Unyielding Performance: The Definitive Guide to Silicon Carbide in Demanding Pump Applications

Share

In the relentless world of industrial operations, pumps are the unsung heroes, tirelessly moving fluids under often extreme conditions. For engineers, procurement managers, and technical buyers in sectors like chemical processing, mining, energy, and advanced manufacturing, the reliability and longevity of pump components are paramount. Traditional materials often fall short when faced with abrasive slurries, corrosive chemicals, and high temperatures. This is where custom silicon carbide (SiC) pump components emerge as a game-changing solution, offering unparalleled durability and efficiency. This comprehensive guide delves into the critical role of SiC in modern pump technology, exploring its applications, benefits, and the crucial factors in selecting a supplier for these advanced ceramic solutions.

The Indispensable Role of Silicon Carbide in High-Performance Pumps

Silicon carbide, a synthetic crystalline compound of silicon and carbon, stands out as a premier technical ceramic due to its exceptional hardness, second only to diamond. Its unique combination of properties makes it an ideal material for pump components subjected to severe operational demands. In essence, custom SiC products are engineered to precise specifications, ensuring optimal fit and function within a pump, thereby enhancing overall system performance and significantly reducing downtime.

The need for custom silicon carbide solutions arises from the diverse and often harsh environments in which industrial pumps operate. Standard off-the-shelf components may not offer the required resistance to specific abrasive particles or corrosive agents, leading to premature failure and costly interruptions. By tailoring the SiC grade, design, and surface finish, manufacturers can produce pump parts that deliver maximum operational life and reliability, even in the most challenging industrial applications. This focus on customization is where companies like Sicarb Tech excel, leveraging their deep expertise in SiC production technology.

Key Applications: Where Silicon Carbide Excels in Pump Technology

The versatility of silicon carbide allows its use in a wide array of pump types and critical components. Its superior resistance to wear, corrosion, and high temperatures makes it indispensable in industries where pump failure is not an option.

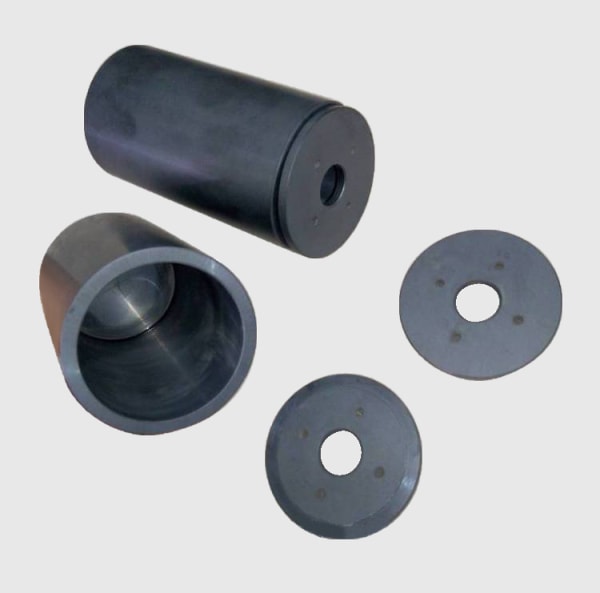

Key Pump Components Made from Silicon Carbide:

- Mechanical Seals: SiC seal faces are a cornerstone of modern pump reliability. Their exceptional hardness and low friction coefficient minimize wear and leakage, even when handling abrasive fluids or operating under high pressure and temperature. This is crucial for chemical pump seals and slurry pump seals.

- Bearings: Silicon carbide bearings (sleeve and thrust bearings) offer outstanding performance in aggressive media where traditional metallic or softer ceramic bearings would quickly degrade. Their ability to operate with thin fluid films or even run dry for short periods provides a significant advantage in industrial pump bearings.

