Silicon Carbide Granules: The Unsung Hero of Advanced Industrial Applications

Share

In the realm of technical ceramics and high-performance materials, few substances command as much respect and versatility as silicon carbide (SiC). While SiC components and finished products often take the spotlight, the foundational material – silicon carbide granules – plays an indispensable role in enabling these advanced applications. These granules are the building blocks for a vast array of products that drive innovation across demanding sectors like semiconductors, aerospace, energy, and heavy industry. For engineers, procurement managers, and technical buyers, understanding the nuances of SiC granules is crucial for optimizing performance, ensuring reliability, and achieving cost-effectiveness in their respective applications. This blog post delves into the world of silicon carbide granules, exploring their properties, applications, and the critical factors to consider when sourcing this essential industrial raw material.

The journey of silicon carbide from raw material to a high-performance component is intricate, and it all begins with the quality and characteristics of the granules. As industries push the boundaries of temperature, pressure, and wear resistance, the demand for superior advanced ceramics like SiC continues to surge. We, at Sicarb Tech, situated in Weifang City, the heart of China’s silicon carbide manufacturing hub, have been at the forefront of SiC production technology since 2015. Leveraging the formidable scientific and technological prowess of the Chinese Academy of Sciences , we not only witness but actively contribute to the evolution of the SiC industry, supporting local enterprises and offering unparalleled expertise in custom SiC solutions.

Key Applications of Silicon Carbide Granules

Silicon carbide granules, often referred to as SiC grit or SiC powder depending on particle size, are not a one-size-fits-all commodity. Their diverse properties make them suitable for a wide spectrum of industrial applications, each demanding specific grades and characteristics. The intrinsic hardness, high thermal conductivity, excellent wear resistance, and chemical inertness of SiC make its granular form a critical input material.

One of the most traditional and widespread uses of silicon carbide granules is in the manufacturing of abrasives. Their exceptional hardness, second only to diamond, makes them ideal for grinding wheels, sandpaper, lapping compounds, and abrasive blasting media. Industries relying on precision machining, surface finishing, and material removal, such as automotive, aerospace, and metal fabrication, heavily depend on SiC-based abrasives for their cutting and shaping processes. The particle size and shape of the SiC granules are critical in determining the aggressiveness and finish of the abrasive product.

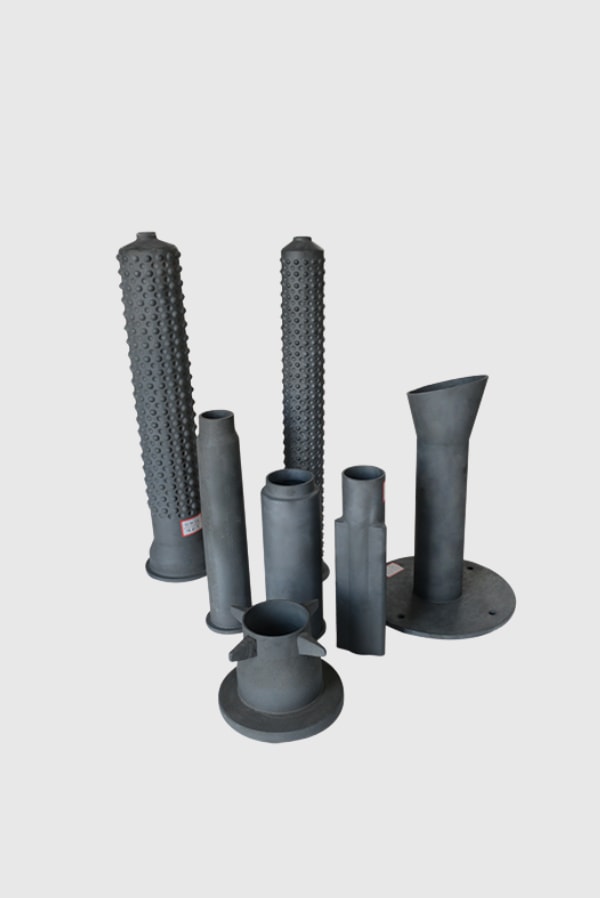

In the realm of refractories, SiC granules are indispensable due to their ability to withstand extreme temperatures and harsh chemical environments. They are used to produce refractory bricks, kiln furniture (beams, rollers, plates, and setters), crucibles, and linings for furnaces and incinerators. These applications are prevalent in industries like metallurgy, glass manufacturing, ceramics firing, and waste-to-energy plants. The thermal shock resistance and high-temperature strength of SiC ensure longevity and efficiency in these demanding thermal processes. For instance, reaction-bonded silicon carbide (RBSC or SiSiC) and sintered silicon carbide (SSiC) components, often starting from specific SiC granule formulations, are key in these high-temperature structural applications.

