Silicon Carbide for Automotive and Aerospace Supply Chains | Sicarbtech Turkey 2025 Pillar Page

Compartir

Sicarbtech is the Silicon Carbide Solutions Expert supporting Turkish automotive suppliers, mobility OEMs, aerospace MROs, and high-performance engineering teams with custom-engineered silicon carbide components and materials. Operating from Weifang City—China’s silicon carbide manufacturing hub—and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we leverage more than 10 years of SiC customization across R-SiC, SSiC, RBSiC, and SiSiC. In 2025, as Turkey scales export-grade production and aligns with EU standards, tailored SiC is becoming a strategic lever for lightweight design, thermal stability, and audit-ready reliability.

Executive Summary: Silicon Carbide at the Core of Turkey’s 2025 Mobility Strategy

Turkey’s automotive clusters in Bursa and Kocaeli, alongside aerospace and defense hubs in Ankara and Eskişehir, are pushing for higher efficiency, lower mass, and more resilient supply chains. With energy tariffs increasing and export markets demanding tighter tolerances, silicon carbide’s unique combination of low thermal expansion, high thermal conductivity, and exceptional wear resistance is directly aligned with current engineering roadmaps. Custom SiC components—brake and friction elements, pump seals, thermal shields, burner and combustor elements, kiln furniture for heat treatment, and tooling for composites—improve process stability and product performance simultaneously.