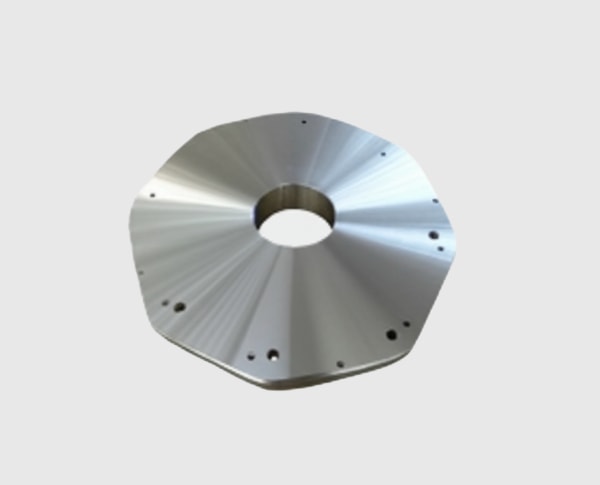

- Impellers and Volutes: In pumps handling highly abrasive slurries, such as those in mining or dredging, SiC impellers and volutes offer dramatically extended service life compared to metal or rubber-lined alternatives. SiC pump impellers maintain their geometry for longer, ensuring sustained hydraulic efficiency.

- Liners and Wear Plates: For pump casings and areas prone to high wear, custom SiC liners provide a robust barrier against erosion and corrosion. These are vital for slurry pump wear parts and components in corrosive fluid pumps.

- Shafts and Sleeves: In applications demanding high stiffness, corrosion resistance, and wear resistance, SiC shafts and sleeves can protect underlying metallic components or provide structural integrity.

Industries Benefiting from SiC Pump Components:

- Chemical Processing: Handling acids, alkalis, and solvents.

- Mining and Mineral Processing: Pumping abrasive slurries and tailings.

- Oil and Gas: Dealing with corrosive media, high pressures, and abrasive particles.

- Pulp and Paper: Resisting abrasive wood fibers and corrosive bleaching chemicals.

- Power Generation: Boiler feedwater pumps, flue gas desulfurization (FGD) pumps.

- Water and Wastewater Treatment: Handling grit, sludge, and corrosive disinfectants.

- Semiconductor Manufacturing: Ultra-pure water systems requiring non-contaminating components.

- Aerospace: Specialized fluid handling systems.

- Industrial Manufacturing: High-temperature fluid circulation, aggressive cleaning solutions.

The demand for high-performance pump materials and durable pump solutions continues to grow, and SiC is at the forefront of meeting these needs for OEMs, distributors, and end-users alike.

The Unmatched Advantages of Custom Silicon Carbide for Pump Longevity and Efficiency

Choosing custom silicon carbide for pump components isn’t merely an upgrade; it’s a strategic investment in operational excellence. The inherent properties of SiC translate directly into tangible benefits for pump performance, reliability, and overall cost of ownership.

Key Benefits for Pump Applications:

- Extreme Wear and Abrasion Resistance: Silicon carbide’s high hardness (typically >2500 Knoop) allows it to withstand aggressive slurries, hard particles, and high-velocity flows with minimal material loss. This leads to significantly longer Mean Time Between Failures (MTBF) for pumps.

- Superior Corrosion Resistance: SiC exhibits excellent chemical inertness across a wide pH range, making it suitable for handling highly corrosive acids, bases, and solvents where even high-alloy stainless steels or other ceramics might fail. This is critical for chemical resistant pump parts.

- High-Temperature Stability: Unlike many metals and plastics, SiC retains its mechanical strength and corrosion resistance at elevated temperatures (up to 1400∘C or higher for some grades). This makes it ideal for high-temperature fluid pumps.

- Excellent Thermal Conductivity: SiC’s ability to dissipate heat quickly is crucial for applications like mechanical seals, preventing thermal distortion and failure due to frictional heat buildup. This property contributes to energy efficient pump components.

- Low Coefficient of Friction: When polished to a fine finish, SiC surfaces have a low coefficient of friction, especially when paired with other SiC components or compatible materials like carbon-graphite. This reduces energy consumption and wear in dynamic sealing and bearing applications.

- High Stiffness and Dimensional Stability: SiC’s high elastic modulus ensures that components maintain their shape under load, critical for maintaining tight tolerances in precision applications like bearings and seals.

- Reduced Downtime and Maintenance Costs: The extended lifespan of SiC components directly translates to fewer pump rebuilds, less unscheduled downtime, and lower overall maintenance expenditures. This is a major draw for wholesale SiC pump components buyers looking for long-term value.

- Improved Pump Efficiency: By maintaining critical clearances and component profiles for longer periods, SiC parts help pumps operate closer to their Best Efficiency Point (BEP), saving energy over the pump’s lifecycle.

