Controladores de puerta de alta frecuencia y alta temperatura optimizados para MOSFET SiC (aislados, alta inmunidad dv/dt)

Compartir

Fiabilidad del accionamiento de puerta para los convertidores de alta eficiencia de Pakistán en 2025

Las industrias textil, cementera y siderúrgico los sectores están acelerando la electrificación y las mejoras de la calidad de la energía, mientras que la capacidad de las energías renovables se expande en Sindh y Baluchistán. Para aprovechar al máximo la eficiencia y la velocidad de los MOSFET de carburo de silicio (SiC) en SVG/STATCOM, APF, accionamientos de alta frecuencia, SAI y fuentes de alimentación industriales, el controlador de puerta es de misión crítica. Los controladores de puerta optimizados para SiC de alta frecuencia y alta temperatura con aislamiento reforzado y alta inmunidad dv/dt evitan la activación falsa, minimizan las pérdidas de conmutación y garantizan un funcionamiento estable a temperaturas ambiente de >45 °C, polvo y humedad.

Sicarb Tech diseña y suministra soluciones de accionamiento de puerta optimizadas para SiC que presentan un aislamiento robusto, una amplia inmunidad transitoria de modo común (CMTI), un control Miller preciso y una dinámica de activación/desactivación programable. Respaldadas por la Academia de Ciencias de China, nuestras plataformas se integran a la perfección en topologías multinivel y sistemas supervisados por la norma IEC 61850, lo que acorta los ciclos de puesta en marcha para la interconexión NTDC/NEPRA y mejora la fiabilidad a largo plazo.

