Diodos Schottky de alta potencia de carburo de silicio para conmutación rápida y rectificación de baja pérdida en HVDC y SMPS

Compartir

Visión general del producto y relevancia para el mercado en 2025

Silicon carbide (SiC) high-power Schottky diodes deliver ultra-fast, low-loss rectification for high-voltage DC (HVDC) links, industrial switch-mode power supplies (SMPS), active front ends, and high-power rectifiers deployed across Pakistan’s textile, cement, steel, and emerging industrial sectors. Built on wide bandgap material with negligible reverse recovery, these devices reduce switching losses dramatically versus silicon diodes, enabling system efficiencies above 98%, compact magnetics, and cooler operation under continuous high-current duty.

In 2025, plants in Punjab and Sindh are accelerating modernization to counter grid instability, rising electricity tariffs, and thermal constraints within crowded motor control centers. SiC Schottky devices rated at ≥1700 V support fast-switching rectification at 20–50 kHz, lowering conduction and switching losses while maintaining high-temperature stability up to 175°C junction. Outcomes include 10%–15% annual energy savings, 30%–40% reductions in cooling hardware, and >50% lower failure rates in high-temperature, high-dust environments such as cement kilns and siderúrgico melt shops. These diodes integrate into multi-pulse rectifier bridges, AFE topologies, and high-frequency SMPS stages, with documentation aligned to IEC 62477-1 (safety), IEC 61000 (EMC), and IEC 60747 (semiconductor devices) to streamline acceptance in local plants.

