Silicon Carbide Abrasives & Refractories for Turkish Industries | Sicarbtech 2025 Pillar Page

Compartir

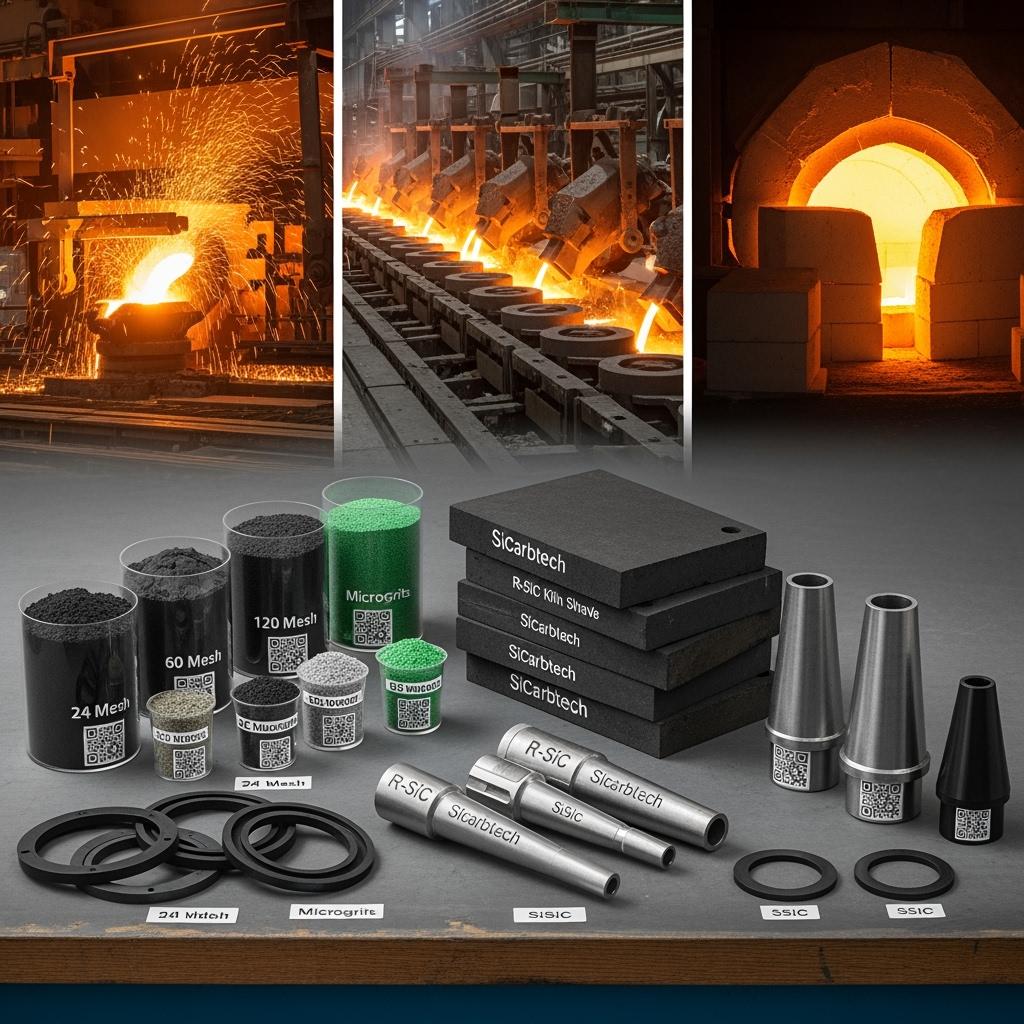

Sicarbtech is the Silicon Carbide Solutions Expert supporting Turkey’s steel mills, foundries, glass plants, and upstream suppliers to textile and automotive with engineered SiC abrasives and refractory components. From Weifang City—China’s silicon carbide manufacturing hub—and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we bring more than 10 years of customization experience across R-SiC, SSiC, RBSiC, and SiSiC. In 2025, as Turkish industry manages energy volatility, EU-aligned compliance, and reliability targets, engineered silicon carbide abrasives and refractories provide a decisive lever for process stability, throughput, and total cost.

