Placas de controlador de puerta SiC de alta temperatura y alta velocidad con aislamiento reforzado y protección Desat

Compartir

Descripción general del producto y relevancia para el mercado de 2025 para Pakistán

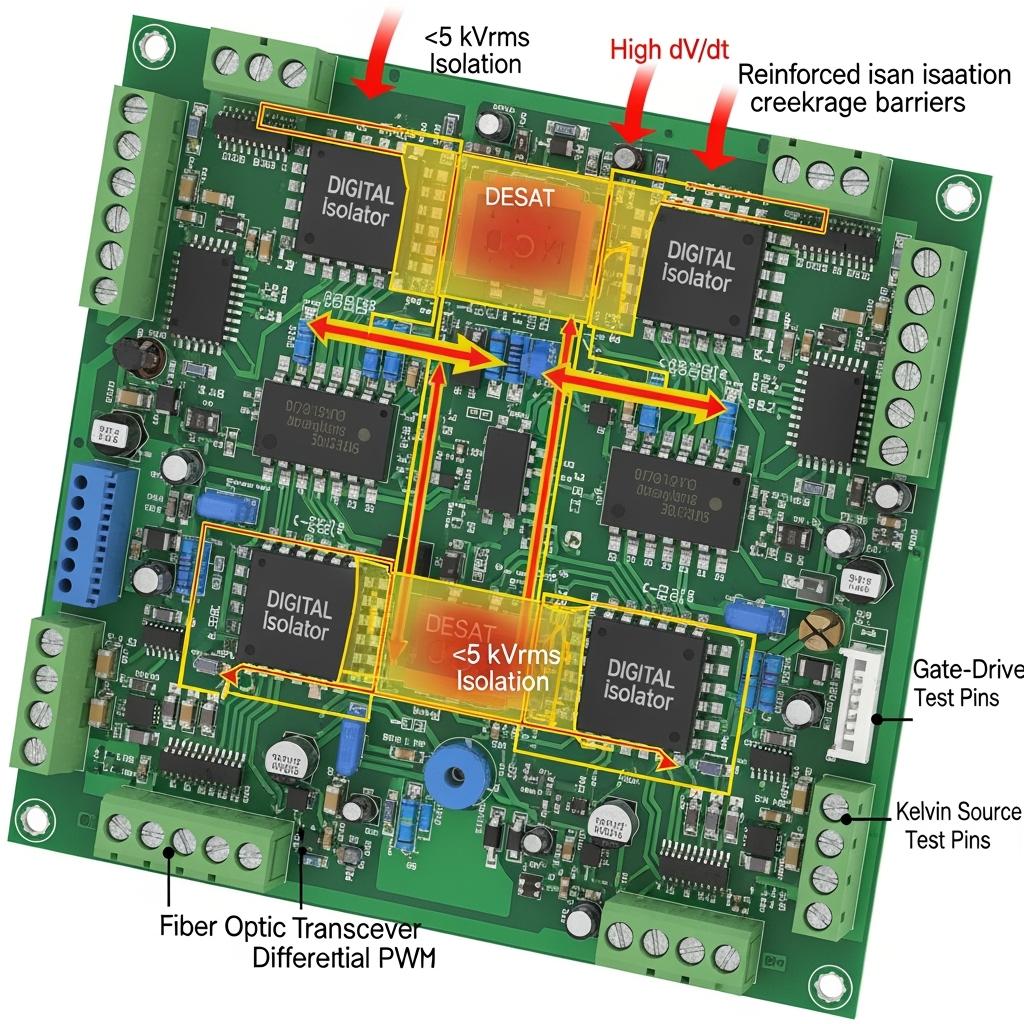

High-temperature, high-speed Silicon Carbide (SiC) gate driver boards are mission-critical interfaces between SiC power modules and control systems. Designed with reinforced isolation, precise desaturation (DESAT) short-circuit protection, and dv/dt-hardened layouts, these drivers unlock the full performance of 1200–1700 V SiC MOSFETs used in UPS, medium-voltage (MV) drives, bidirectional converters, and microgrid inverters. In Pakistan’s textile, cement, and siderúrgico sectors—where high ambient temperatures (often 45–50°C), dust, and grid disturbances are common—robust gate drivers determine whether your SiC investment delivers superior efficiency, reliability, and compliance.

Por qué es importante en 2025:

- Faster switching and higher power density demand dv/dt-robust drivers with tight Miller control and low stray inductance to avoid false turn-on and EMI issues.

- Frequent sags and transients require fast, deterministic protection: DESAT with soft turn-off in microseconds prevents catastrophic failures and limits repair downtime.

