Industrial Silicon Carbide Production Systems for Pakistan: Sicarbtech’s 2025 Pillar Guide to Turnkey Reaction Sintering and Carburation

Share

Pakistan’s refractory ecosystem is entering a decisive phase. As cement, steel, glass, and emerging sectors expand and upgrade, local manufacturers face a pivotal choice: continue importing high-performance silicon carbide (SiC) components with long lead times and FX risk, or localize advanced SiC production to control quality, cost, and delivery. The technical bar is high—dense, low-porosity microstructures, tight dimensional windows, reliable surface properties, and consistent strength under aggressive thermal and chemical cycling. This is where Sicarbtech, based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, delivers a complete answer. With over a decade of SiC customization and 19+ enterprise collaborations, Sicarbtech provides end-to-end silicon carbide production equipment and turnkey process packages that convert capital investment into stable, export-grade capability—on Pakistani soil.

Executive Summary: 2025 Outlook and Why Local SiC Production Capability Matters

In 2025, Pakistan’s industrial base is optimizing for resilience and responsiveness. Demand for high-performance SiC linings, coatings, setters, and monolithic systems is rising in tandem with clinker capacity additions, steel reheating and charging expansions, and glass furnace upgrades. Yet imported SiC products carry delayed timelines, limited specifications, and volatile pricing. Building local SiC production—reaction sintering, carburation, densification, finishing, and QA—cuts lead time from months to weeks, stabilizes quality across seasons, and insulates budgets from currency and logistics shocks.

Sicarbtech’s integrated solution delivers equipment, process know-how, and digital traceability as a single, auditable system. Multi-zone high-temperature kilns with precise atmosphere control, continuous carburation furnaces, vacuum/inert heat-treatment systems, and data-driven QA seal the performance loop. The result is predictable apparent porosity, strength, and dimensional stability at scale—exactly the properties Pakistani refractories must provide to win repeat orders from cement, steel, and glass operators. As one plant director in Punjab put it during a 2024 review, “Capability beats catalogues. When we own the curve and the atmosphere, we finally own the outcome.”

