Mastering Surface Perfection: A Guide to Silicon Carbide Polishing Machines

Share

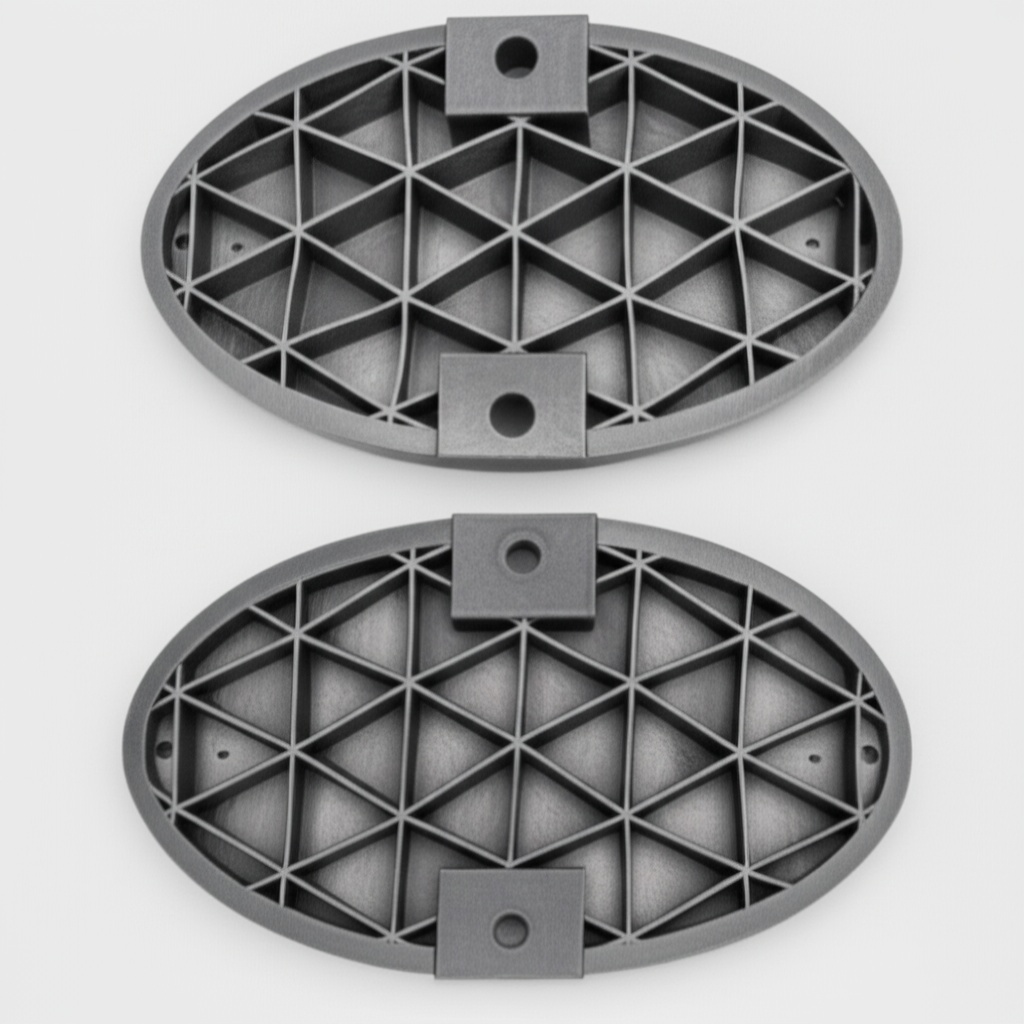

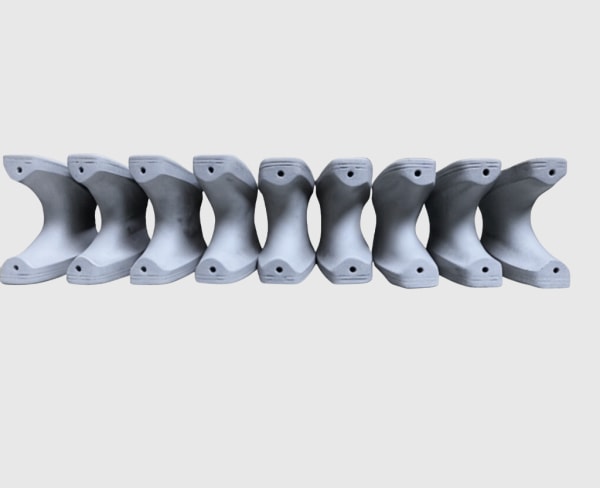

Silicon carbide (SiC) has emerged as a critical material in numerous high-performance industrial applications, prized for its exceptional hardness, thermal conductivity, and chemical inertness. However, harnessing these properties often requires components manufactured to exacting dimensional tolerances and superior surface finishes. This is where the silicon carbide polishing machines play an indispensable role. Achieving a flawless, mirror-like polish or a precisely controlled surface roughness on SiC components is paramount for their optimal performance in demanding environments, from semiconductor manufacturing to advanced optics. This blog post will delve into the intricacies of SiC polishing machines, their applications, the benefits of achieving an optimal polish, and how to select the right equipment and partner for your custom SiC needs. For businesses looking for custom SiC parts wholesale or technical ceramic components, understanding the nuances of SiC polishing is crucial for ensuring product quality and performance.

The Indispensable Role of Polishing for Silicon Carbide Components

Silicon carbide’s inherent characteristics, particularly its extreme hardness (typically ranking around 9 on the Mohs scale, second only to diamond), make it notoriously difficult to machine and finish. Standard machining processes often leave behind surface and subsurface damage, micro-cracks, and an unsatisfactory surface roughness that can compromise the mechanical strength, optical properties, or electrical performance of the SiC component. Precision SiC machining and subsequent polishing are therefore not merely aesthetic enhancements but critical manufacturing steps.

Effective polishing of SiC:

- Removes surface and subsurface damage: Grinding, cutting, and lapping can introduce defects. Polishing eliminates these, enhancing the material’s integrity.

- Achieves ultra-smooth surfaces: For applications like SiC wafers in semiconductor device manufacturing or mirrors in aerospace optical systems, a low Ra (average roughness) value is essential.

- Ensures dimensional accuracy: Polishing can bring components to their final, precise dimensions, critical for high-precision industrial components.