Selecting the Right Silicon Carbide Grade and Optimizing Design for Pump Components

Choosing the appropriate grade of silicon carbide and optimizing the component design are critical steps in maximizing the performance and longevity of SiC parts in pump applications. Different SiC grades offer varying property profiles, making them suitable for specific operational demands.

Common Silicon Carbide Grades for Pump Applications:

| SiC Grade | Key Characteristics | Typical Pump Applications | Relative Cost |

|---|---|---|---|

| Reaction-Bonded SiC (RBSiC / SiSiC) | Good wear resistance, excellent thermal shock resistance, moderate corrosion resistance, relatively easier to manufacture complex shapes. Contains free silicon (typically 8-15%). | Seals, bearings, nozzles, impellers, liners in moderately corrosive and abrasive environments. | Moderate |

| Sintered SiC (SSiC) | Very high hardness, superior corrosion resistance (especially to strong acids and alkalis), excellent wear resistance, high-temperature strength. No free silicon. | Mechanical seals, bearings, valve components in highly corrosive and abrasive duties, high-purity applications. | High |

| Nitride-Bonded SiC (NBSiC) | Good thermal shock resistance, good strength, fair wear resistance. Often used for larger, complex shapes. | Liners, furnace components, not as common for precision pump parts compared to RBSiC and SSiC. | Moderate |

| Graphite-Loaded SiC | Enhanced tribological properties (self-lubrication), improved dry-running capability, good thermal shock resistance. | Mechanical seals, bearings where intermittent dry running is possible. | High |

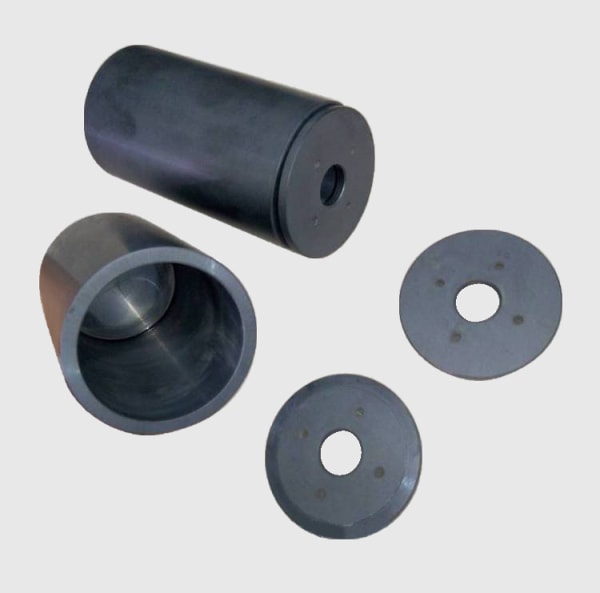

Design Considerations for Silicon Carbide Pump Components:

Designing with technical ceramics like silicon carbide requires a different approach than with metals due to their inherent brittleness. Attention to detail during the design phase is crucial for manufacturability and in-service reliability.

- Designing for Brittleness: Avoid sharp corners and stress concentrations. Use generous radii and chamfers.

- Wall Thickness and Aspect Ratios: Maintain uniform wall thicknesses where possible to prevent stress during sintering and operation. Consider practical limits on aspect ratios for robust manufacturing.

- Complexity of Geometry: While SiC can be formed into complex shapes, simplifying designs can reduce manufacturing costs and improve component integrity. Advanced SiC forming techniques are continuously expanding design possibilities.

- Interference Fits and Mounting: Design for appropriate interference fits, considering the thermal expansion coefficients of SiC and mating materials. Avoid point loads and ensure even stress distribution in mounting arrangements.

- Surface Features: Specify critical surface finishes, flatness, and parallelism, especially for sealing faces and bearing running surfaces.

- Impact Resistance: While SiC is extremely hard, it has lower impact toughness than metals. Designs should aim to shield SiC components from direct impact where possible.

- Collaboration with Supplier: Early engagement with an experienced SiC manufacturer like SicSino is highly recommended. Their expertise in custom SiC fabrication and material science can provide invaluable input during the design phase, ensuring that the component is optimized for both performance and manufacturability. SicSino’s base in Weifang, the hub of China’s SiC production, gives them access to a vast ecosystem of expertise and resources.

