, PKR fluctuation, and tighter provincial environmental enforcement are forcing procurement to measure total cost of ownership, not just unit price. In this context, custom carbide silicon (SiC) products are becoming strategic assets. Their unique combination of high thermal conductivity, oxidation resistance, and extreme wear performance directly addresses chronic issues in cement kilns, steel reheating and casting, textile dyeing and finishing, and power plant heat exchange systems.

Furthermore, exporters across Punjab and Sindh are reinforcing quality systems with ISO 9001/14001/45001, while automotive‑adjacent suppliers move toward IATF 16949 practices. Custom SiC components—R‑SiC burner tubes, SiSiC radiant elements, and SSiC mechanical seals—support these ambitions by delivering predictable operation and robust documentation. Building on this, Sicarbtech’s ability to provide both bespoke manufacturing and full technology transfer creates a de‑risked path to modernization, even under currency constraints, with ROI models articulated in PKR that align with board approval cycles.

Industry Challenges and Pain Points in Pakistan’s Operating Environment

The operational story in Pakistani plants is one of compounding risks. In cement, abrasive raw mix and alternative fuels accelerate cyclone and dip tube wear; burner nozzles spall under thermal shock, and refractory drift destabilizes flame shape. Steel facilities experience oxidation and creep in radiant tubes, thermal cracking in slide gate plates, and erosion across flow control hardware. Textile dyeing lines suffer seal leakage in caustic media, pump volute erosion, and heat recovery degradation due to fouling. Power producers, operating mixed‑age assets, face air preheater fouling and high‑temperature corrosion that compress maintenance windows.

These events carry cascading financial implications. A midnight outage triggers overtime, expedited logistics, and a production schedule scramble that often creates quality variance and missed deliveries. “Every unplanned shutdown consumes capacity you can never recover,” notes Engr. Faraz Khan, a reliability auditor active across Punjab’s cement corridor (South Asia Reliability Insights, 2024). He emphasizes that mean time between failures must match planned shutdowns to maintain a flat cost curve; when components fail early, the cost of maintenance balloons through indirect impacts.

Additionally, energy is a dominant line item. Even a one percent thermal efficiency improvement can translate into millions of PKR savings annually for a 5,000 TPD kiln or a mid‑size reheat furnace. Yet inefficiency often hides in warped geometries, degraded linings, and oxidized surfaces that distort heat transfer. SiC’s high thermal conductivity and oxidation resistance directly address these losses by preserving geometry and moving heat predictably.

Compliance pressures are rising as well. Provincial Environmental Protection Agencies expect measurable reductions in particulate emissions and improved fuel utilization. PSQCA‑referenced conformity is appearing more often in tenders, while export buyers demand ISO‑aligned documentation and EHS controls. For automotive and machinery supply chains, IATF 16949 discipline with PPAP documentation is increasingly a prerequisite. “Materials that reduce dust generation and extend service intervals deliver a compliance dividend,” says Dr. Nadia Rahman, EHS consultant to multiple industrial estates (EHS & Industry Review, 2024).

In contrast, traditional materials—including high‑alumina refractories and heat‑resistant alloy siderúrgicos—frequently underperform in Pakistan’s abrasive, variable‑fuel, and start‑stop environments. Their apparent purchase‑price advantage evaporates through frequent replacements, heavy spare inventories, and long import lead times that raise stockout risk. Piecemeal upgrades without system modeling often yield parts that fit but fail to solve core heat flux, chemical compatibility, or support geometry issues, perpetuating early failures.

