Durable SiC Valves for Demanding System Control

Share

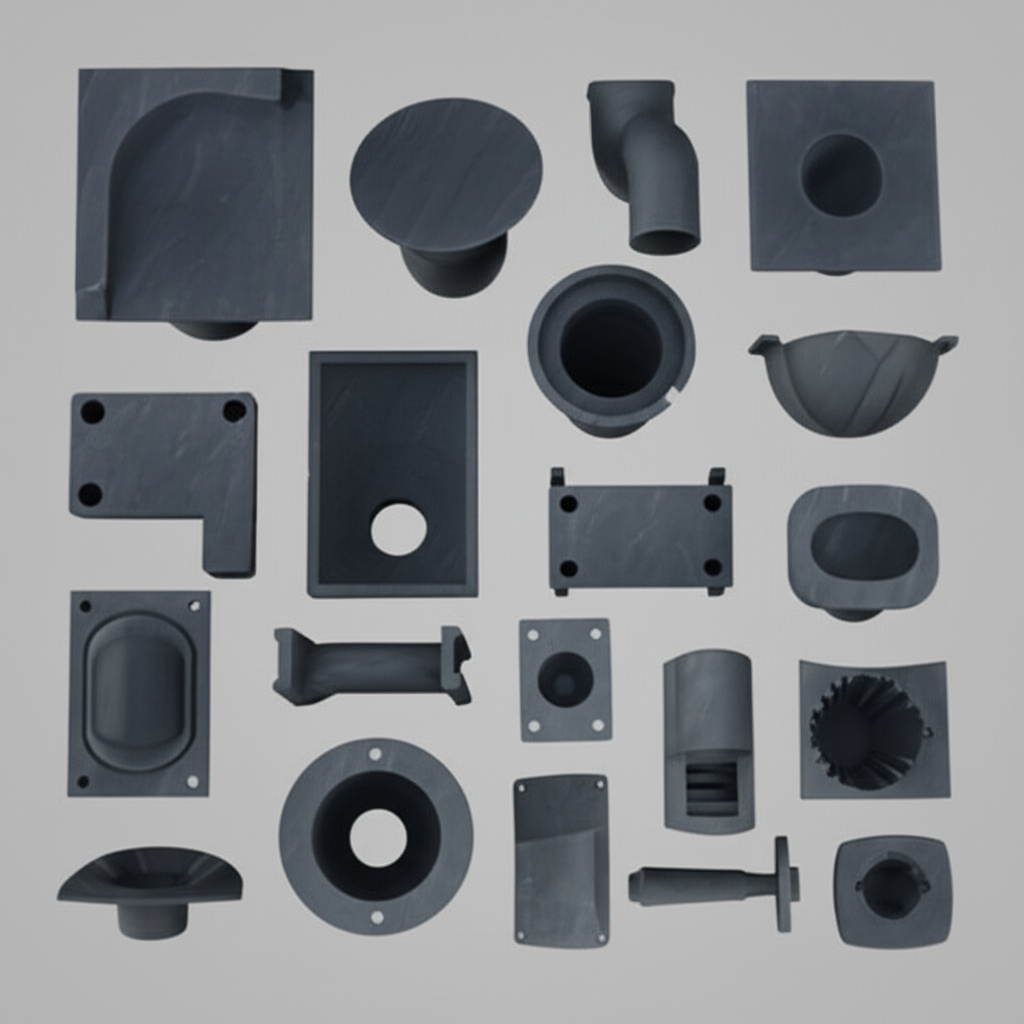

Introduction: The Unyielding Strength of Silicon Carbide in Demanding Valve Applications

In the realm of industrial fluid and gas control, the performance and longevity of system components are paramount. For applications characterized by extreme temperatures, high pressures, corrosive media, and abrasive slurries, conventional valve materials often fall short, leading to frequent maintenance, costly downtime, and compromised operational safety. This is where Silicon Carbide (SiC) valves emerge as a transformative solution. Silicon Carbide, an advanced technical ceramic, is renowned for its exceptional hardness, superior strength at elevated temperatures, and remarkable resistance to chemical attack and wear. These properties make SiC control valves and components indispensable in today’s most demanding industrial environments, ensuring reliable and precise system control where other materials fail.

