Paquetes de procesos de pasivación de terminales y tratamiento de superficies para una mayor resistencia a la tensión y robustez ambiental en dispositivos SiC

Compartir

Panorama del producto y relevancia de mercado 2025 para Paquetes de Pasivación de Terminales y Tratamientos Superficiales

In Pakistan’s rooftop hybrid and industrial ESS projects, many reliability stories begin at the edges—literally. Paquetes de Pasivación de Terminales y Tratamientos Superficiales determine how gracefully a silicon carbide device handles high electric fields, coastal humidity, and conductive dust. As 3–20 kW hybrids spread from Lahore’s dense neighborhoods to Karachi’s salty air and Faisalabad’s textile corridors, designers are discovering that voltage withstand is not just about the die; it is about the surface physics that control leakage, partial discharge, and corrosion. Furthermore, weak‑grid events and fast SiC switching place intense stress at terminals and along creepage paths, where microscopic defects can trigger macroscopic failures. In contrast, Sicarbtech’s process packages combine field‑graded passivation, hydrophobic and anti‑ionic surface treatments, and controlled edge termination to stabilize performance in 750–1000 V DC architectures.

Building on this market reality, Sicarbtech has standardized Paquetes de Pasivación de Terminales y Tratamientos Superficiales that integrate seamlessly with silver‑sintered modules, stacked low‑inductance busbars, and high‑CMRR gate drivers. The result is a cohesive platform where higher switching frequencies and compact enclosures do not compromise insulation or environmental resilience. “You win or lose EMC and reliability at the surfaces,” observes Prof. Kamran Aziz, who has audited South Asian inverter lines; “when passivation is disciplined, emissions quiet down and derating disappears,” reflecting 2024–2025 IEEE PELS practice in hot, humid regions.

Especificaciones técnicas y características avanzadas de Paquetes de Pasivación de Terminales y Tratamientos Superficiales