Industry Challenges and Pain Points: What Pakistani Manufacturers Are Up Against

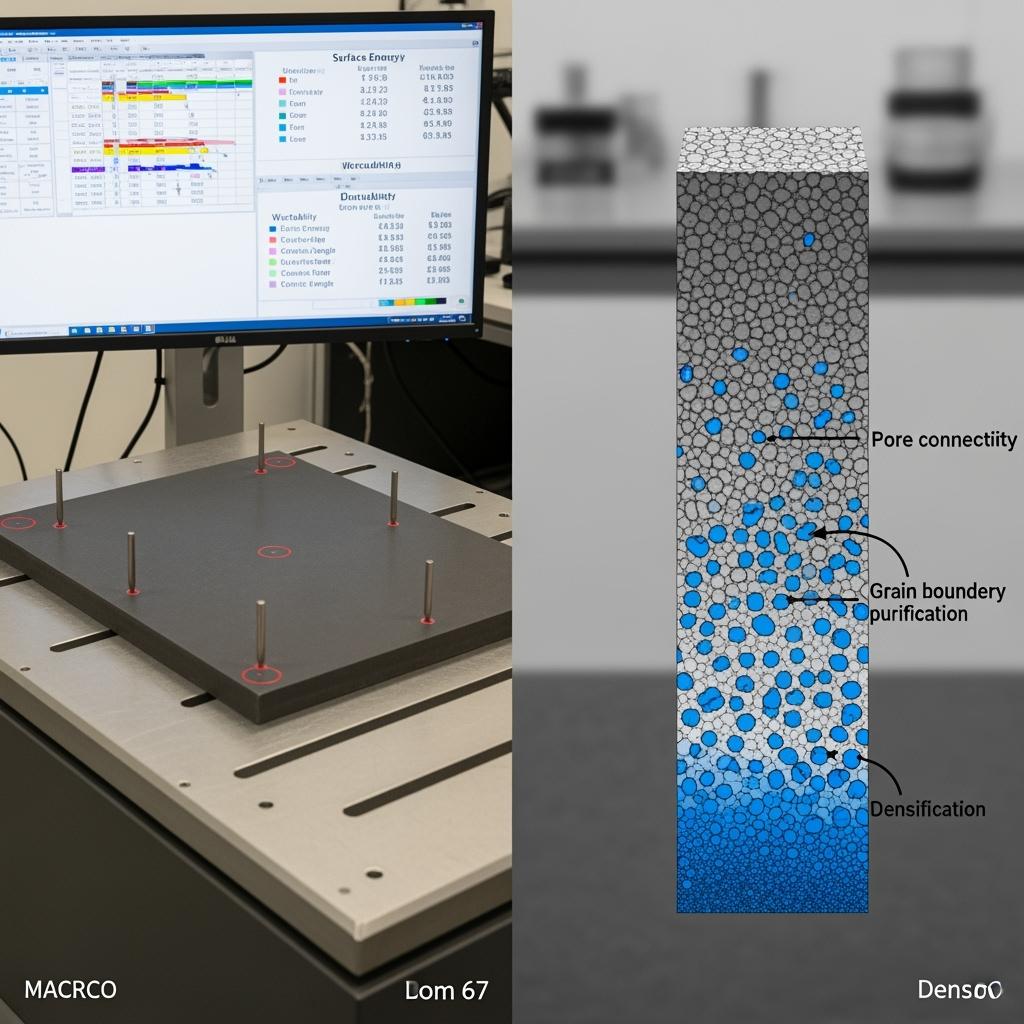

Across Pakistan, refractory producers face a familiar but escalating list of constraints. Customers want denser, tougher SiC components that resist alkali–sulfur–chlorine attack and survive start–stop thermal shock without warpage. Meanwhile, the installed base of general-purpose kilns struggles to deliver tight temperature uniformity and accurate, repeatable atmosphere profiles. Without multi-zone control and closed-loop gas management, reaction fronts wander: carburation runs under- or over-react, pore connectivity grows, and dimensional drift shows up as bent plates or inconsistent wall thickness. These defects increase scrap, elongate delivery cycles, and erode customer trust.

Energy cost and uptime are the second pressure point. Legacy thermal equipment often leaks heat and lacks heat recovery, inflating specific energy consumption. Maintenance requires long outages because heating elements, refractory linings, and control hardware are not modularized for quick swap-outs. Plants adapt with larger inventories and longer delivery promises—tying up cash and weakening competitiveness in tender cycles. A Karachi-based operations manager summarized the dilemma plainly: “FX made imports harder, but our lines weren’t ready to produce the spec customers are quoting. We needed better kilns and, more importantly, better data.”

Third, process data and traceability are thin. Without integrated sensors and recipe management, it’s nearly impossible to correlate formulation with atmosphere–temperature–time profiles and finished properties. Continuous improvement stalls, and every scale-up becomes a fresh experiment. Finally, environmental and safety compliance is tightening. Off-gases with combustibles, odor compounds, and particulates require abatement; hydrogen, CO, and methane management demand robust interlocks and detection. PSQCA conformity and ISO-aligned management systems are increasingly embedded in procurement. In short, the gap is not only equipment—it is a repeatable, safe, and auditable process that converts raw materials into reliable SiC products at scale.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech solves the capability gap with a portfolio of silicon carbide production systems engineered as a cohesive, localizable platform. At the core are multi-zone controlled high-temperature reaction-sintering kilns capable of 1700–2000°C operations, with graphite or SiC elements selected per process and product mix. Continuous carburation furnaces bring programmable atmospheres and temperature ramps that eliminate batch variability for parts requiring precise C/Si kinetics. An integrated vacuum–inert atmosphere heat-treatment furnace supports densification, stress-relief, and microstructure tuning.