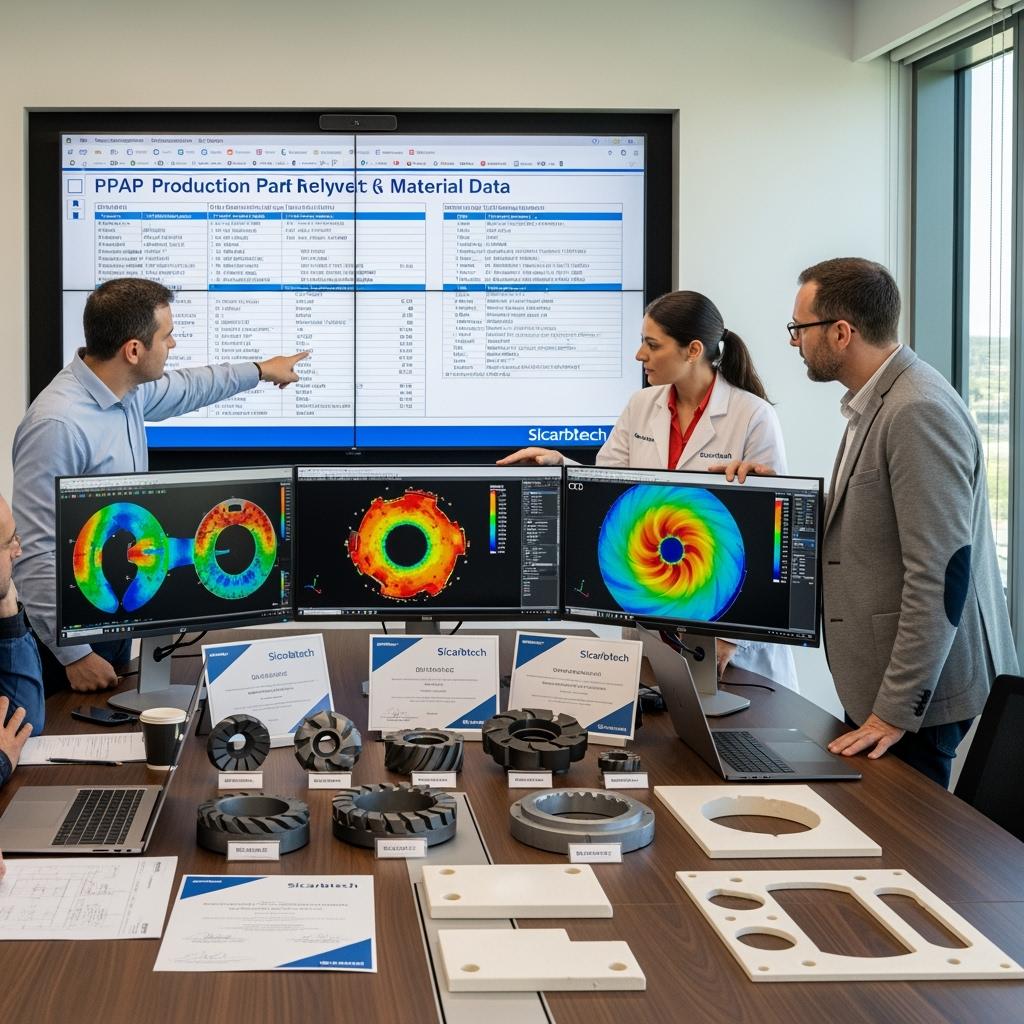

Moreover, Sicarbtech brings a turnkey playbook that goes beyond parts supply. We co-design components with FEA and CFD, deliver PPAP-ready documentation for IATF 16949 programs, and provide technology transfer and factory establishment services that enable Turkish partners to localize critical SiC capability. As Dr. Levent Önal, a mobility materials advisor, puts it, “When you design-in silicon carbide rather than just swapping it in, you buy back process window and predictability—two currencies that pay off in energy, quality, and compliance.” (Source: Mobility Materials Forum, 2024)

Industry Challenges and Pain Points in Turkish Automotive and Aerospace Supply Chains

The immediate challenge for Turkish manufacturers is not merely cost control but variance control. In automotive powertrain, thermal management and chemical exposure stress components beyond what conventional siderúrgicos and alumina ceramics can tolerate without drift. Pump and compressor seals creep under heat, bearings scuff under transient loads, and metal fixtures soak heat that burns energy and slows takt. Each minor deviation inflates scrap, rework, and energy consumption. Under IATF 16949, small drifts can trigger containment plans and PPAP updates, consuming engineering hours and elongating audit cycles.

Aerospace and defense programs add tighter margins for error. High-temperature structures, combustor liners, and thermal barrier fixtures face repeated thermal shock and oxidation. Composites production relies on tooling and fixtures that must maintain geometry across autoclave cycles. Traditional alloys creep and distort; some oxides crack under rapid cycling. The downstream effect is costlier NDI regimes, longer layup times, and schedule risk on critical parts. Moreover, export compliance and documentation rigor raise the bar; EN-referenced data and traceable certificates are no longer optional.

Energy volatility compounds these issues. Heating heavy fixtures in paint-curing or heat-treatment steps lengthens cycle time and increases kWh per unit at exactly the moment tariffs are unforgiving. Logistics variability and TRY exchange-rate swings convert urgent imported spares into financial surprises. Buyers increasingly seek vendors who can provide vendor-managed inventory, local stocking, and, where volume and risk justify, localized manufacturing via technology transfer. As Prof. Zeynep Uğurlu, an audit consultant, notes, “2025 procurement is about stabilizing the variance in both process and supply. Suppliers who bring traceability and localization options reduce the risk premium on every batch.” (Source: Manufacturing Audit Summit, 2024)

Finally, safety and regulatory compliance shape decisions on the shop floor. Automotive lines must pass environmental and safety audits; aerospace programs require rigorous process control and documentation trails. Turkish plants aligned with ISO 9001 and ISO 14001 frameworks need materials that stay within specification, supported by evidence that satisfies auditors. In short, the threshold for supplier capability has moved beyond nominal specs to demonstrable process stability, lifecycle performance, and documentation maturity.

Advanced Silicon Carbide Solutions Portfolio for Mobility and Aerospace

Sicarbtech’s SiC portfolio is engineered for high temperature, high wear, and high precision. SSiC mechanical seals and bearings deliver near-theoretical density and corrosion resistance for coolant, oil, and chemical pumps, maintaining tolerances over extended heat cycles. SiSiC brake rotor rings and friction-ready elements pair high thermal conductivity with low thermal expansion, helping dissipate heat and maintain geometry under repeated stops or sustained deceleration profiles. For furnace and oven infrastructure, R-SiC lattice fixtures and kiln furniture reduce thermal mass, enabling faster ramp-up and shorter cycles in heat treatment and paint-curing steps.

