Mastering Precision: The Essential Guide to Silicon Carbide Molding Machines for Industrial Excellence

Share

The demand for high-performance materials capable of withstanding extreme industrial environments has never been greater. Silicon carbide (SiC) has emerged as a frontrunner, prized for its exceptional hardness, thermal conductivity, and resistance to wear and corrosion. However, harnessing these properties effectively in manufactured components hinges on the sophistication of production technologies, particularly silicon carbide molding machines. These specialized pieces of equipment are the bedrock of creating intricate, high-precision custom SiC products essential across a multitude of demanding sectors. For engineers, procurement managers, and technical buyers in industries like semiconductors, high-temperature processing, aerospace, energy, and industrial manufacturing, understanding the capabilities and nuances of SiC molding machines is crucial for sourcing superior components and optimizing production.

This comprehensive guide delves into the world of silicon carbide molding machines, exploring their critical role in modern manufacturing. We will examine the various molding technologies, the advantages these machines offer, key design and operational considerations, and how to select the right equipment. Furthermore, we will highlight how partners like Sicarb Tech , a leader in SiC technology and production solutions, can empower businesses to achieve unparalleled quality and efficiency in their technical ceramic applications. Based in Weifang City, the hub of China’s silicon carbide customizable parts manufacturing, Sicarb Tech leverages the extensive capabilities of the Chinese Academy of Sciences to deliver cutting-edge solutions and support the global SiC industry.

Key Molding Technologies for Silicon Carbide: A Machine-Centric Perspective

The production of silicon carbide components involves shaping SiC powders, often mixed with binders, into a desired “green” form, which is then subjected to heat treatment (sintering) to achieve its final properties. The initial shaping or molding process is critical as it largely determines the final component’s geometry, density, and integrity. Various molding technologies have been adapted and optimized for SiC, each requiring specific types of silicon carbide molding machines.

The choice of molding technology and machine depends on several factors, including the complexity of the part, the desired production volume, the specific grade of SiC being used (e.g., Reaction Bonded Silicon Carbide (RBSiC), Sintered Silicon Carbide (SSiC)), and the required dimensional tolerances.

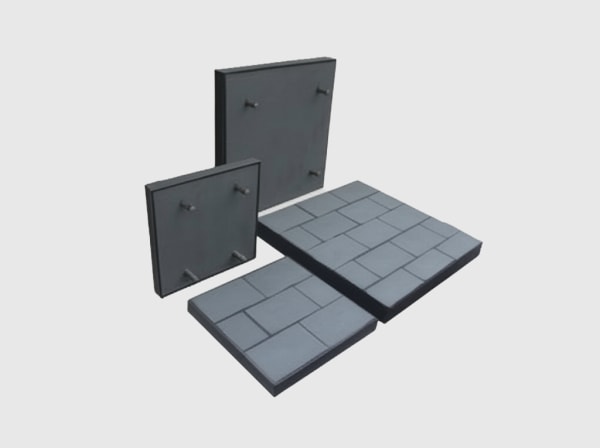

- Dry Pressing: This is one of the most common and cost-effective methods for producing simple to moderately complex SiC shapes in high volumes. SiC powder molding machines for dry pressing, typically mechanical or hydraulic presses, compact granulated SiC powder within a rigid die. The pressure applied is a critical parameter controlled by the machine.

- Machine Focus: Robust hydraulic or mechanical presses with precise pressure and stroke control. Automated powder filling and part ejection systems are common for high throughput.

- Applications: Tiles, plates, simple seals, wear liners.

- Isostatic Pressing: This technique involves subjecting SiC powder to equal pressure from all directions.

- Cold Isostatic Pressing (CIP): SiC powder is loaded into a flexible mold, which is then submerged in a fluid and pressurized. CIP machines are used to produce green bodies with uniform density and complex geometries.

- Hot Isostatic Pressing (HIP): This process combines high pressure and high temperature simultaneously. HIP machines are often used as a post-sintering step to eliminate residual porosity and further enhance the density and mechanical properties of SiC parts, but can also be used for direct consolidation of powders.

- Machine Focus: CIP machines consist of a pressure vessel, fluid pressurization system, and mold handling. HIP machines are more complex, incorporating heating elements and atmosphere control within the high-pressure vessel.

- Slip Casting: Suitable for complex shapes, especially hollow ones. A stable suspension of SiC powder in a liquid (slip) is poured into a porous mold (typically plaster). The liquid is drawn into the mold by capillary action, leaving a consolidated layer of SiC particles on the mold surface.

- Machine Focus: While the mold itself is key, auxiliary equipment includes slip mixing and de-airing units, and controlled drying environments. Automated slip dispensing systems can be used for consistency.

- Injection Molding (including Ceramic Injection Molding – CIM): This process is ideal for producing small, highly complex, and precise SiC parts in large quantities. SiC powder is mixed with a thermoplastic binder to create a feedstock, which is then heated and injected under high pressure into a mold cavity using a specialized ceramic injection molding machine.