Especificaciones técnicas y funciones avanzadas

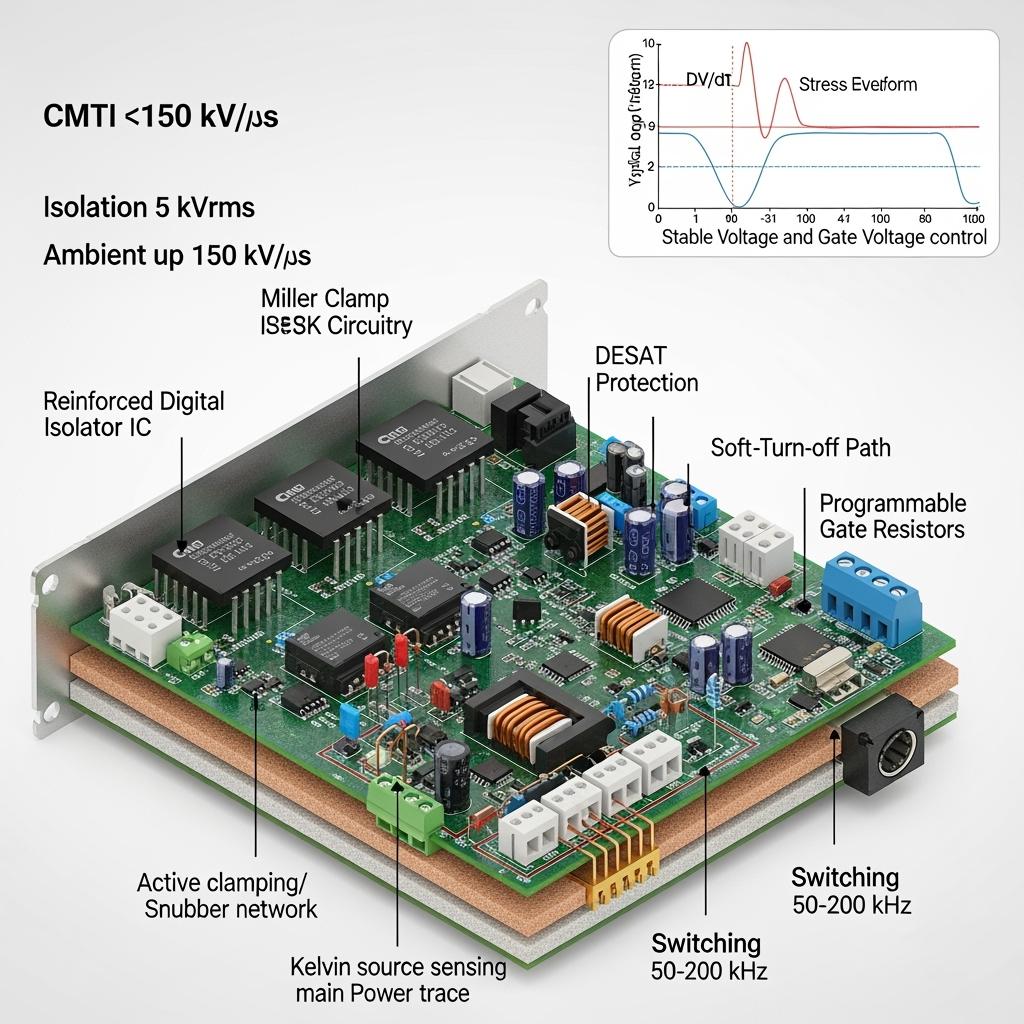

- Aislamiento e inmunidad al ruido

- Aislamiento reforzado de hasta 5 kVrms; arrastre/espacio libre diseñado según la norma IEC 60664-1

- CMTI ≥150 kV/µs para tolerar los bordes de conmutación rápidos de SiC sin corrupción de datos

- Opciones de enlace diferencial o de fibra óptica para largas tiradas de cables ruidosos en subestaciones y fábricas

- Control y protección de puerta

- Resistencias de puerta programables y RG dividida (activación/desactivación) para el control de EMI y sobreimpulso

- Abrazadera Miller y polarización de puerta negativa (por ejemplo, +18 V / −3 a −5 V) para evitar la activación falsa

- Protección contra sobrecorriente DESAT con desactivación suave; coordinación de resistencia a cortocircuitos

- Perfiles de control de puerta activos: modelado di/dt y dv/dt para equilibrar la pérdida y la EMI

- Potencia y térmica

- Suministro de polarización aislado ±18 V clase, 3–6 W por canal; umbrales UVLO adaptados a los requisitos de los MOSFET de SiC

- Funciona en ambientes de hasta 105 °C; componentes clasificados para temperaturas de unión alineadas con la calidad industrial

- Diseño optimizado para la eficiencia con baja inductancia parásita y retorno de fuente Kelvin

- Tiempo y diagnósticos

- Retraso de propagación <100 ns con coincidencia de canal a canal ≤20 ns para pilas multinivel

- Bloqueo de fallos, registro de eventos y supervisión del estado mediante enlaces SPI/CAN/ópticos

- Listo para la integración en pasarelas IEC 61850 a través de la placa de control principal (interfaz a nivel de sistema)

- Cumplimiento y fiabilidad

- Diseñado para cumplir con los requisitos de seguridad del convertidor IEC 62477-1 y los requisitos EMC industriales

- Opciones de recubrimiento de conformidad para polvo de cemento y humedad costera; envolventes con clasificación IP disponibles a nivel de sistema

Por qué los controladores de puerta optimizados para SiC superan a los controladores convencionales en entornos hostiles y de alta conmutación

| Enfoque de diseño | Controlador de puerta aislado optimizado para SiC (esta solución) | Controlador convencional de la era IGBT | Impacto operativo en Pakistán |

|---|---|---|---|

| dv/dt y CMTI | ≥150 | 25–50 kV/µs; propenso a falsos disparos | Estabilidad en eventos de red débil y subestaciones ruidosas |

| Control de compuerta | RG dividido, abrazadera Miller, desconexión −Vge, control activo | RG fijo, opciones de abrazadera limitadas | EMI inferior, menos disparos molestos, mejor eficiencia |

| Protección | DESAT con desconexión suave, respuesta rápida a cortocircuitos | Detección OC más lenta; desconexión más brusca | Protege los costosos módulos SiC y reduce el tiempo de inactividad |

| Clasificación térmica | Ambiente hasta 105°C; componentes de alta fiabilidad | 70–85°C típico | Fiable en ambientes de >45°C y plantas con polvo |

| Sincronización | Coincidencia de retardo ajustada para topologías multinivel | Coincidencia floja | Conmutación equilibrada, reducción de corrientes circulantes |

Ventajas clave y beneficios probados

- Equilibrio de eficiencia y EMI a alta frecuencia (50–200 kHz): Los perfiles de compuerta programables reducen la pérdida de conmutación sin sacrificar la EMC.