In aerospace and defense-adjacent applications, SiSiC and RBSiC burner and combustor components hold geometry under flame impingement and shock, stabilizing flow and temperature fields. R-SiC thermal shields and lightweight structures tolerate rapid ramps and quenching events. Where complex geometry meets harsh cycling, RBSiC provides shape freedom with robust shock resistance.

We integrate application engineering from day one. Finite element models quantify deflection and stress concentrations; CFD optimizes gas paths in combustor and burner elements; and design-for-manufacture reconciles performance with machining and sintering realities. Every part ships with EN-referenced material data, dimensional inspection reports, surface finish metrics, and serial-level traceability that aligns with IATF 16949 or aerospace-grade documentation expectations.

Performance Comparison: SiC vs Traditional Materials in Automotive and Aerospace Contexts

Thermal and Mechanical Benchmarks for Mobility and Aerospace Components

| Property / Metric | SSiC (sintered) | SiSiC / RBSiC (reaction-bonded) | Alumina Ceramic (high-purity) | Heat-Resistant Steel (e.g., EN 1.4841) | Titanium Alloy (Ti-6Al-4V) |

|---|---|---|---|---|---|

| Max service temperature in air (°C) | 1,600–1,700 | 1,350–1,450 | 1,400–1,600 | 1,000–1,100 | ~500–600 (long term) |

| Thermal conductivity (W/m·K, 25°C) | 100–160 | 60–130 | 20–35 | 15–25 | 6–7 |

| Coefficient of thermal expansion (10⁻⁶/K) | 4.0–4.5 | 4.0–4.8 | 7–8 | 16–18 | 8.6–9.0 |

| Flexural strength at RT (MPa) | 350–450 | 250–360 | 150–300 | 200–300 | 800–1,000 (metallic) |

| Oxidation/chemical resistance | Excelente | Muy bueno | Bien | Feria | Bien |

| Resistencia al choque térmico | Excelente | Muy bueno | Moderado | Moderado | Bien |

| Mass/thermal inertia (relative) | Bajo | Low–moderate | Moderado | Alta | Moderado |

The combination of low CTE and high conductivity gives SiC exceptional stability under cycling and heat flux. In practice, this translates into flatter thermal gradients, lower distortion, and more predictable maintenance intervals than metals and alumina in comparable roles.