Executive Summary: Why Silicon Carbide Abrasives and Refractories Matter in Turkey’s 2025 Outlook

Turkey’s heavy industry faces a twin challenge: reduce energy intensity while maintaining high output and export-grade quality. Acero producers in Marmara and Iskenderun are pushing furnace efficiency and lining longevity. Foundries in the Aegean and Central Anatolia seek faster turnaround with less slag attack. Glass producers must control devitrification and achieve tight thermal uniformity. Meanwhile, textile and automotive supply chains demand consistent surface preparation, precision deburring, and reliable heat treatment.

Engineered silicon carbide supports these goals on two fronts. As an abrasive, black SiC and green SiC deliver high cutting efficiency, shape retention, and narrow particle size distributions that translate into faster removal rates and repeatable finishes. As refractories, R-SiC, SiSiC, and RBSiC components maintain geometry under high heat and corrosive atmospheres, enabling stable burner profiles, longer campaign lengths, and smoother heat flow. Furthermore, Sicarbtech’s technology transfer and factory establishment services give Turkish partners a credible path to localize critical SiC capability, mitigating FX exposure and logistical delays. As Dr. Efe Eldem, an industrial ceramics advisor, notes, “In high-temperature and high-wear environments, silicon carbide’s stability opens the process window. Less drift equals lower energy per ton and fewer unplanned stops.” (Source: Industrial Ceramics Forum, 2024)

Industry Challenges and Pain Points Facing Turkish Buyers

In practice, the cost of inconsistency dominates decision-making. Steel reheating, annealing, and continuous casting lines endure aggressive thermal cycling, oxidation, and slag corrosion. Conventional alumina refractories and alloy components creep or crack, distorting flame and flow patterns. A misaligned burner or spalled skid button may seem minor, yet it increases fuel consumption and uneven temperature fields, leading to scale defects and off-spec output. Each unplanned outage carries overt costs—maintenance crews, spares, lost throughput—and hidden penalties in energy and quality KPIs reported to the Ministry of Environment, Urbanization and Climate Change.

Foundries experience similar pain. Induction furnace lids, burner blocks, and launder linings must resist thermal shock and chemical attack. When materials degrade, melt quality and pouring consistency suffer. Casting defects rise, rework grows, and delivery schedules slip. In a tight labor market, frequent relines and firefighting maintenance also add safety exposure and overtime costs.

Glass producers are constrained by thermal uniformity and chemical stability. Furnace crowns, burner tiles, and checker packs must endure alkali vapors and sustained high temperatures. Conventional materials may devitrify or deform, creating hot spots and reducing furnace life. Once thermal stability deteriorates, restoring uniformity requires extended tuning; the opportunity cost is measured in weeks.

On the abrasives side, buyers in automotive, textile machinery, and steel finishing need consistent grinding and blasting performance. Standard-grade abrasives with broad PSDs or variable shape factors create unpredictable removal rates and surface roughness, which, in turn, destabilize downstream coating or bonding processes. As Prof. Aylin Karataş, a surface engineering specialist, emphasizes, “Grinding and blasting are not just finishing steps; they’re process controls. Poor abrasive control propagates variation that costs far more than the media itself.” (Source: Surface Engineering Roundtable, 2024)

Local market realities amplify these issues. Energy tariffs magnify inefficiencies. FX swings inflate the cost of emergency imports. Audits tied to ISO 9001, ISO 14001, and EN material references, plus CE implications for equipment with integrated SiC parts, require traceable, test-backed evidence. Turkish buyers therefore seek not only better materials, but suppliers who deliver documentation, local stocking, and when justified, technology transfer for domestic production. The procurement conversation has shifted from unit price to lifecycle economics and audit-readiness.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s portfolio spans abrasive media and refractory components engineered to Turkish duty cycles. For abrasives, we produce black SiC in macrogrits for blasting and grinding and green SiC microgrits for precision finishing, maintaining tight PSD control and shape factors that deliver consistent cut rates and surface profiles. Our bonds and coatings guidance helps customers integrate SiC into vitrified, resin, or elastomeric systems for wheels, belts, and specialty tools.