By carefully selecting the SiC grade and adhering to ceramic design principles, engineers can unlock the full potential of these advanced materials in demanding pump applications. Sicarb Tech, with its extensive knowledge in material selection and custom design support, assists clients in navigating these critical decisions to achieve optimal performance and reliability.

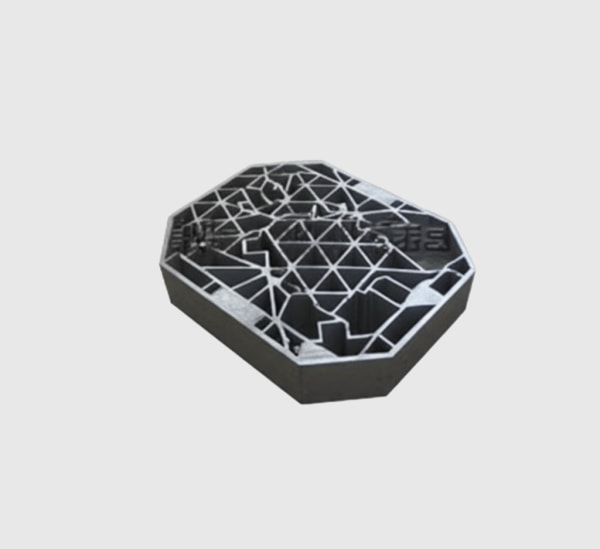

Manufacturing Excellence: Tolerances, Surface Finish, and Post-Processing for SiC Pump Components

Achieving the superior performance expected from silicon carbide pump components hinges on precision manufacturing, tight dimensional tolerances, optimized surface finishes, and appropriate post-processing techniques. These elements are critical, especially for dynamic components like mechanical seals and bearings.

Tolerances and Dimensional Accuracy:

Silicon carbide components can be manufactured to very tight tolerances, often comparable to or exceeding those achievable with precision-machined metals. However, due to SiC’s hardness, achieving these tolerances typically involves diamond grinding and lapping operations after the initial forming and sintering stages.

- Typical Achievable Tolerances: Depending on the size and complexity of the part, dimensional tolerances in the range of ±0.001 mm to ±0.01 mm (or even tighter for specialized applications) can be achieved.

- Geometric Tolerances: Critical geometric characteristics such as flatness, parallelism, roundness, and cylindricity are meticulously controlled, especially for seal faces and bearing surfaces. For instance, SiC seal faces often require flatness values within a few helium light bands (HLBs).

Surface Finish:

The surface finish of SiC components is crucial for their performance, particularly in tribological applications.

- Mechanical Seals: Seal faces require an extremely smooth, flat, and often highly polished surface (e.g., Ra<0.2 µm) to ensure a tight seal, minimize friction, and reduce wear. Lapping and polishing are standard finishing operations.

- Bearings: Bearing running surfaces also demand smooth finishes to optimize hydrodynamic lubrication and minimize wear during contact.

- Liners and Impellers: While extremely smooth finishes may not always be necessary for liners or impellers handling coarse slurries, a controlled surface texture can influence flow characteristics and wear patterns.

Post-Processing Needs:

After the primary shaping (e.g., pressing, slip casting, extrusion) and sintering processes, SiC components often undergo several post-processing steps to meet final specifications:

- Diamond Grinding: This is the most common method for machining SiC to achieve precise dimensions and remove any distortions that may have occurred during sintering. Specialized diamond grinding wheels and techniques are employed due to SiC’s extreme hardness.

- Lapping and Polishing: Essential for achieving the high-quality surface finishes and flatness required for seal faces and precision bearings. Diamond slurries of various grit sizes are used in these processes.

- Edge Chamfering/Radiusing: To reduce the risk of chipping on brittle edges, precise chamfers or radii are often ground onto component edges.

- Cleaning: Thorough cleaning is performed to remove any contaminants from machining and handling.

- Inspection and Quality Control: Rigorous inspection using advanced metrology equipment (CMMs, optical profilometers, interferometers) is vital to ensure all dimensional and surface specifications are met. Sicarb Tech emphasizes its integrated process from materials to products, including robust measurement and evaluation technologies to guarantee quality.

