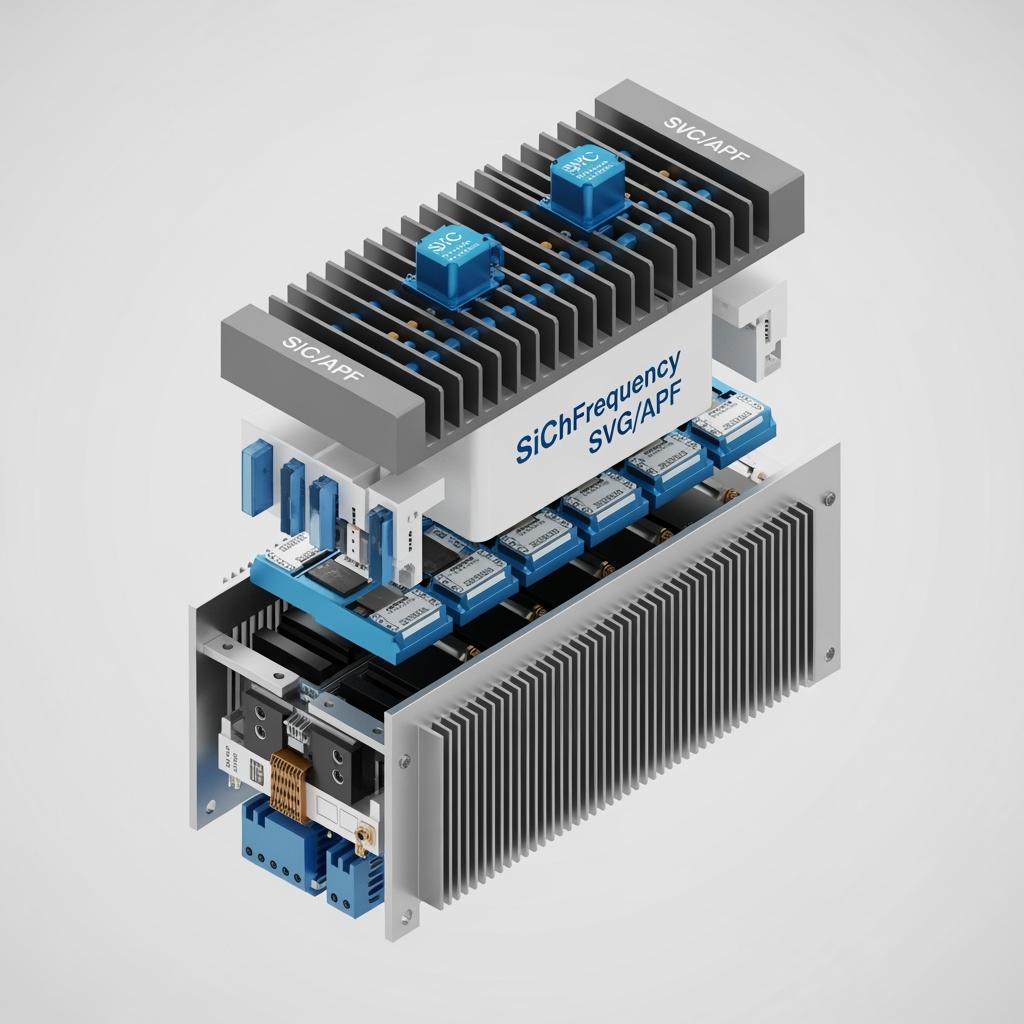

Módulos de potencia de carburo de silicio de alta frecuencia para SVG/APF y accionamientos de media tensión

Compartir

Calidad y eficiencia de la energía para el crecimiento industrial de Pakistán en 2025

Las industrias textil, cementera y siderúrgico de Pakistán, junto con los activos eólicos y solares en rápida expansión, requieren una conversión de energía robusta, compacta y eficiente. Los módulos de potencia de carburo de silicio (SiC) de alta frecuencia ofrecen una eficiencia de conversión >98% y una respuesta dinámica inferior a 10 ms para los generadores estáticos de VAR (SVG/STATCOM), los filtros de potencia activos (APF) y los accionamientos de media tensión (MV). Estas capacidades ayudan a las instalaciones a cumplir los criterios de interconexión NTDC/NEPRA, a ajustarse a las directrices de armónicos IEEE 519 e IEC 61000-3-6 y a mantener el rendimiento a altas temperaturas ambiente comunes en Sindh y el sur de Punjab.