The inherent characteristics of silicon carbide translate directly into tangible benefits for valve applications. Imagine a valve seat that doesn’t erode under the constant assault of abrasive particles, or a valve ball that maintains its dimensional integrity at temperatures exceeding 1000°C. This level of performance is not just an improvement; it’s a paradigm shift for industries striving for greater efficiency, reduced operational expenditure, and enhanced process reliability. As we delve deeper, we will explore why high-performance valves crafted from silicon carbide are increasingly becoming the material of choice for forward-thinking engineers and procurement specialists.

Unlocking Performance: Key Industrial Applications for SiC Valves

The exceptional properties of silicon carbide valves make them suitable for a diverse range of challenging industrial applications. Their ability to withstand harsh conditions ensures uninterrupted operations and longevity, providing significant advantages across multiple sectors. Key industries benefiting from SiC valve solutions include:

- Semiconductor Manufacturing: Used in handling corrosive gases and high-purity chemicals where contamination is a critical concern. SiC’s inertness and resistance to plasma erosion are vital.

- Chemical Processing: Ideal for valves handling highly corrosive acids, alkalis, and solvents, even at elevated temperatures and pressures. Chemical resistant valves made from SiC significantly reduce replacement rates.

- Power Generation (including Nuclear Energy): In conventional and nuclear power plants, SiC valves manage abrasive slurries (e.g., flue gas desulfurization), high-temperature steam, and radioactive coolants. Their thermal shock resistance is also crucial.

- Oil and Gas: Downhole tools, refineries, and petrochemical plants benefit from SiC’s resistance to erosion from sand-laden crude oil, sour gas, and aggressive chemicals.

- Metallurgy and High-Temperature Furnaces: Control of molten metals, high-temperature gases, and abrasive dusts in furnaces and foundries.

- Aerospace and Defense: Applications requiring lightweight, high-strength components capable of operating in extreme temperature fluctuations and harsh environments, such as rocket propulsion systems or fuel handling.

- Pulp and Paper: Handling abrasive lime slurry, green liquor, and other corrosive media that quickly degrade metallic valves.

- Mining and Mineral Processing: Managing highly abrasive slurries containing hard rock particles, where wear-resistant valves are essential.

- LED Manufacturing: In MOCVD reactors where high temperatures and corrosive precursors are used.

- Renewable Energy: Components in geothermal energy systems or concentrated solar power plants dealing with high-temperature fluids.

The versatility and robust performance of industrial SiC valves position them as critical components for enhancing process efficiency and safety. For instance, you can see proven applications in demanding industries where standard materials would quickly succumb to failure.

Why Custom Silicon Carbide Valves? The Edge in System Durability and Efficiency

While standard SiC components offer significant advantages, custom silicon carbide valves and valve parts provide a tailored solution that maximizes performance and longevity for specific applications. Customization allows for designs optimized to the unique operational parameters of a system, leading to enhanced durability and overall efficiency.

The primary benefits of choosing custom SiC valves include:

- Unmatched Wear Resistance: Silicon carbide is one of the hardest commercially available materials, second only to diamond. This translates to exceptional resistance against abrasive wear from slurries, powders, and high-velocity particles. Custom designs can further optimize flow paths to minimize impingement angles and wear points.

- Superior Thermal Stability and Shock Resistance: SiC maintains its mechanical strength and structural integrity at extremely high temperatures (up to 1650°C or higher for some grades). It also exhibits excellent thermal shock resistance, allowing it to withstand rapid temperature changes without cracking or failing. Custom geometries can be designed to manage thermal stresses effectively.

- Exceptional Chemical Inertness and Corrosion Resistance: SiC is highly resistant to a wide range of corrosive media, including strong acids, bases, and oxidizing agents, even at elevated temperatures. This makes it ideal for corrosion-resistant valves in aggressive chemical environments. Custom material grade selection can further fine-tune this resistance.

- High Hardness and Strength: The inherent hardness contributes to dimensional stability under high loads and prevents deformation, ensuring tight seals and consistent performance over time.

- Optimized Flow Characteristics: Custom valve trim designs (e.g., seats, plugs, balls, stems) can be engineered for specific flow rates, pressure drops, and control requirements, improving process efficiency.