- Machine Focus: These machines are similar to those used for plastic injection molding but are adapted for abrasive ceramic feedstocks. They feature precise control over injection speed, pressure, temperature, and mold handling. Wear-resistant barrels and screws are essential.

- Gel Casting: This is a newer forming technique that allows for the production of complex, near-net-shape ceramic parts with uniform microstructure. A concentrated SiC slurry containing monomers and an initiator is poured into a mold. In-situ polymerization of the monomers forms a gel, entrapping the SiC particles and forming a strong green body.

- Machine Focus: Requires equipment for slurry preparation, controlled polymerization (often temperature-controlled chambers), and demolding.

The table below summarizes these key molding technologies and their associated machine characteristics:

| Molding Technology | Machine Type/Focus | Typical SiC Applications | Complexity Capability | Volume Suitability |

|---|---|---|---|---|

| Dry Pressing | Hydraulic/Mechanical Presses | Tiles, simple seals, wear plates | Low to Medium | High |

| Cold Isostatic Pressing | CIP Pressure Vessels | Rods, tubes, preforms for machining, complex blanks | Medium to High | Medium |

| Hot Isostatic Pressing | HIP Furnaces (High Pressure & Temperature) | Densification of sintered parts, powder consolidation | High | Low to Medium |

| Slip Casting | Slip Preparation Units, Porous Molds, Drying Chambers | Crucibles, nozzles, complex hollow shapes | High | Low to Medium |

| Injection Molding (CIM) | Specialized Injection Molding Machines (wear-resistant) | Small intricate parts, turbocharger rotors, nozzles | Very High | High |

| Gel Casting | Slurry Prep, Polymerization Chambers, Demolding Stations | Complex near-net-shape parts, turbine components | Very High | Medium |

Understanding these technologies and the capabilities of the associated silicon carbide molding machines is paramount for manufacturers aiming to produce high-quality technical ceramic components. Sicarb Tech , with its deep-rooted expertise in SiC production processes, can guide businesses in selecting the most appropriate molding technology and machinery for their specific needs, ensuring optimal results for their industrial applications.

Why Invest in Specialized Silicon Carbide Molding Machines? Core Advantages for Manufacturers

Investing in specialized silicon carbide molding machines is not merely an equipment upgrade; it’s a strategic move towards achieving superior product quality, operational efficiency, and a competitive edge in the demanding market for advanced ceramics. The inherent properties of silicon carbide – its hardness, high-temperature resilience, and chemical inertness – make it an ideal material for challenging applications. However, shaping this robust material into precise components requires machinery specifically designed to handle its unique characteristics. Generic molding equipment often falls short, leading to inconsistencies, higher wear and tear, and an inability to produce complex geometries efficiently.

The core advantages of utilizing dedicated SiC molding equipment are manifold:

- Enhanced Precision and Dimensional Accuracy: Specialized machines offer finer control over molding parameters such as pressure, temperature, and injection speed. This precision is critical for producing custom SiC products that meet tight tolerances, which is often a non-negotiable requirement in aerospace, semiconductor, and precision engineering applications. This reduces the need for extensive and costly post-machining.

- Improved Material Utilization and Reduced Waste: SiC powders and raw materials can be expensive. Silicon carbide molding machines designed for specific processes like injection molding or precision pressing optimize feedstock usage and minimize material waste. Efficient mold design, facilitated by understanding the machine’s capabilities, also contributes to less scrap. This is particularly beneficial for wholesale SiC parts production where cost-efficiency is key.

- Capability to Create Complex Geometries: Modern advanced ceramic molding techniques, such as Ceramic Injection Molding (CIM) performed on specialized machines, allow for the creation of highly intricate and complex shapes that would be difficult or impossible to achieve through traditional machining from a solid SiC block. This opens up new design possibilities for OEM SiC components and specialized industrial parts.

- Consistency and Repeatability in Production: Automation and precise control systems integrated into modern SiC molding machines ensure high levels of consistency from part to part and batch to batch. This repeatability is crucial for large-scale industrial ceramic manufacturing and for maintaining quality standards expected by technical procurement professionals.

- Increased Productivity and Efficiency: Machines designed for SiC often incorporate features that enhance cycle times, facilitate quicker mold changes, and allow for easier maintenance, even when dealing with abrasive SiC materials. Automation features further reduce manual intervention, leading to higher throughput and lower labor costs.

- Optimized for Abrasive Materials: Silicon carbide is extremely abrasive. Specialized molding machines are constructed with wear-resistant components (e.g., barrels, screws, dies) and designs that mitigate the abrasive effects of SiC powders. This leads to longer machine life, reduced downtime, and lower maintenance costs compared to using standard equipment.

- Better Green Body Quality: The quality of the “green” SiC part (before sintering) significantly impacts the final properties of the sintered component. Specialized molding machines ensure uniform density and defect-free green bodies, leading to superior mechanical strength, thermal properties, and overall performance of the final precision SiC components.