- Improves mechanical strength: By removing stress concentrators like micro-cracks, polishing can increase the fracture toughness and overall reliability of SiC parts.

- Enhances functional performance: For instance, in SiC seal faces or industrial wear parts, a smooth surface reduces friction and wear, extending operational life.

The demand for advanced ceramic polishing techniques is continually driven by industries requiring components that can withstand extreme conditions without faltering.

Exploring the Landscape of SiC Polishing Machines and Technologies

The challenging nature of silicon carbide necessitates specialized polishing machines and techniques. These are distinct from general-purpose polishing equipment due to the material’s hardness and the precision required. The choice of machine and technology often depends on the SiC grade (e.g., reaction-bonded SiC (RBSiC), sintered SiC (SSiC)), the initial surface condition, the desired final finish, and the geometry of the component.

Common types of machines and technologies include:

- Lapping Machines: Often a precursor to fine polishing, lapping machines use a loose abrasive slurry (typically diamond) on a flat rotating plate (lap plate) to achieve a uniform, matte surface and improve flatness. This step is crucial for preparing SiC substrates or custom ceramic parts for finer polishing stages.

- Diamond Polishing Machines: These machines are specifically designed for hard materials. They utilize fixed or loose diamond abrasives in various forms, such as diamond slurries, pastes, or fixed-abrasive pads. The platen material, polishing pad type, abrasive size, and applied pressure are critical parameters.

- Chemical Mechanical Polishing/Planarization (CMP) Systems: Predominantly used in the semiconductor industry for SiC wafer polishing, CMP combines chemical etching and mechanical abrasion. A specialized slurry containing both chemical etchants and fine abrasive particles works with a polishing pad to achieve exceptionally smooth and planar surfaces, essential for SiC semiconductor substrates.

- Grinding Machines with Polishing Capabilities: Some advanced grinding machines can be equipped with fine grinding wheels or polishing tools to perform initial shaping and subsequent polishing steps, offering a multi-process solution for complex SiC geometries.

