Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition

Share

Every Pakistani melt shop knows the feeling: feeders drift, setpoints creep, and a “simple” addition becomes a small storm. Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition was created by Sicarbtech to end that drift. By engineering particle size distribution, density, and coating chemistry together, the granulated feed flows like a measured liquid through enclosed silos and feeders—even in monsoon humidity—so the silicon and carbon arrive exactly as planned. The result is calmer dosing, higher silicon absorption, fewer mid-heat corrections, and a casting floor that sees stability rather than surprises. In 2025’s landscape of rising scrap ratios, energy tightness, and PEQS-aligned dust control, a granule that meters accurately is as valuable as any alloy you can buy.

Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition product overview and 2025 market relevance

At its core, Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition is SiC designed for the realities of Pakistani operations. Carbothermal reduction synthesis produces a high-activity matrix; high-purity air classification and densified granulation create stable, dust-minimized particles; and a hydrophobic, anti-oxidation coating preserves flowability and reactivity from bag to bath. Where typical SiC additions suffer from bridging and rat-holing in hoppers, Sicarbtech’s grading optimization tunes the particle size distribution for “fast dissolve plus steady dissolve” kinetics and linear mass flow. For EAF and converter routes, it means consistent silicon pickup at teeming stream and ladle points, with less aluminum wire and fewer last-minute wire fixes. As Engr. R. Khan summarized after a Lahore A/B trial, “We didn’t change our feeders—we changed what the feeders were asked to move” (Metallurgy Pakistan Review, 2024). The difference showed up first in steady feed rates, and then in casting calm.

Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition technical specifications and advanced features