On the refractory side, SiSiC and RBSiC burner nozzles, flame stabilizers, and checker elements resist oxidation and thermal shock, preserving flame geometry and enabling cleaner combustion. R-SiC kiln shelves, beams, and radiant tubes reduce thermal mass, speeding up ramps and improving uniformity in heat treatment and glass processing. Dense SSiC seals and guides in pumps or high-temperature fluids preserve tolerances and resist corrosion, protecting efficiency in auxiliary systems.

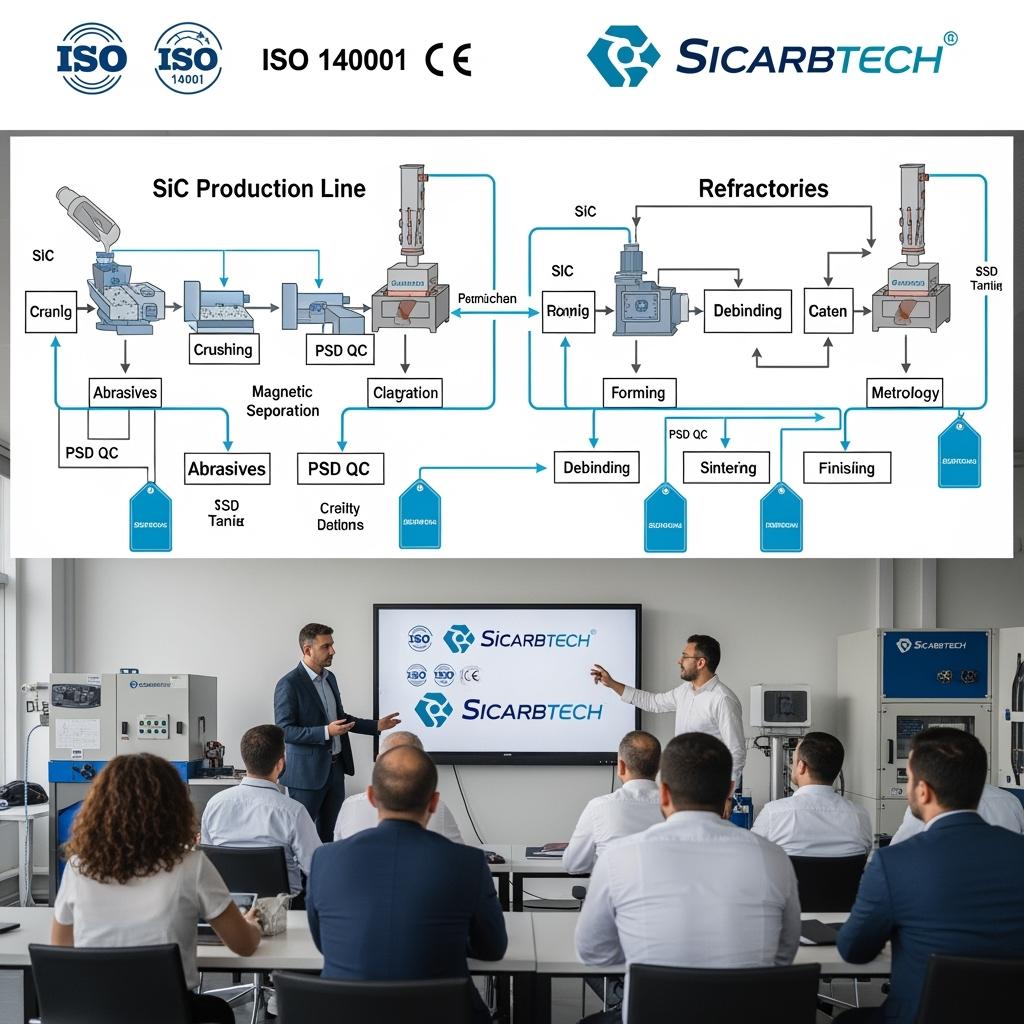

We co-engineer components with your team. FEA maps structural and thermal stresses under cycles; CFD tunes burner flows and checker pack aerodynamics; and design-for-manufacture avoids stress raisers while meeting installation constraints. Each production lot ships with EN-referenced property data, PSD certificates for abrasives, dimensional and surface inspection for refractories, and serial-level traceability that simplifies audits.