Metallurgical applications also benefit significantly from silicon carbide granules. In iron and steel production, SiC is used as a deoxidizer, a source of silicon and carbon, and as a fuel in foundries. Its use can lead to cleaner steel, improved casting quality, and more efficient furnace operations. Specific metallurgical grade SiC granules with controlled purity and sizing are preferred for these applications to ensure predictable reactions and optimal results.

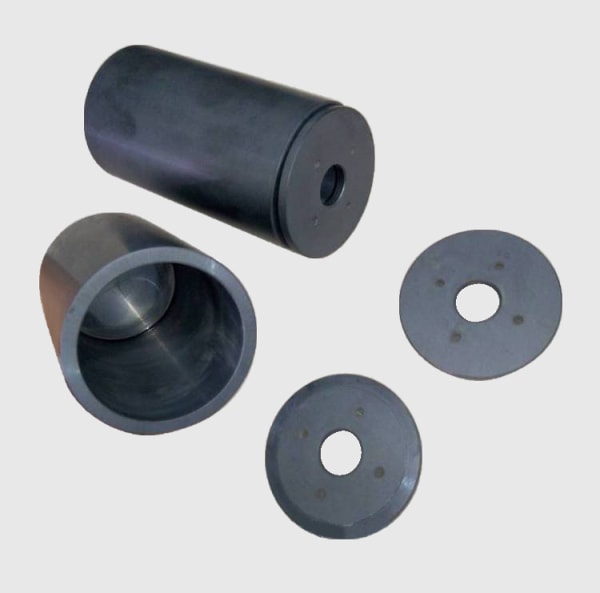

Furthermore, the production of advanced ceramic components themselves relies heavily on high-quality SiC granules and powders. These are the starting materials for manufacturing sophisticated SiC parts through processes like sintering, reaction bonding, or chemical vapor deposition. Applications range from wear-resistant nozzles, pump components, and mechanical seals to semiconductor processing equipment parts like wafer chucks, etching rings, and susceptors. The purity and particle size distribution of the initial SiC granules are paramount in achieving the desired density, microstructure, and performance of the final ceramic product. Custom SiC materials are often developed by carefully selecting and processing specific granule types.

The versatility extends to other areas as well:

- Composites: SiC granules are used as reinforcement in metal matrix composites (MMCs) and ceramic matrix composites (CMCs) to enhance strength, stiffness, and wear resistance.

- Electronics: While less common for granules directly, ultra-high purity SiC powders (derived from granules) are crucial for growing SiC single crystals used in power electronics and high-frequency devices.

- Coatings: Fine SiC granules can be incorporated into wear-resistant coatings applied through thermal spray processes, enhancing the surface properties of various substrates.

Understanding these diverse applications helps technical buyers and engineers appreciate the importance of selecting the right type and quality of silicon carbide granules for their specific needs. Sicarb Tech provides a comprehensive range of SiC granules and possesses the expertise to guide clients in choosing the optimal material for their unique industrial challenges.

Advantages of Using High-Quality Silicon Carbide Granules

The decision to use silicon carbide granules in an industrial process or product is driven by a unique combination of properties that translate into tangible performance benefits. Opting for high-quality granules ensures that these inherent advantages are maximized, leading to superior end-products, improved process efficiency, and enhanced operational reliability. For procurement professionals and engineers in sectors like semiconductor manufacturing, aerospace components, and industrial furnaces, the quality of SiC granules is not just a preference but a critical requirement.

The primary advantages stem from the fundamental characteristics of silicon carbide:

- Exceptional Hardness and Wear Resistance: Silicon carbide is one of the hardest commercially available synthetic materials, typically ranking around 9.0-9.5 on the Mohs scale. This makes SiC grit and components derived from SiC granules incredibly resistant to abrasion, erosion, and general wear and tear.

- Benefit for B2B: Longer lifespan for components like nozzles, seals, and grinding media; reduced maintenance downtime; consistent performance in abrasive environments. This translates to significant cost savings for OEMs and end-users in industrial manufacturing.