The complexity and cost of these post-processing steps are significant factors in the overall cost of SiC components. Therefore, designing for manufacturability and minimizing the amount of material removal required during grinding can help optimize costs. Partnering with a supplier like SicSino, which possesses a domestic top-tier professional team specializing in customized SiC production and a wide array of technologies, ensures that these critical manufacturing steps are executed to the highest standards, delivering reliable and high-performance pump components.

Overcoming Challenges with SiC in Pumps and Choosing Your Expert Supplier

While silicon carbide offers substantial advantages for pump applications, engineers and procurement professionals should be aware of certain challenges and, more importantly, how to mitigate them. Selecting a knowledgeable and capable supplier is paramount in navigating these complexities and ensuring successful implementation.

Common Challenges and Mitigation Strategies:

- Brittleness: SiC is a brittle material, meaning it has low fracture toughness compared to metals.

- Mitigation: Proper design (avoiding stress concentrators, using generous radii), careful handling during assembly and maintenance, and selecting SiC grades with enhanced toughness or composite structures. Supplier expertise in ceramic design is crucial here.

- Machining Complexity and Cost: Due to its extreme hardness, SiC can only be effectively machined using diamond tooling, which is a slower and more expensive process than machining metals.

- Mitigation: Design components to near-net shape to minimize machining. Work with suppliers who have advanced machining capabilities and experience to optimize the process. The initial higher cost of SiC parts is often offset by their significantly longer life and reduced pump downtime.

- Thermal Shock Sensitivity (for some grades/conditions): Rapid and severe temperature changes can potentially cause cracking in some SiC components, although many grades have excellent thermal shock resistance.

- Mitigation: Select grades with high thermal conductivity and low thermal expansion (like RBSiC or specially formulated SSiC). Design for gradual temperature transitions where possible. Consult with material experts to choose the best grade for specific thermal cycling conditions.

- Initial Component Cost: SiC components generally have a higher upfront cost compared to those made from conventional materials like stainless steel or cast iron.

- Mitigation: Focus on the Total Cost of Ownership (TCO). The extended service life, reduced maintenance, minimized downtime, and improved energy efficiency of SiC components often lead to significant long-term savings.

- Joining to Other Materials: Creating robust and reliable joints between SiC and metallic pump components can be challenging due to differences in thermal expansion and mechanical properties.

- Mitigation: Utilize advanced joining techniques such as brazing, shrink-fitting, or specialized adhesive bonding, often requiring supplier expertise. Design joints to accommodate differential expansion.

How to Choose the Right SiC Supplier for Pump Applications:

Selecting the right supplier is a critical decision that directly impacts the quality, reliability, and cost-effectiveness of your SiC pump components. Consider the following factors:

- Technical Expertise and Experience: Look for a supplier with deep knowledge of SiC materials science, manufacturing processes, and specific experience in pump applications. They should be able to provide design assistance and recommend the optimal SiC grade.

- Material Quality and Consistency: The supplier must have stringent quality control over raw materials and manufacturing processes to ensure consistent material properties and component performance.

- Customization Capabilities: For specialized pump requirements, the ability to produce custom-designed and manufactured SiC components is essential. This includes handling complex geometries and tight tolerances.

- Manufacturing Capabilities: Assess their forming, sintering, grinding, lapping, and polishing capabilities. Do they have the necessary equipment and skilled personnel?

- Quality Certifications: Certifications like ISO 9001 indicate a commitment to quality management systems.

- Track Record and References: Request case studies or references from other clients in similar industries or applications.

- Supply Chain Reliability: Especially for OEM SiC pump components and wholesale SiC pump parts, a reliable supply chain is crucial.

- Location and Support: Consider the supplier’s location and their ability to provide local technical support if needed.

This is where Sicarb Tech stands out. Located in Weifang City, the heart of China’s silicon carbide customizable parts manufacturing hub (accounting for over 80% of the nation’s SiC output), SicSino is not just a supplier but a technology leader. Having introduced and implemented SiC production technology since 2015, they have witnessed and contributed to the industry’s growth. As part of the Chinese Academy of Sciences (Weifang) Innovation Park and backed by the National Technology Transfer Center of the Chinese Academy of Sciences , SicSino leverages robust scientific capabilities and a top-tier professional team. They have supported over 10 local enterprises with their technologies, demonstrating a wide array of expertise from materials and processes to design and evaluation. This allows them to offer higher-quality, cost-competitive customized silicon carbide components with reliable quality and supply assurance within China. Their commitment extends to even helping clients establish their own specialized SiC factories via technology transfer and turnkey project services.