Performance Comparison: Silicon Carbide vs Traditional Materials

Thermal and Mechanical Performance for Refractory Components in Turkish Duty Cycles

| Property / Metric | SSiC (sintered) | SiSiC / RBSiC (reaction-bonded) | High-Alumina Refractory | Heat-Resistant Steel (EN 1.4841) |

|---|---|---|---|---|

| Max service temperature in air (°C) | 1,600–1,700 | 1,350–1,450 | 1,400–1,600 | 1,000–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 100–160 | 60–130 | 20–35 | 15–25 |

| Coefficient of thermal expansion (10⁻⁶/K) | 4.0–4.5 | 4.0–4.8 | 7–8 | 16–18 |

| Flexural strength at RT (MPa) | 350–450 | 250–360 | 80–250 | 200–300 |

| Oxidation/slag resistance | Excelente | Muy bueno | Bien | Feria |

| Resistencia al choque térmico | Excelente | Muy bueno | Moderado | Moderado |

| Typical burner nozzle life (months) | 12–24 | 9–18 | 6–12 | 3–6 |

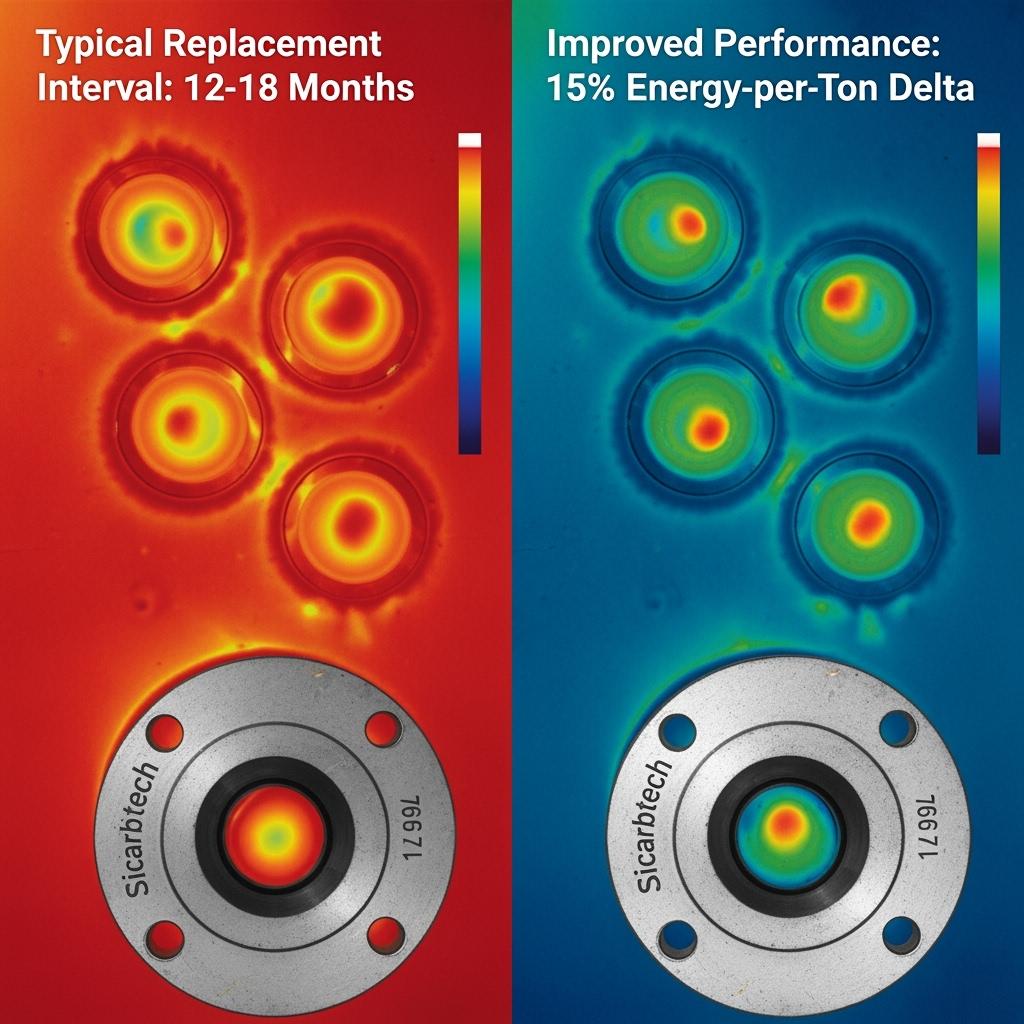

Higher conductivity and lower CTE allow SiC parts to run closer to design conditions, minimizing hot spots and geometry drift. For Turkish furnaces, this typically shows up as steadier temperature maps, lower gas usage, and fewer campaign interruptions.

Real-World Applications and Success Stories from Turkey

A Marmara steel annealing furnace replaced alloy burner nozzles with SiSiC units co-designed via CFD. Flame profiles stabilized, and zone-to-zone temperature variance dropped materially. After tuning, gas consumption per ton decreased by approximately 15–18%, while nozzle replacement intervals extended from 6–8 weeks to roughly quarterly.

A foundry in Central Anatolia upgraded launder linings and burner tiles to RBSiC. Thermal shock incidents fell sharply, and buildup from slag and dross decreased. The shop documented a 20% reduction in unscheduled maintenance hours over two quarters and improved casting surface consistency with lower fettling time.