- Reduced Total Cost of Ownership (TCO): Although the initial investment in custom SiC valves might be higher than conventional alternatives, their extended service life, reduced maintenance requirements, and prevention of unscheduled downtime lead to a significantly lower TCO.

- Lightweight Potential: Compared to some high-performance metal alloys, SiC offers a lower density, which can be advantageous in weight-sensitive applications, particularly in aerospace.

By opting for bespoke SiC solutions, engineers can specify precise dimensions, tolerances, surface finishes, and even material compositions to create valve components that perfectly integrate into their systems and deliver optimal performance under the most challenging conditions.

Choosing Your Champion: Recommended SiC Grades for Valve Components

Silicon Carbide is not a one-size-fits-all material. Different manufacturing processes result in various grades of SiC, each with a unique combination of properties. Selecting the appropriate grade is crucial for optimizing valve performance and longevity in specific applications. The most common SiC grades used for technical ceramics valves include:

| SiC Grade | Key Characteristics | Typical Valve Applications |

|---|---|---|

| Reaction-Bonded Silicon Carbide (RBSC or SiSiC) | Contains free silicon (typically 8-15%), good mechanical strength, excellent wear resistance, good thermal conductivity, relatively easier to produce complex shapes, cost-effective. Maximum service temperature around 1350°C. | Valve seats, nozzles, pump components, wear liners in moderately high temperatures and abrasive environments. Good for larger, intricate parts. |

| Sintered Silicon Carbide (SSiC) | Very high purity (typically >98% SiC), no free silicon, superior corrosion resistance (especially to strong acids and alkalis), excellent high-temperature strength (up to 1600°C+), highest hardness among SiC types. Can be α-SSiC or β-SSiC. | High-purity chemical handling, severe corrosion environments, extreme wear applications, valve balls, seats, mechanical seals. Preferred for advanced ceramic valves in critical services. |

| Nitride-Bonded Silicon Carbide (NBSC) | SiC grains bonded by a silicon nitride phase. Good thermal shock resistance, good resistance to molten metals (especially non-ferrous), moderate strength. | Applications involving thermal cycling, handling molten aluminum or other non-ferrous metals, thermocouple protection tubes. Less common for general valve components compared to RBSC and SSiC. |

| Recrystallized Silicon Carbide (RSiC) | High porosity, excellent thermal shock resistance, very high-temperature stability (up to 1650°C in oxidizing atmospheres). Lower strength than dense SiC grades. | Primarily used for kiln furniture and high-temperature supports. Not typically used for pressure-retaining valve components due to porosity but can be used for specific internal parts where flow isn’t critical. |

| CVD Silicon Carbide (Chemical Vapor Deposition SiC) | Extremely high purity (99.999%+), dense, excellent corrosion resistance, smooth surfaces. Often used as a coating on other materials or for very high-purity applications. | Semiconductor processing equipment, protective coatings on valve components to enhance surface properties. Higher cost. |

The choice of SiC grade for valve components depends on a careful analysis of the service conditions, including temperature, pressure, chemical environment, nature of abrasives, and required mechanical properties. Consulting with a knowledgeable silicon carbide valve supplier is crucial to ensure the optimal material selection for your silicon carbide valve specifications.

Precision Engineering: Critical Design Considerations for SiC Valves

Designing valve components with silicon carbide requires a different approach than with metals due to its inherent ceramic nature, primarily its hardness and lower fracture toughness (brittleness). Proper design is paramount to harness SiC’s strengths while mitigating its limitations. Key considerations for silicon carbide valve design include:

- Designing for Manufacturability:

- Simplify Geometries: Complex shapes are more challenging and costly to produce in SiC. Aim for simpler geometries where possible. Avoid sharp internal corners and abrupt changes in cross-section, which can act as stress concentrators. Use generous radii instead.

- Near-Net Shaping: Manufacturing processes like pressing, slip casting, or injection molding aim for near-net shapes to minimize post-sintering machining, which is difficult and expensive for SiC.

- Consider Diamond Grinding: Final dimensions and tight tolerances are typically achieved through diamond grinding. Design features should be accessible for grinding tools.