- Vibratory Polishers and Tumblers: For smaller, complex-shaped parts or for achieving a uniform finish on multiple components simultaneously, vibratory polishers or tumblers with appropriate SiC-compatible media can be effective, particularly for deburring and surface finishing of SiC parts.

At Sicarb Tech, located in Weifang City, the hub of China’s silicon carbide customizable parts manufacturing, we have witnessed and contributed to the evolution of these polishing technologies since 2015. Our deep understanding of SiC material properties and processing enables us to guide clients in selecting or developing optimal polishing strategies for their customized SiC components.

| Machine/Technology Type | Primary Application | Key Advantages | Typical SiC Grades |

|---|---|---|---|

| Lapping Machines | Initial surface flattening, matte finishing | Good for bulk material removal, improves flatness, prepares for polishing | All SiC grades |

| Diamond Polishing Machines | Achieving high gloss, low Ra surfaces | Precise control over surface finish, versatile for various SiC components | SSiC, RBSiC, CVD-SiC |

| Chemical Mechanical Polishing (CMP) | Ultra-smooth, planar surfaces for semiconductor wafers | Superior planarity, minimal subsurface damage, ideal for demanding electronics | Single crystal SiC, SSiC |

| Grinding/Polishing Combo Machines | Multi-stage processing for complex parts | Combines shaping and finishing, reduces handling | All SiC grades |

| Vibratory Polishers/Tumblers | Deburring, surface finishing of small/complex parts | Batch processing, uniform finish on irregular shapes | Smaller SiC components |

This table provides a general overview, and the suitability of each technology can vary based on specific application requirements and the scale of SiC parts production.

Critical Components and Consumables for SiC Polishing Success

The performance of a silicon carbide polishing machine is heavily reliant on its key components and the quality of consumables used. Procurement managers and technical buyers should pay close attention to these aspects when investing in or specifying SiC polishing processes.

Key Machine Components:

- Platen/Wheel: The rotating surface that drives the polishing pad or carries the loose abrasive slurry. Its material (e.g., cast iron, stainless steel, aluminum), flatness, and balance are crucial for consistent results.

- Polishing Pad: The interface between the platen and the SiC workpiece. Pads come in various materials (e.g., polyurethane, synthetic fabrics, metal-resin composites) and hardness, each offering different removal rates and surface finishes. The choice is critical for technical ceramic polishing.

- Slurry Delivery System: For processes using loose abrasives, a reliable system that delivers a consistent flow and concentration of slurry is essential. This includes pumps, reservoirs, and dispensing nozzles.

- Workpiece Holder/Fixture: Securely holding the SiC component without inducing stress or damage is vital, especially for precision SiC optics or delicate custom ceramic prototypes. Custom fixtures are often required for complex geometries.

- Pressure and Speed Controls: Precise control over the applied pressure and the rotational speed of the platen/wheel allows for fine-tuning the polishing process to achieve the desired outcome for industrial SiC manufacturing.

Essential Consumables:

- Diamond Abrasives: Diamond is the most common abrasive for SiC due to its superior hardness. It’s available as:

- Diamond Slurries/Suspensions: Pre-mixed liquids containing diamond particles of specific sizes (from tens of microns for lapping down to sub-micron or nanometer sizes for final polishing).

- Diamond Pastes: Higher viscosity diamond compounds applied directly to the polishing pad.

- Fixed Diamond Pads: Polishing pads with diamond particles embedded in their surface.

- Polishing Pads: As mentioned above, these are consumables and need regular replacement. Their lifespan depends on the process parameters and the SiC material being polished.

- Lapping Vehicles/Lubricants: Liquids used to carry the abrasive particles in lapping processes and to provide lubrication and cooling.

- Cleaning Agents: Essential for removing slurry residues and contaminants from the SiC components post-polishing.

Sourcing high-quality consumables is paramount for achieving consistent results in SiC component polishing. Sicarb Tech leverages its extensive network within Weifang’s SiC manufacturing ecosystem, which accounts for over 80% of China’s total SiC output, to help clients source or develop the most effective consumables for their specific applications.