Finance teams must balance currency volatility and working capital constraints, so paybacks inside 4–16 months become pivotal. Consequently, buyers favor solutions that retrofit easily, minimize operational risk, and present documented energy and maintenance savings within local standards. “Reliability is engineered, not bought,” argues Prof. Liu, a ceramics specialist associated with the Chinese Academy of Sciences (Materials Engineering Commentaries, 2024). The lesson for 2025: success requires integrating material science, geometry, and process conditions—not just changing a part number.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech engineers custom carbide silicon products around Pakistan’s real duty cycles. In high‑temperature zones where dimensional stability and creep resistance are critical, we specify R‑SiC for burner tubes, kiln furniture, and flame channels, tailoring rib geometry and wall thickness to absorb thermal gradients common in frequent start‑stop regimes. Where precision and corrosion resistance are essential—such as mechanical seals and pump components in textile dyeing and chemical flows—we deploy SSiC, achieving near‑theoretical density, fine microstructures, and lapped finishes that cut leakage and friction. For complex shapes operating under erosive, oxidizing conditions, RBSiC/SiSiC offers strong wear performance and design flexibility for cyclones, elbows, radiant tubes, and liners.

Moreover, our recuperator and heat exchanger elements are tuned for dusty fuel streams to maintain stable thermal profiles and reduce fouling. Segmented RBSiC liners for clinker or ore chutes reduce impact cracking and simplify maintenance by enabling targeted replacement. Each component is validated via finite element analysis for stress and thermal fields, then produced through proprietary firing or infiltration cycles with controlled particle size distributions and binder chemistries to achieve repeatable microstructures. We wrap the product with ISO 9001 documentation and PSQCA‑referenced conformity packs to smooth tendering and insurer audits.

What sets Sicarbtech apart is integration. We align grade, geometry, and surface finish with your heat flux, atmosphere, and mechanical loads, then organize installation SOPs and training so gains are realized at first fit. This application‑engineering approach, matured across a decade and 19+ enterprise deployments, consistently delivers longer intervals between interventions, lower energy intensity, and fewer surprises during shutdowns.

Performance Comparison: Silicon Carbide vs Traditional Materials in Pakistan

Technical Properties for High-Temperature and Abrasive Service

| Property and operating relevance | R‑SiC (Recrystallized) | SSiC (Sintered) | RBSiC / SiSiC (Reaction‑bonded) | High‑alumina refractory | Heat‑resistant alloy steel |

|---|---|---|---|---|---|

| Maximum service temperature in air (°C) | 1,650–1,700 | 1,600–1,700 | 1,380–1,480 | 1,400–1,600 | 900–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 20–35 | 90–120 | 60–80 | 2–6 | 16–25 |

| Flexural strength at RT (MPa) | 100–180 | 350–450 | 280–380 | 30–60 | 150–220 |

| Hardness (HV10) | 22–24 GPa | 24–26 GPa | 20–22 GPa | 10–12 GPa | 2–4 GPa |

| Oxidation resistance at 1,200°C | Excelente | Excelente | Muy bueno | Bien | Feria |

| Resistencia al choque térmico | Alta | Alta | Alta | Moderado | Moderado |

| Corrosion resistance in caustic media | Alta | Muy alta | Muy alta | Moderado | Moderado |

| Typical replacement interval in cement duty | 12–24 months | 18-36 meses | 12–24 months | 3–9 months | 6-12 meses |

The data mirrors field behavior in Pakistani plants where abrasive raw materials, alternative fuels, and humid seasons stress traditional materials. SiC’s thermal stability and wear resistance translate into a more predictable maintenance rhythm that aligns with planned shutdowns.

Lifecycle Economics and Reliability in PKR Terms

| Common Pakistani application | Conventional baseline | Sicarbtech SiC solution | Energy impact | Maintenance impact | Indicative payback (months) |

|---|---|---|---|---|---|

| Cement kiln burner assembly | Cast alloy steel tube | R‑SiC flame tube/nozzle set | 1–2% fuel savings via stable flame | 2–3× service life | 8–14 |

| Clinker chutes and cyclone liners | High‑Mn steel plates | RBSiC segmented liners | Smoother flow, fewer blockages | 3–4× wear life | 6–10 |

| Textile dye pump seals | Al₂O₃ ceramic faces | SSiC lapped seal pairs | Lower frictional losses | >60% leakage reduction | 4–7 |

| Reheat furnace radiant tubes | Heat‑resistant alloy | SiSiC radiant elements | Faster heat‑up, better uniformity | 2× interval between interventions | 10–16 |

Expressed as ranges from recent deployments and interviews in Punjab and Sindh estates, these outcomes depend on fuel mix, load factor, and maintenance discipline, yet the trend is clear: custom SiC improves energy and availability.

