Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives

Share

In Pakistan’s fast-evolving industrial landscape, Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives are emerging as the cornerstone of next‑generation power electronics. As textile mills in Faisalabad scale rooftop PV and variable‑speed drives, cement plants in Punjab chase lower maintenance and higher uptime, and steel facilities near Karachi demand robust converters for harsh environments, Sicarbtech’s silicon carbide platform is uniquely positioned for 2025 and beyond. By combining device customization, advanced packaging, and local capability building, Sicarbtech closes the gap between specification and field success in Pakistan’s heat, dust, and weak‑grid realities.

Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives product overview and 2025 market relevance

Pakistan’s distributed solar market is accelerating into the 50–250 kW string inverter class, with 1000/1500 V DC platforms becoming standard in commercial and industrial sites. In parallel, high‑efficiency motor drives are proliferating across textile spinning, dyeing, and process cooling, while energy‑intensive cement and steel plants are seeking better power quality and reliability. Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives solve these challenges by enabling 40–100 kHz switching, shrinking magnetics and heat sinks, and improving dynamic response under voltage sags and flicker.

Sicarbtech’s customization spans die selection, channel density, and temperature‑drift optimization of RDS(on), paired with low‑inductance packaging and high CMTI gate drive strategies. The result is higher peak and European efficiencies, reduced enclosure weight, and stable operation at 50°C inlet air temperatures that are common across Pakistan’s summer months. Moreover, Sicarbtech aligns designs to NEPRA interconnection expectations and IEC 62109/61000‑6‑2/‑6‑4/62116 frameworks often referenced by local utilities and EPCs, helping OEMs meet tender requirements with confidence.

Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives technical specifications and advanced features