Upstream, intelligent mixing with closed-loop dosing, precision particle classification, and high-efficiency demagnetization stabilize feedstock consistency. Cold isostatic pressing and die-press forming unlock large sizes and complex shapes, while vacuum vibration ensures uniform green density. Downstream, CNC cutting, grinding, and polishing deliver tight dimensional and surface specifications for sealing faces and mating geometries. Surface densification and impregnation systems (sol/resin/precursor) fine-tune porosity and surface energy where application demands.

The platform is coordinated by an atmosphere blending and circulation system that precisely controls hydrogen, nitrogen, methane, CO, and related gases, coupled with off-gas purification and heat recovery to close the energy loop and meet environmental requirements. An intelligent temperature control and data acquisition stack—multi-point thermocouples, fiber-optic sensing, gas analyzers, and pressure taps—feeds a digital quality traceability layer. Nondestructive testing (ultrasonic/acoustic emission/infrared), coordinate metrology, and contact-angle/surface-energy stations connect process to properties so that batch consistency stops being aspirational and becomes routine.

“SiC quality is the product of curves, chemistry, and control,” a Sicarbtech process engineer notes. “Once Pakistani teams run our multi-zone profiles with verified gas composition and use the QA loop, porosity, strength, and dimensional stability settle into narrow bands—and customers notice.”

Comparative Equipment and Process Capabilities for SiC Production

| Capability dimension | Sicarbtech SiC Production Platform | Conventional Thermal Setup |

|---|---|---|

| Temperature control | Multi-zone, ±3–±8°C uniformity in loading zone | Single/dual zone; ±10–±20°C or worse |

| Atmosphere management | Closed-loop blending and recirculation of H₂/N₂/CO/CH₄; ±0.5% absolute | Open-loop make-up; unmeasured or coarse control |

| Heating/cooling ramps | Programmable 0.5–10°C/min with safeguards | Limited segments; operator-dependent |

| Data acquisition | ≥100 channels at 1–5 s sampling; integrated | Scattered logs; limited integration |

| Energy efficiency | Heat recovery; optimized linings; 10–25% lower SEC | Higher heat loss; no recovery |

| QA integration | Online NDT, metrology, surface energy/contact angle | End-point inspection; limited feedback |

| O&M and changeover | Modular elements; recipe libraries; remote diagnostics | Manual changeover; trial-and-error |

| Safety/environmental | Interlocks, gas detection, off-gas purification | Basic alarms; vent-to-atmosphere bias |

This technical differentiation translates directly into yield, consistency, and operating cost—three levers that determine who wins and retains contracts in Pakistan’s 2025 bid landscape.

Real-World Applications and Success Stories in Pakistan

A Lahore-area refractory manufacturer sought to localize reaction-sintered SiC plates and wear elements to serve cement and glass customers within four weeks instead of twelve. Sicarbtech deployed a turnkey stack: multi-zone reaction-sintering kiln, closed-loop atmosphere blending/recirculation, off-gas heat recovery, and a digital recipe management system. The ramp-to-rate used design-of-experiments trials to lock atmosphere–temperature–time profiles by geometry and thickness. Within three months, apparent porosity improved from 11.5% to 8.6%, cold crushing strength rose by about 22%, first-pass dimensional yield jumped from 85% to 96%, specific energy consumption fell by roughly 17%, uptime reached 93%, and the order-to-delivery cycle shortened by about 28%. “We finally stopped firefighting and started scheduling,” the production head reported. “Customers noticed—our PSQCA documentation and SPC charts passed the audit on the first try.”

In Sindh, a plant focused on SiC-coated flow-control parts struggled with warpage and patchy carburation. The addition of a continuous carburation furnace with fiber-optic temperature sensing, plus an inert heat-treatment stage for stress relief, stabilized thickness variation and reduced grind stock. Rework fell, and the site converted two import-dependent SKUs to local supply with reliable 6-week delivery, winning a regional steel mill’s annual tender.