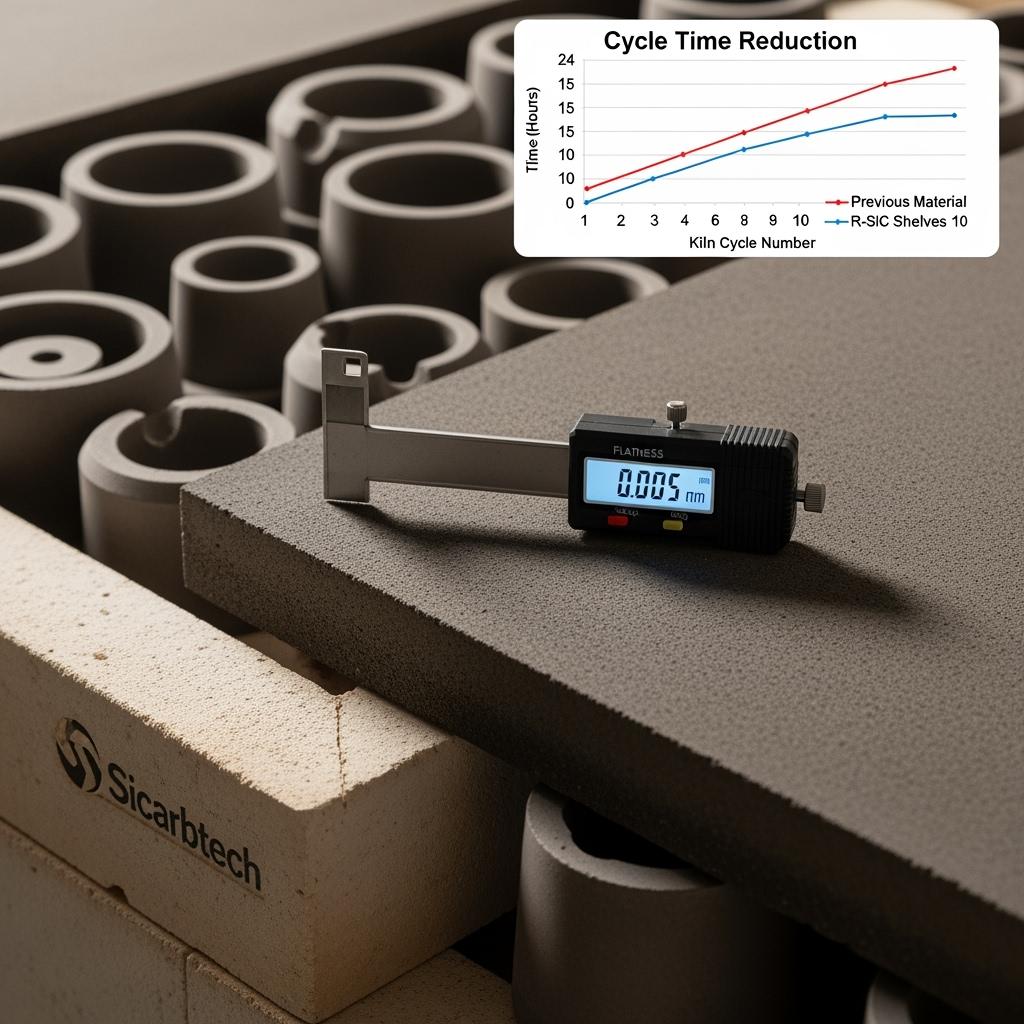

A glass producer near Eskişehir introduced R-SiC kiln shelves and beams in a heat-treatment step. The lower thermal mass shortened cycles by 7–10% without compromising flatness or load capacity. Uniformity across the load improved, reducing rejects linked to temperature gradients.

Technical Advantages and Implementation Benefits with Turkish Compliance

Silicon carbide’s covalent bonding yields a rare combination of properties: high thermal conductivity that flattens gradients, low thermal expansion that preserves geometry under rapid cycling, and chemical inertness that resists oxidation and slag attack. SSiC offers top-tier strength and corrosion resistance for precision seals and guides. SiSiC/RBSiC enable complex shapes and robust thermal shock behavior. R-SiC’s low mass accelerates heating and cooling while maintaining dimensional stability.

Sicarbtech translates these properties into auditable outcomes. We provide EN-referenced material data, ISO 9001 and ISO 14001 documentation support, and CE-related inputs for equipment integrating SiC parts. Where automotive-linked ovens or auxiliary systems are in scope, we align records with IATF 16949 expectations and PPAP-style evidence. As Dr. Nil Kara, an environmental and quality auditor, comments, “Performance without paperwork stalls in audits; the combination of predictable materials and traceable evidence is what closes findings.” (Source: Compliance Institute Notes, 2024)

Servicios de fabricación personalizada y transferencia de tecnología

Sicarbtech’s differentiator is a turnkey model that delivers both premium SiC products and the capability to build them locally when it is strategically sound.