- Fiabilidad a temperatura: El funcionamiento estable en entornos calientes y polvorientos de cemento y acero minimiza la reducción de potencia y los apagados.

- Protección ajustada para SiC: DESAT rápido y desconexión suave reducen la tensión del dispositivo durante fallos y eventos de red.

- Puesta en marcha más rápida: Los diagnósticos integrados y las interfaces estandarizadas aceleran la aceptación FAT/SAT y NTDC/NEPRA.

Cita de un experto:

“Gate drivers are the linchpin for realizing SiC’s promise—robust isolation, high CMTI, and precise gate shaping are essential to avoid EMI issues and unlock efficiency gains.” — Interpreted from IEEE Power Electronics Magazine perspectives on WBG gate driving (https://ieeexplore.ieee.org/xpl/RecentIssue.jsp?punumber=6161321)

Aplicaciones reales e historias de éxito mensurables

- SVG/STATCOM en la planta eólica de Sindh (compuesto): Los controladores optimizados para SiC mejorados mejoraron la respuesta reactiva a pasos a <10 ms y redujeron las pérdidas de conmutación en ~12%, elevando la eficiencia de la cadena de compensación por encima del 98%.

- Adaptación de la parte frontal de VFD textil en Faisalabad: La conformación de la compuerta redujo los disparos inducidos por EMI en un 70% y permitió aumentar la frecuencia de 20 kHz a 60 kHz, reduciendo la magnética en ~25%.

- APF de acero en Karachi: La polarización negativa de la compuerta y la abrazadera Miller eliminaron la activación falsa durante los transitorios de EAF; la THD se estabilizó dentro de los límites de IEEE 519 con menos reajustes del filtro.

- Auxiliares de la planta de cemento en KP: Los conjuntos de controladores de compuerta con revestimiento conforme mantuvieron el tiempo de actividad durante la temporada de polvo con <0,5% de eventos de fallo relacionados con el controlador durante 12 meses.

Selección y mantenimiento

- Compatibilidad eléctrica

- Ajustar la corriente de salida del controlador (2–10 A pico) a la carga de la compuerta del dispositivo y a la velocidad de conmutación deseada

- Seleccionar el nivel de polarización negativa de la compuerta para suprimir la activación Miller sin sobrecargar el óxido de la compuerta

- Asegurar que los umbrales UVLO se alineen con los requisitos de MOSFET (+/− carriles)

- Aislamiento y diseño

- Elegir aislamiento reforzado para pilas MV; verificar la distancia de fuga/separación para el grado de contaminación local

- Enrutamiento de retorno de fuente Kelvin para minimizar la inductancia parásita y el error de medición

- Protección y detección

- Ajuste del umbral DESAT y tiempo de borrado ajustado a las características del dispositivo y a la topología (NPC/ANPC/MMC)

- Incorporar detección NTC/RTD cerca de los chips para la reducción térmica; asegurar las rutas de propagación de fallos al controlador principal

- Robustez ambiental

- Especificar revestimiento conforme y recintos con juntas en sitios con polvo/humedad

- Validar los caminos de flujo de aire o refrigeración líquida alrededor de los controladores y las resistencias de compuerta

- Ciclo de vida y repuestos

- Mantener copias de seguridad de firmware/configuración; mantener repuestos calibrados para alimentadores críticos

- Planificar la revisión anual para el ajuste de parámetros a medida que evolucionan los perfiles de funcionamiento

Factores de éxito del sector y testimonios de clientes

- Diseño conjunto temprano con EPC/integradores para alinear la frecuencia de conmutación, los objetivos de EMI y el cumplimiento de la red

- Oscilografía in situ durante la puesta en marcha para finalizar la división RG, los umbrales de la abrazadera y los tiempos de borrado

- Formación local para los equipos de O&M para interpretar los diagnósticos y mantener la integridad de los parámetros