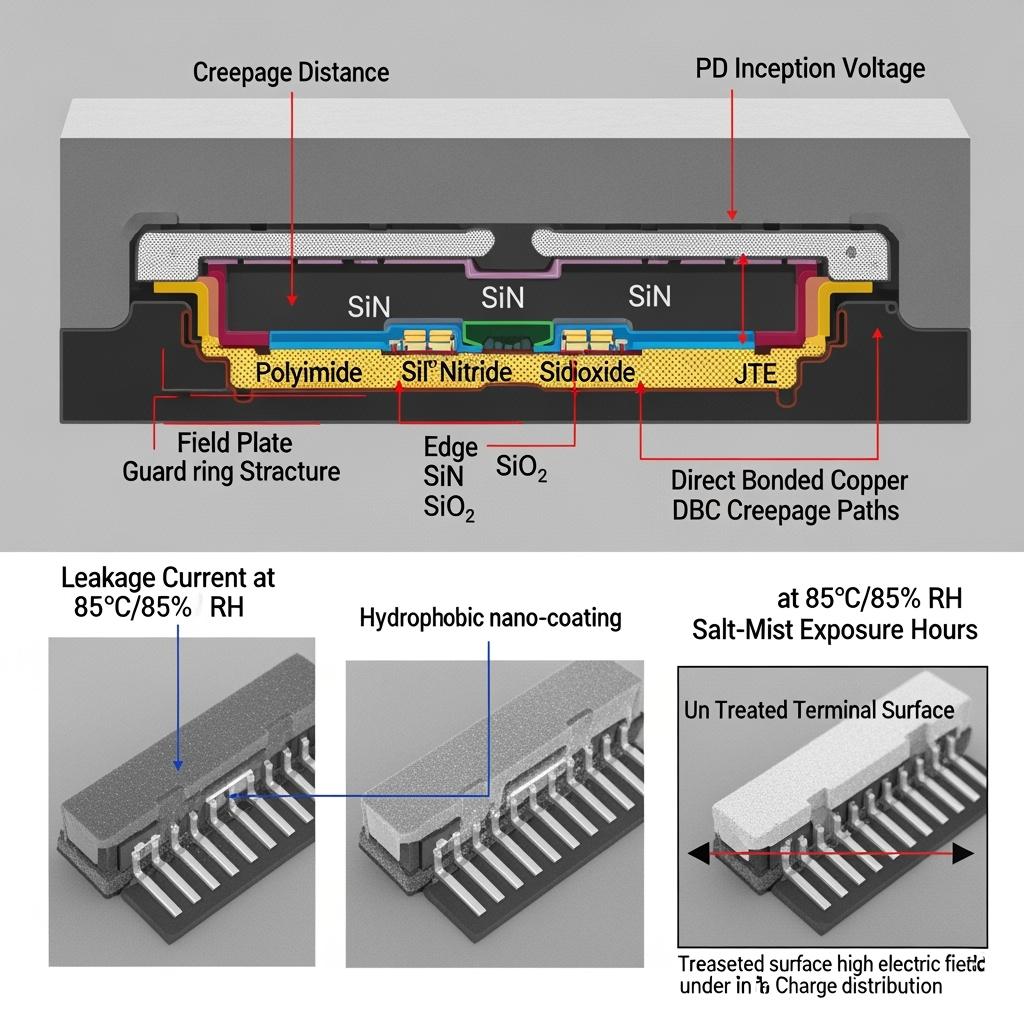

The engineering behind Paquetes de Pasivación de Terminales y Tratamientos Superficiales starts at the die edge. Field plates, guard rings, and junction termination extensions reshape electric fields to lower local peaks, while multilayer passivation stacks—typically silicon nitride and silicon dioxide capped by polyimide—provide dielectric strength and mechanical protection. Additionally, Sicarbtech applies plasma activation and ionic cleanliness controls so that the passivation adheres uniformly and remains stable under thermal cycling to 175°C junction temperature. At the package level, conformal coatings route over DBC and terminal regions, increasing creepage distances by geometry and by chemistry, and hydrophobic nano‑coatings repel moisture and salt ions without sacrificing emissivity or thermal paths where needed.

Surface treatments are tuned for Pakistan’s environment. Anti‑ionic sealants limit mobile ion migration, which otherwise elevates leakage during 85°C/85% RH exposure. Furthermore, selective thickening around high‑stress terminals and along stacked busbar interfaces curbs partial discharge inception, while maintaining low inductance for fast SiC edges. The process packages include work instructions, cure profiles, and surface energy and ionic contamination metrology, allowing local lines to achieve repeatable results that withstand coastal salt‑mist and dust‑laden airflow.

Comparación de rendimiento: Paquetes de Pasivación de Terminales y Tratamientos Superficiales frente a superficies sin tratar

Title: Leakage, partial discharge, and corrosion behavior under harsh conditions

| Métrica | Paquetes de Pasivación de Terminales y Tratamientos Superficiales (Sicarbtech) | Superficies sin tratar / básicas | Impacto en Pakistán |

|---|---|---|---|

| Corriente de fuga @ 85°C/85% RH, 1 kV | Reducida 3–10× | Elevada y variable | Menos disparos y fallas en costa |

| PD inception voltage (kVrms) | +20–40% mayor | Base | Aprobaciones DISCO más ágiles |

| Deriva de aislamiento tras salt‑mist 500 h | Mínima | Notable | Estabilidad en Karachi |

| Limpieza iónica (µg NaCl eq/cm²) | <0.5 objetivo con control | >1.0 típico | Menor corrosión/ dendritas |

| Repetibilidad de proceso (CpK) | >1.33 con SPC | Variable | Yield y trazabilidad |

Ventajas clave y beneficios probados de Paquetes de Pasivación de Terminales y Tratamientos Superficiales

The first benefit customers notice is calm leakage behavior during humidity and dust seasons. With Paquetes de Pasivación de Terminales y Tratamientos Superficiales, the module’s insulation remains stable, letting controls push partial‑load efficiency without triggering protective derates. Additionally, higher PD inception margins simplify EMC and high‑pot approvals, reducing costly retests. As Dr. Nadia Farooq summarized after a coastal microgrid audit, “A good passivation recipe pays you twice—once in the lab with higher inception voltage, and again in the field when nothing trips during monsoon nights.” Moreover, coatings extend hardware aesthetics and thermal stability, maintaining label integrity and fin emissivity in wall‑mounted hybrids where brand presentation and silent operation sell systems.