- Managing Brittleness:

- Avoid Tensile Stresses: Design components to be primarily under compressive loads, as ceramics are much stronger in compression than in tension.

- Impact Resistance: SiC has lower impact resistance than metals. Protect SiC components from direct impact during assembly, operation, and maintenance. Consider hybrid designs where a metal housing supports the SiC wear parts.

- Stress Concentration: Minimize stress concentrators by using fillets and radii. Holes and slots should be carefully designed and located.

- Valve Trim Design:

- Sealing Surfaces: The mating surfaces of SiC valve seats and plugs/balls can be lapped to achieve extremely tight seals. The design must allow for precise control of these surfaces.

- Attachment Methods: Consider how SiC components will be assembled with other parts (e.g., metallic actuators, bodies). Methods include shrink fitting, brazing (with metallization), mechanical clamping, or adhesive bonding. The differential thermal expansion between SiC and metals must be accounted for.

- Wall Thickness and Aspect Ratios: Maintain uniform wall thicknesses where possible to prevent cracking during sintering and thermal cycling. Avoid very thin sections or high aspect ratios unless specifically engineered and validated.

- Thermal Management: While SiC has excellent thermal shock resistance, extreme and localized thermal gradients can still cause failure. Design for uniform heating and cooling where possible.

- Load Distribution: Ensure that loads are distributed evenly across SiC components to prevent localized stress peaks.

Collaborating closely with experienced engineered ceramics specialists during the design phase is crucial. They can provide valuable insights into material-specific design rules and help optimize the component for both performance and manufacturability. Precision SiC machining techniques are advanced, but designing with these in mind from the outset saves time and cost.

Achieving Perfection: Tolerances, Surface Finish, and Dimensional Accuracy in SiC Valves

The performance of silicon carbide valves, particularly in critical sealing applications and precision flow control, heavily relies on the achievable tolerances, surface finish, and overall dimensional accuracy of the SiC components. Due to its extreme hardness, machining SiC to tight specifications requires specialized processes, primarily diamond grinding and lapping/polishing.

Tolerances:

- As-Sintered Tolerances: Parts coming directly from the sintering furnace will have relatively loose tolerances, typically in the range of ±0.5% to ±2% of the dimension, depending on the SiC grade, part size, and complexity. This is due to shrinkage during sintering.

- Ground Tolerances: Through precision diamond grinding, much tighter tolerances can be achieved. Standard ground tolerances for SiC components are often in the range of ±0.01 mm to ±0.05 mm (±0.0004″ to ±0.002″). For critical applications, even tighter tolerances, down to a few microns (e.g., ±0.002 mm or ±0.0001″), are possible but come at a higher cost due to increased machining time and complexity.

Surface Finish:

- As-Sintered Surface: The surface finish of as-sintered SiC parts is relatively rough, often in the range of Ra 1.6 to 6.3 µm (63 to 250 µinch).

- Ground Surface: Diamond grinding can significantly improve the surface finish, typically achieving Ra 0.4 to 0.8 µm (16 to 32 µinch).

- Lapped/Polished Surface: For applications requiring exceptionally smooth surfaces, such as dynamic sealing faces in valve seats and balls, lapping and polishing processes are employed. These can achieve mirror-like finishes with Ra values below 0.1 µm (4 µinch), sometimes even down to Ra 0.02 µm (0.8 µinch). Such fine finishes are critical for achieving leak-tight seals and minimizing friction and wear in dynamic applications.

Dimensional Accuracy:

Achieving high dimensional accuracy involves controlling not just linear dimensions but also geometric features such as flatness, parallelism, perpendicularity, roundness, and concentricity. For mating valve components like seats and plugs, precise control over these geometric tolerances is essential for proper sealing and operation. Precision SiC machining capabilities of the supplier are therefore a critical factor in valve sourcing.

When specifying SiC valve components, it’s important to:

- Define only the necessary tight tolerances and fine surface finishes on critical features to manage costs. Over-specifying can lead to significantly higher component prices.

- Clearly communicate the functional requirements of the part so the manufacturer can recommend appropriate and achievable specifications.