- High-Temperature Stability and Strength: SiC maintains its mechanical strength and structural integrity at very high temperatures (up to 1600 ∘C or higher, depending on the grade and manufacturing method). It does not melt at atmospheric pressure but rather dissociates at temperatures above 2500 ∘C.

- Benefit for B2B: Ideal for refractory materials, kiln furniture, and components in high-temperature furnaces. Ensures operational safety and efficiency in thermal processing industries. Procurement managers for energy sector applications (e.g., heat exchangers, burner components) value this stability.

- Excellent Thermal Conductivity: Silicon carbide exhibits high thermal conductivity, which allows it to dissipate heat effectively. This property is crucial for applications requiring rapid heat transfer or thermal shock resistance.

- Benefit for B2B: Enhanced performance in heat exchangers, susceptors for semiconductor processing, and crucibles. Improved thermal management leads to better process control and product quality. For technical buyers in electronics, this means more efficient thermal management solutions.

- Superior Chemical Inertness: SiC is highly resistant to corrosion by most acids, alkalis, and molten salts, even at elevated temperatures. This chemical stability makes it suitable for use in aggressive chemical environments.

- Benefit for B2B: Longevity and reliability in chemical processing equipment, pump components handling corrosive fluids, and parts exposed to harsh industrial atmospheres. This is a key factor for wholesale buyers supplying to chemical plants and related industries.

- Low Thermal Expansion: Silicon carbide has a relatively low coefficient of thermal expansion, which contributes to its excellent thermal shock resistance. Components made from SiC granules can withstand rapid temperature changes without cracking or failing.

- Benefit for B2B: Increased durability of parts subjected to thermal cycling, such as kiln supports or furnace linings. Critical for applications in foundries and heat treatment processes.

- Electrical Properties: While generally considered a semiconductor, the electrical conductivity of SiC can be tailored through doping and manufacturing processes. This allows for its use in heating elements (e.g., Globar), varistors, and advanced electronic devices. Granules of specific purity are essential for these applications.

- Benefit for B2B: Enables specialized applications in electrical heating, surge protection, and high-power/high-frequency electronics, opening doors for distributors focusing on niche electronic components.

- Material Purity and Consistency: Sourcing high-quality silicon carbide granules from reputable suppliers like Sicarb Tech ensures high levels of purity and lot-to-lot consistency. This is vital for applications where even trace impurities can affect performance, such as in semiconductor manufacturing or the production of high-performance ceramics.

- Benefit for B2B: Predictable material behavior, reproducible results in manufacturing, and reduced risk of product failure. This is paramount for industries with stringent quality control standards.

The table below summarizes some key advantages and their relevance to B2B buyers:

| Advantage | Key Property | B2B Relevance | Target Industries |

|---|---|---|---|

| Extreme Hardness | High Mohs Hardness (9.0-9.5) | Extended component life, reduced wear, lower maintenance costs | Abrasives, Mining, Metal Fabrication |

| High-Temperature Strength | Retains strength >1400 ∘C | Reliable performance in furnaces, kilns, engines | Refractories, Metallurgy, Aerospace, Energy |

| Thermal Conductivity | High κ (e.g., >100 W/mK) | Efficient heat dissipation, improved thermal shock resistance | Heat Exchangers, Semiconductor Equipment, Power Electronics |

| Chemical Inertness | Resists acids & alkalis | Durability in corrosive environments, suitable for chemical processing | Chemical, Petrochemical, Pharmaceutical |

| Low Thermal Expansion | Low CTE | Dimensional stability, resistance to thermal shock | Precision Optics, Kiln Furniture, Foundry |

| Controllable Purity | Up to 99.9%+ SiC | Consistent performance in sensitive applications, fewer defects in end-products | Semiconductor, Advanced Ceramics, Electronics |

By focusing on these advantages, Sicarb Tech delivers silicon carbide granules that empower industries to achieve new levels of performance and efficiency. Our deep understanding of material science, backed by the Chinese Academy of Sciences, ensures that our clients receive SiC granules tailored to unlock these benefits for their specific industrial applications.

Types and Grades of Silicon Carbide Granules

Silicon carbide granules are not a monolithic product category. They are differentiated by several factors, including the manufacturing process, purity level, color, crystal structure, and, most critically for many applications, particle size distribution. Understanding these distinctions is essential for technical procurement professionals and engineers to select the optimal SiC grit or powder for their needs. The two primary types of SiC based on their raw material production method and resulting color are Black SiC and Green SiC.