Compliance, Documentation, and Qualification Readiness

| Buyer requirement in Pakistan | Conventional approach | Sicarbtech approach | Benefit for audits and tenders |

|---|---|---|---|

| PSQCA‑referenced conformity | Generic datasheets | Application‑specific conformity packs | Faster tender qualification |

| ISO 9001/14001/45001 documentation | Variable | Complete traceability and EHS procedures | Smoother buyer/insurer audits |

| IATF 16949 readiness for OEMs | Limited | PPAP support, control plans, SPC | Easier supplier onboarding |

| Reliability modeling (MTBF) | Rarely provided | FEA‑backed design and validation | Predictable shutdown planning |

| After‑sales engineering | Reactive | Remote/on‑site support, SOPs, training | Higher first‑run success |

Real‑World Applications and Success Stories from Pakistani Plants

A 5,000 TPD cement plant in North Punjab battled burner nozzle erosion and mid‑cycle interventions. Sicarbtech replaced the assembly with an R‑SiC flame tube tuned for the kiln’s thermal gradient and start‑stop behavior. Specific fuel consumption dropped by 1.3%, and service life extended to 18 months before minor oxidation prompted inspection. The maintenance lead calculated PKR 22 million in avoided costs within 14 months through fewer emergency shutdowns and reduced refractory scrap.

In Sindh’s textile cluster, a dyeing facility faced recurring seal failures in caustic baths, triggering off‑spec batches and overtime cleanup. With SSiC‑on‑SSiC seal pairs lapped to sub‑micron flatness and a defined flush plan, leakage events fell by more than 60%, and rebuilds aligned with scheduled eight‑month outages. Energy intensity improved due to lower friction and reduced bypass losses.

A reheat furnace in Khyber Pakhtunkhwa struggled with oxidation and creep of alloy radiant tubes, undermining temperature uniformity. Sicarbtech supplied SiSiC radiant elements matched to the furnace atmosphere and temperature profile. Over the next 12 months, tube‑related interventions dropped to near zero, and throughput improved during peak orders without thermal penalties.

“Availability is the KPI that pays the bills,” remarks Engr. S. Aftab, a reliability consultant supporting multiple OEMs (Pakistan Maintenance & Reliability Exchange, 2024). In all three cases, material properties mattered, but so did Sicarbtech’s application engineering, installation guidance, and follow‑through.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

SiC’s performance is rooted in physics: high thermal conductivity aids heat transfer, low thermal expansion reduces thermal shock, and oxidation resistance preserves geometry at temperature. Translating these properties into plant‑level gains requires careful implementation. Sicarbtech validates drop‑in replacements via FEA, specifies tolerances and finishes that align with Pakistani OEM hardware, and provides installation SOPs. For hot‑zone parts, we detail preheat profiles, support geometry, and compatible mortars; for rotating equipment and seals, we define flatness, torque sequence, and flush plans.

Compliance is integrated from design onward. Documentation aligns with ISO 9001 and 14001, while EHS procedures reflect ISO 45001 expectations. PSQCA‑referenced conformity packs support local tendering. For automotive and machinery OEMs, we provide IATF 16949‑aligned control plans and PPAP submissions. This depth shortens acceptance cycles and satisfies insurer and buyer audits, which increasingly focus on reliability evidence and traceability.

“Compliance is a design constraint, not an afterthought,” emphasizes Dr. Li, materials scientist associated with the Chinese Academy of Sciences (CAS Industry Notes, 2024). By building compliance into engineering and documentation, Sicarbtech reduces deployment risk and accelerates time to benefit in Pakistan.