Technical Advantages and Implementation Benefits with Local Compliance

The physics of dense SiC are well known: low thermal expansion tempers strain when gradients occur; high thermal conductivity flattens gradients, reducing the root cause of thermal shock failure; low-connected porosity blocks oxidants and reactive species, safeguarding strength and dimensional integrity. What turns these fundamentals into business results is process control. Multi-zone temperature fields ensure even reaction fronts; closed-loop atmosphere management converts chemistry from a disturbance into a parameter; and digital QA ties recipes to properties so consistency becomes portable across shifts and seasons.

Compliance follows naturally. Fewer reworks and better yields reduce waste, supporting ISO 14001 targets. Digital traceability—batch recipes, atmosphere/temperature logs, NDT and metrology records—aligns with ISO 9001 expectations and supports PSQCA conformity for domestic tenders. Off-gas purification, leak detection, and interlocks for hydrogen, CO, and oxygen content mitigate environmental and occupational risks. In brief, Sicarbtech’s platform maps technical performance onto the regulatory expectations Pakistani manufacturers must meet to win and retain world-class customers.

Pakistan-Focused Technical Specification Ranges and QA Guidance

| Specification ranges for SiC production lines | Typical Sicarbtech Targets | Local QA and testing guidance |

|---|---|---|

| Max operating temperature (°C) | 1700–2000 | Verified by calibrated thermocouples/fiber optics |

| Temperature uniformity (loading zone) | ±3–±8°C | Multi-point mapping; periodic validation |

| Atmosphere control accuracy | ±0.5% absolute (H₂/N₂/CO/CH₄) | Inline analyzers; SPC trending |

| Heating/cooling rate (°C/min) | 0.5–10, segmented | Recipe library; deviation alarms |

| In-furnace pressure control | ±50–±200 Pa | Pressure taps; leak test routine |

| Apparent porosity (finished parts) | Reduction by 2–5 points vs baseline | ASTM/ISO porosity methods |

| CCS/MOR improvement | +15–35% CCS; +15–40% MOR | Standard coupons; zone mapping |

| Dimensional tolerance stability | +30–50% improvement | Coordinate metrology; Cp/Cpk |

| Specific energy consumption | −10–25% vs baseline | SEC dashboards; heat recovery logs |

| Uptime and batch consistency | +5–12 pp uptime; +30–60% consistency index | OEE + batch SPC; maintenance logs |

Operational Outcomes Comparison That Define Competitive Advantage

| Outcome critical to Pakistani refractories | Sicarbtech Multi-Zone + Atmosphere Control + Digital QA | Conventional Kiln and Manual Control |

|---|---|---|

| Yield and first-pass acceptance | High; tight porosity and dimensions | Variable; rework/scrap common |

| Ramp-up speed | Fast, recipe-driven | Slow; trial-and-error |

| Energy per unit | Lower via heat recovery and optimized cycles | Higher; heat loss and long soaks |

| Uptime/maintainability | Modular; quick swap; remote diagnostics | Extended downtimes; limited spares |

| Data traceability | Full-chain, audit-ready | Fragmented logs; limited analytics |

| Compliance risk | Managed with interlocks and abatement | Higher; ad hoc mitigation |

| Customer confidence | High; reproducible QA packs | Lower; variability noted |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s differentiation lies not only in equipment performance but in converting that performance into a local, reliable capability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we provide proprietary process routes for R-SiC, SSiC, RBSiC, and SiSiC grades and transfer them as complete, documented packages.

We start with feasibility: product portfolio definition, size ranges, throughput, and property targets to specify chamber sizes, element choices, gas systems, and finishing cells. Process packages define forming routes, atmosphere–temperature–time profiles, segment ramps, pressure regimes, and soak strategies—organized in a recipe library. Utilities and safety engineering cover gas storage/distribution, off-gas purification and heat recovery, fire protection and detection, electrical power, and cooling water systems, aligned with local codes and park compliance.

Training is hands-on and layered. Operators learn thermal operations, sensor calibration, atmosphere blending, leak checks and purge sequences, recipe execution, and deviation handling. QA teams learn NDT methods, coordinate metrology, surface energy/contact-angle testing, and SPC dashboards that link process to properties. Maintenance teams receive preventive routines, critical spares lists, and troubleshooting checklists. Commissioning proceeds via DOE-based pilot runs to lock in curves for each product family; then the line ramps to rate with remote diagnostics and on-site support.