Achieving Superior Surface Quality and Dimensional Integrity

The goal of SiC polishing is not just a shiny surface but achieving specific, measurable surface quality and dimensional characteristics. This involves careful process control, metrology, and an understanding of how polishing parameters affect the final outcome. This is particularly important for OEMs requiring custom SiC solutions and distributors of high-performance ceramics.

Key Process Parameters to Control:

- Abrasive Type and Size: Coarser abrasives remove material faster but leave a rougher surface. Progressively finer abrasives are used to achieve smoother finishes. Diamond particle morphology (monocrystalline vs. polycrystalline) also plays a role.

- Polishing Pad Material and Design: Pad hardness, porosity, and groove patterns influence slurry distribution, waste removal, and the contact mechanics with the SiC surface.

- Applied Pressure: Higher pressure generally increases the material removal rate (MRR) but can also lead to increased subsurface damage if not carefully controlled.

- Relative Speed: The speed of the platen and/or workpiece holder affects the polishing efficiency and heat generation.

- Slurry Composition and Flow Rate: The concentration of abrasives, pH (for CMP), and flow rate must be optimized and maintained.

- Polishing Time: Duration of each polishing step is critical to achieve the target removal and surface finish.

Metrology and Quality Control:

Verifying the results of SiC polishing requires appropriate metrology tools:

- Profilometers (Stylus and Optical): To measure surface roughness parameters like Ra (average roughness), Rq (root mean square roughness), and Rz (maximum height of the profile).

- Interferometers: For non-contact, high-precision measurement of surface flatness and form, especially for optical components.

- Atomic Force Microscopy (AFM): To characterize surface topography at the nanometer scale, crucial for ultra-smooth surfaces in semiconductor and optics applications.

- Microscopes (Optical and Electron): For visual inspection of surface defects, grain structure, and edge quality.

- Coordinate Measuring Machines (CMMs): To verify dimensional accuracy of complex custom SiC shapes.

Sicarb Tech, backed by the robust scientific and technological capabilities of the Chinese Academy of Sciences National Technology Transfer Center, possesses a comprehensive suite of material, process, design, measurement, and evaluation technologies. This integrated approach allows us to assist clients in not only producing high-quality polished SiC components but also in establishing rigorous quality control protocols.

Diverse Applications Driving Demand for Precision SiC Polishing

The unique combination of properties offered by polished silicon carbide makes it indispensable across a wide array of demanding industries. The need for industrial SiC polishing services and equipment is continually growing.

- Semiconductor Manufacturing:

- SiC Wafers: As substrates for power electronics (MOSFETs, SBDs) and high-frequency devices, requiring ultra-smooth, defect-free surfaces (Ra < 0.5 nm). CMP is standard here.

- Wafer Chucks and End Effectors: Requiring high flatness, wear resistance, and thermal stability.

- Optics and Photonics:

- Mirrors and Reflectors: For telescopes, lasers, and synchrotron radiation, needing exceptional surface finish (Ra < 1 nm) and figure accuracy.

- Optical Windows: For harsh environments, requiring good transmission and durability.

- Aerospace and Defense:

- High-Temperature Sensor Components: Requiring thermal shock resistance and stability.

- Lightweight Armor Components: Benefiting from SiC’s hardness and low density.

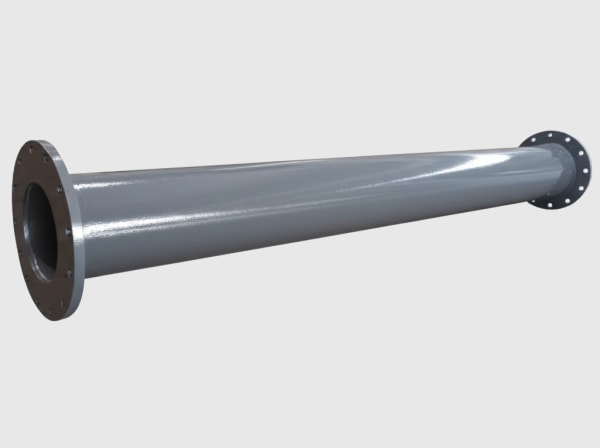

- High-Temperature Processing:

- Furnace Components (Beams, Rollers, Nozzles): Where smooth surfaces can improve material flow and reduce wear.