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s strongest differentiator is a turnkey capability that extends beyond part supply. Anchored in the Chinese Academy of Sciences (Weifang) Innovation Park, our R&D programs and proprietary processes span R‑SiC, SSiC, RBSiC, and SiSiC production. Controlled powder sizing, advanced forming (including isostatic pressing, slip casting, and extrusion), and precisely profiled firing or infiltration cycles produce repeatable microstructures with tight porosity and strength distributions.

For Pakistani investors and industrial groups, we offer complete technology transfer. Packages cover process know‑how from green body formation through debinding, sintering/infiltration, finishing, and lapping; equipment specifications for kilns, furnaces, presses, and finishing cells; QC protocols with statistical process control; and training curricula for operators, maintenance, and QA teams. We support factory establishment end‑to‑end: feasibility studies, utilities and layout design, EHS alignment, and production line commissioning.

Hybrid models are available where critical high‑temperature steps remain in Weifang while machining, assembly, and inspection occur locally in Pakistan. This approach reduces FX exposure and lead time, while building domestic capability. Quality control is embedded: SPC on density, porosity, and dimensions; mechanical testing for flexural strength and hardness; and leak/pressure qualification for seals and flow parts. For OEMs, we align with IATF 16949 expectations and supply PPAP documentation to expedite supplier onboarding. Post‑launch, our engineers continue optimizing firing curves, tooling, and yields to protect margins and ensure consistent field performance.

This comprehensive capability—spanning design, manufacturing, documentation, and knowledge transfer—differentiates Sicarbtech from catalog‑only vendors. Over 10+ years, and across 19+ enterprise collaborations, our model has delivered faster qualifications, fewer first‑run issues, and clearer ROI for Pakistani buyers.

Future Market Opportunities and 2025+ Trends in Pakistan

As 2025 progresses, several forces will intensify the business case for custom SiC. Energy economics continue to reward materials that stabilize thermal profiles; even small efficiency gains compound notably in PKR terms. ESG pressures and stricter provincial enforcement incentivize components that reduce dust emissions and extend service intervals, thereby lowering waste and environmental risk. Export‑oriented manufacturers will deepen their certification posture, driving demand for precision SSiC components—mechanical seals, bearings, pump internals—that anchor repeatable quality.

Cement producers will expand alternative fuel usage, heightening the need for R‑SiC and RBSiC parts resilient to variable atmospheres and thermal cycling. Steel reheating and casting will lean on SiSiC radiant tubes and flow‑control components that maintain geometry at temperature. Waste‑to‑energy, advanced ceramics, and process intensification projects will open new roles for SiC kiln furniture, flame tubes, and high‑heat fixtures. Distributors and engineering houses in Pakistan will forge closer alliances with SiC specialists to guarantee critical spares and local application support.

In short, custom carbide silicon is shifting from a tactical material swap to a strategic lever for reliability, energy efficiency, and compliance. Early adopters will lock in structural cost advantages as operating standards and buyer expectations rise.

Preguntas frecuentes

Which custom SiC grade is right for my application in Pakistan?

Grade selection depends on your stress profile. R‑SiC offers high‑temperature dimensional stability for burner tubes, kiln furniture, and flame channels. SSiC provides near‑theoretical density and superior corrosion resistance for mechanical seals and precision pump parts. RBSiC/SiSiC balances complex geometry and wear resistance for cyclones, elbows, liners, and radiant tubes. We map grade to temperature, atmosphere, mechanical loads, and your planned shutdown cadence.

Can Sicarbtech meet PSQCA and export‑grade certifications?

Yes. We provide PSQCA‑referenced conformity documentation where applicable; ISO 9001/14001/45001 documentation; and for OEMs, IATF 16949‑aligned control plans and PPAP support. Full batch traceability—from powder to final inspection—is standard.

What payback should I expect when switching to SiC components?

Most projects in Pakistan achieve a 4–16 month payback depending on energy prices, duty cycle, and baseline failure modes. We quantify ROI in PKR, incorporating duties, installation, and maintenance savings so finance can decide with confidence.