Optimizing Investment: Cost Drivers and Lead Time Considerations for Custom SiC Pump Components

Understanding the factors that influence the cost and lead times of custom silicon carbide pump components is essential for procurement professionals and engineers to effectively budget and plan projects. While SiC components may have a higher initial purchase price compared to traditional materials, their long-term value often justifies the investment.

Key Cost Drivers for Custom SiC Pump Components:

- Silicon Carbide Grade:

- Sintered SiC (SSiC) is generally more expensive than Reaction-Bonded SiC (RBSiC/SiSiC) due to more complex raw material processing and higher sintering temperatures.

- Specialty grades, such as graphite-loaded SiC or highly purified SiC for semiconductor applications, will also command premium pricing.

- Component Size and Complexity:

- Larger components require more raw material and may necessitate larger, more specialized processing equipment.

- Complex geometries with intricate features, thin walls, or undercuts increase tooling costs and manufacturing difficulty, leading to higher prices. Advanced SiC design and manufacturing capabilities can mitigate some of this, but complexity remains a driver.

- Order Volume (Quantity):

- Like most manufactured goods, larger production runs typically benefit from economies of scale, reducing the per-unit cost. Tooling and setup costs are amortized over more parts.

- Small, custom orders or prototypes will naturally have a higher per-unit cost.

- Tolerances and Surface Finish Requirements:

- Tighter dimensional tolerances and finer surface finishes (e.g., for mechanical seal faces) require more extensive and precise diamond grinding, lapping, and polishing operations. These are labor-intensive and time-consuming, adding significantly to the cost.

- Machining and Post-Processing Intensity:

- The amount of material that needs to be removed after sintering directly impacts machining time and cost. Near-net-shape forming techniques can help reduce this.

- Raw Material Purity and Sourcing:

- The cost of high-purity SiC powders is higher. Fluctuations in raw material markets can also impact pricing.

- Tooling Costs:

- For custom designs, the initial cost of molds, dies, or other specialized tooling will be factored into the price, especially for smaller volume orders.

Typical Lead Time Considerations:

Lead times for custom SiC pump components can vary significantly based on similar factors that drive cost, as well as the supplier’s current capacity and order backlog.

- Prototyping: 4-8 weeks is a common range, but can be shorter or longer depending on complexity.

- Production Orders: 6-16 weeks is typical, but large or highly complex orders can extend beyond this.

- Factors Influencing Lead Times:

- Design Complexity: More intricate parts take longer to tool and manufacture.

- Material Availability: Standard grades are often more readily available.

- Tooling Creation: If new tooling is required, this adds to the initial lead time.

- Manufacturing Processes: Sintering cycles can be lengthy (days), and extensive machining adds time.

- Quality Control and Testing: Thorough inspection procedures, while essential, also contribute to the overall timeline.

- Order Backlog: Supplier capacity will play a role.

Achieving Value for Money:

While the upfront cost of industrial SiC components is a consideration, it’s crucial to evaluate the Total Cost of Ownership (TCO). The superior wear resistance, corrosion resistance, and thermal stability of SiC lead to:

- Longer component lifespan

- Reduced pump maintenance frequency

- Minimized unscheduled downtime and associated production losses

- Improved pump efficiency and energy savings

When these long-term benefits are factored in, custom SiC components often prove to be the most economical choice for demanding pump applications. Companies like Sicarb Tech, by leveraging their extensive manufacturing experience and technological base in Weifang, strive to provide cost-competitive customized SiC components without compromising on quality, ensuring customers receive optimal value and performance. Their deep understanding of the entire process, from raw materials to finished products, allows for efficient production planning and reliable delivery schedules.

Frequently Asked Questions (FAQ)

Q1: Is silicon carbide suitable for pumping all types of corrosive fluids?