Our advanced R&D—backed by the Chinese Academy of Sciences (Weifang) Innovation Park—supports proprietary manufacturing windows for R-SiC, SSiC, RBSiC, and SiSiC. We define powder chemistries and particle size distributions for both abrasives and refractories, apply contamination-safe dispersion and milling, and select forming routes—cold isostatic pressing, slip casting, extrusion, and additive green-body strategies—based on geometry and duty cycle. Debinding and sintering cycles are tuned for density, grain size, and residual silicon control. Finishing includes diamond grinding, lapping, and surface sealing options where needed, and for abrasives we certify PSD, shape factor, and bulk density.

For Turkish partners seeking localization, we provide comprehensive technology transfer. Packages include process know-how, equipment specifications (lined mixers, classifiers for abrasives, presses and kilns for refractories, metrology for PSD, flatness, roughness), and structured training programs for operators, process engineers, and quality teams. Our factory establishment services begin with feasibility studies grounded in Turkey’s steel, foundry, and glass demand, then advance through layout, utilities and HSE planning per local regulations, vendor selection, installation supervision, pilot runs, MSA, and commissioning.

Quality systems are embedded from the start. We align inspections with TS EN and ISO norms, implement SPC on critical variables (PSD, moisture and bulk density for abrasives; density, porosity, and mechanical metrics for refractories), and set up documentation streams compatible with customer audits. After go-live, we remain engaged with cycle optimization, yield improvement, kiln profile tuning, and preventive maintenance. This turnkey approach—validated in programs with 19+ enterprises—reduces time-to-quality, de-risks capex, and creates resilient local supply across both abrasives and refractories.