Types of Silicon Carbide Molding Machines and Their Suitability

The selection of a silicon carbide molding machine is a critical decision that directly impacts production efficiency, component quality, and cost-effectiveness. Different molding techniques necessitate distinct machine types, each with specific capabilities tailored to certain SiC grades (like RBSiC, SiSiC, SSiC), component complexities, and production volumes. Understanding the landscape of available SiC molding equipment is essential for technical buyers and engineers.

Here’s a breakdown of common types of silicon carbide molding machines and their typical suitability:

- Mechanical and Hydraulic Presses (for Dry Pressing):

- Description: These are the workhorses for producing simpler SiC shapes. Mechanical presses offer high speed for smaller parts, while hydraulic presses provide higher and more controllable pressure, suitable for larger or denser components.

- Machine Features: Force rating (tonnage), platen size, stroke length, speed control, and level of automation (e.g., powder feeding, part ejection). Modern presses offer programmable logic controllers (PLCs) for precise cycle management.

- Suitability:

- SiC Grades: Suitable for most SiC powders that can be granulated for pressing, including precursors for SSiC and RBSiC.

- Applications: Flat tiles, discs, wear liners, simple blocks, and kiln furniture.

- Advantages: Relatively low tooling costs for simple shapes, high production rates, good for wholesale SiC parts.

- Considerations: Limited to relatively simple geometries. Achieving uniform density in complex or tall parts can be challenging.

- Isostatic Presses (Cold and Hot):

- Cold Isostatic Presses (CIP):

- Description: CIP machines use fluid pressure applied uniformly to a flexible mold containing SiC powder.

- Machine Features: Pressure vessel size and rating, pumping system, cycle time, automation of loading/unloading.

- Suitability:

- SiC Grades: All SiC powders.

- Applications: Rods, tubes, nozzles, larger complex blanks requiring uniform density before machining or sintering. Ideal for creating custom SiC products with improved green strength.

- Advantages: Uniform density, ability to form complex shapes, reduced internal stresses in the green body.

- Hot Isostatic Presses (HIP):

- Description: HIP machines apply high pressure and high temperature simultaneously. Often used for densification post-sintering or for powder metallurgy routes.

- Machine Features: High-pressure containment, high-temperature furnace system (graphite or molybdenum), inert gas atmosphere control, precise temperature and pressure programming.

- Suitability:

- SiC Grades: Primarily for SSiC and sometimes other grades to achieve near-theoretical density.

- Applications: Critical high-performance components like turbine parts, bearings, and advanced armor where maximum density and flaw elimination are crucial for high-temperature SiC applications.

- Advantages: Achieves highest possible density, removes internal porosity, significantly improves mechanical properties.

- Cold Isostatic Presses (CIP):

- Ceramic Injection Molding (CIM) Machines:

- Description: These machines are adapted from plastic injection molding but are built to handle abrasive ceramic-binder feedstocks.

- Machine Features: Wear-resistant screw and barrel (often made of hardened tool steels or ceramics), precise temperature control zones for barrel and mold, accurate injection speed and pressure control, and robust clamping units.

- Suitability:

- SiC Grades: Fine SiC powders suitable for mixing with binders (SSiC, sometimes RBSiC precursors).

- Applications: Small, highly complex, net-shape or near-net-shape parts such as turbocharger rotors, intricate nozzles, dental brackets, and electronic components. Excellent for mass production of precision SiC components.

- Advantages: High complexity, excellent surface finish, tight tolerances, high volume production.

- Considerations: Higher initial tooling costs, requires a debinding step after molding.

- Slip Casting and Pressure Casting Equipment:

- Description: While traditional slip casting relies heavily on mold properties, pressure casting machines apply external pressure to the slip to accelerate casting and improve green density.

- Machine Features (Pressure Casting): Pressure-tight mold assembly, slip reservoir, pressure application system, and de-molding mechanisms.

- Suitability:

- SiC Grades: Fine SiC powders that can form stable slips.

- Applications: Complex hollow shapes, sanitaryware (less common for technical SiC), larger components where CIM is not feasible.

- Advantages: Good for complex internal geometries. Pressure casting can improve density and reduce casting times compared to conventional slip casting.