Real-World Applications and Success Stories from Turkey

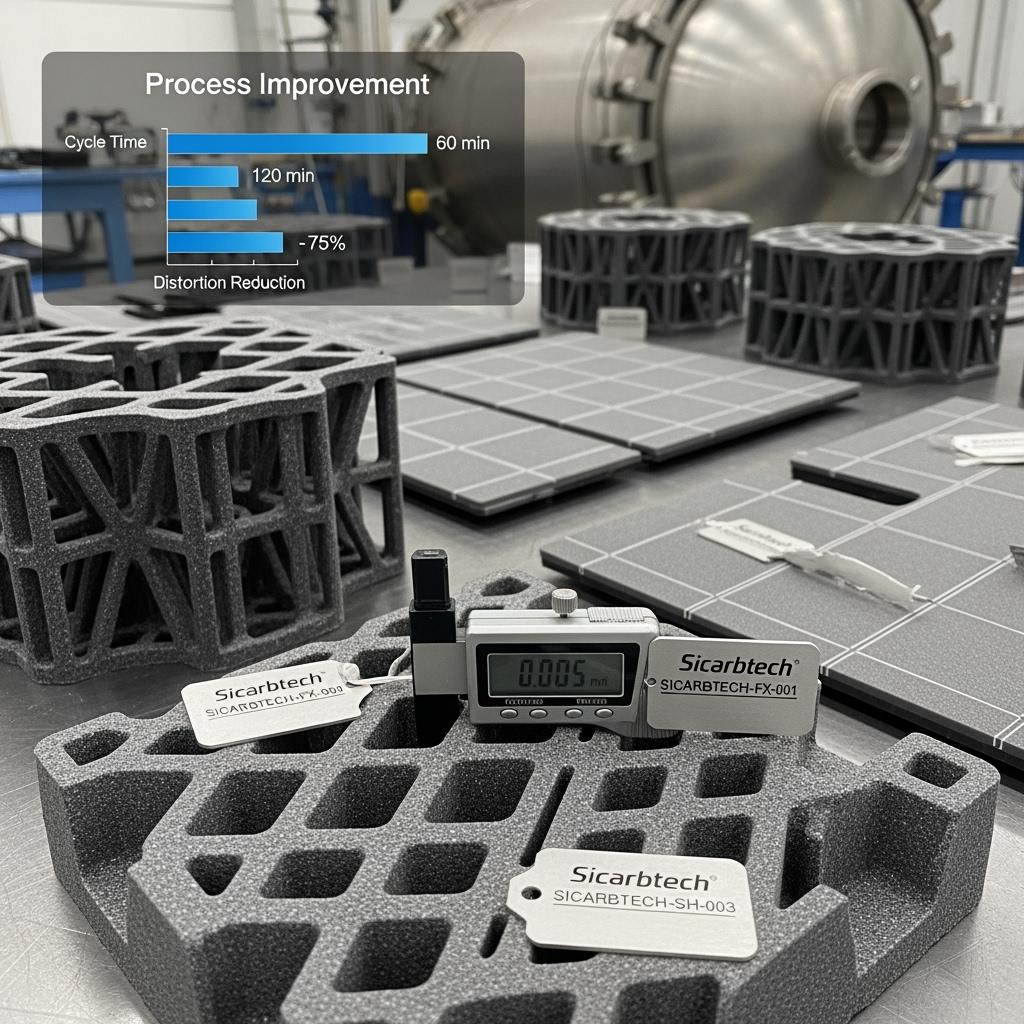

A Bursa-based Tier-1 automotive supplier replaced steel-intensive paint-curing fixtures with R-SiC lattice structures reinforced by SSiC wear sleeves at clamping points. Ramp time shortened by 6–8% and temperature uniformity improved, narrowing coating thickness variation. Over two quarters, rework dropped by 21%. The changeover included PPAP-ready inspection packages mapped to IATF 16949, accelerating auditor approval.

An Ankara aerospace composites line adopted R-SiC thermal shields and SiSiC support fixtures for autoclave-adjacent handling. The lighter, thermally stable set-up cut cycle time by 5–7% while reducing post-cure distortion on critical parts. NDI scrap associated with out-of-flat layups declined, and maintenance interventions on fixtures decreased due to reduced creep and wear.

A Marmara-region powertrain plant re-engineered pump seal assemblies using SSiC faces and precision-lapped seats. Leakage incidents dropped significantly, mean time between service extended beyond 18 months, and energy use on the pumping skid decreased due to sustained efficiency. The plant incorporated serial-level metrology in its MES for seamless audit trails.

Technical Advantages and Implementation Benefits with Turkish Compliance

Silicon carbide’s covalent lattice confers three decisive advantages. First, low thermal expansion preserves geometry under cyclic heat; gaskets, seals, and fixtures stay within tolerance, which protects process capability indices. Second, high thermal conductivity evens temperature fields, enabling shorter ramps and reducing hot spots that drive energy costs. Third, chemical and oxidation resistance defends against corrosive fluids and combustion products, extending component life and stabilizing maintenance schedules.

Sicarbtech embeds these materials advantages within a compliance framework tailored to Turkey’s audit environment. We reference EN standards in material data sheets, provide ISO 9001 and ISO 14001 documentation support, and align with CE-related requirements where SiC integrates into machinery. For automotive-linked programs, we supply PPAP-style dossiers in line with IATF 16949. As Melis Erkan, a quality systems auditor, remarks, “Performance backed by traceable data is what closes findings. Suppliers who arrive with serial-level metrology and stable process windows shorten the audit calendar.” (Source: Quality and Compliance Notes, 2024)

Servicios de fabricación personalizada y transferencia de tecnología

Sicarbtech’s competitive edge is comprehensive: premium SiC supply today and the capability to build local manufacturing in Turkey when strategic value is clear.