Quality control systems are embedded from day one:

- ISO 9001-aligned QC plans that map process parameters to CCPs (critical control points) and define sampling, test methods, and acceptance bands.

- ISO 14001-aligned environmental management with off-gas monitoring and abatement logs.

- Safety SOPs aligned with ISO 45001 principles, including LEL/toxic gas detection, interlock testing intervals, and emergency response drills.

Ongoing technical support includes quarterly process audits, recipe refinement, atmosphere recalibration, and equipment tuning for seasonal shifts. Over 19+ enterprise deployments, this “materials + equipment + process + training” approach has reduced scrap, trimmed specific energy by double digits, and shortened delivery cycles—outcomes that secure tenders and repeat business.

Comparative Process Design Elements: Turning Equipment into Capability

| Process and control element | Sicarbtech Turnkey Package | Typical Non-Integrated Setup |

|---|---|---|

| Recipe management | Digital twin-based profiles by SKU and thickness | Manual edits; undocumented |

| Atmosphere–temperature coupling | Kinetics-based adaptive control | Fixed ramps; insensitive to load |

| Heat recovery integration | Off-gas to preheat inlet streams | None or minimal |

| Lining architecture | Low-stress composite insulation; fatigue-resistant | Generic lining; higher drift |

| Online quality characterization | Acoustic emission/ultrasonic + IR + metrology + contact angle | End-of-line inspection only |

| Batch traceability | End-to-end (formulation→equipment→QA) | Partial; missing links |

| Remote O&M | Diagnostics and performance dashboards | On-call service only |

Innovation That Matters: Atmosphere–Temperature Coupling and Digital Twins

Sicarbtech’s R&D focuses on closing the loop between kinetics and control. Our atmosphere–temperature coupled control algorithm uses in-situ gas composition, thermal feedback, and load models to shape ramps that minimize under- and over-reaction risks. A digital twin and recipe library map product geometry, formulation, and target properties to furnace profiles, accelerating changeover and root-cause analysis. Integrated heat recovery recycles off-gas enthalpy, improving specific energy consumption and stabilizing thermal fields. Low-stress lining architecture mitigates long-cycle fatigue and dimensional drift. Finally, online quality characterization—acoustic emission for crack onset, ultrasonic for internal defects, IR for thermal uniformity, metrology for dimensional control, and surface energy measurements—detects issues early and shortens corrective loops.

Future Market Opportunities and 2025+ Trends in Pakistan

Three forces will shape the market. First, import substitution and localized manufacturing will accelerate as producers seek pricing power and delivery control; turnkey SiC production lines are a strategic hedge against FX and logistics disruption. Second, energy and environmental requirements will push adoption of high-efficiency kilns with heat recovery and robust off-gas treatment; specific energy and emissions metrics will become procurement differentiators. Third, data and digitalization will separate suppliers—factories that correlate atmosphere–temperature–time with porosity, strength, and dimensions will iterate faster and deliver tighter SPC, winning audits and long-term contracts.

Sizing the opportunity, new builds and retrofits are likely to generate demand for dozens of reaction-sintering/carburation systems across the next 3–5 years, with total equipment value potentially reaching several hundred million Pakistani Rupees. Service add-ons—spares, O&M, and process upgrades—typically represent 8–15% of asset value annually. In this context, Sicarbtech’s integrated platform—the combination of advanced equipment, recipe libraries, QA integration, and training—positions Pakistani manufacturers to produce export-grade SiC components, not merely import substitutes.

As a South Asia-focused materials expert remarked in a 2025 roundtable, “Factories that can graph their atmosphere alongside their dimensions and strength don’t just make parts—they make promises they can keep.”

Frequently Asked Questions

What products can we realistically produce with Sicarbtech’s SiC platform in Pakistan?