- Kiln Furniture: For supporting wares during firing, where surface quality can impact product aesthetics.

- Mechanical Seals and Bearings:

- Seal Faces and Rings: Demanding excellent flatness, low friction, and wear resistance in pumps and compressors.

- High-Performance Bearings: For corrosive or high-temperature environments.

- Metrology and Calibration:

- Gauge Blocks and Reference Surfaces: Requiring exceptional dimensional stability and surface finish.

The following table illustrates how different SiC grades and their polished characteristics are utilized across various sectors:

| Industry | Common SiC Components | Key Polished Surface Requirements | Typical SiC Grades Used |

|---|---|---|---|

| Semiconductor | Wafers, chucks, CMP rings, end effectors | Ultra-smooth (Ra < 0.5 nm), low defect density, high planarity | SSiC, CVD-SiC, Single Crystal SiC |

| Optics & Photonics | Mirrors, optical windows, laser components | Very low Ra (< 1 nm), precise figure accuracy, minimal scattering | SSiC, RBSiC (for some mirrors) |

| Aerospace & Defense | Sensor housings, mirror substrates, armor tiles | High strength, dimensional stability, specific optical/thermal properties | SSiC, RBSiC |

| Mechanical Engineering | Seal faces, bearings, nozzles, wear plates | Low friction, high wear resistance, excellent flatness | SSiC, RBSiC (SiSiC) |

| High-Temp Furnaces | Beams, rollers, tubes, setters, crucibles | Thermal stability, wear resistance, controlled porosity/smoothness | RBSiC (SiSiC), RSiC, SSiC |

This highlights the versatility of polished SiC and the critical role of specialized SiC polishing equipment in enabling these applications. For procurement professionals looking for SiC components for high-temperature applications or wear-resistant ceramic solutions, partnering with a supplier knowledgeable in polishing is key.

Choosing Your SiC Polishing Machine and Supplier: The Sicarb Tech Advantage

Selecting the right silicon carbide polishing machine or a supplier for polished SiC components involves considering several factors beyond just the equipment’s technical specifications. For businesses seeking reliable SiC component manufacturing and custom technical ceramic solutions, a holistic approach to supplier selection is vital.

Key Considerations for Machine Selection:

- Application Specificity: Does the machine cater to your component size, geometry, and required surface finish?

- Process Capability: Can it handle the specific SiC grade and achieve the target Ra, flatness, and dimensional tolerances?

- Throughput and Scalability: Does it meet your production volume requirements?

- Control and Automation: Level of process control, ease of use, and potential for automation.

- Supplier Support and Expertise: Availability of technical support, training, and process development assistance.

- Cost of Ownership: Initial investment, consumables cost, maintenance, and operational expenses.

Why Partner with Sicarb Tech for your SiC Needs?

Located in Weifang, the heart of China’s SiC industry, Sicarb Tech is not just a supplier but a technology partner. We leverage our affiliation with the Chinese Academy of Sciences (Weifang) Innovation Park and the National Technology Transfer Center of the Chinese Academy of Sciences to offer unparalleled expertise.

- Deep Industry Knowledge: Since 2015, we’ve been instrumental in advancing SiC production technology for local enterprises, contributing to the region’s dominance in SiC output.

- Comprehensive Technical Capabilities: Our domestic top-tier professional team specializes in customized SiC production, encompassing material science, process engineering, design optimization, and advanced measurement and evaluation. We’ve supported over 10 local enterprises with our technologies.

- Customization Expertise: We excel in meeting diverse customization needs, offering higher-quality, cost-competitive customized silicon carbide components in China.

- Integrated Solutions: We provide an integrated process from raw materials to finished, polished products, ensuring quality and consistency.

- Technology Transfer Services: For clients looking to establish their own professional silicon carbide products manufacturing plant,Sicarb Tech offers comprehensive technology transfer (turnkey projects). This includes factory design, procurement of specialized equipment (including polishing machines), installation, commissioning, and trial production, ensuring a reliable and effective investment.