Black Silicon Carbide Granules:

- Production: Produced from high-purity silica sand and petroleum coke in an electric resistance furnace at temperatures exceeding 2400 ∘C.

- Purity: Typically contains at least 98.5% SiC, though grades with 99% or higher are available. It is slightly less pure but tougher than green SiC.

- Properties: Characterized by its high hardness, good toughness, and excellent abrasive capabilities. It’s generally more cost-effective than green SiC.

- Applications: Widely used for grinding non-ferrous metals, cast iron, brass, aluminum, stone, leather, and rubber. Also used in refractories, metallurgical additives (deoxidizer), ceramic components, and lapping applications. Abrasive grade SiC for general purposes often falls into this category.

Green Silicon Carbide Granules:

- Production: Made similarly to black SiC but with higher purity raw materials (silica sand and petroleum coke) and often with the addition of salt to facilitate the removal of impurities during the process.

- Purity: Higher purity than black SiC, typically exceeding 99% SiC, with some grades reaching 99.5% or even higher.

- Properties: Harder and more friable (breaks down to create new sharp edges) than black SiC. It also possesses slightly better electrical and thermal conductivity due to its higher purity.

- Applications: Preferred for grinding hard and brittle materials such as cemented carbides, optical glass, ceramics, and titanium alloys. Used in precision grinding, wire sawing of silicon wafers, high-performance refractories, fine ceramics, and some electrical applications. Semiconductor grade SiC powder often requires the purity levels found in green SiC.

Beyond these two primary color-based classifications, SiC granules are further categorized by grade based on their intended application and specific properties:

- Abrasive Grade SiC: This is a broad category encompassing both black and green SiC granules specifically sized and processed for abrasive applications. Key characteristics include hardness, particle shape (blocky vs. sharp), and particle size distribution (PSD). Standards like FEPA (Federation of European Producers of Abrasives) for bonded abrasives (F grits) and coated abrasives (P grits), or ANSI/JIS for grit sizing are commonly used. Custom SiC materials may involve tailored PSDs for specialized abrasive tasks.

- Refractory Grade SiC: These granules are selected for their high-temperature stability, thermal shock resistance, and chemical inertness. Purity requirements might be slightly less stringent than for abrasive or ceramic grades, but consistency and thermal properties are paramount. Both black and green SiC can be used, often in coarser grit sizes. They are used in monolithic refractories, bricks, and kiln furniture. Industrial buyers in steel, cement, and glass industries are key consumers.

- Metallurgical Grade SiC: Typically black SiC with a SiC content of around 88-90% (though higher purities are also used). It’s valued for its silicon and carbon content, as well as its deoxidizing capabilities in iron and steel production. Particle size is an important consideration for reaction kinetics in the melt.

- Technical or Ceramic Grade SiC Powder/Granules: These are high-purity SiC materials (often green SiC, but also highly purified black SiC) used as the raw material for producing sintered silicon carbide (SSiC), reaction-bonded silicon carbide (RBSC/SiSiC), or other advanced SiC ceramic components. Extremely fine powders (micron or sub-micron) are often required, necessitating specialized milling of granules. Purity, PSD, and surface chemistry are critical parameters. Sicarb Tech excels in providing these high-specification granules and powders for technical ceramics manufacturing.

The table below highlights key differences between common SiC granule types:

| Feature | Black Silicon Carbide | Green Silicon Carbide | Metallurgical Grade SiC |

|---|---|---|---|

| Typical Purity | 98.5% – 99%+ SiC | >99% – 99.5%+ SiC | 88% – 90%+ SiC (can be higher) |

| Relative Hardness | Very Hard | Harder & More Friable than Black SiC | Hard |

| Typical Color | Black | Green | Black / Greyish-Black |

| Primary Uses | General abrasives, refractories, metallurgy | Precision abrasives, fine ceramics, wire sawing | Steel deoxidation, iron additive |

| Key Benefit | Cost-effective toughness | Highest purity, extreme hardness for fine work | Economic source of Si & C for foundries |

| Common Forms | Coarse to fine SiC grit, powders | Fine SiC grit, micro powders | Granules, briquettes |

At Sicarb Tech, we leverage our location in Weifang, the hub of China’s SiC production, and our deep technological partnership with the Chinese Academy of Sciences. This allows us to offer a comprehensive portfolio of both black and green silicon carbide granules across various grades and precisely controlled particle size distributions. Our expertise ensures that OEMs, distributors, and wholesale buyers can source the exact SiC material that meets their stringent application requirements, backed by reliable quality and supply assurance. We understand the importance of particle size distribution and purity for industrial procurement and are equipped to provide detailed material specifications and support for your custom SiC needs.