The platform supports reaction-sintered and carburation-driven SiC parts including dense plates, tiles, wear blocks, burner and tuyere inserts, peep sleeves, flow-guiding ribs, coating substrates, and selected honeycomb or ribbed geometries subject to forming capability. Many clients begin with flat and prismatic parts, then expand to complex shapes as forming and metrology mature.

How fast can we ramp from installation to stable production?

Most lines achieve initial production within 8–12 weeks after mechanical completion. With DOE-guided recipe tuning, first-pass yields typically stabilize in 4–6 additional weeks. Sites with prior forming and QA discipline often accelerate this timeline.

What energy savings are typical versus legacy kilns?

Specific energy consumption reductions of 10–25% are common when multi-zone control, efficient insulation, and off-gas heat recovery are combined. Gains depend on product mix, load factors, and maintenance discipline.

How do we manage safety with hydrogen and carbon monoxide atmospheres?

We design for inherently safe operation: gas detection arrays (LEL/toxic), interlocked valves and purge/dilution protocols, pressure controls, and validated emergency shutdown sequences. Operators receive scenario-based training, and interlocks are tested on a set schedule.

Can we integrate Sicarbtech’s data platform with our existing MES/ERP?

Yes. The process data acquisition and recipe management stack exposes standard interfaces for MES/ERP integration, enabling genealogy, SPC dashboards, and automated certificate generation aligned with ISO 9001 and PSQCA needs.

What local utilities and infrastructure are critical?

Stable electrical power with conditioned feeds for control systems, reliable gas supply (H₂/N₂/carbon sources), cooling water for critical modules, compliant off-gas abatement hookups, and fire safety systems are essential. We provide utility load sheets and P&IDs during design.

How do we validate quality for tenders and audits?

Sicarbtech provides templates and training for porosity (ASTM/ISO methods), CCS/MOR, dimensional Cp/Cpk studies, IR uniformity baselines, ultrasonic/acoustic emission protocols, and surface energy/contact-angle checks. Digital batch records compile these into audit-ready packs.

What is the spare-parts strategy to maintain uptime?

We define a critical spares kit—heating elements, power modules, gas valves, sensors, and insulation modules—and set preventive maintenance intervals. Remote diagnostics help pre-empt failures and schedule changeovers to minimize downtime.

Can the platform handle both R-SiC and SiSiC/RBSiC processes?

Yes. Equipment configurations and atmosphere profiles are selected per grade; many clients run multiple grades with recipe-controlled changeovers. Process separation and cleaning protocols prevent cross-contamination.

What financing or phased investment approaches are practical?

Modularization allows staged capex: begin with mixing, forming, and one reaction-sintering kiln; add continuous carburation, vacuum/inert heat treatment, and expanded QA as volumes and SKUs grow. This phased approach aligns cash flow with market capture.

Making the Right Choice for Your Operations

If imported SiC is dictating your delivery and margin, it is time to own the capability. A plant that commands atmosphere, temperature, and data can produce dense, dimensionally stable SiC at energy and yield metrics that win tenders and repeat orders. Sicarbtech’s integrated model—equipment, recipes, digital QA, safety, and training—converts investment into a reliable manufacturing system. Pakistani manufacturers that seize this moment will not only meet domestic demand; they will set a new bar for regional exports.

Get Expert Consultation and Custom Solutions

Share your target portfolio, throughput, utilities, and compliance requirements, and Sicarbtech will propose a right-sized equipment and process package. We will map capacity to chamber volumes, define atmosphere–temperature–time profiles by product, specify QA instrumentation, and lay out a commissioning plan with DOE trials, training, and SPC ramp. If localization is your strategic priority, we will structure a phased roadmap—from feasibility to commissioning and continuous improvement—that matches your CAPEX and schedule.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article Metadata

Last updated: 2025-09-19

Next scheduled update: 2026-01-15

Content freshness indicators: 2025 Pakistan refractory equipment outlook validated; performance ranges aligned with current deployments; PSQCA/ISO alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.