Especificaciones técnicas y funciones avanzadas

- Características eléctricas

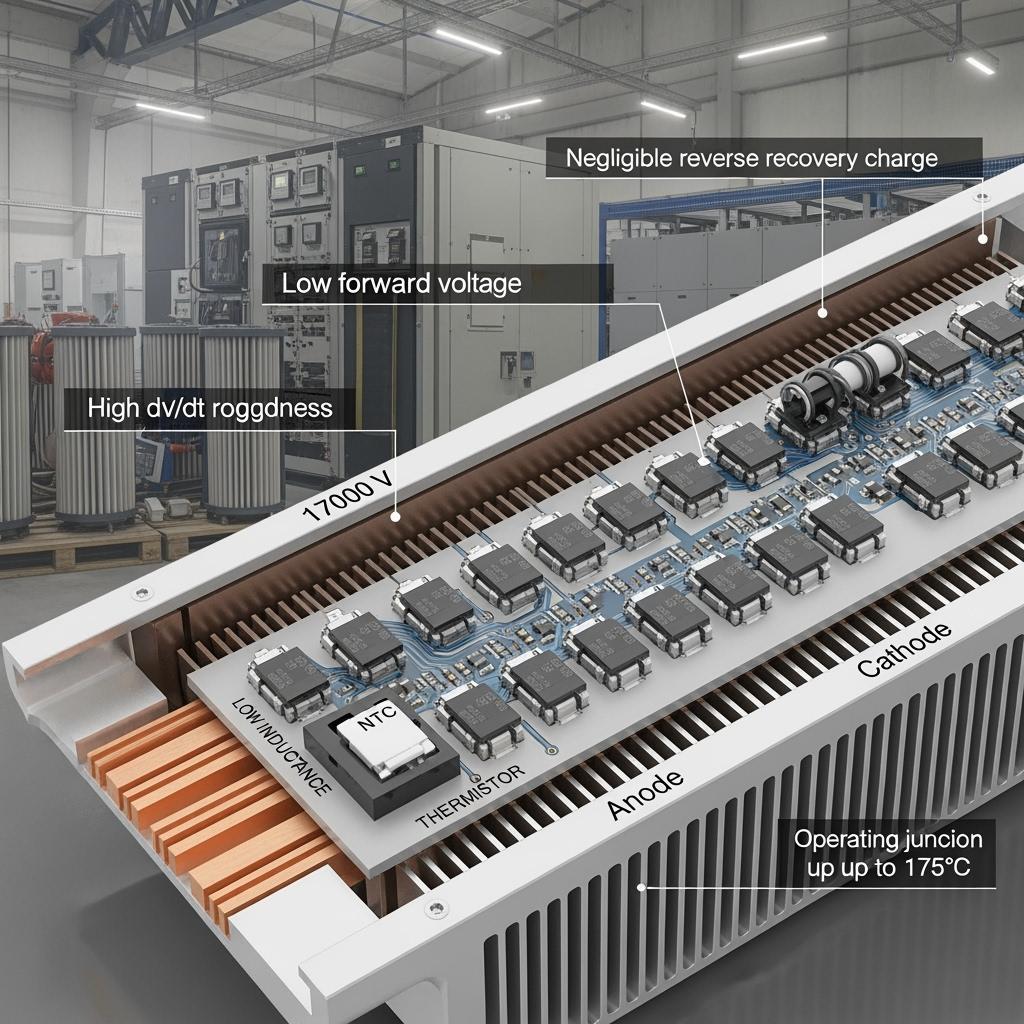

- Voltage class: ≥1200 V and ≥1700 V options for HVDC and high-voltage rectifiers

- Current ratings: From tens to several hundred amperes per diode/module; parallelable for kA-class rectifiers

- Reverse recovery: Virtually zero reverse recovery charge (Qrr≈0), enabling fast switching at 20–50 kHz

- Forward voltage: Low Vf with stable temperature behavior; reduced conduction loss at operating current

- Surge capability: High surge current tolerance with robust thermal paths and protection guidance

- Térmico y mecánico

- Rango de temperatura de unión: -55 °C a 175 °C

- Thermal resistance: <0.2°C/W at module level with high-thermal-conductivity ceramic substrates (AlN/Si3N4)

- Packaging: Low-inductance layouts to minimize EMI; IP54-ready enclosures with conformal coating for dust and humidity

- Cooling: Liquid cooling or optimized forced-air; 30%–40% reduction in cooling system size versus silicon