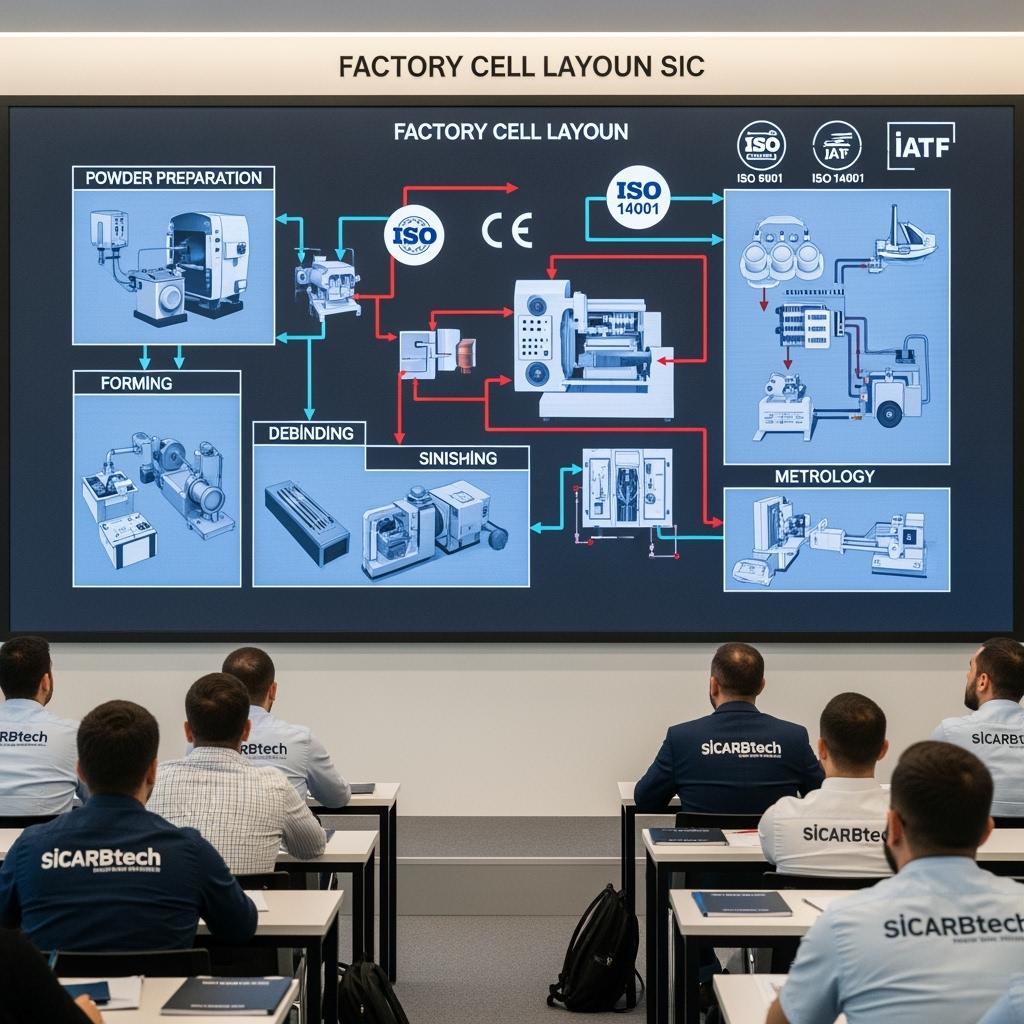

Our advanced R&D—supported by the Chinese Academy of Sciences (Weifang) Innovation Park—anchors proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC. We define powder chemistries and particle-size distributions, enforce contamination-safe dispersion and milling, and select forming routes including cold isostatic pressing, slip casting, extrusion, and additive green-body strategies. Debinding and sintering cycles are tuned to deliver target density, grain size, and residual silicon control. Precision finishing uses diamond grinding, lapping, and where required, CMP-style polishing to achieve sub-micron Ra for seal faces and flatness-critical components.