Voz del cliente (compuesto):

“Después de adoptar los controladores específicos de SiC, nos esforzamos por alcanzar una frecuencia más alta sin penalizaciones de EMI y eliminamos los disparos molestos durante los eventos de parpadeo de la red”. — Jefe de Mantenimiento Eléctrico, Cluster Textil, Punjab

Innovaciones futuras y tendencias del mercado 2025+

- Controladores integrados en módulos de potencia SiC: Inductancia de bucle más corta, detección integrada y protección más inteligente

- Control de compuerta adaptativo que utiliza la temperatura y la corriente del dispositivo en tiempo real para minimizar la pérdida de conmutación dinámicamente

- CMTI superior (>200 kV/µs) y aislamiento digital con menor fluctuación para convertidores de utilidad basados en MMC

- Canales de diagnóstico ciberseguros para alinearse con IEC 62443 para infraestructuras críticas

Preguntas frecuentes y respuestas de expertos

- ¿Qué CMTI se recomienda para SiC con una conmutación de 50–100 kHz?

Se recomienda ≥100–150 kV/µs; nuestros diseños apuntan a ≥150 kV/µs para obtener margen en entornos de red débil y EAF. - ¿Necesito polarización de puerta negativa para los MOSFET de SiC?

A menudo sí, especialmente en topologías de conmutación rápida o con alto dv/dt. La desconexión de −3 a −5 V con abrazadera Miller reduce el riesgo de activación falsa. - ¿Cómo se establece el DESAT y el tiempo de borrado?

Calculamos en función de la SOA del dispositivo, la inductancia parásita y la topología, y luego validamos con capturas de osciloscopio durante FAT/SAT para asegurar la desconexión suave sin una disipación excesiva de energía. - ¿Pueden estos controladores integrarse con sistemas IEC 61850?

A nivel de sistema, el controlador principal agrega la telemetría del controlador a través de SPI/CAN/óptico y publica a través de IEC 61850 MMS/GOOSE con marcas de tiempo sincronizadas. - ¿Qué pasa con el funcionamiento a >45°C y polvo?

Especificamos componentes de grado industrial, revestimiento conforme y márgenes de diseño térmico; los recintos alcanzan IP54–IP65 según los requisitos del sitio.

Por qué esta solución es adecuada para sus operaciones

Los controladores de compuerta SiC diseñados para alta dv/dt y temperatura desbloquean el rendimiento completo de los MOSFET SiC—mayor eficiencia, magnéticos más pequeños y dinámica estable—al tiempo que protegen los dispositivos durante fallos. En las duras condiciones de Pakistán y las interconexiones de red débil, eso se traduce directamente en menos disparos, aprobaciones más rápidas y un menor coste de por vida.

Conecte con especialistas para soluciones personalizadas

Asóciese con Sicarb Tech para diseñar conjuntamente la estrategia de accionamiento de compuerta adecuada para sus SVG/STATCOM, APF, frontales de VFD y UPS:

- Más de 10 años de experiencia en la fabricación de SiC

- I+D y validación respaldadas por la Academia de Ciencias de China

- Desarrollo de productos personalizados en todos los materiales R‑SiC, SSiC, RBSiC, SiSiC y módulos de potencia SiC

- Servicios de transferencia de tecnología y establecimiento de fábricas, desde la viabilidad hasta la puesta en marcha

- Soluciones llave en mano desde el procesamiento de materiales y sustratos hasta sistemas y controles terminados

- Historial probado con más de 19 empresas que ofrecen ganancias medibles de eficiencia y PQ

Obtenga una consulta gratuita, una revisión del diseño y un plan de puesta en marcha in situ.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Metadatos del artículo

- Última actualización: 2025-09-11

- Próxima actualización programada: 2025-12-15

- Preparado por: Equipo de ingeniería de aplicaciones de Sicarb Tech

- Referencias: IEEE Power Electronics Magazine sobre accionamiento de compuerta WBG; IEC 62477-1; IEC 60664-1; IEEE 519; IEC 61000-3-6; prácticas de interconexión NTDC/NEPRA

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.