- Understand the metrology capabilities of the SiC valve manufacturer to ensure they can verify the specified tolerances and finishes.

The ability to consistently produce SiC components with high precision is a hallmark of a quality supplier, ensuring reliable and high-performance valves.

Enhancing Capabilities: Post-Processing Techniques for Silicon Carbide Valves

While the inherent properties of silicon carbide are outstanding, various post-processing techniques can be employed to further enhance the performance, durability, or functionality of SiC valve components for specific applications. These treatments are typically applied after the primary shaping and sintering processes.

Common post-processing steps include:

- Grinding: As discussed, diamond grinding is essential for achieving precise dimensional tolerances and desired surface finishes on sintered SiC parts. This is often the most critical post-processing step for industrial fluid control components like valve seats, stems, and balls.

- Lapping and Polishing: For applications requiring ultra-smooth surfaces and extremely tight seals (e.g., valve faces, mechanical seals), lapping and polishing are employed. These processes use progressively finer abrasive slurries to achieve mirror-like finishes, minimizing friction and wear and improving sealing efficiency.

- Edge Chamfering/Radiusing: Sharp edges on brittle SiC components can be prone to chipping. Adding chamfers or radii to edges through grinding can improve handling robustness and reduce stress concentrations.

- Cleaning: Thorough cleaning processes are necessary to remove any residues from machining, handling, or prior processing steps, especially for high-purity applications like those in the semiconductor industry.

- Annealing: In some cases, a post-sintering annealing step may be used to relieve internal stresses that might have developed during cooling or aggressive machining, potentially improving toughness or stability.

- Surface Treatments/Coatings (Less Common for Bulk SiC, More for Hybrid Approaches):

- CVD SiC Coating: A thin layer of ultra-pure, dense CVD SiC can be applied to a sintered SiC substrate (or other materials) to enhance corrosion resistance or provide a very smooth, inert surface.

- Diamond-Like Carbon (DLC) Coating: While SiC is already very hard, DLC coatings can sometimes be applied to further reduce friction in specific dynamic applications, though this is more common on metallic parts.

- Metallization: To facilitate brazing SiC components to metallic parts (e.g., attaching a SiC valve seat to a metal housing), the SiC surface can be metallized using techniques like active metal brazing or applying molybdenum-manganese coatings followed by nickel plating.

- Impregnation/Sealing (for porous grades): For certain lower-density or intentionally porous SiC grades (not typically SSiC or dense RBSC used in valves), pores can be infiltrated with other materials (e.g., silicon, resins, or other ceramics) to improve density, strength, or reduce permeability. However, for high-performance valves, dense SiC grades are usually preferred to avoid this.

The selection of post-processing techniques depends heavily on the specific requirements of the valve application, the grade of SiC used, and the desired final properties of the custom SiC components. Each step adds to the cost and complexity, so they are chosen judiciously to meet defined performance targets.

Navigating Challenges: Overcoming Hurdles in SiC Valve Implementation

While silicon carbide offers exceptional advantages for demanding valve applications, its unique material properties also present certain challenges that engineers and procurement managers must consider during design, manufacturing, and implementation. Understanding and proactively addressing these hurdles is key to successfully leveraging SiC technology.

Common challenges include:

- Brittleness and Low Fracture Toughness:

- Challenge: Unlike metals, SiC does not deform plastically before fracture. It is brittle and can chip or crack under sharp impacts or high tensile stresses.

- Mitigation: Design SiC components to be under compressive loads, avoid stress concentrations with generous radii, protect from mechanical shock during assembly and operation, and consider hybrid designs (e.g., SiC internals within a tougher metallic housing). Proper handling protocols are essential.

- Machining Complexity and Cost:

- Challenge: The extreme hardness of SiC makes machining (grinding, lapping) slow, specialized, and expensive, requiring diamond tooling.

- Mitigation: Design for near-net shaping to minimize material removal. Specify tight tolerances and fine surface finishes only where functionally necessary. Collaborate with experienced SiC manufacturers who have optimized machining processes.

- Joining SiC to Other Materials:

- Challenge: Differences in thermal expansion coefficients between SiC and metals can create significant stresses at joints during temperature cycling, potentially leading to failure.