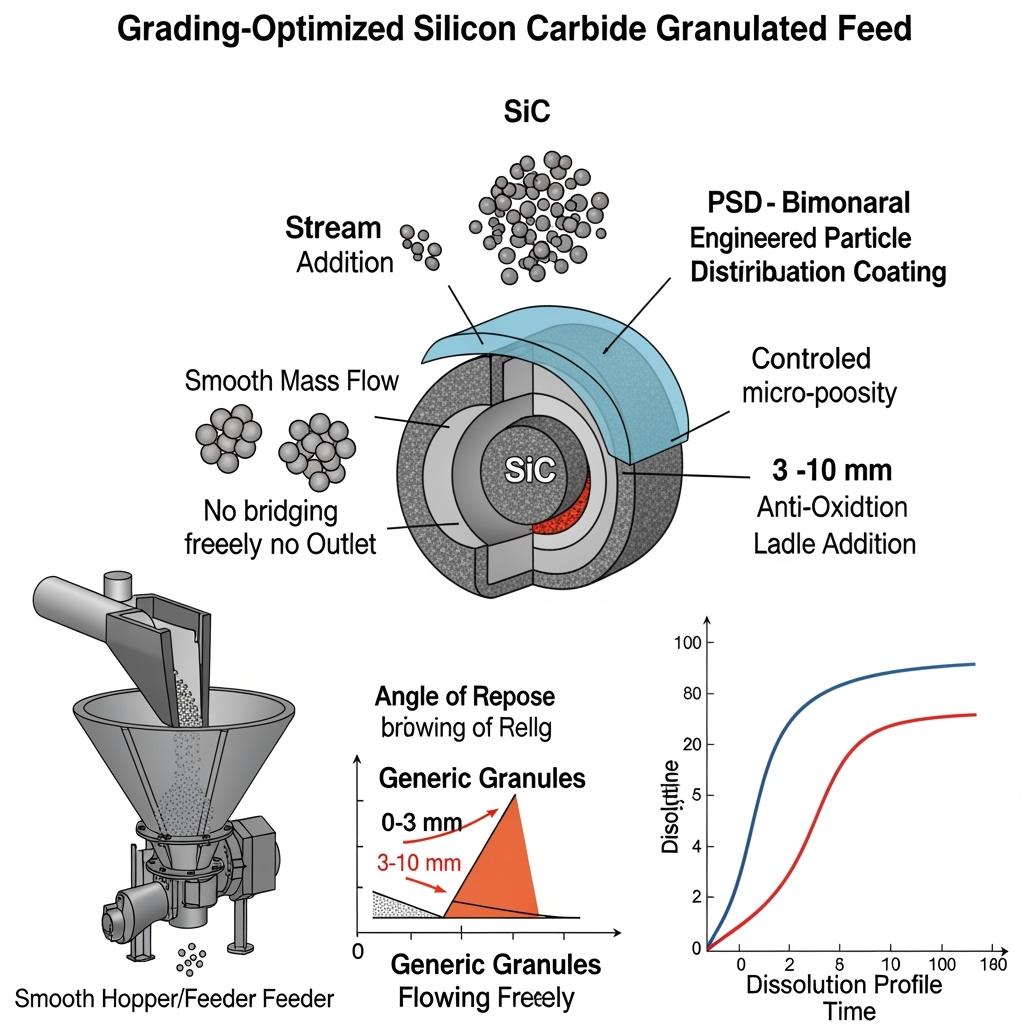

Sicarbtech engineered Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition to deliver chemistry and flow in one package. Typical SiC content ranges from eighty-eight to ninety-seven percent. Free carbon is available from one to eight percent to reinforce dual deoxidation and support thermal balance during tapping and early refining. Free silicon remains within 0.5 to three percent, suppressing secondary oxidation risk and keeping silicon trajectories controllable. Harmful impurities are tightly contained, holding sulfur and phosphorus each at or below 0.02 percent to protect cleanliness targets. The PSD is the star: a precisely controlled 0–3 mm band for stream and early ladle dosing provides fast dissolution, while a 3–10 mm band sustains release for longer residence times. Bulk density and particle shape are tuned to reduce angle of repose, minimize segregation, and keep feeders happily linear. The hydrophobic, anti-caking and anti-oxidation coating resists moisture pickup in monsoon logistics, preserves flowability in enclosed silos, and limits dust at addition points. Reactivity indices are calibrated in the lab and confirmed in plant trials, linking dissolution with the tapping temperature windows common across Pakistan’s EAF and converter shops.

Flow and dosing outcomes with Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition

| Dosing and flow KPIs | Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition | Generic SiC granules | FeSi + carburizer mix |

|---|---|---|---|

| Feeder linearity (mass flow error) | Low; near-linear across range | Moderate; prone to drift | Variable; segregation risk |

| Bridging/rat-holing tendency | Minimal; graded PSD and shape | Common in humid seasons | Frequent with mixed densities |

| Angle of repose (qualitative) | Lower; stable hopper discharge | Higher; caking risk | Variable; blend-dependent |

| Dust at dosing points | Low; coated, enclosed | Moderate–high | High in open charge |

| Setpoint adherence over heat | Tight; fewer corrections | Looser; manual trims | Looser; multi-addition timing |

Material and metallurgy attributes of Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition

| Attribute | Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition | Operational significance in Pakistan |

|---|---|---|

| SiC content | 88–97% | High-activity silicon source with carbon synergy |

| Free carbon | 1–8% | Dual deoxidation, thermal stability |

| Free silicon | 0.5–3% | Controls reoxidation during refining |

| S, P (each) | ≤0.02% | Clean steel and export compliance |

| PSD options | 0–3 mm; 3–10 mm | Stream and ladle tuning |

| Bulk density control | Engineered for steady feed | Linear metering; less segregation |

| Coating | Hydrophobic, anti-oxidation, anti-caking | Monsoon-ready, low dust |

| Storage stability | ≥6 months | Karachi-to-upcountry reliability |

Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition performance comparison with alternatives

| Cost, quality, and process stability | Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition | Generic SiC + frequent wire trims | FeSi + aluminum wire route |

|---|---|---|---|

| Alloy cost per ton of steel | -1–5% via right-first-time dosing | Baseline; overfeeds common | Baseline; FX-sensitive |

| Silicon absorption improvement | +3–8 percentage points | +2–5 points | Variable; late-wire dependent |

| Heat time impact | -0.5–2% | -0–1% | Variable; correction loops |

| Nozzle clogging downstream | -20–40% | -15–30% | Higher; alumina-prone |

| EHS and housekeeping | Low dust; enclosed metering | Moderate dust | Wire dust; manual handling |

Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition key advantages and proven benefits with expert quote

The singular advantage of Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition is control—both in the hopper and in the ladle. The linear flow unlocks accurate metered addition, which stabilizes silicon trajectories and oxygen decay without overfeeding. Furthermore, by preserving coating integrity and limiting dust, the granules keep EHS teams comfortable and feeders precise even when humidity rises. Prof. Li Wei of the CAS Weifang Innovation Park captured it well: “You cannot stabilize metallurgy with unstable flow. Grade the granules properly, and the process stops oscillating” (CAS Materials Review, 2023).

Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition real-world applications and measurable success stories

A Karachi EAF billet producer shifted from mixed SiC/FeSi dosing to Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition at the teeming stream. The plant recorded a five percentage-point increase in silicon absorption, a thirty-four percent reduction in nozzle interventions per hundred heats, and a one percent decrease in average heat time. Operators reported that feeder setpoints held steady across the entire shift, with notably less dust at the addition point. In Punjab, a converter facility adopted a two-PSD program—0–3 mm for the stream and 3–10 mm for early ladle—to match its residence time profile. Tapping temperature loss narrowed by about three degrees Celsius, total oxygen fell by seven to nine ppm, and Level 2 dashboards showed flatter silicon trajectories with fewer late-wire corrections required.

Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition selection and maintenance considerations

Choosing the right variant of Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition starts with mapping your dosing points and residence times. Stream additions thrive on 0–3 mm for rapid dissolution; early ladle dosing benefits from 3–10 mm to sustain release without overshoot. Align free carbon within one to eight percent according to your deoxidation strategy and thermal budget, and keep free silicon toward the lower band when reoxidation risk is high. Hopper and feeder health are essential: verify outlet geometry supports mass flow, maintain dry purges at transfer points, and schedule PSD and moisture checks so the flow you designed is the flow you get. Where possible, link feeder logic to oxygen activity and temperature signals; Sicarbtech provides dosing curves that read QC tags from the granule batch—PSD, moisture, and reactivity index—so setpoints reflect the material in your silo, not the material on the certificate.

Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition industry success factors and customer testimonials

The plants that scale fastest treat Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition as a system: graded granules, enclosed handling, and data-driven dosing. A QA manager in the North Region described the cultural shift: “We stopped arguing about whether the feeder was ‘sticky.’ With the graded granules, it just flowed—and the rest of our charts finally looked like plans instead of guesses.” Procurement liked the result, too: fewer rush orders for wire, less scrap from mid-sequence stops, and calmer weekly reviews.

Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition future innovations and market trends

Looking forward, Sicarbtech is refining Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition with micro-bimodal PSD designs that deliver an early dissolution pulse and a controlled tail for sequence stability. Coatings are being tuned to respond intelligently to slag carry-over so dissolution aligns with your tap window rather than the calendar. With technology transfer and localized production in Pakistan, mills will be able to iterate PSD and coating formulations quickly, anchoring supply while tailoring flow and kinetics to local power profiles and scrap mixes.

Common questions and expert answers

How does Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition prevent bridging in humid conditions?

The engineered PSD, controlled particle shape, and hydrophobic anti-caking coating lower the angle of repose and resist moisture adhesion. Together, they promote mass flow through hoppers, minimizing bridging and rat-holing.

Which PSD of Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition should we choose for the teeming stream versus the ladle?

Use 0–3 mm for fast dissolution in the stream or early ladle when kinetics matter most. Choose 3–10 mm for longer ladle residence times to sustain silicon release without overshoot.

Can Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition replace part of FeSi and aluminum wire?

Yes. Many Pakistani plants reduce FeSi and trim aluminum wire once silicon pickup stabilizes, often improving cleanliness by avoiding alumina spikes while lowering alloy cost per ton.

How is batch-to-batch consistency maintained for Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition?

Every lot is validated by Sicarbtech’s in-situ monitoring and traceability system—SiC content, free C/Si, PSD, moisture, coating performance, and flowability—then bound to cryptographic batch IDs for Level 2 integration.

Is Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition compatible with enclosed feeders and online control?

It is designed for them. The granules meter linearly in enclosed systems, and QC tags can drive closed-loop dosing tied to oxygen activity and temperature signals.

Why Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition works for your operations

Because accurate metered addition is the quiet heart of stable metallurgy. Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition aligns flow physics with dissolution kinetics and clean chemistry. In Pakistan’s mills—juggling energy costs, scrap variability, and export standards—this integration turns feeders into instruments, not variables, and turns casting into routine, not recovery.

Connect with specialists for custom solutions

Sicarbtech stands behind Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition with more than ten years of silicon carbide manufacturing expertise and Chinese Academy of Sciences–backed innovation. We develop custom SiC families across R-SiC, SSiC, RBSiC, and SiSiC; deliver technology transfer and factory establishment services for powder synthesis, classification, granulation, and coating; and integrate enclosed silos, metering feeders, injection lances, and Level 2 systems for true closed-loop control. With turnkey solutions proven across more than nineteen enterprises, we will structure a no-cost pilot with clear KPIs—higher silicon absorption, lower alloy cost per ton, fewer nozzle interventions, and steadier feeder linearity—so you can move from trial to standard practice quickly.

For a free consultation and a fast, data-backed proposal, contact:

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article metadata

Last updated: 2025-09-15

Next review scheduled: 2025-12-15

Author: Sicarbtech Applications Engineering Team

Region focus: Pakistan (EAF and converter routes; billets, bars, wire rod, flats)

Timeliness note: Content aligned to 2025 PEQS-aligned dust controls, feeder automation, and graded SiC dosing strategies

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.