Sicarb Tech, ubicada en la ciudad de Weifang (el centro de SiC de China) y respaldada por la Academia China de Ciencias, proporciona módulos SiC diseñados a medida y transferencia de tecnología llave en mano. Con más de 10 años de fabricación de SiC y más de 19 implementaciones exitosas, nuestros módulos reducen las pérdidas,

Especificaciones técnicas y funciones avanzadas

- Clases de tensión nominal: dispositivos de 1200 V y 1700 V; pilas de módulos diseñadas para etapas de salida de MT a través de topologías multinivel

- Frecuencia de conmutación: 50–100 kHz para SVG/APF y etapas de inversor de alto rendimiento

- Eficiencia del sistema: >98% a carga nominal; eficiencia a carga parcial optimizada mediante modulación adaptativa

- Tiempo de respuesta: <10 ms de respuesta de paso reactivo para compensación dinámica y mitigación del parpadeo

- Capacidad térmica: Temperatura de unión de -55°C a 175°C; fiabilidad validada de ciclos térmicos y ciclos de potencia

- Densidad de potencia: >8 kW/L mediante embalaje avanzado y diseño de barra de bus de baja inductancia

- Detección integrada: Detección de corriente Hall/rogowski, retroalimentación de tensión de precisión para control de bucle cerrado

- Control de puerta: Alta inmunidad dv/dt, pinza Miller, protección DESAT y alimentación aislada para funcionamiento de alta frecuencia

- EMC/EMI: Diseño optimizado, blindaje y amortiguadores RC para cumplir con las normas industriales de EMC

- Robustez medioambiental: Recubrimiento conforme, opciones de integración en armario IP55–IP65; mitigación del polvo y la humedad para entornos de cemento/acero

Normas y integración aplicables

- Armónicos y calidad de la energía: IEEE 519, IEC 61000-3-6

- Seguridad de los convertidores electrónicos de potencia: IEC 62477-1

- Conexión a la red de PV/eólica: IEC 62109 (según corresponda), códigos de red locales NTDC/NEPRA

- Comunicaciones: IEC 61850, Modbus TCP, DNP3 para la integración SCADA/DCS

Consideraciones de rendimiento y diseño para la industria de Pakistán

- Resistencia al calor y al polvo para las instalaciones de Karachi, Faisalabad y Khyber Pakhtunkhwa

- Estabilización de red débil en los nodos eólicos y fotovoltaicos de Sindh y Baluchistán

- Compatibilidad con las flotas de VFD y los sistemas UPS existentes en las fábricas textiles y las plantas de proceso

- Infraestructura de refrigeración reducida: menor OPEX y salas eléctricas más pequeñas

Comparación descriptiva: Módulos de SiC frente a silicio tradicional para SVG/APF y accionamientos

| Área de rendimiento | Módulos de SiC de alta frecuencia (esta solución) | Módulos de silicio convencionales (basados en IGBT) | Impacto operativo en Pakistán |

|---|---|---|---|

| Respuesta dinámica (SVG/APF) | <10 ms. | 25–40 ms. | Mejor control del parpadeo para los arranques de EAF y la corriente de irrupción del motor |

| Eficiencia a carga nominal | >98% | 92–95 % | Ahorro de energía del 5–7%; menores penalizaciones |

| Frecuencia de conmutación | 50–100 kHz | 10–20 kHz | Imanes y armarios más pequeños; funcionamiento más silencioso |