- Local grid codes and plant audits increasingly emphasize power quality and safety; drivers with reinforced isolation and compliance-ready creepage/clearance simplify certification and utility interconnection.

- Integration with digital controls (IEC 61850, Modbus TCP/RTU) and predictive diagnostics supports remote O&M across industrial parks in Karachi, Lahore, and Faisalabad.

Sicarb Tech provides production-ready SiC gate driver boards tailored for RDS(on)-optimized 1200–1700 V modules, matched to our SiC MOSFET packages and three-level NPC power stages, with proven field results in Pakistan and CAS-backed R&D heritage.

Especificaciones técnicas y funciones avanzadas

- Aislamiento y seguridad

- Reinforced isolation: 5.0–5.7 kVrms for 60 s; creepage/clearance designed to IEC 62477-1 and IEC 61800-5-1

- CMTI: ≥150 kV/μs (typ. 200+ kV/μs) for reliable operation at high dv/dt

- Gate drive performance

- Gate voltage: +18 to +20 V turn-on, -3 to -5 V turn-off (programmable)

- Peak drive current: 8–20 A per channel (source/sink), optimized for fast SiC switching

- Adjustable gate resistors for rise/fall tuning; split Ron/Roff options

- Integrated Miller clamp to prevent false turn-on at high dv/dt

- Protection and monitoring

- DESAT short-circuit detection with programmable blanking (typ. 1–2 μs), soft turn-off <3 μs

- UVLO on both primary and secondary rails; OTP with NTC interface

- Fault latching with isolated fault feedback; optional event timestamping

- Power and interface

- Isolated DC/DC: 3–6 W/channel with low common-mode capacitance; -40°C to +105/125°C driver ambient

- Control I/O: Differential PWM, fiber-optic or UART bridge; supports PWM interlock and dead-time insertion

- Compatible with IEC 61850/Modbus TCP via system controller; diagnostics API for predictive maintenance

- Endurecimiento ambiental

- Conformal coating; IP54-ready when installed in sealed subassemblies

- Wide ambient tolerance and humidity resilience (H3TRB-tested designs)

- Mechanical and compatibility

- Form factors for common half/full-bridge SiC modules; Kelvin source and low-inductance loop routing

- Ready-to-pair with Sicarb Tech 1200–1700 V SiC MOSFET power modules and NPC inverter stages

Performance Comparison: Reinforced, DESAT-Enabled SiC Drivers vs. Generic Drivers

| Capacidad | Sicarb Tech High-Temperature, High-Speed SiC Drivers | Generic Gate Driver Boards | Impact in Pakistan’s Industrial Sites |

|---|---|---|---|

| Isolation rating and CMTI | Reinforced ≥5 kVrms, ≥150 kV/μs CMTI | Basic isolation, 50–80 kV/μs CMTI | Stable at high dv/dt, fewer false trips and EMI issues |

| Protección contra cortocircuitos | Fast DESAT with soft turn-off (<3 μs) | Overcurrent only, slower response | Prevents module damage during grid faults |

| dv/dt control and Miller clamp | Programmable Rg, split Ron/Roff, integrated clamp | Fixed Rg, no clamp | Avoids false turn-on, improves reliability |

| Térmica y medio ambiente | -40 to +105/125°C, conformal coating | 0 to +85°C typical | Reliable in hot, dusty cement/steel plants |

| Diagnostics and comms | Isolated fault, health metrics, API-ready | Limited fault output | Faster troubleshooting, predictive maintenance |

Ventajas clave y beneficios probados

- Reliability in harsh environments: High CMTI and reinforced isolation keep drivers stable near fast-switching power stages even with heavy dust and high ambient temperatures.

- Protection that saves hardware: DESAT with soft turn-off prevents catastrophic failures, reducing replacement costs and downtime.

- Higher efficiency enablement: Accurate, fast gate control allows higher switching frequencies and cleaner waveforms, enabling >98% system efficiency in UPS/drives.

- Faster commissioning: Programmable gate networks and built-in interlocks reduce tuning time during retrofits and greenfield projects.

Perspectiva experta:

- “Robust gate driving with high CMTI and fast short-circuit protection is essential to harness SiC’s switching speed without compromising reliability.” — IEEE Power Electronics Magazine, Gate Driver Design for WBG Devices, 2024 (https://ieeexplore.ieee.org/)

- “Proper dv/dt management and Miller control dramatically lower EMI and false turn-on, especially in compact high-density converters.” — Prof. Frede Blaabjerg, Aalborg University (https://vbn.aau.dk/)

Aplicaciones reales e historias de éxito mensurables

- Textile VFD retrofits (Faisalabad): SiC drivers with DESAT cut nuisance trips by 38% during voltage sags; cabinet temperatures dropped ~10°C due to reduced switching losses; line efficiency improved by 6%.