- Mitigation: Utilize specialized joining techniques like active metal brazing, shrink fitting with carefully calculated interference, or mechanical clamping designs that accommodate differential expansion. Employ functionally graded materials or compliant interlayers where appropriate.

- Sealing Challenges:

- Challenge: While SiC can be lapped to excellent sealing surfaces, achieving and maintaining a perfect seal in dynamic applications or under severe conditions requires careful design of both the SiC components and the overall valve assembly.

- Mitigation: Ensure precise dimensional and geometric control of sealing faces. Select appropriate SiC grades for wear and chemical resistance. Consider the compatibility of SiC with any elastomeric or soft seals used in the valve design. For critical applications, hard-on-hard sealing (e.g., SiC ball on SiC seat) often provides the best longevity.

- Thermal Shock Management:

- Challenge: Although SiC has good thermal shock resistance compared to many ceramics, very rapid and non-uniform temperature changes can still induce stress fractures, especially in complex shapes or constrained parts.

- Mitigation: Design for uniform heating/cooling where possible. Select SiC grades (like NBSC or some RBSC grades) with optimized thermal shock parameters if this is a primary concern. Analyze thermal gradients during the design phase.

- Initial Cost Perception:

- Challenge: The upfront cost of SiC valve components can be higher than those made from conventional metals or less advanced ceramics.

- Mitigation: Focus on the Total Cost of Ownership (TCO). The extended service life, reduced maintenance, and prevention of downtime offered by corrosion-resistant valves and wear-resistant valves made from SiC often result in significant long-term savings. Present a clear TCO analysis to stakeholders.

Overcoming these challenges requires a combination of robust engineering design, careful material selection, skilled manufacturing, and close collaboration with experienced SiC valve specification experts and suppliers. By understanding these potential issues, companies can implement SiC valves effectively and reap their substantial benefits in harsh service conditions.

Partnering for Success: Selecting the Right SiC Valve Supplier – Introducing Sicarb Tech

Choosing the right supplier for your silicon carbide valves and components is as critical as the material selection itself. The supplier’s technical expertise, manufacturing capabilities, quality control systems, and understanding of your application requirements will directly impact the performance and reliability of the final product. When evaluating potential partners for valve sourcing, consider the following:

- Technical Expertise and Material Knowledge: Do they have a deep understanding of different SiC grades and their suitability for various applications? Can they provide design assistance and material selection guidance?

- Manufacturing Capabilities: What forming (pressing, casting, etc.), sintering, and precision machining (diamond grinding, lapping) capabilities do they possess? Can they achieve the required tolerances and surface finishes?

- Quality Control and Certifications: What quality management systems (e.g., ISO 9001) are in place? What are their inspection and testing procedures for raw materials, in-process components, and final products?

- Customization Capabilities: Can they produce custom SiC components tailored to your specific designs and requirements?

- Track Record and Experience: Do they have a proven history of supplying high-quality SiC components to your industry or for similar applications? Can they provide case studies or references?

- Supply Chain Reliability and Lead Times: Can they ensure a stable supply of materials and provide realistic lead times for production and delivery?

- Cost-Effectiveness: While not the sole factor, their pricing should be competitive, reflecting the value and quality offered. Look for suppliers who can offer a good balance of quality, service, and cost.

Your Trusted Partner in Custom Silicon Carbide: Sicarb Tech

When seeking a reliable source for high-quality, custom silicon carbide components, it’s beneficial to look towards global centers of excellence. An important global hub for China’s silicon carbide customizable parts manufacturing is situated in Weifang City. This region is home to over 40 silicon carbide production enterprises, collectively accounting for more than 80% of China’s total SiC output. This concentration of expertise and production capacity offers significant advantages for sourcing specialized SiC products.

At the forefront of this industrial cluster is Sicarb Tech. Since 2015, we have been instrumental in introducing and implementing advanced silicon carbide production technology, assisting local enterprises in achieving large-scale production and significant technological advancements. As part of the Chinese Academy of Sciences(Weifang) Innovation Park, an entrepreneurial park collaborating with the National Technology Transfer Center of the Chinese Academy of Sciences , SicSino leverages the immense scientific and technological capabilities of Chinese Academy of Sciences.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.