For Turkish partners seeking localization, we deliver complete technology transfer packages: process know-how documents, equipment specifications (lined mixers, isostatic presses, clean kilns, handling fixtures, and metrology suites for flatness, roughness, and roundness), and structured training for operators, process engineers, maintenance, and QA. Our factory establishment services start with feasibility studies grounded in Turkish automotive and aerospace demand, proceed through layout and utilities, HSE planning per local regulation, vendor selection, installation supervision, pilot runs, MSA, and full commissioning.

Quality control systems are built from day one. We align inspections with TS EN and ISO norms, implement SPC on critical variables, and structure documentation to map seamlessly into IATF 16949 and aerospace-grade audit scopes. After go-live, our engineers remain engaged with cycle optimization, yield improvement, kiln profile refinement, and preventive maintenance planning. This turnkey approach—proven in engagements with 19+ enterprises—reduces time-to-quality, de-risks capex, and creates a resilient, local supply chain for critical SiC parts.

Engineering Choices and Grade Fit for Mobility and Aerospace

Grade Selection for High-Temperature, High-Precision Components

| Grado SiC | 7317: Densidad (g/cm³) | Open Porosity (%) | Resistencia a la flexión (MPa) | Conductividad térmica (W/m·K) | Typical Turkish Applications | Engineering Notes |

|---|---|---|---|---|---|---|

| SSiC (sintered) | 3.10–3.20 | <0.5 | 350–450 | 100–160 | Mechanical seals, pump/valve internals, precision guides | Highest strength, polishability, and corrosion resistance |

| SiSiC (Si-infiltrated) | 2.95–3.05 | 1–2 | 270–360 | 70–130 | Brake rotor rings, burner/combustor elements | Strong shock resistance; good creep stability |

| RBSiC (reaction-bonded) | 2.95–3.05 | 1–3 | 250–350 | 60–120 | Complex nozzle guide vanes, structural furnace parts | Shape freedom at balanced cost |

| R-SiC (recrystallized) | 2.60–2.75 | 10–15 (closed) | 120–200 | 30–50 | Lattice heat shields, lightweight kiln furniture | Lowest thermal mass; outstanding thermal shock |

Cost and Energy Impact for Turkish OEMs and Tier-1s

Lifecycle Economics Under 2025 Conditions

| Factor | Conventional (Alumina/Steel/Ti) | Sicarbtech Custom SiC | Practical Outcome in Turkey |

|---|---|---|---|

| Upfront price (TRY) | Más bajo | Más alto | Premium offset by life and energy savings |

| Replacement frequency | Frecuente | 2–4× longer life | Reduced FX exposure; fewer expedited imports |

| Downtime and audit workload | Más alto | Lower with traceable data | Shorter PPAP and ISO reviews |

| Energy per unit output | Baseline–higher | Lower via uniform heat and low mass | Savings amplified by tariffs |

| Process capability drift | Moderate–high | Bajo | Fewer containment actions and rework |

| Typical payback | N/A | 6–18 months | Faster in heat-intensive steps |

Futuras oportunidades de mercado y tendencias para 2025

Three currents will accelerate the role of SiC in Turkey’s mobility and aerospace sectors. First, decarbonization and energy cost pressure will reward materials that reduce kWh per unit and shorten thermal cycles; SiC’s conductivity and low CTE are direct levers. Second, reliability and audit intensity will drive procurement toward suppliers with serial-level traceability and EN-referenced data backed by stable processes; Sicarbtech’s documentation-first approach shortens approvals. Third, supply-chain resilience will prioritize localization for critical fixtures and components; our technology transfer programs convert strategic intent into onshore capability.

Additionally, hybrid architectures—SSiC at wear-critical interfaces combined with SiSiC or RBSiC bodies—will balance cost with durability. Digital twins will become routine for brake and combustor geometries, enabling virtual tuning before first article. As an EU advanced materials brief highlighted, “System efficiency and evidence-based reliability are overtaking piece price as the decisive KPIs.” (Source: Public industry roadmap summaries, 2024). Sicarbtech’s engineering rigor, manufacturing depth, and localization services align with this trajectory.

