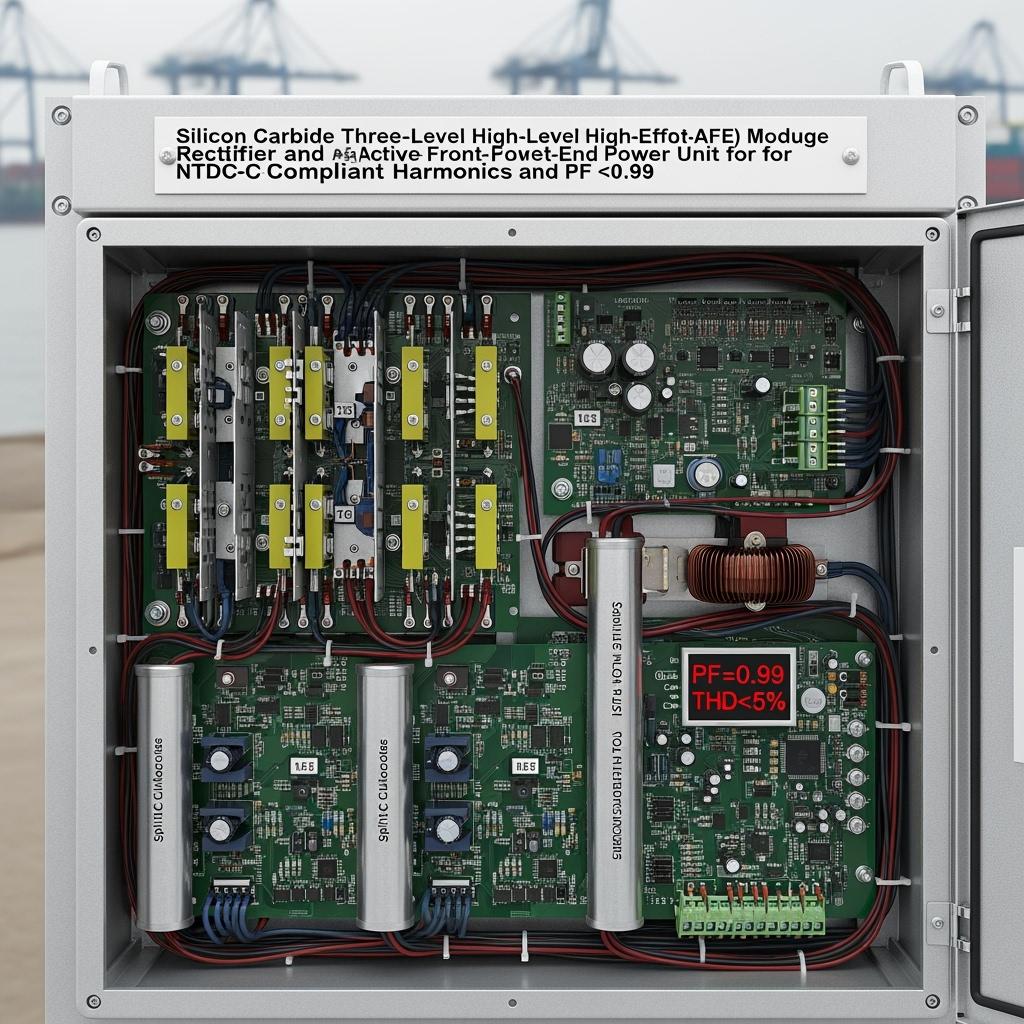

Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99

Share

Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 product overview and 2025 market relevance

Across Karachi’s terminals and along the industrial corridors that feed Pakistan’s textile, cement, and steel exports, the shore-power bus has become the heartbeat of operations. When that bus is clean—low harmonics, tight voltage, high power factor—cranes move with confidence, reefer yards stay cold, and dispatch centers remain calm. The Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 is Sicarbtech’s flagship entry at this critical interface. Built from the wafer up in Sicarbtech’s vertically integrated SiC manufacturing chain—crystal growth, epitaxy, chip fabrication, module packaging, and system-level validation—the unit delivers NTDC-aligned current THD with power factor of 0.99 or better, all while raising efficiency and shrinking thermal footprints.

In 2025, Pakistan’s push toward green, electrified ports is colliding with the realities of heat, humidity, and salt-laden air. Moreover, tariff pressures make every percentage point of efficiency matter in PKR terms. The Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 addresses both fronts by operating at 20–60 kHz with a three-level topology that lowers device stress and reduces filter sizes. The result is quieter cabinets, less waste heat, and a shore-power bus whose quality satisfies audits without the need for oversized passive filters. In short, it is the foundation on which reliable UPS, static transfer, and crane drives can perform at their peak.

Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 technical specifications and coordinated power quality features

At the heart of the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 is a neutral-point-clamped topology that halves device voltage stress compared with two-level architectures. This, combined with SiC’s low switching and conduction losses, enables 20–60 kHz operation with compact LCL filtering that maintains NTDC-compliant THD for a wide range of shore-side loads. The DC bus typically spans 600–1200 V, aligning with Sicarbtech UPS and drive ecosystems, while device and insulation stacks are qualified to 1200–1700 V at the module level for transient durability.

Control is model-based and fast. A synchronous frame current controller shapes grid currents to near-perfect sine waves and holds PF ≥0.99 even as crane hoists ramp or reefer compressors cycle. Harmonic observers and adaptive notch filters damp resonance with site-specific cable impedances. Meanwhile, the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 coordinates with Sicarbtech’s silicon carbide active filtering and reactive compensation integrated module for shore power, allowing the AFE to prioritize real power while the filter module manages dynamic VARs and residual harmonics. Thermal design uses high-thermal-conductivity substrates and vapor chamber spreaders beneath the hottest die, allowing a smaller, quieter cooling system to maintain junction temperatures with ample margin even in Karachi’s summer.

Protection is comprehensive: overcurrent and desaturation detection, bus over/undervoltage, grid out-of-step, and anti-islanding. Environmental hardening includes conformal-coated electronics, plated bus bars, and salt-fog-validated seals. The Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 also integrates natively with Sicarbtech’s silicon carbide power module online monitoring and health diagnostics acquisition unit, streaming PF, THD, temperature margins, switching loss proxies, and event logs to a central dashboard for predictive maintenance and compliance reporting.

Power quality and efficiency comparison with the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99

| Shore-Bus KPI in Pakistani Terminals | Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 | Legacy Diode Rectifier + Passive Filter |

|---|---|---|

| Input current THD across load range | <3–5% typical with compact LCL | 8–15% typical; detuning with load shifts |

| Power factor at nominal load | ≥0.99 with synchronous control | 0.85–0.95; depends on capacitors |

| Efficiency at rated output | 97–98% class with SiC three-level | 92–94% with diode/thyristor stages |

| Acoustic and electrical noise | Lower; high-frequency but filtered | Higher; bulky filters, audible hum |

| Response to grid disturbances | Fast dynamic shaping and ride-through | Slow; risk of voltage dips and trips |

Lifecycle and PKR-denominated ROI enabled by the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99

| Five-Year Operational Outcomes | Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 | Conventional Front-End Approach |

|---|---|---|

| Energy cost due to conversion losses | 10–20% lower losses → reduced PKR spend | Higher ongoing losses |

| Harmonic penalty risk and audits | Minimal; NTDC-aligned THD | Elevated; periodic penalties and rework |

| Cooling and maintenance overhead | Lower fan duty; predictive O&M | Higher airflow; reactive maintenance |

| PLC/drive trips linked to PQ | 40–60% reduction | Persistent alarms and resets |

| Payback horizon | 24–36 months typical | 48+ months for passive-heavy systems |

System integration view of the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99

| Integration Aspect | Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 Implementation | Impact in Karachi/Gwadar Operations |

|---|---|---|

| UPS and DC bus | Tight DC regulation; coordinated with STS | Stable transfers; fewer DC dips |

| Active filter/VAR | Telemetry sharing avoids loop conflicts | THD <5% with PF held near unity |

| Storage/DC/DC | Smooth regen and charge control | Peak shaving and ride-through support |

| Environmental sealing | Conformal coat, hydrophobic filters | Reliability through monsoon seasons |

| Monitoring and analytics | Health diagnostics integration | Faster root cause and trend-based service |

Key advantages and proven benefits of the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 with expert perspective

The pivotal advantage is disciplined current shaping without thermal compromise. By combining a three-level topology with SiC switching, the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 delivers near-ideal grid behavior while freeing space and cooling capacity for other cabinet functions. As Dr. Sana Rehman, a power quality advisor involved with industrial electrification programs in Pakistan, put it during a 2025 briefing, “The moment PF holds at 0.99 and THD stays under five percent during crane hoists, the rest of the system becomes predictable. That’s when downtime curves bend in the right direction” (industry roundtable notes, Karachi). Predictability, in this context, is the highest form of performance.

Real-world applications and measurable success using the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99

At a Karachi reefer terminal, replacing a thyristor-front end with the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 reduced input THD from roughly 11% to under 4% across evening compressor cycles. Power factor rose to 0.99 under mixed loads, and fan duty within the UPS cabinet dropped by 18%, lowering acoustic noise in adjacent workspaces. Over two quarters, the site documented a 46% decline in power-quality alarms and saved measurable PKR on energy due to improved conversion efficiency.