The following table provides a comparative overview of these machine types:

| Machine Type | Primary Molding Principle | Typical Pressure Range | Temperature Involved | Complexity Capability | Key Advantage | Sicarb Tech Relevance |

|---|---|---|---|---|---|---|

| Mechanical/Hydraulic Press | Uniaxial Compaction | 50 – 2000+ MPa | Ambient | Low to Medium | High speed, cost-effective for simple shapes | Advising on press selection for specific RBSiC, SiSiC products and local Weifang manufacturing capabilities. |

| Cold Isostatic Press (CIP) | Hydrostatic Pressure | 100 – 600 MPa | Ambient | Medium to High | Uniform green density, complex blanks | Guidance on CIP for producing high-quality preforms for custom SiC parts. |

| Hot Isostatic Press (HIP) | Hydrostatic Pressure | 100 – 300 MPa | Up to 2000°C+ | High | Maximum densification, superior properties | Expertise in advanced densification for critical applications; can integrate into turnkey SiC production lines. |

| Ceramic Injection Molding | Injection into Mold | 50 – 200 MPa (melt) | 150 – 250°C (melt) | Very High | Net-shape complex parts, high volume production | Technology transfer for CIM processes, vital for producing OEM SiC components with intricate designs. |

| Pressure Casting Equipment | Pressurized Slip | 0.1 – 5 MPa | Ambient | Medium to High | Complex hollow shapes, improved slip casting | Support in setting up advanced casting lines for specialized technical ceramic components. |

Design and Operational Considerations for Optimal SiC Molding Machine Performance

Achieving optimal performance from silicon carbide molding machines and consistently producing high-quality custom SiC products goes beyond simply selecting the right equipment. It requires careful attention to design principles, meticulous operational practices, and a deep understanding of how SiC materials behave during the molding process. Engineers and operators must collaborate to ensure that both the machine and the process are finely tuned.

Mold Design for Silicon Carbide: The mold is a critical interface in the SiC molding process. Its design directly impacts part quality, dimensional accuracy, and production efficiency.

- Material Selection: Molds for SiC processing, especially for abrasive techniques like injection molding or dry pressing, must be made from hardened tool steels, carbide alloys, or even ceramic materials to withstand wear. Surface coatings (e.g., TiN, CrN) can further enhance mold life.

- Draft Angles: Adequate draft angles are essential to facilitate easy ejection of the green SiC part from the mold, preventing damage and reducing cycle times.

- Gate and Runner Design (for Injection Molding/Slip Casting): Proper design of gates and runners ensures uniform filling of the mold cavity, minimizes turbulence, prevents air entrapment, and controls the weld line locations.

- Venting: Air trapped in the mold cavity can cause defects in the molded part. Effective venting allows air to escape as the SiC material fills the mold.

- Shrinkage Allowance: SiC components undergo significant shrinkage during drying and sintering (can be 15-25% or more depending on the SiC grade and green density). Mold cavities must be designed oversized to compensate for this shrinkage accurately. This requires precise knowledge of the specific SiC powder and process parameters.

- Thermal Management (for CIM): For processes like Ceramic Injection Molding, the mold temperature needs to be precisely controlled to ensure proper flow of the feedstock and solidification of the part. Cooling/heating channels within the mold are crucial.

Machine Parameter Settings: Optimizing machine parameters is key to achieving consistent results and maximizing the potential of your SiC molding equipment.

- Pressure: Whether it’s compaction pressure in dry pressing, injection pressure in CIM, or isostatic pressure in CIP, applying the correct and consistent pressure is vital for achieving the desired green density and minimizing porosity.

- Temperature: For CIM, barrel and nozzle temperatures must be carefully controlled to ensure the feedstock has the right viscosity. Mold temperature also plays a significant role. For other processes, ambient temperature control might be important for material consistency.

- Cycle Time: This includes filling time, pressure hold time, cooling/curing time, and ejection time. Optimizing each phase of the cycle is crucial for productivity without compromising part quality.

- Speed: Injection speed in CIM or pressing speed in mechanical presses can affect material flow, part density, and potential for defects.

- Material Feeding Systems: Consistent and accurate material feeding into the molding machine is essential. For powders, this means uniform flow and preventing segregation. For CIM feedstock, it means consistent melt delivery.

Operational Best Practices:

- Raw Material Control: The quality and consistency of the SiC powder and any binders used are paramount. Variations in particle size, purity, or binder characteristics will directly impact molding performance and final product properties.

- Machine Calibration and Maintenance: Regular calibration of pressure sensors, temperature controllers, and other critical machine components is essential. A proactive maintenance schedule, especially for wear parts like screws, barrels, and die components exposed to abrasive SiC, will prevent unexpected downtime and ensure consistent industrial ceramic manufacturing.

- Process Monitoring: Implementing real-time monitoring of key process parameters (e.g., pressure profiles, temperatures, fill times) can help detect deviations early and allow for corrective actions.

- Operator Training: Well-trained operators who understand the nuances of SiC materials and the specific silicon carbide forming technology being used are invaluable. They can identify potential issues and make appropriate adjustments.

- Minimizing Wear:

- Use wear-resistant materials for machine components in contact with SiC.

- Optimize process parameters to reduce abrasive wear (e.g., avoid excessive speeds or pressures if not necessary).

- Ensure proper alignment of mold components.