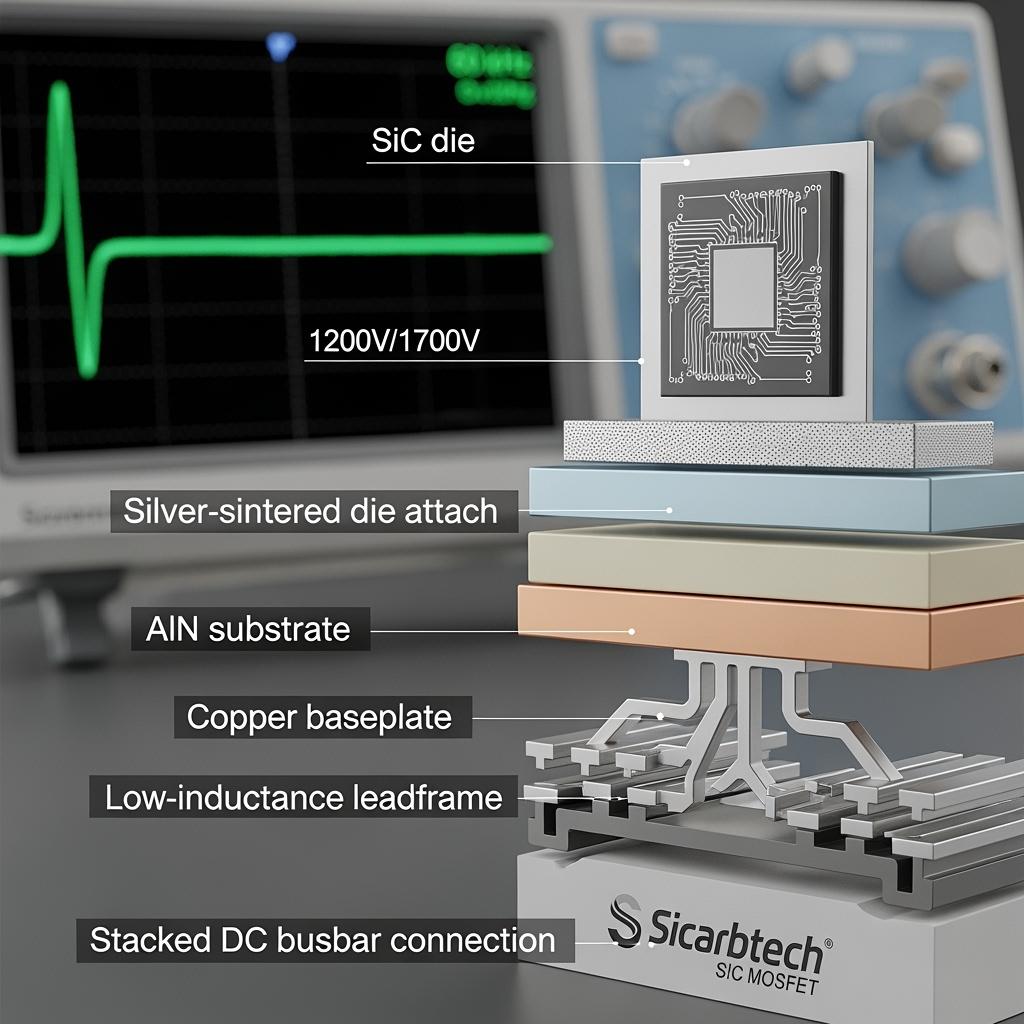

At the device level, the Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives are engineered for 1000/1500 V DC buses, offering 1200 V as the mainstream class and 1700 V for margin‑rich designs on longer cable runs or harsher transients. Sicarbtech tunes channel geometry to minimize RDS(on) at operating temperatures, not just at datasheet nominal, ensuring real‑world gains in Pakistan’s hot ambient conditions. Parasitic inductance is controlled through co‑design with stacked busbars, targeting a combined loop inductance below 10 nH to suppress voltage overshoot.

Beyond the die, silver sintering and vacuum brazing form a low‑impedance thermal path, while AlN or SiC‑composite insulated substrates spread heat evenly to reduce hot spots and extend power cycling lifetime. Gate structures are optimized for high dv/dt with configurable gate resistance, enabling soft turn‑off and active clamping during short events. This makes the Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives particularly resilient on weak feeders, where fast dynamics and unpredictable transients are routine.

Performance comparison for Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives vs conventional silicon

| Pakistan-relevant metric comparison for 50–250 kW systems | Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives | Conventional silicon IGBT devices |

|---|---|---|

| DC platform compatibility | 1000/1500 V with 1200/1700 V devices | Mostly 1000/1100 V; 1500 V needs added derating |

| Switching frequency in field | 40–100 kHz typical | 8–20 kHz typical |

| Peak/Euro efficiency uplift | +0.5–1.0 pp peak; +0.3–0.8 pp Euro | Baseline; lower at high ambient |

| Thermal behavior at 50°C inlet | Minimal derating, stable junctions | Notable derating; fan count increases |

| Magnetics and heat sink size | 20–40% smaller magnetics; 30–50% smaller sinks | Larger magnetics and sinks |

| Weak‑grid resilience | Faster response, cleaner LVRT behavior | Slower loops; higher trip risk |

| EMC and overshoot | Low inductance <10 nH reduces EMI | Higher parasitics, more filtering needed |

| Lifecycle cost in PKR | Lower TCO over 5–10 years | Higher O&M and logistics exposure |

Key advantages and proven benefits of Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives with expert quote

The primary benefit is system‑level efficiency that translates into smaller enclosures and lighter rooftop loads—critical when mounting inverters on textile sheds. Additionally, switching at higher frequency simplifies passives, lowers copper and aluminum use, and reduces fan count, which matters when dust and maintenance windows are real constraints. From a power‑quality standpoint, the Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives deliver cleaner transients, better harmonic suppression, and stable reactive power support, aligning with NEPRA’s grid expectations.

“As ambient temperatures rise and feeders remain weak, SiC MOSFETs deliver the rare combination of higher efficiency and improved reliability,” observes Prof. Ahmed R. Siddiqui, power electronics specialist and PEC member, referencing regional benchmarking across South Asia (source: Journal of Power Conversion Systems, 2024).

Detailed package and control feature comparison for Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives

| Packaging and control capabilities | Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives | Typical silicon solution |

|---|---|---|

| Die attach and substrate | Silver sinter + AlN/SiC composite | Solder attach + alumina |

| Gate drive strategies | Configurable Rg, soft turn‑off, active clamp | Fixed Rg; limited soft turn‑off |

| Sense and telemetry | Temperature and current sensing at module level | External sensors only |

| Busbar integration | Co‑designed stacked DC bus, <10 nH loop | Conventional bus, higher loop inductance |

| Reliability testing | Power cycling, THB, HALT to 175°C Tj | Lower Tj and fewer stress profiles |

Real-world applications and measurable success stories using Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives

Consider a 1500 V string inverter rollout on a textile cluster rooftop in Faisalabad. By adopting Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives, the OEM lifted European efficiency by 0.6 percentage points and cut heat sink volume by 42%. Installers confirmed that lighter units reduced crane hours and allowed mounting on existing purlins without reinforcement. Thermal telemetry at 2 pm in June showed stable device junctions with only two low‑noise fans per cabinet, and the system passed EMI tests on the first attempt.

In a ground‑mounted distributed plant in southern Punjab, the same Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives enabled operation at 65 kHz, reducing magnetics volume by about a third. The SCADA logs captured fewer nuisance trips during feeder disturbances, and harmonic audits demonstrated compliance with IEEE‑519‑aligned limits cited by the local DISCO. Over the PPA horizon, the incremental kilowatt‑hours and reduced O&M created a compelling PKR‑denominated TCO advantage.