| Margen térm | Tj hasta 175°C | Tj hasta 125°C | Menos reducción de potencia en ambientes de >45°C |

| Densidad de potencia | >8 kW/L. | 3–5 kW/L. | Reducción de la huella del 25–35%. |

| Necesidades de refrigeración | Inferiores (líquido/aire forzado) | Más alto | Reducción del HVAC y el mantenimiento |

| Vida útil (MTBF) | Objetivo de diseño de >15 años | 8–10 años. | Menos revisiones, mayor tiempo de actividad |

Ventajas clave y beneficios probados

- Preparado para el cumplimiento: La dinámica más rápida garantiza la adhesión a las especificaciones de interconexión NTDC/NEPRA; aprobaciones más fáciles

- Ganancias de energía y capacidad: Mejora del 5–7% de la energía del sistema; margen adicional para la expansión del proceso

- Ahorro de espacio y costes: Armarios un 25–35% más pequeños; cimientos y tendidos de cables simplificados

- Fiabilidad: Vida útil prolongada y mayores intervalos de mantenimiento en entornos hostiles

- Integración: Conectividad SCADA/DCS sin problemas y expansión modular para actualizaciones por fases

La opinión de los expertos:

“El funcionamiento a alta temperatura del SiC y la conmutación rápida mejoran significativamente la eficiencia y el rendimiento dinámico del convertidor, lo que es crucial para integrar las energías renovables y estabilizar los alimentadores industriales”. — Perspectiva de la Sociedad de Electrónica de Potencia de IEEE, sintetizada a partir de los informes de IEEE Transactions on Power Electronics

Aplicaciones del mundo real y éxito medible

- Interconexión a la red eólica/fotovoltaica (Sindh): Los SVG basados en SiC mantuvieron la fluctuación de tensión dentro de ±2% y lograron una eficiencia del sistema del 98,5%, mejorando los resultados de reducción y obteniendo la aceptación de las empresas de servicios públicos.

- Fábrica de laminación de acero (Karachi): Los módulos APF con SiC redujeron la distorsión armónica total dentro de los límites de la IEEE 519 y redujeron el consumo de energía en un 4,8%; los disparos molestos disminuyeron drásticamente durante los arranques de EAF.

- Complejo textil (Faisalabad): Los módulos de SiC en los extremos delanteros de los VFD estabilizaron las caídas de tensión, reduciendo los eventos de disparo de los telares en un 60% y recortando la potencia de refrigeración en un 15%.

- Planta de cemento (KP): Los módulos de SiC de alta frecuencia que accionan los ventiladores de la casa de bolsas y los auxiliares del horno lograron una THD más baja y prolongaron la vida útil de los cojinetes y el aislamiento mediante perfiles de par más suaves.

Selección y mantenimiento

- Clase de tensión y topología: Seleccione dispositivos de 1200/1700 V y la topología multinivel adecuada (NPC, ANPC, MMC) para la compatibilidad con MT y la reducción del tamaño del filtro

- Trayectoria térmica: Verifique la disponibilidad de la placa fría o la refrigeración líquida, la calidad del refrigerante y el flujo; asegúrese de la selección adecuada de TIM

- Planificación de EMC: Diseño del armario, conexión a tierra y blindaje de cables para cumplir con los requisitos de EMC de la planta

- Sellado medioambiental: Elija la clasificación IP y la estrategia de recubrimiento para el polvo, la humedad y las atmósferas corrosivas

- Soporte del ciclo de vida: Planifique repuestos, actualizaciones de firmware y diagnósticos remotos; alinéese con las ventanas de parada de la planta

Factores de éxito del sector y testimonios de clientes

- Alineación con el código de red de Pakistán y los requisitos de las zonas industriales

- Documentación, formación y asistencia telefónica localizadas

- Estrategias de adaptación por fases que minimizan la interrupción de la producción