Achieving Tight Tolerances and Superior Surface Finish with Modern SiC Molding Machines

In the realm of high-performance industrial components, particularly for applications in semiconductors, aerospace, and precision metrology, the demand for tight dimensional tolerances and impeccable surface finishes is relentless. Silicon carbide, with its exceptional properties, is often the material of choice for these critical applications. Modern silicon carbide molding machines, when coupled with optimized processes and high-quality tooling, play a pivotal role in achieving these stringent requirements directly from the molding stage, thereby minimizing the need for costly and time-consuming secondary finishing operations.

The ability of SiC molding equipment to produce parts with high precision stems from several key factors:

- Machine Rigidity and Precision Control: Advanced molding machines are built with high structural rigidity to minimize deflection under high molding pressures. This, combined with sophisticated servo-electric or hydraulic control systems, allows for extremely precise and repeatable movements of machine platens, injection units, and mold components. This precision directly translates to consistent part dimensions.

- Mold Quality and Design: The mold is the negative of the part; thus, its accuracy is paramount. High-precision machining of mold cavities, coupled with the use of dimensionally stable and wear-resistant mold materials, is essential. The design must also account for uniform material flow and predictable shrinkage of the custom SiC products during subsequent debinding and sintering.

- Process Parameter Optimization:

- For Injection Molding (CIM): Precise control over injection speed, pressure, hold pressure, melt temperature, and mold temperature is crucial. Modern ceramic injection molding machines offer closed-loop control over these parameters, ensuring that the mold cavity is filled completely and uniformly, and that the part solidifies with minimal internal stress and warpage.

- For Pressing (Dry/Isostatic): Accurate control of compaction pressure and pressure distribution ensures uniform green density. Variations in green density can lead to differential shrinkage during sintering, affecting final dimensions and tolerances. Isostatic pressing SiC methods, by their nature, provide more uniform compaction leading to better dimensional control for complex shapes.

- Material Consistency: The characteristics of the SiC powder (particle size distribution, morphology) and the binder system (for CIM or granulation) must be highly consistent. Variations can affect flow behavior, packing density, and shrinkage, all of which influence final tolerances and surface finish.

- Near-Net-Shape Manufacturing: Technologies like CIM are particularly adept at producing near-net-shape parts. This means the molded component is very close to its final required dimensions, significantly reducing or even eliminating the need for grinding, lapping, or polishing. This is a major cost and time saver, especially for complex OEM SiC components.

Impact on Surface Finish: The surface finish of a molded SiC part is largely determined by the surface finish of the mold cavity and the particle size of the SiC powder used.

- Highly polished mold surfaces will impart a smoother finish to the green SiC part.

- Finer SiC powders generally result in smoother as-sintered surfaces.

- The molding process itself, if well-controlled, can minimize surface defects like flow lines or knit lines, which can be critical for technical ceramic parts used in sealing or bearing applications.

The table below illustrates how different molding techniques, enabled by specific machine capabilities, contribute to tolerance and surface finish:

| Molding Technique | Typical Achievable Tolerances (Relative) | Typical Surface Finish (Ra) – As-Molded/Green | Key Machine Attributes for Precision |

|---|---|---|---|

| Dry Pressing | Moderate | 0.8 – 3.2 µm (depends on powder/die) | Precise pressure control, die quality, automated fill consistency. |

| Cold Isostatic Pressing | Good | 0.4 – 1.6 µm (depends on mold material) | Uniform pressure application, quality of flexible tooling. |

| Ceramic Injection Molding | Excellent (Tightest) | 0.2 – 0.8 µm (highly dependent on mold finish) | High-precision injection control, temperature stability, superior mold construction, fine powders. |

| Slip Casting | Fair to Moderate | 1.6 – 6.3 µm (depends on mold material) | Slip quality, mold surface quality. Pressure-assisted can improve. |

While modern SiC molding machines can achieve remarkable precision, it’s important to note that the final, as-sintered tolerances and surface finish will also be influenced by the sintering process itself. However, starting with a highly accurate and well-formed green part is the most critical step.

Sicarb Tech understands the intricate relationship between silicon carbide manufacturing equipment, process control, and final component quality. Leveraging their expertise and the advanced technological resources from the Chinese Academy of Sciences, they assist clients in specifying and sourcing SiC molding equipment capable of meeting the most demanding tolerance and surface finish requirements. Their support extends to optimizing the entire production chain, from SiC powder molding and preparation to final quality assessment, ensuring that businesses can confidently produce precision SiC components for high-value industrial applications.

Beyond the Machine: Essential Post-Molding Processes and Equipment Integration

The journey of a silicon carbide component from raw powder to a finished, high-performance part involves several critical stages beyond the initial molding process. While the silicon carbide molding machine plays a crucial role in shaping the green component, subsequent post-molding processes are equally vital for achieving the desired material properties, dimensional accuracy, and overall functionality. Furthermore, seamless integration of molding machines with downstream and upstream equipment is key to establishing an efficient and coherent SiC production line.

Key Post-Molding Processes:

- Debinding (Binder Removal):

- This step is essential for parts produced by processes like Ceramic Injection Molding (CIM) or other binder-assisted forming techniques. The molded green part contains a significant amount of organic binder that provided plasticity during molding. This binder must be carefully removed before sintering to avoid defects like cracks, blisters, or carbon contamination in the final SiC part.