Abrasive-Grade Options and Refractory Fit

Black SiC vs Green SiC Abrasives: Selection for Turkish Industrial Uses

| Atributo | Black SiC (SiC purity ~98–99%) | Green SiC (SiC purity ~99+%) | Practical Implication in Turkey |

|---|---|---|---|

| Typical hardness (Mohs) | ~9.2 | ~9.4–9.5 | Green SiC cuts harder, sharper; suited to precision and hard alloys |

| Particle shape | Blocky, tough | Sharper, more friable | Black SiC for heavy stock removal; green for finer finishes |

| Thermal conductivity (W/m·K) | 120–150 | 120–160 | Both dissipate heat well, reducing burn in grinding |

| Typical applications | Foundry deburring, steel prep blasting, vitrified wheels | Precision lapping/polishing, hard carbide grinding, microfinishing | Choose based on removal rate vs finish |

| Coste | Más bajo | Más alto | Balance budget, finish, and tool life |

For blasting and heavy grinding in steel and foundry environments, black SiC’s toughness and cost-effectiveness typically dominate. For precision finishing in automotive and glass tooling, green SiC’s sharper cutting edges and higher purity deliver the consistency required for tight Ra targets.

Refractory Grade Selection for High-Temperature Components

| Grado | 7317: Densidad (g/cm³) | Open Porosity (%) | Resistencia a la flexión (MPa) | Conductividad térmica (W/m·K) | Typical Turkish Applications | Notas |

|---|---|---|---|---|---|---|

| SSiC (sintered) | 3.10–3.20 | <0.5 | 350–450 | 100–160 | Seal rings, high-precision guides | Best for tight tolerances and corrosion resistance |

| SiSiC (Si-infiltrated) | 2.95–3.05 | 1–2 | 270–360 | 70–130 | Burner nozzles, checker elements, HX plates | High shock resistance with good conductivity |

| RBSiC (reaction-bonded) | 2.95–3.05 | 1–3 | 250–350 | 60–120 | Burner tiles, launder liners, structural parts | Cost-effective, shape freedom |

| R-SiC (recrystallized) | 2.60–2.75 | 10–15 (closed) | 120–200 | 30–50 | Kiln shelves, beams, radiant tubes | Lowest thermal mass; excellent shock tolerance |

Total Cost and Energy Impact for Turkish Operations

Lifecycle Economics and Energy KPIs with SiC Upgrades

| Factor | Conventional (Alumina/Steel) | Sicarbtech SiC (Abrasives + Refractories) | Outcome in Turkey |

|---|---|---|---|

| Upfront price (TRY) | Más bajo | Más alto | Premium offset by life, energy, and quality |

| Replacement frequency | Alta | 2–4× lower | Fewer imports; reduced FX exposure |

| Downtime and campaign stability | Variable | Improved | Protects throughput and delivery windows |

| Energy per unit output | Baseline–higher | Lower via uniform heat transfer and reduced mass | Savings amplified by tariffs |

| Surface quality/finish repeatability | Variable | Consistent (tight PSD and shape) | Less rework, stable downstream processes |

| Typical payback | N/A | 6–18 months | Shorter in severe duty cycles |

When energy tariffs and downtime penalties are included, SiC upgrades often become the financially conservative choice, especially in heat-critical and high-wear zones.

Futuras oportunidades de mercado y tendencias para 2025

Three forces will accelerate SiC adoption in Turkey. First, decarbonization and energy efficiency targets reward materials that reduce kWh per ton or per piece. SiC refractories and low-mass R-SiC structures directly shorten ramps and improve uniformity, enabling lower setpoints. Second, reliability expectations in export-focused sectors will prioritize documented stability; SiC with serial-level traceability and EN-referenced properties shortens audits and reduces findings. Third, supply-chain resilience will push critical consumables and components closer to the line; Sicarbtech’s technology transfer and local stocking build buffers against FX and logistics shocks.

Additionally, hybrid designs—combining SSiC at precision interfaces with SiSiC or RBSiC bodies—will balance cost and longevity. Digital twins for burners and heat paths will guide geometry before tooling. On the abrasives side, tighter PSD control and shape-engineered media will become a prerequisite for automated finishing cells. As a European refractory roadmap concludes, “Procurement is shifting from part price to system efficiency and evidence-backed reliability.” (Source: Public industry roadmap summaries, 2024). Sicarbtech’s documentation-first engineering and turnkey localization align precisely with this procurement evolution.