In a crane cluster near Gwadar, the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 stabilized the shore bus during simultaneous hoist operations. Torque ripple in drives decreased, PLC nuisance resets vanished, and the commissioning team closed SAT three days early thanks to built-in oscillography and harmonics reports. The terminal’s operations report cited a 5–7% reduction in energy consumption per container move, attributable to lower electrical losses and smoother dynamics.

Selection and maintenance considerations for the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99

Selecting the optimal rating begins with a candid look at load diversity and feeder impedance. Sicarbtech engineers profile crane duty cycles, reefer load ramps, and dispatch center sensitivities to tune LCL filters and current-control bandwidths that maintain NTDC-compliant THD with headroom. The Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 benefits from symmetric busbar layouts and short loop inductances, reducing EMI and improving stability. For maintenance, the health diagnostics platform tracks PF trends, harmonic content, device temperatures, and switching metrics, surfacing early warnings—such as rising neutral-point imbalance or filter drift—so teams can schedule targeted service during planned windows rather than reacting to alarms.

Industry success factors and customer testimonials around the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99

Sustained gains appear when the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 operates as part of a coherent stack: SiC UPS inverters, sub‑2 ms static transfer switching, active filtering with dynamic VARs, and, where needed, DC-bus energy storage. A Karachi terminal electrical supervisor summarized the change: “Once the AFE went live, our shore bus stopped arguing with the grid. Audits got easier, and operators stopped noticing transfers altogether.” That shift—from managing symptoms to managing capacity—is the defining feature of modernized Pakistani berths.

Future innovations and market trends linked to the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99

The next chapter tightens integration with storage and predictive controls. The Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 is evolving toward model-predictive current control that anticipates crane lifts from work orders and adapts harmonic targeting seasonally as feeder behavior shifts with monsoon conditions. Higher-density planar magnetics and next-generation SiC gate drivers will push switching frequencies upward without efficiency penalties, shrinking filters further. Cyber-secure telemetry and standardized reporting will streamline NTDC audits, while digital twins will enable lab rehearsal of commissioning sequences that translate directly to faster SAT on the pier.

Common questions and expert answers about the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99

How does the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 maintain PF ≥0.99 during dynamic crane loads?

It uses synchronous frame current control with fast observers to shape grid currents in real time, holding reactive power near zero even as hoist and trolley loads change rapidly.

What THD can be expected from the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 without oversized passive filters?

Typical input current THD remains under 3–5% across the operating range thanks to high-frequency switching and optimized LCL filtering, aligned with NTDC expectations.

Is the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 compatible with energy storage on the DC bus?

Yes. It coordinates with Sicarbtech’s bidirectional DC/DC modules to manage regen, peak shaving, and ride-through while preserving low AC-side harmonics.

How is salt-mist resilience addressed in the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99?

Conformal-coated PCBs, corrosion-resistant bus bars, sealed airflow with hydrophobic filters, and validated salt-fog/humidity cycling ensure reliable operation in Karachi/Gwadar climates.

What commissioning support accompanies the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99?

The unit integrates with Sicarbtech’s type testing and reliability verification platform, providing scripted FAT/SAT, built-in oscillography, and harmonics reports to accelerate acceptance.

Why the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 works for your operations

Clean input current and high power factor are more than audit line items—they are the preconditions for quiet, predictable operations on the quay and in connected industries. The Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99 achieves both with SiC speed, a three-level topology, and port-grade packaging that stands up to heat and salt. In Pakistan’s high-stakes, high-humidity reality, it turns power quality compliance into everyday normalcy and converts efficiency gains into tangible PKR savings.

Connect with specialists for custom solutions on the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99

Sicarbtech is Pakistan’s trusted partner for silicon carbide power conversion. Backed by more than 10 years of SiC manufacturing expertise and the innovation ecosystem of the Chinese Academy of Sciences, we deliver custom product development across R-SiC, SSiC, RBSiC, and SiSiC, along with technology transfer and factory establishment services. Our turnkey scope spans material processing through finished AFEs, UPS stacks, and verification platforms, supported by a track record with 19+ enterprises. Engage us for a free consultation: we will model your feeder and load profiles, size the Silicon Carbide Three-Level High-Efficiency Rectifier and Active Front-End Power Unit for NTDC-Compliant Harmonics and PF ≥0.99, estimate PKR-denominated ROI, and script a FAT/SAT plan that compresses timelines.

Contact Sicarbtech: [email protected] | +86 133 6536 0038. Reserve production slots ahead of peak season and lock in NTDC-compliant PF and THD for 2025 and beyond.

Article Metadata

Last updated: 2025-09-15

Next scheduled review: 2026-01-15

Timeliness note: Reflects 2025 Pakistan port electrification priorities, NTDC power quality expectations, and Sicarbtech’s latest SiC three-level AFE advancements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.