- Equipment: Debinding is typically carried out in specialized ovens or furnaces with precise temperature control and often controlled atmospheres (air, inert gas, or vacuum). Thermal debinding involves slowly heating the parts to pyrolyze the binder. Solvent debinding or catalytic debinding can also be used for specific binder systems.

- Integration: The output from the silicon carbide molding machines (green parts) needs to be carefully handled and transferred to the debinding furnaces. Automated handling systems can be beneficial for high-volume production.

- Sintering:

- Sintering is the high-temperature process that transforms the porous, debound (or directly molded, in the case of binderless pressing) SiC green body into a dense, strong ceramic component. During sintering, SiC particles bond together, and the part shrinks significantly.

- Equipment: Sintering of SiC requires very high temperatures (often >2000°C for SSiC) and controlled atmospheres (e.g., argon, vacuum, or specific reactive gases for RBSiC). Specialized high-temperature sintering furnaces are used, which can be batch or continuous types. These include graphite resistance heated furnaces, induction heated furnaces, or microwave furnaces.

- Integration: The debound parts are carefully loaded onto sintering setters (often made of graphite or SiC itself) and transferred to the sintering furnace. The choice of sintering cycle (temperature profile, atmosphere, duration) is critical and depends on the SiC grade and desired final properties.

- Machining/Finishing (If Required):

- While near-net-shape molding techniques aim to minimize or eliminate machining, some custom SiC products may require further grinding, lapping, polishing, or cutting to achieve extremely tight tolerances, specific surface finishes, or complex features not achievable through molding alone.

- Equipment: Due to SiC’s extreme hardness, diamond tooling is exclusively used. This includes diamond grinding wheels, lapping plates with diamond slurries, diamond wire saws, and ultrasonic machining setups.

- Integration: Parts from the sintering furnace, after cooling and inspection, are moved to the machining area. Precision fixtures are often required to hold the hard ceramic parts during machining.

- Cleaning and Quality Control:

- After all processing steps, SiC components are typically cleaned to remove any contaminants or residues.

- Comprehensive quality control is performed, including dimensional checks (using CMMs, laser scanners), surface roughness measurements, density measurements, visual inspection for defects, and potentially non-destructive testing (NDT) like X-ray or ultrasonic inspection for critical OEM SiC components.

- Equipment: Cleaning stations (ultrasonic cleaners), metrology equipment, NDT systems.

Turnkey SiC Production Lines: Establishing a complete SiC production facility requires careful planning and integration of all these stages. This is where a knowledgeable partner becomes invaluable. Sicarb Tech excels in this area, offering turnkey project services. Drawing on their deep understanding of silicon carbide forming technology and the broader SiC manufacturing ecosystem in Weifang and beyond, they can assist clients in:

- Designing the optimal factory layout.

- Specifying and procuring all necessary equipment, from powder preparation units and silicon carbide molding machines to debinding ovens, high-temperature sintering furnaces, and finishing/QC equipment.

- Overseeing installation and commissioning of the entire industrial ceramic machinery line.

- Providing technology transfer, process know-how, and training for trial production and ongoing operations.

Sicarb Tech ‘s connection to the Chinese Academy of Sciences ensures that the technology and processes implemented are state-of-the-art and reliable. Their holistic approach ensures that the silicon carbide molding machine is not an isolated piece of equipment but an integral part of a well-orchestrated manufacturing system designed to produce high-quality technical ceramic parts efficiently and cost-effectively. This is particularly beneficial for companies looking to establish specialized SiC production capabilities in their own countries, ensuring a more effective investment and guaranteed input-output ratio.

Sicarb Tech : Your Partner in Advanced SiC Manufacturing Technology and Equipment

In the complex and rapidly evolving landscape of advanced ceramics, particularly silicon carbide, having a knowledgeable and reliable partner can be the differentiator between success and stagnation. Sicarb Tech stands out as such a partner, deeply embedded in the heart of China’s SiC industry in Weifang City – a region responsible for over 80% of the nation’s silicon carbide output. Since 2015, SicSino has been instrumental in introducing and implementing advanced SiC production technology, fostering large-scale production and significant technological advancements among local enterprises. Their journey has been one of witnessing and actively contributing to the growth and development of this vital industrial cluster.

Comprehensive Expertise in Custom SiC Production: SicSino boasts a domestic top-tier professional team specializing in the customized production of silicon carbide products. Their expertise is not confined to a single aspect of SiC manufacturing; instead, they possess a wide array of technologies encompassing:

- Material Technology: Deep understanding of different SiC grades (RBSiC, SSiC, SiSiC, etc.), powder characteristics, and their suitability for various applications.

- Process Technology: Mastery over various forming techniques including those requiring specialized silicon carbide molding machines, as well as debinding, sintering, and finishing processes.