A: Silicon carbide, particularly Sintered SiC (SSiC), exhibits excellent corrosion resistance to a very wide range of acids, alkalis, and solvents, making it superior to most metals and many other ceramics in harsh chemical environments. Reaction-Bonded SiC (RBSiC), which contains some free silicon, is also highly resistant but may be less suitable for certain extremely aggressive oxidizing acids or hot alkaline solutions compared to SSiC. It’s always best to discuss the specific chemical composition, concentration, and temperature of the fluid with a knowledgeable SiC supplier like Sicarb Tech to confirm material compatibility and select the optimal grade.

Q2: What is the typical lifespan of SiC pump components compared to traditional materials like stainless steel or hardened alloys in abrasive applications?

A: In applications involving abrasive slurries or aggressive wear conditions, SiC components can outlast traditional metallic materials by a significant margin – often 3 to 10 times longer, and in some cases, even more. For example, SiC mechanical seals, bearings, or impellers in slurry pumps or chemical agitators can provide dramatically extended service intervals, leading to substantial reductions in maintenance costs and pump downtime. The exact lifespan improvement depends heavily on the specific application, the nature of the abrasive media, and the operating conditions.

Q3: How does the initial cost of custom SiC pump parts compare to alternatives, and is it justified?

A: Custom SiC pump components generally have a higher initial purchase price compared to parts made from conventional materials like stainless steel, hardened alloys, or some other ceramics. This is due to the cost of high-purity raw materials and the specialized, energy-intensive manufacturing processes required, including diamond grinding for precision finishing. However, the higher upfront cost is often overwhelmingly justified by a lower Total Cost of Ownership (TCO). The extended lifespan, significantly reduced maintenance needs, minimized production downtime due to pump failures, and improved operational efficiency (e.g., sustained hydraulic performance, lower friction) offered by SiC components frequently result in substantial long-term savings that far outweigh the initial investment. It’s crucial to analyze the TCO when making procurement decisions for critical pump spares.

Q4: Can Sicarb Tech assist with the design of custom SiC pump components for our specific application?

A: Absolutely. Sicarb Tech prides itself on its comprehensive customization support, which includes leveraging its domestic top-tier professional team and wide array of technologies in material science, process engineering, and design. They can collaborate closely with your engineering team to understand your specific operational challenges and performance requirements. Based on this, they can provide expert guidance on material selection (choosing the right SiC grade), component design optimization for manufacturability and performance in pump environments, and defining appropriate tolerances and surface finishes. Their integrated process from materials to finished products ensures that design considerations are seamlessly translated into high-quality, reliable components.

Q5: We are considering setting up our own SiC component production. Can SicSino help with that?

A: Yes, Sicarb Tech offers comprehensive technology transfer services for clients interested in establishing their own specialized silicon carbide products manufacturing plant. Leveraging their deep expertise and connection with the Chinese Academy of Sciences National Technology Transfer Center, they can provide a full range of services (a turnkey project) including factory design, procurement of specialized equipment, installation and commissioning, and trial production support. This enables your company to own a professional SiC production facility with a more effective investment, reliable technology transformation, and a guaranteed input-output ratio, effectively bringing advanced SiC manufacturing capabilities in-house or to your local region.

Conclusion: Elevating Pump Performance with Custom Silicon Carbide

In the demanding landscape of modern industry, the quest for enhanced reliability, efficiency, and longevity in pumping systems is perpetual. Custom silicon carbide components have unequivocally proven their ability to meet and exceed these challenges, offering a step-change in performance over traditional materials in abrasive, corrosive, and high-temperature environments. From mechanical seals and bearings to impellers and liners, the strategic implementation of SiC translates into reduced downtime, lower maintenance costs, and improved overall operational effectiveness.

Choosing the right material grade, optimizing component design, and partnering with an expert supplier are key to unlocking the full potential of this advanced ceramic. Sicarb Tech, with its profound expertise rooted in Weifang – China’s SiC manufacturing heartland – and its strong backing from the Chinese Academy of Sciences, stands as a distinguished partner. Their commitment to quality, customization, and technological advancement ensures that engineers and procurement professionals can confidently integrate high-performance SiC pump solutions into their critical operations. By investing in custom silicon carbide, industries not only enhance their current processes but also pave the way for more resilient and productive future operations.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.