When you partner with Sicarb Tech, you gain access to a wealth of knowledge in SiC material processing, including the critical step of polishing. We can help you specify the right polishing approach for your custom components or assist you in setting up your own advanced SiC manufacturing capabilities. Our commitment is to provide more reliable quality and supply assurance within China and globally.

Frequently Asked Questions (FAQ)

Q1: What is the typical surface roughness (Ra) achievable with SiC polishing machines? A1: The achievable Ra depends on the SiC grade, the polishing technique, and the application. For general industrial parts, Ra values from 0.1μm to 0.8μm might be sufficient. For optical components, Ra can be pushed below 1nm (0.001μm). Semiconductor SiC wafers often require Ra values below 0.5nm. Sicarb Tech can work with you to define and achieve the specific Ra values your application demands for precision ceramic components.

Q2: How does the choice of SiC grade (e.g., SSiC vs. RBSiC) affect the polishing process and machine selection? A2: Different SiC grades have varying microstructures and densities, which influence their polishing behavior. Sintered SiC (SSiC) is generally denser and harder to polish than Reaction-Bonded SiC (RBSiC), which may contain some free silicon. The polishing parameters (abrasive type, pad, pressure, speed) and sometimes the machine type (e.g., CMP is more common for high-purity SSiC wafers) need to be adjusted accordingly. Our experts at Sicarb Tech can advise on the optimal polishing strategies for various SiC material grades.

Q3: Can Sicarb Tech provide custom SiC components with specific polished finishes? A3: Absolutely. Sicarb Tech specializes in custom silicon carbide product manufacturing. We possess a wide array of technologies, from material synthesis to final polishing and metrology. We work closely with our clients to understand their specific surface finish requirements, dimensional tolerances, and application needs to deliver high-quality, cost-competitive customized SiC components. Our integrated process ensures that the polishing step is optimized for the chosen SiC grade and component design.

Q4: What are the main challenges in polishing silicon carbide, and how are they overcome? A4: The primary challenges include SiC’s extreme hardness, which leads to slow material removal rates and high wear on consumables. Its brittleness can lead to chipping or cracking if not handled carefully. Achieving ultra-low Ra values without subsurface damage is also a significant hurdle. These are overcome by: * Using superabrasives like diamond. * Optimizing polishing parameters (pressure, speed, abrasive size). * Employing multi-step polishing processes, starting with coarser abrasives and moving to finer ones. * Utilizing advanced techniques like CMP for critical applications. * Careful workpiece handling and fixturing. Sicarb Tech has extensive experience in addressing these challenges, ensuring high-yield production of quality SiC parts.

Q5: What information is needed to get a quote for custom polished SiC components or SiC polishing machine consultation? A5: To provide an accurate quote or consultation, we typically require: * Detailed drawings or CAD models of the component. * The specific grade of SiC material required (e.g., SSiC, RBSiC). * Required surface roughness (Ra, Rq, Rz) and any other surface finish specifications. * Dimensional tolerances. * Application details (to understand performance requirements). * Quantity and desired lead time. For machine consultation, details about your current capabilities, production goals, and specific challenges are helpful. Contact Sicarb Tech to discuss your custom SiC manufacturing needs.

Conclusion: The Clear Advantage of Expert SiC Polishing

The journey of a silicon carbide component from raw material to a high-performance part often culminates in the critical step of polishing. A silicon carbide polishing machine, coupled with optimized processes and high-quality consumables, is essential for unlocking the full potential of this advanced ceramic. Whether you are an engineer designing for extreme environments, a procurement manager sourcing wholesale technical ceramics, or an OEM seeking a reliable partner for custom SiC solutions, understanding the intricacies of SiC polishing is key to achieving superior product quality, performance, and reliability.

Sicarb Tech stands ready to be your trusted partner in the world of custom silicon carbide. Leveraging our deep expertise rooted in Weifang, the heart of China’s SiC industry, and backed by the scientific prowess of the Chinese Academy of Sciences, we offer not only high-quality polished SiC components but also comprehensive support and technology transfer services. We are committed to helping you navigate the complexities of SiC manufacturing, ensuring your components meet the most demanding specifications and deliver unparalleled performance in your industrial applications. Partner with us for more reliable quality, supply assurance, and innovative SiC solutions.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.