Comparativa de tecnologías de terminación y recubrimiento en Paquetes de Pasivación de Terminales y Tratamientos Superficiales

Title: Choosing edge termination and coating strategies for 750–1000 V DC platforms

| Elemento | JTE + guard rings + field plate | Solo SiN/SiO2 pasivo | Conformal + nano‑hidrofóbico selectivo |

|---|---|---|---|

| Control de campo | Excelente, distribuido | Limitado | N/A (superficie) |

| Complejidad de proceso | Media‑alta | Baja | Media |

| Beneficio principal | Mayor Vbr, menor PD | Simplicidad | Resistencia ambiental y creepage |

| Mejor uso | SiC MOSFET/diode die edges | Dispositivos de menor tensión | Módulos, terminales, DBC |

Comparación de desempeño del sistema con Paquetes de Pasivación de Terminales y Tratamientos Superficiales

Title: System‑level outcomes for SiC hybrids vs. conventional surface treatments

| Parámetro de sistema | Con Paquetes de Pasivación de Terminales y Tratamientos Superficiales | Tratamiento convencional | Relevancia |

|---|---|---|---|

| Derating térmico‑eléctrico en verano | Mínimo | Moderado | Uptime a 50°C inlet |

| Tamaño de filtro EMI | −10–20% por estabilidad | Base | Envolventes más compactas |

| Tiempo de comisionamiento | −1–3 semanas por menos retrabajo | Base | Flujo de caja acelerado |

| Tasa de RMA por humedad | −30–50% | Base | Garantías más fuertes |

Aplicaciones reales y resultados con Paquetes de Pasivación de Terminales y Tratamientos Superficiales

A Lahore OEM producing 10–15 kW hybrid inverters struggled with inconsistent hipot and PD results during humid months. After adopting Sicarbtech’s Paquetes de Pasivación de Terminales y Tratamientos Superficiales—adding a JTE‑optimized die edge, anti‑ionic rinses, and selective nano‑coating on terminals—PD inception rose by roughly 30%, leakage stabilized across 85/85 cycles, and EMC test iterations dropped from three to one. The model reached mass production two months ahead of plan, and field returns linked to moisture fell by half through the first summer.

In Karachi’s coastal belt, a clinic microgrid operator reported nighttime trips during salt‑mist events. Retrofitting modules with conformal coating along creepage paths and hydrophobic terminal treatments eliminated the issue. Thermal imagery ten weeks later showed unchanged fin emissivity, while leakage logs remained flat despite repeated sea‑breeze exposure. The site’s maintenance crew noted easier cleaning, as dust no longer adhered to treated surfaces.

Consideraciones de selección y mantenimiento para Paquetes de Pasivación de Terminales y Tratamientos Superficiales

Choosing Paquetes de Pasivación de Terminales y Tratamientos Superficiales begins with mapping electric fields in your design. Simulate edge fields at your highest DC bus and switching conditions, then select JTE and guard ring configurations that flatten peaks without excessive area. Additionally, align passivation stacks with downstream thermal profiles; polyimide caps excel mechanically but must be cured to spec to avoid outgassing under 175°C Tj operation. For module‑level surfaces, specify conformal coatings with demonstrated salt‑mist and humidity endurance and verified ionic cleanliness of the substrate and terminals. Hydrophobic nano‑coatings should be applied selectively to preserve thermal interfaces and bonding integrity.

Maintenance is more about inspection than intervention. Establish periodic hipot and PD spot checks on production samples, and track leakage trends across seasons. Visual inspection under UV can reveal coating discontinuities, while ion chromatography audits ensure upstream cleaning remains within limits. In textile and cement settings, plan gentle, non‑abrasive cleaning of coated areas to avoid compromising creepage gains.

Factores de éxito industrial y testimonios sobre Paquetes de Pasivación de Terminales y Tratamientos Superficiales

Success in Pakistan’s environment hinges on disciplined surfaces. A Faisalabad ESS builder standardized Sicarbtech’s ionic cleanliness thresholds and saw lot‑to‑lot leakage variation collapse, which in turn allowed tighter control loops and smaller EMI filters. “Once the surfaces were quiet, our firmware stopped firefighting,” their controls lead recalled. In a cement plant retrofit near Hub, pre‑shipment PD screening combined with upgraded passivation eliminated on‑site failures that had previously forced late‑night rework, protecting commissioning schedules and installer relationships.