- Design Technology: Expertise in designing custom SiC products for manufacturability, optimizing for performance in demanding industrial applications.

- Measurement & Evaluation Technologies: Capabilities for thorough quality control and performance validation of technical ceramic components.

This integrated process, from raw materials to finished products, enables Sicarb Tech to meet diverse customization needs for wholesale SiC parts, OEM SiC components, and specialized precision SiC components. They have successfully supported over ten local enterprises with their technologies, enhancing their production capabilities and product quality.

Turnkey Solutions and Technology Transfer: Beyond supplying high-quality, cost-competitive customized silicon carbide components from China, Sicarb Tech is committed to empowering global partners. For clients looking to establish their own specialized SiC manufacturing plants, SicSino offers comprehensive turnkey project services. This includes:

- Technology Transfer: Providing the know-how for professional silicon carbide production.

- Factory Design: Tailoring plant layouts for optimal workflow and efficiency.

- Procurement of Specialized Equipment: Assisting in the selection and sourcing of all necessary machinery, including advanced silicon carbide molding machines, sintering furnaces, and quality control instrumentation.

- Installation and Commissioning: Overseeing the setup and startup of the production line.

- Trial Production Support: Guiding the initial production runs to ensure smooth operations and quality output.

This holistic service offering ensures that clients receive not just equipment, but a fully operational and efficient manufacturing capability, leading to a more effective investment, reliable technology transformation, and a guaranteed input-output ratio.

The table below highlights the key strengths of Sicarb Tech as a partner:

| SicSino Capability | Description | Benefit to Client |

|---|---|---|

| Location & Industry Insight | Based in Weifang, the hub of China’s SiC production. Deep understanding of the local industry and supply chain. | Access to a vast network of resources, cost-effective solutions, and insights into industry best practices. |

| Chinese Academy of Sciences Affiliation | Backed by the Chinese Academy of Sciences National Technology Transfer Center. | Access to cutting-edge R&D, reliable technology, and a strong foundation of scientific expertise. |

| Customization Expertise | Top-tier team for custom SiC product development and manufacturing (RBSiC, SSiC, etc.). | High-quality, tailored custom SiC products meeting specific technical requirements. |

| Integrated Process Knowledge | Expertise spanning materials, process, design, measurement, and evaluation. | Comprehensive solutions from concept to final product, ensuring quality and performance. |

| Turnkey Project Services | Full-range services for establishing SiC production plants (design, equipment, installation, training). | Reduced risk, faster setup, reliable technology transfer, and optimized investment for new SiC manufacturing ventures. |

| Support for Local & Global Partners | Proven track record of assisting local enterprises and commitment to supporting international clients. | A trusted partner for both sourcing components and establishing independent production capabilities. |

Choosing Sicarb Tech means partnering with an organization that is not just a supplier but a comprehensive solution provider, deeply invested in the advancement of silicon carbide technology and dedicated to the success of its clients in diverse industrial ceramic manufacturing sectors. Whether you need high-quality SiC wear parts or are planning to invest in silicon carbide manufacturing equipment, SicSino offers the expertise and support to achieve your goals.

Frequently Asked Questions (FAQ) about Silicon Carbide Molding Machines

Technical buyers, engineers, and procurement managers often have specific questions when considering investments in silicon carbide molding machines or sourcing components made using these technologies. Here are some common queries with concise, practical answers:

1. What are the typical cycle times for SiC molding using different types of machines? Cycle times can vary significantly based on the molding technique, machine type, part size, and complexity:

- Dry Pressing: Can be very fast, often a few seconds to 15-30 seconds per part for automated presses, making it suitable for high-volume production of simpler wholesale SiC parts.

- Ceramic Injection Molding (CIM): Molding cycle times typically range from 30 seconds to a few minutes, depending on part size and cooling requirements. However, the overall process includes lengthy debinding and sintering steps.

- Cold Isostatic Pressing (CIP): Cycle times can range from a few minutes to 30 minutes or more, depending on the size of the part and the pressurization/depressurization rates of the SiC molding equipment.

- Slip Casting: This is generally a slower process, with casting times ranging from minutes to hours, followed by drying which can take many hours or even days for large parts.

2. What level of precision and tolerances can be realistically achieved with modern SiC molding machines for custom SiC products? Modern SiC molding machines, particularly CIM and high-precision presses, can achieve very tight tolerances on the green part.

- CIM: Can often achieve green part tolerances in the range of ±0.3% to ±0.5% of the nominal dimension. After sintering, typical as-sintered tolerances for well-controlled SSiC parts might be around ±0.5% to ±1%, or even tighter for specific dimensions with optimized processes. For extremely high precision, post-sintering grinding/lapping is usually required.

- Dry Pressing: Tolerances are generally wider than CIM, perhaps ±1% to ±2% on green parts, and correspondingly wider after sintering.