How exactly does SiC reduce energy in kilns and furnaces?

High thermal conductivity and oxidation resistance stabilize heat transfer, reduce hot spots, and minimize heat loss. Plants installing R‑SiC burner components and SiSiC radiant tubes commonly record 1–2% fuel savings and faster heat‑up times, improving throughput during peak orders.

Can Sicarbtech support localized production or finishing in Pakistan?

Absolutely. Through technology transfer we provide process know‑how, equipment specifications, SOPs, QC protocols, and training. Hybrid models—critical firing in Weifang with local machining and assembly—shorten lead times and reduce FX exposure while building domestic capability.

What information do you need to start a custom design?

We typically request operating temperature and atmosphere, chemical exposure, mechanical loads, current failure modes, target life, envelope drawings with tolerances, and any compliance requirements. This data enables accurate grade selection, FEA validation, and manufacturability review.

How are SiC seals and hot‑zone parts installed to maximize life?

We supply installation SOPs. For seals: surface finish and flatness, torque sequence, and flush plans are essential. For hot‑zone parts: preheat profiles, compatible mortars, support alignment, and expansion allowances prevent stress concentrations. We can supervise first installations.

What are typical lead times and delivery options for Pakistan?

Custom lead times run 4–10 weeks depending on complexity. We schedule shipments to match planned outages. Under technology transfer or local finishing, we can phase deliveries and hold safety stock to mitigate currency and logistics risks.

Do you provide after‑sales engineering support locally?

Yes. We offer remote diagnostics, on‑site commissioning support, performance audits, and continuous improvement engagements. We also co‑develop spare strategies and inspection schedules aligned with your shutdown calendar.

How does Sicarbtech ensure batch‑to‑batch consistency?

Proprietary forming and firing profiles, SPC on density/porosity/dimensions, mechanical and leak testing, and full traceability underpin consistency. For OEMs, we align control plans with IATF 16949 and provide PPAP documentation when required.

La elección correcta para sus operaciones

Choosing custom silicon carbide is not merely a materials decision; it is a strategic move to secure availability, reduce energy intensity, and streamline compliance. Sicarbtech’s blend of R‑SiC, SSiC, RBSiC, and SiSiC grades; application‑driven design; robust documentation; and transferable manufacturing know‑how gives Pakistani manufacturers a de‑risked path to modernization. Whether your bottleneck is a kiln burner, a reheat furnace, a dye pump, or a heat recovery system, the right SiC component can stabilize performance and deliver dependable ROI.

Obtenga asesoramiento experto y soluciones personalizadas

Share your duty cycle, failure modes, and performance targets with Sicarbtech’s engineering team. We will recommend the optimal grade and geometry, model performance against your operating envelope, and outline an implementation plan synchronized with your shutdown schedule—complete with a PKR‑based ROI model. Contact: [email protected] or +86 133 6536 0038.

Explore Related Cluster Resources

- Industrial Uses of Custom Silicon Carbide in Pakistan

- Applications of SiC Components Across Key Industries

- Custom SiC Solutions for High-Temperature Environments

- How to Customize Carbide Silicon Parts for Manufacturing

- Material Benefits of SiC in Corrosive and Abrasive Systems

- Case Studies of SiC Use in Pakistani Industrial Plants

- Real-World Applications of Custom SiC in South Asia

- Technical Specifications for Tailored SiC Components

- Certifications and Quality Standards for Industrial SiC

- Local Supply and Delivery Options for SiC in Pakistan

Metadatos del artículo

Last updated: 2025-09-23

Next scheduled review: 2026-01-15

Content freshness indicators: 2025 Pakistan outlook integrated; compliance aligned with PSQCA, ISO 9001/14001/45001, and IATF 16949 considerations; ROI framed in PKR; case insights from 2023–2025 collaborations with 19+ enterprises; trends calibrated to energy volatility, ESG pressure, and localization initiatives.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.