- Switching and integration

- Frequency operation: 20–50 kHz rectification and PFC stages

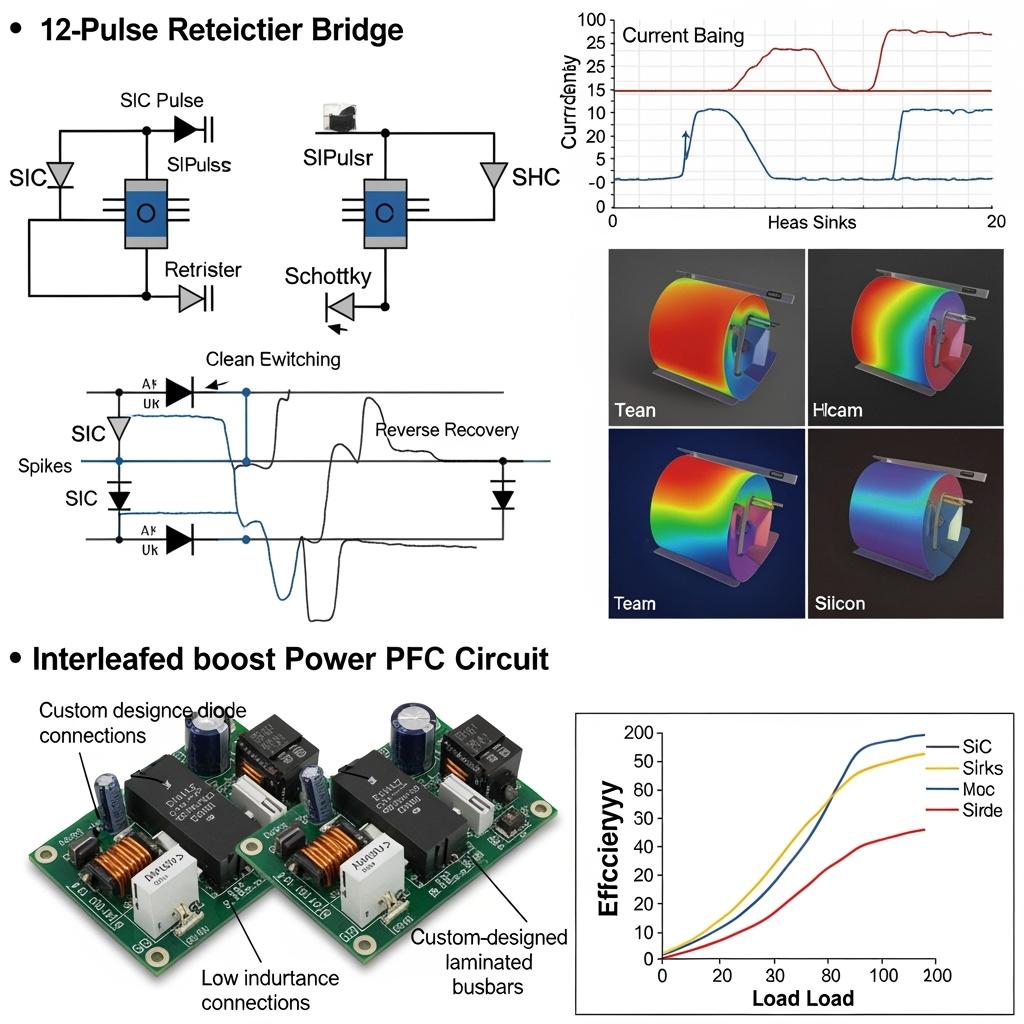

- Topologies supported: Multi-pulse rectifiers (6/12/24-pulse), boost PFC, interleaved SMPS, HVDC front ends

- Control compatibility: Works with modern gate-driven MOSFET/IGBT stages; reduces diode-related switching loss in bridge legs

- Compliance and documentation

- Standards: IEC 62477-1 safety, IEC 61000 EMC, IEC 60747 device data

- Plant integration: MODBUS TCP/OPC UA data capture via system controllers for ISO 50001 and ISO 14001 reporting

Performance Advantages in Industrial Rectification and SMPS

| System outcome | SiC High-Power Schottky Diodes | Traditional Silicon Fast-Recovery Diodes |

|---|---|---|

| Pérdidas de conmutación | Extremely low due to near-zero Qrr | High reverse recovery losses at kHz rates |

| Eficiencia | >98% chain efficiency achievable | 90%–94% typical in heavy-duty duty |

| Thermal footprint | 30%–40% smaller cooling systems | Disipadores de calor y flujo de aire más grandes |

| High-temperature operation | Junction up to 175°C with stable parameters | Menor margen térmico; es necesario el desclasamiento |

| Fiabilidad en polvo/calor | >50% de reducción en la tasa de fallos en entornos hostiles | Higher failure and maintenance frequency |

| Intervalo de mantenimiento | Una vez cada 2 años | Aproximadamente dos veces al año |

| Harmonic/EMI impact | Lower EMI due to soft recovery behavior | Higher di/dt spikes and EMI from recovery |

Ventajas clave y beneficios probados con la opinión de expertos

- Ultra-fast rectification: Negligible reverse recovery eliminates diode-induced turn-off losses in companion switches, enabling higher switching frequencies and smaller magnetics.

- Energy savings and OPEX reduction: 10%–15% annual energy savings via lower conduction and switching losses, with >98% rectification efficiency sustained.

- High-temperature resilience: 175°C junction capability supports continuous duty in hot, dust-laden environments with reduced derating.

- Simplified thermal design: Lower heat generation reduces cooling plant size, cabinet HVAC load, and total system weight.

Cita de un experto:

“SiC Schottky diodes virtually eliminate reverse recovery, drastically cutting switching losses and enabling compact, high-efficiency power conversion across industrial voltage classes.” — IEEE Power Electronics Magazine, Wide Bandgap Devices in High-Power Rectifiers (2023)

Referencia de autoridad:

“By 2025, the shift to SiC in rectification and PFC stages is driven by system-level savings, improved reliability, and thermal headroom.” — Yole Group, Power SiC Market Monitor (2024)

Aplicaciones reales e historias de éxito mensurables

- Cement plant HV rectifiers and PFC stages

- Result: Efficiency uplift from 92.3% to 98.1% with SiC Schottky retrofits; cooling skid downsized by ~35%; uninterrupted 8,760-hour operation achieved in a Karachi clinker workshop with annual electricity savings exceeding 120,000 USD.

- Steel mill SMPS for drives and auxiliary systems

- Result: High-frequency operation (20–30 kHz) reduced passive size; improved line power factor via AFE/PFC; fewer heat-related trips during peak production.

- Textile mill distributed power supplies

- Result: Cabinet temperatures lowered; harmonic emissions reduced; denser cabinet layouts with stable operation under dust and humidity.

Selección y mantenimiento

- Voltage/current rating: Choose ≥1700 V class for HVDC and high-voltage rectifiers prevalent in steel and cement; size current with headroom for surge conditions.

- Thermal path design: Use high-thermal-conductivity ceramics and verified TIMs; validate Rth(j-c) and coolant flow for continuous duty.