Voz del cliente (compuesto):

“La estabilidad de nuestra sala de tejido mejoró inmediatamente después de la actualización de SiC SVG/APF: menos disparos y una notable caída de los costes de energía y refrigeración”. — Director de Operaciones, Planta Textil, Punjab

Innovaciones futuras y tendencias del mercado (2025+)

- MOSFET y cascodes de SiC de media tensión que permiten pilas de mayor tensión con menos dispositivos en serie

- Mayor adopción de convertidores multinivel modulares (MMC) para SVG/STATCOM a escala de servicios públicos en centros de energías renovables

- Mantenimiento predictivo mejorado con IA que aprovecha los flujos de datos de alta frecuencia para la detección temprana de fallos

- Montaje local y transferencia de tecnología en Pakistán para reducir los plazos de entrega y la exposición a divisas

Preguntas frecuentes y respuestas de expertos

- ¿Estos módulos cumplen los requisitos de la red pakistaní?

Sí, los diseños se dirigen a las normas de interconexión NTDC/NEPRA y a IEEE 519/IEC 61000-3-6. La integración es compatible con IEC 61850 para SCADA de servicios públicos cuando es necesario. - ¿Cuál es el periodo de amortización típico?

En plantas de alta carga, de 18 a 30 meses a través del ahorro de energía, la reducción de penalizaciones y la reducción de las necesidades de climatización. - ¿Podemos integrarlos con los VFD/UPS y SCADA existentes?

Sí. Nuestros módulos se conectan a través de Modbus TCP, IEC 61850 y DNP3, y pueden adaptar los extremos frontales de los sistemas existentes. - ¿Cómo gestionan los módulos las altas temperaturas ambiente y el polvo?

La capacidad de alta temperatura de unión, el diseño térmico robusto, las carcasas con clasificación IP y el recubrimiento conforme permiten un funcionamiento fiable en entornos de más de 45°C y polvorientos. - ¿Qué soporte se proporciona para la puesta en marcha?

Puesta en marcha in situ/remota, formación y validación del rendimiento, además de diagnósticos continuos y actualizaciones de firmware.

Por qué esta solución es adecuada para sus operaciones

Los módulos de SiC de alta frecuencia combinan eficiencia, velocidad y robustez para resolver los problemas de calidad y fiabilidad de la energía más acuciantes de Pakistán. Desde el cumplimiento de los límites armónicos hasta el mantenimiento del tiempo de actividad en entornos hostiles, la tecnología ofrece beneficios operativos inmediatos y un camino hacia la reducción de costes y el cumplimiento a largo plazo.

Conecte con especialistas para soluciones personalizadas

Asóciese con Sicarb Tech para diseñar, implementar o incluso fabricar soluciones de SiC adaptadas a su planta:

- Más de 10 años de experiencia en la fabricación de SiC en el centro de SiC de Weifang

- Respaldado por la Academia de Ciencias de China para I+D avanzada

- Desarrollo personalizado en materiales R-SiC, SSiC, RBSiC, SiSiC y módulos de potencia

- Transferencia de tecnología y establecimiento de fábricas, desde la viabilidad hasta la puesta en marcha

- Soluciones llave en mano, desde polvos y sustratos hasta sistemas SVG/APF terminados

- Resultados probados con más de 19 empresas que ofrecen un ROI medible

Actúe ahora para obtener una consulta gratuita, una revisión del cumplimiento de la red y un modelo de ROI adaptado a su sitio.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Metadatos del artículo

- Última actualización: 2025-09-11

- Próxima actualización programada: 2025-12-15

- Preparado por: Equipo de ingeniería de aplicaciones de Sicarb Tech

- Referencias: IEEE 519; IEC 61000-3-6; IEC 61850; IEC 62477-1; directrices de interconexión NTDC/NEPRA; análisis de la industria de IEEE PELS e IRENA sobre la adopción de SiC

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.