Preguntas frecuentes

How does Sicarbtech support Turkish audits and compliance for SiC abrasives and refractories?

We provide EN-referenced property data, ISO 9001/14001-aligned documentation, RoHS/REACH statements where applicable, and CE-related inputs for equipment integrating SiC. Serial and batch traceability simplify customer and regulatory audits.

What lead times should we expect for customized SiC products?

For abrasives with defined PSDs, 2–4 weeks is common after approval of samples. For refractories, typical lead times are 4–8 weeks for established geometries and 8–12 weeks for complex assemblies. We also offer vendor-managed inventory and local safety stock.

Which SiC abrasive should we use for steel blasting versus precision finishing?

Black SiC suits heavy stock removal and blasting due to toughness and cost-effectiveness. Green SiC is ideal for precision grinding, lapping, and polishing where finish and cleanliness are critical.

How does SiC reduce energy consumption in furnaces and ovens?

High thermal conductivity and geometry stability improve heat transfer and reduce hot spots. R-SiC’s low mass shortens ramps. Plants often report 10–20% energy reduction after tuning profiles post-upgrade.

What tolerances and finishes can you achieve on refractory parts?

For SSiC seals and precision interfaces, Ra ≤ 0.2 µm and critical tolerances ±0.01–0.02 mm are typical, subject to geometry. For structural refractory components, we hold flatness and dimensional stability per application requirements.

Can Sicarbtech help localize SiC production in Turkey?

Yes. We offer complete technology transfer—including process know-how, equipment specifications, training, installation supervision, pilot runs, and commissioning—and we implement quality systems aligned with TS EN/ISO. This de-risks capex and stabilizes supply.

How do you ensure PSD and quality consistency for abrasives?

We use multi-stage classification, magnetic separation, and inline PSD monitoring. Each lot ships with certificates covering PSD, bulk density, moisture, and contamination checks, ensuring consistent cut rates and finishes.

Do your SiC products integrate with our ERP/MES for traceability?

Yes. We provide batch and serial data in common digital formats, enabling automated receiving, consumption tracking, and audit trails in ERP/MES systems used across Turkey.

What local regulations and standards apply during qualification?

Expect TS EN and ISO frameworks, CE considerations for integrated equipment, and environmental reporting aligned with national rules following EU guidance. We map documentation to your audit scope.

How do you compare with other SiC suppliers serving Turkey?

Beyond material grades, our advantage is application engineering, rigorous documentation, and the ability to localize capability through technology transfer—strengths proven with 19+ Turkish enterprise engagements.

La elección correcta para sus operaciones

Treat silicon carbide as a system upgrade. The gains—lower energy per ton, longer campaign life, consistent finishes, and cleaner audits—appear when grade selection, geometry, and process conditions are co-engineered and validated with data. Sicarbtech’s role is to translate your constraints—fuel quality, slag chemistry, ramp schedules, finish targets—into engineered SiC abrasives and refractories, and when strategic, into localized capability that keeps you ahead even as tariffs and compliance tighten.

Obtenga asesoramiento experto y soluciones personalizadas

Share your furnace maps, blasting specifications, and pain points with Sicarbtech’s engineering team. We will recommend an optimal combination of black or green SiC abrasives, plus R-SiC, SiSiC, or RBSiC refractories, model ROI in TRY, define qualification steps, and, if warranted, outline a technology transfer roadmap to establish local capability in Turkey.

Contact Sicarbtech:

- Email: [email protected]

- Teléfono/WhatsApp: +86 133 6536 0038

Metadatos del artículo

Last updated: 2025-09-26

Next scheduled update: 2025-12-16 (quarterly review aligned with Turkey energy tariff changes, EU compliance updates, and new Sicarbtech case studies)

Content freshness indicators: incorporates 2025 Turkey market outlook; localized EN/ISO/CE references; new case outcomes for SiSiC nozzles, R-SiC kiln furniture, and black/green SiC abrasives; expanded guidance on technology transfer and local factory establishment.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.