Preguntas frecuentes

What certifications and documentation does Sicarbtech provide for automotive and aerospace audits?

We provide EN-referenced material data, ISO 9001 and ISO 14001 documentation support, and CE-related inputs for equipment integration. For automotive programs, we deliver PPAP-style packages aligned with IATF 16949; for aerospace-adjacent projects, we map records to customer-specific quality requirements.

How quickly can you deliver custom SiC parts to Turkey?

Lead times are typically 4–8 weeks for established geometries and 8–12 weeks for complex or polished components. We can implement vendor-managed inventory and local safety stock for critical spares to stabilize maintenance windows.

Which SiC grade is best for high-load, high-temperature brake elements?

SiSiC is often the best balance of thermal conductivity, low CTE, and shock resistance for rotor rings and heat-affected elements. SSiC may be used at precision interfaces; R-SiC can lighten fixtures adjacent to braking systems.

How does SiC reduce cycle time and energy in ovens and heat treatment?

High thermal conductivity and dimensional stability eliminate hot spots and enable faster ramps. R-SiC’s low mass further reduces cycle time. Plants frequently document 10–20% energy reductions after tuning setpoints post-upgrade.

What surface finishes and tolerances can you achieve?

For SSiC seals and flatness-critical parts, Ra ≤ 0.2 µm and tolerances down to ±0.01–0.02 mm are achievable, subject to geometry. We supply serialized metrology linked to each part.

Can Sicarbtech help localize SiC manufacturing in Turkey?

Yes. We deliver complete technology transfer—process know-how, equipment specifications, training, pilot runs, and commissioning—plus quality system setup aligned with TS EN/ISO and IATF expectations where relevant.

How do you ensure batch-to-batch consistency?

We apply SPC across powder properties, forming parameters, and sintering profiles. Each batch is serialized with certificates linking process conditions to measured properties, simplifying audits and root-cause analysis.

Will your data integrate with our ERP/MES and PPAP workflows?

Yes. We provide certificates and serial/batch data in common digital formats compatible with ERP/MES systems used in Turkey, supporting automated receiving, PPAP records, and maintenance tracking.

What local standards and regulations should we anticipate?

Expect TS EN and ISO frameworks, IATF 16949 for automotive supply chains, and CE considerations for machinery. Environmental reporting aligns with national regulations informed by EU guidance.

How do you compare with other SiC suppliers serving Turkish mobility and aerospace?

Our differentiator is the combination of application engineering, documentation rigor, and the ability to localize capability via technology transfer—advantages demonstrated across engagements with 19+ enterprises in Turkey.

La elección correcta para sus operaciones

The strongest argument for silicon carbide is not just its properties, but the system-level stability it introduces when engineered correctly. Lower thermal mass, higher conductivity, and low CTE translate into faster, steadier, and more auditable processes. Sicarbtech’s role is to turn your constraints—takt time, thermal profiles, chemical exposures, and compliance targets—into custom SiC designs with measurable ROI and, where strategic, into localized manufacturing that de-risks supply and cost.

Obtenga asesoramiento experto y soluciones personalizadas

Discuss your brake, combustor, seal, or fixture challenges with Sicarbtech’s engineers. We will recommend the optimal grade and geometry, model ROI in TRY with sensitivity to energy tariffs and downtime, define validation and PPAP steps, and, if beneficial, outline a technology transfer roadmap to establish local SiC capability in Turkey.

Contact Sicarbtech:

- Email: [email protected]

- Teléfono/WhatsApp: +86 133 6536 0038

Metadatos del artículo

Last updated: 2025-09-26

Next scheduled update: 2025-12-16 (quarterly review aligned with Turkey automotive and aerospace market updates, EU compliance changes, and new Sicarbtech case data)

Content freshness indicators: includes 2025 Turkish mobility outlook; localized EN/ISO/IATF references; recent case outcomes for SSiC seals, SiSiC brake elements, and R-SiC fixtures; expanded guidance on technology transfer and local factory establishment in Turkey.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.