- EMI and layout: Minimize loop inductance; pair with snubbers where necessary; ensure proper creepage/clearance for dust-prone sites.

- Protection: Coordinate surge suppression and inrush control; validate overcurrent and thermal shutdown settings at system level.

- Maintenance plan: 24-month checks on fasteners, TIM integrity, filter cleanliness/coolant quality, and verification of diode parameter drift (Vf, leakage).

Factores de éxito del sector y testimonios de clientes

- Success factors: Power-quality audits, accurate thermal modeling, EMI-aware PCB/busbar layouts, and harmonics compliance with AFE or multi-pulse strategies.

- Customer voice: “SiC Schottky diodes cut our rectifier losses and cooling complexity, delivering immediate energy savings and higher uptime.” — Electrical Manager, integrated steel producer in Punjab.

Innovaciones futuras y tendencias del mercado 2025+

- Higher-voltage expansion: Emerging 3.3 kV SiC diodes for medium-voltage rectifiers with fewer series components.

- Co-packaged power stages: Integration with SiC MOSFETs to reduce inductance and further improve switching efficiency.

- Smart monitoring: On-die temperature sensing and health telemetry to support predictive maintenance.

- Localization: Technology transfer and local module assembly/testing to shorten lead times and tailor products for Pakistan’s conditions.

Perspectivas de la industria:

“Efficiency improvements in rectification stages are central to industrial decarbonization, with SiC diodes playing a pivotal role in reducing conversion losses.” — International Energy Agency, Technology Perspectives (2024)

Preguntas frecuentes y respuestas de expertos

- How do SiC Schottky diodes improve efficiency versus silicon fast diodes?

- Near-zero reverse recovery eliminates significant switching losses, allowing higher frequency and smaller passives while maintaining >98% efficiency.

- Are SiC diodes suitable for harsh, dusty environments?

- Yes. With high-temperature capability and ceramic substrates, modules maintain performance in heat and dust when paired with IP54+ enclosures and proper filtration.

- What is the recommended switching frequency range?

- 20–50 kHz for industrial rectification and SMPS, balancing EMI, magnetics size, and thermal performance.

- Can they retrofit into existing rectifier bridges?

- Yes. Mechanical/electrical adapter kits and low-inductance busbar designs enable drop-in replacement with minimal cabinet changes.

- What standards and documentation are provided?

- IEC 62477-1 safety alignment, IEC 61000 EMC-friendly design notes, IEC 60747 device datasheets, and acceptance test guides supporting ISO 50001/14001.

Por qué esta solución es adecuada para sus operaciones

SiC high-power Schottky diodes deliver fast, low-loss rectification that sustains >98% efficiency in Pakistan’s heavy-duty industrial applications. Their high-temperature resilience, negligible reverse recovery, and compact thermal footprint reduce OPEX, shrink cooling systems by 30%–40%, and improve uptime by cutting heat-related failures. They integrate seamlessly with existing rectifiers and SMPS, accelerating modernization and ensuring compliance with plant standards.

Conecte con especialistas para soluciones personalizadas

Accelerate your rectifier and SMPS upgrades with end-to-end SiC expertise and turnkey delivery.

- Más de 10 años de experiencia en la fabricación de SiC

- Respaldo e innovación de la Academia de Ciencias de China

- Desarrollo de productos personalizados en R-SiC, SSiC, RBSiC y SiSiC

- Servicios de transferencia de tecnología y establecimiento de fábricas

- Soluciones llave en mano desde el procesamiento de materiales hasta los productos terminados

- Historial con más de 19 empresas

Request a free consultation and a plant-specific ROI model. Secure engineering support for thermal/EMI design, rapid prototyping, and on-site commissioning.

- Email: [email protected]

- Teléfono/WhatsApp: +86 133 6536 0038

Recommended next steps: Share single-line diagrams, rectifier/SMPS specifications, thermal constraints, and power-quality requirements; schedule a design review; plan a pilot retrofit with measurable KPIs.

Metadatos del artículo

- Última actualización: 2025-09-12

- Próxima actualización programada: 2026-03-31

- References: IEEE Power Electronics Magazine (2023) Wide Bandgap Devices in High-Power Rectifiers; Yole Group Power SiC Market Monitor (2024); International Energy Agency Technology Perspectives (2024)

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.