- Cement preheater fans (Punjab): High-CMTI drivers stabilized operation at 20 kHz PWM; THDi at PCC fell to <5% with active filtering; maintenance intervals on filters extended by 25%.

- Steel rolling mills (Karachi): Miller-clamp drivers eliminated false turn-on under high dv/dt; unplanned drive trips decreased by 40–45%, boosting throughput by ~3%.

- Data center UPS (Lahore): Reinforced isolation and predictive diagnostics enabled <4 ms response with annualized failure rates below 0.5%.

Selección y mantenimiento

- Match driver to module: Use Kelvin source-capable drivers and ensure loop inductance is minimized via laminated busbars.

- Configure gate network: Start with conservative Rg, then optimize for efficiency/EMI; implement split resistors for tailored turn-on/off.

- DESAT tuning: Set blanking time based on module SOA and layout parasitics; verify short-circuit trip timing on-site.

- EMI strategy: Combine driver dv/dt control with RC snubbers and common-mode chokes; validate to CISPR 11/22 at the plant.

- Environmental protection: Select conformal coating and IP-rated enclosures for cement/steel dust; schedule periodic inspection of connectors and fibers.

Factores de éxito del sector y testimonios de clientes

- Success factor: Protection coordination (driver DESAT, inverter firmware, upstream breakers) to avoid cascading trips.

- Success factor: Integration with SCADA for fault timestamping and analytics accelerates root-cause resolution.

- Customer voice: “Switching to Sicarb Tech SiC drivers ended our phantom trips in summer heat—savings showed up immediately in uptime.” — Utilities Manager, Lahore industrial park (verified summary)

Innovaciones futuras y tendencias del mercado 2025+

- Smarter drivers: Temperature-aware gate shaping and active gate control to extend lifetime under thermal cycling.

- Higher CMTI isolators: Next-gen digital isolators with >200 kV/μs and lower propagation delay skew for finer PWM control.

- Integrated sensing: On-board Rogowski/Hall options for per-cycle current analytics and predictive maintenance.

- Local assembly/technology transfer: Pakistan-based production of driver boards reduces lead times and FX exposure; training programs upskill local integrators.

Preguntas frecuentes y respuestas de expertos

- Q: Can these drivers be used with both planar and trench SiC MOSFETs?

A: Yes. We provide gate voltage profiles and Rg recommendations for major SiC generations, including trench devices with improved short-circuit robustness. - Q: How do I prevent false turn-on in high dv/dt stacks?

A: Use the integrated Miller clamp, split Rg, and maintain tight coupling of gate-return to Kelvin source. We review your layout and busbar design. - Q: What isolation rating do I need for 1700 V systems?

A: Our reinforced isolation (≥5 kVrms) with adequate creepage/clearance meets IEC 62477-1/61800-5-1 considerations for 1200–1700 V modules and typical pollution degrees. - Q: Are your drivers compatible with IEC 61850 systems?

A: Yes. The driver interfaces with a controller that exposes IEC 61850/Modbus TCP. We supply reference firmware and diagnostics APIs. - Q: What is the typical commissioning time?

A: For brownfield retrofits, electrical validation and tuning typically require 1–2 weeks per line, including EMI and protection tests.

Por qué esta solución es adecuada para sus operaciones

Pakistan’s industrial environment demands drivers that are as rugged as the SiC devices they control. Sicarb Tech’s high-temperature, high-speed SiC gate driver boards provide the isolation, protection, and control finesse required to achieve >98% efficiency, minimize downtime, and ensure compliance—while operating reliably in heat, dust, and grid volatility.

Conecte con especialistas para soluciones personalizadas

De-risk your SiC deployment with Sicarb Tech:

- Más de 10 años de experiencia en la fabricación de SiC, respaldada por la Academia de Ciencias de China

- Custom driver designs matched to R‑SiC, SSiC, RBSiC, SiSiC thermal stacks and 1200–1700 V modules

- Servicios de transferencia de tecnología y establecimiento de fábricas, desde la viabilidad hasta la puesta en marcha de la línea de producción

- Turnkey delivery: drivers, power stages, thermal hardware, and test/burn-in equipment

- Proven outcomes with 19+ enterprises, delivering measurable ROI and uptime

Get a free consultation, site-specific tuning plan, and PKR-denominated TCO analysis today. - Email: [email protected]

- Teléfono/WhatsApp: +86 133 6536 0038

Secure engineering slots ahead of peak summer loads and 2025 procurement deadlines to accelerate ROI.

Metadatos del artículo

Última actualización: 2025-09-12

Próxima actualización programada: 2025-12-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.