- Isostatic Pressing: Offers good dimensional consistency, with sintered tolerances often falling within ±1%. It’s crucial to discuss specific tolerance requirements with your technical ceramic supplier or machine manufacturer, as it depends heavily on the SiC grade, part geometry, and overall process control. Sicarb Tech can provide detailed guidance on achievable tolerances for their custom SiC products and the capabilities of production lines they help establish.

3. How does the choice of molding machine and process affect the final properties (e.g., density, strength) of the silicon carbide component? The molding machine and process directly influence the green body’s characteristics (density, uniformity, presence of defects), which in turn significantly impact the final sintered properties:

- Green Density: Higher and more uniform green density generally leads to higher sintered density, reduced shrinkage variability, and improved mechanical strength. Machines offering higher compaction pressures (presses, HIP) or better particle packing (optimized CIM, gel casting) contribute to better green bodies.

- Defect Introduction: Poor molding (e.g., air entrapment, weld lines in CIM, density gradients in pressing) can introduce defects in the green body that may persist or worsen during sintering, leading to lower strength and reliability in the final precision SiC component.

- Microstructure: The forming process can influence particle arrangement and pore distribution in the green state, which affects the evolution of the microstructure during sintering. Specialized silicon carbide manufacturing equipment is designed to optimize green body formation for specific SiC grades, maximizing the potential for superior final properties.

4. What are the primary maintenance considerations for silicon carbide molding machines, especially given SiC’s abrasive nature? Silicon carbide is highly abrasive, so maintenance is a critical aspect:

- Wear Parts Replacement: Components in direct contact with SiC powder or feedstock (e.g., screws and barrels in CIM machines, dies and punches in presses, nozzles) will experience wear and require periodic replacement. Using machines designed with hardened, wear-resistant materials is essential to prolong their life.

- Calibration: Regular calibration of pressure sensors, temperature controllers, and displacement transducers is vital for consistent performance.

- Lubrication: Proper lubrication of moving parts as per the manufacturer’s schedule.

- Hydraulic Systems (if applicable): Monitoring hydraulic fluid levels, quality, and filters.

- Cleaning: Regular cleaning to prevent accumulation of SiC dust or residues, which can accelerate wear or cause operational issues. Partnering with a supplier like Sicarb Tech , who can advise on maintenance protocols as part of their turnkey project services or equipment consultation, is highly beneficial for ensuring the longevity and reliability of your industrial ceramic machinery.

5. Can Sicarb Tech assist in selecting the right molding machine if we want to produce a specific type of SiC component in-house? Absolutely. Sicarb Tech excels in providing comprehensive support for clients looking to establish or upgrade their SiC production capabilities. Leveraging their deep expertise in various silicon carbide forming technologies and their access to the Chinese Academy of Sciences National Technology Transfer Center, they can:

- Analyze your specific component requirements (geometry, material grade, volume, tolerances).

- Recommend the most suitable molding technology and type of silicon carbide molding machine.

- Assist in sourcing high-quality, cost-effective SiC molding equipment, potentially leveraging their network within the Weifang SiC cluster.

- Provide support for integrating the machine into your production line and offer technology transfer for efficient operation. Their goal is to ensure you invest in machinery that not only meets your current needs for OEM SiC components or other parts but also supports your future growth.

Conclusion: Embracing Advanced Molding for Superior Silicon Carbide Solutions

The journey through the intricacies of silicon carbide molding machines underscores their pivotal role in unlocking the full potential of this extraordinary material for demanding industrial environments. From enhancing the precision of custom SiC products to enabling the mass production of complex OEM SiC components, these specialized machines are indispensable tools for manufacturers striving for excellence. The ability to achieve tight tolerances, superior surface finishes, and consistent material properties directly translates into enhanced performance and reliability in applications spanning aerospace, semiconductor manufacturing, energy, and beyond.

Choosing the right SiC molding equipment, optimizing its operation, and integrating it effectively into a comprehensive production line requires a blend of technical expertise, material science knowledge, and practical manufacturing insight. The considerations are multifaceted, ranging from mold design and material selection to precise parameter control and diligent maintenance, especially when handling the abrasive nature of silicon carbide.

In this complex landscape, partners like Sicarb Tech emerge as invaluable assets. Their deep-rooted expertise in Weifang, the epicenter of China’s SiC industry, combined with the formidable scientific backing of the Chinese Academy of Sciences , positions them uniquely to guide businesses. Whether it’s sourcing high-quality technical ceramic parts, providing consultation on silicon carbide manufacturing equipment, or delivering complete turnkey SiC production lines, SicSino offers a pathway to reliable, high-quality, and cost-effective manufacturing solutions. Their commitment to technology transfer and comprehensive support empowers industries worldwide to leverage the exceptional benefits of silicon carbide, driving innovation and efficiency in the most challenging applications. By embracing advanced molding technologies and partnering with knowledgeable experts, businesses can confidently navigate the complexities of SiC manufacturing and secure a competitive edge in the global market.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.