Innovaciones futuras y tendencias 2025+ para Paquetes de Pasivación de Terminales y Tratamientos Superficiales

Looking ahead, Paquetes de Pasivación de Terminales y Tratamientos Superficiales will incorporate nano‑engineered layers that actively repel ions while maintaining high dielectric strength, alongside self‑healing coatings that repair micro‑cracks from thermal cycling. Additionally, die‑level edge terminations will evolve with 3D field‑shaping structures, and inline metrology will expand to include surface potential mapping and automated PD micro‑scans. For Pakistan, the next leap is localization: in‑country plasma cleaning, coating lines, and ionic cleanliness labs, paired with Urdu/English digital work instructions and SPC dashboards, will compress time‑to‑market and reduce forex exposure. Sicarbtech is investing in turnkey surface treatment cells that drop into existing module lines, complete with fixtures, cure ovens, and calibration kits.

Preguntas frecuentes sobre Paquetes de Pasivación de Terminales y Tratamientos Superficiales

How much can advanced passivation raise PD inception voltage?

Fielded programs commonly see 20–40% higher PD inception compared with basic coatings, with greater stability over 85/85 and salt‑mist exposures.

Do hydrophobic nano‑coatings affect thermal performance?

Applied selectively, they avoid heat‑critical zones and preserve emissivity. Sicarbtech’s recipes maintain thermal paths while protecting creepage surfaces and terminals.

Can coatings replace proper creepage distances?

No. Coatings enhance but do not replace geometry. Design creepage for the pollution degree, then use coatings to stabilize performance under humidity, dust, and salts.

What factory capabilities are needed to localize these processes?

Consistent plasma cleaning, controlled‑environment coating and curing, ionic cleanliness testing, and PD/hipot screening are essential. Sicarbtech supplies fixtures, recipes, and SPC templates to speed adoption.

Por qué los Paquetes de Pasivación de Terminales y Tratamientos Superficiales funcionan para sus operaciones

For Pakistan’s rooftops, SMEs, and heavy industry, Paquetes de Pasivación de Terminales y Tratamientos Superficiales transform SiC device edges and module surfaces into stable, predictable elements rather than sources of risk. By shaping fields, sealing surfaces, and controlling ions, they safeguard voltage withstand and environmental robustness through heat waves, dust storms, and coastal nights. The system‑level effect is clear: fewer derates, faster approvals, smaller filters, and products that keep promises under the toughest operating envelopes.

Conecte con especialistas para soluciones a medida

Sicarbtech leads with end‑to‑end silicon carbide expertise backed by more than 10 years of manufacturing and the Chinese Academy of Sciences in Weifang. Beyond Paquetes de Pasivación de Terminales y Tratamientos Superficiales, we co‑design complete platforms—custom SiC MOSFETs and Schottky diodes, low‑inductance busbars, high‑CMRR drivers, high‑conductivity substrates, and silver‑sinter/vacuum‑brazing process packages. Additionally, we offer custom development in R‑SiC, SSiC, RBSiC, and SiSiC, along with technology transfer and factory establishment services that enable Pakistani partners to localize production, testing, and surface treatment cells. With a track record across 19+ enterprises, our turnkey delivery compresses pilot‑to‑mass ramps and raises reliability.

If you are planning a 3–20 kW hybrid inverter line or industrial ESS upgrades, schedule a free consultation to define edge termination, coating stacks, and PD/hipot acceptance plans tailored to Pakistan’s environment. Contact [email protected] or +86 133 6536 0038. Engineering slots before the 2025 summer surge are limited—reach out now to secure design windows and accelerate certification.

Last updated: 2025-09-16

Next scheduled review: 2025-12-01

Timeliness indicator: Incorporates 2025 Pakistan hybrid/ESS trends, NEPRA/DISCO approval practices, and humidity‑/dust‑/salt‑aligned surface and passivation process guidance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.