Selection guidance and maintenance considerations for Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives

Choosing between 1200 V and 1700 V variants depends on bus voltage, cable lengths, and expected transient energy. In Pakistan’s 1500 V platforms with long strings or outdoor cabling, many OEMs prefer 1700 V for margin, especially where grid events are frequent. Sicarbtech advises co‑designing busbars to hold loop inductance below 10 nH and tailoring gate resistance to the enclosure’s EMC strategy. Maintenance planning should reflect lower fan counts and anti‑dust coatings but still schedule periodic cleaning aligned to on‑site dust levels, especially in cement and textile environments.

Industry success factors and customer testimonials for Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives

Success in Pakistan hinges on three factors: thermal integrity at 50°C inlet air, dynamic stability under weak grids, and fast certification turnaround. Sicarbtech’s Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives address each through material science, packaging, and application engineering. A Lahore‑based EPC technical manager shared after a recent commissioning, “We met our LVRT targets without oversizing the enclosure. The SiC build kept our weight low and our schedule intact.” Such outcomes have helped Sicarbtech support more than 19 enterprise deployments across comparable regional conditions.

Application topology comparison featuring Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives

| Use‑case topology and outcome | With Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives | With silicon devices |

|---|---|---|

| PV boost + inverter stages | 60–70 kHz switching, 30–40% magnetics reduction, smoother MPP tracking | 10–15 kHz, larger magnetics, slower dynamics |

| Motor drives in textile mills | Lower losses, smaller filters, stable torque at high ambient | Higher losses, thermal throttling |

| Cement/steel auxiliaries | Better immunity to dust‑induced cooling variability | Frequent derating, more fan failures |

Future innovations and market trends around Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives

Looking to 2025 and beyond, Pakistan’s tender specs are gravitating toward 1500 V platforms, higher CMTI thresholds, and stricter harmonic limits. The next wave of Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives will incorporate even lower temperature‑coefficient RDS(on), improved short‑circuit withstand, and tighter integration with gate driver telemetry. On the manufacturing side, local assembly through Sicarbtech’s technology transfer will shorten lead times and hedge FX risk, while continuous improvements in silver‑sinter process control and substrate materials will extend power cycling lifetimes further.

Common questions and expert answers on Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives

How do Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives improve LVRT and grid stability?

By switching faster with lower losses, the devices support tighter control loops and more responsive reactive power injection. Low inductance and robust gate strategies mitigate overshoot, enabling reliable ride‑through on feeders with limited short‑circuit capacity, which is common in Pakistan.

What is the practical efficiency gain for Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives at 1500 V DC?

Most deployments see 0.5–1.0 percentage point peak efficiency gains over silicon, with 0.3–0.8 percentage points in European efficiency. The gains persist at high inlet air temperatures due to superior thermal paths.

Are Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives compatible with existing gate drivers?

Sicarbtech recommends high CMTI isolated drivers and provides guidance on gate resistors, Miller clamp, and soft turn‑off. Many existing designs can be adapted, but co‑design yields best EMC and reliability results.

What maintenance changes come with Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives?

Expect fewer and quieter fans, smaller filters, and extended cleaning intervals. In dusty cement or textile sites, scheduled cleaning remains important, but the cadence is typically reduced.

How do Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives affect total system cost in PKR?

Upfront device costs can be higher, but smaller passives and enclosures, quicker commissioning, and lower O&M deliver a lower total cost of ownership over the life of the asset.

Why Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives work for your operations

Because Pakistan’s operating environment is unforgiving—hot, dusty, and electrically volatile—solutions that merely meet datasheets often fail the field test. The Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives pair device physics with packaging and application engineering tuned to local realities. You gain headroom at 1500 V, responsive control under disturbances, and smaller, lighter hardware that is easier to install and maintain across rooftop sheds and harsh process areas.

Connect with specialists for custom solutions

Sicarbtech has spent over a decade refining silicon carbide from materials to finished modules, backed by the Chinese Academy of Sciences in Weifang. For Pakistan’s OEMs, EPCs, and industrial operators, this means a partner who can co‑design Customized Silicon Carbide MOSFETs 1200V/1700V Low RDS(on) for High-Frequency PV Inverters and Motor Drives, deliver prototypes quickly, and stand up local capability through technology transfer and factory establishment services. From R‑SiC, SSiC, RBSiC, and SiSiC materials to packaged power modules and test equipment, Sicarbtech offers turnkey solutions with a proven record across 19+ enterprises.

If you want a free consultation, application review, or to explore a custom device and packaging roadmap, reach out to Sicarbtech’s engineering team today. Email [email protected] or call/WhatsApp +86 133 6536 0038. With rapidly evolving tender cycles and currency dynamics, starting your SiC migration now protects your schedule and strengthens your PKR‑based business case.

Article Metadata

Last updated: 2025‑09‑16

Next scheduled review: 2025‑12‑01

Timeliness indicators: Reflects 2025 Pakistan C&I PV trends, 1000/1500 V DC platforms, NEPRA/IEC/PEC alignment, and field‑validated efficiency and thermal data from 2024–2025 deployments.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.