Critical Quality Considerations for Silicon Carbide Granules

For industries relying on the high-performance characteristics of silicon carbide, the quality of the initial SiC granules is a non-negotiable aspect. Sub-par or inconsistent granules can lead to product defects, premature failures, process inefficiencies, and ultimately, increased costs. Therefore, technical buyers and engineers must pay close attention to several critical quality parameters when sourcing silicon carbide grit or powders. These considerations are paramount for applications in advanced ceramics, semiconductor processing equipment, and precision abrasives.

Particle Size Distribution (PSD): This is perhaps one of the most critical factors. PSD refers to the range and proportion of different particle sizes within a batch of granules.

- Importance: Affects packing density (for refractories and ceramics), surface finish (for abrasives), reaction rates (for metallurgical SiC), and flowability. A narrow PSD is often desired for consistency.

- Specification: Typically defined by standard sieves (e.g., FEPA, ANSI, JIS, ISO) or laser diffraction analysis for finer powders. Buyers should specify D10, D50 (median particle size), and D90 values, or request specific sieve cuts.

- Challenges: Inconsistent PSD can lead to variations in product performance, such as uneven wear in abrasives or variable porosity in ceramics.

- Sicarb Tech Approach: We employ advanced sizing and classification techniques to ensure tight PSD control according to customer specifications or industry standards, providing consistent industrial raw materials.

Purity (SiC Content and Impurities): The percentage of actual silicon carbide and the levels of impurities significantly impact the material’s properties.

- Importance: Affects thermal conductivity, electrical resistivity, chemical resistance, and high-temperature strength. Impurities like free silicon, free carbon, iron oxide (Fe2O3), aluminum oxide (Al2O3), and calcium oxide (CaO) can be detrimental.

- Specification: Minimum SiC content (e.g., 98.5%, 99%, 99.5%+). Maximum allowable levels for specific impurities should be defined, especially for sensitive applications like technical ceramics manufacturing or electronics.

- Challenges: High impurity levels can lower melting points, reduce corrosion resistance, or cause unwanted reactions. For instance, iron can act as a catalyst for oxidation.

- Sicarb Tech Approach: We source high-quality raw materials and utilize optimized furnace processes. Our access to Chinese Academy of Sciences’s analytical capabilities allows for rigorous testing and certification of purity, ensuring our SiC powder meets the demanding material specifications of our clients.

Particle Morphology (Shape): The shape of individual granules can influence their behavior in various applications.

- Importance:

- Blocky/Equiaxed: Often preferred for refractories and some ceramic applications due to better packing and strength.

- Sharp/Angular: Desirable for abrasives as it provides more cutting edges.

- Friability: The tendency of particles to break down and expose new sharp edges (important for green SiC in precision grinding).

- Specification: While harder to quantify than PSD or purity, shape can be assessed through microscopy. Terms like “blocky,” “angular,” or “sharp-edged” are used. Friability can also be a specified parameter.

- Challenges: Incorrect particle shape can reduce cutting efficiency in abrasives or lead to lower density in pressed ceramic parts.

- Sicarb Tech Approach: Our manufacturing processes and crushing/milling techniques are designed to produce granules with morphologies suitable for their intended applications. We can discuss specific shape requirements for custom SiC materials.

Consistency (Lot-to-Lot Variation): Ensuring that each batch of SiC granules meets the same specifications is crucial for maintaining consistent end-product quality and manufacturing processes.

- Importance: Predictable performance, stable process parameters, and reduced need for recalibration or adjustments in manufacturing.

- Specification: Tolerance limits for key parameters like PSD, purity, and density should be agreed upon.

- Challenges: Variations can disrupt automated processes, lead to higher rejection rates, and damage a supplier’s reputation.

- Sicarb Tech Approach: We implement stringent quality control measures at every stage, from raw material inspection to final product testing. Our commitment to Chinese Academy of Sciences standards and continuous improvement helps us deliver exceptional lot-to-lot consistency, vital for industrial procurement professionals who demand reliability.

Other Important Parameters:

- Bulk Density/Tap Density: Important for shipping, storage, and for calculating die fill in ceramic pressing.

- Specific Surface Area (SSA): Particularly relevant for fine powders used in sintering, as it influences reactivity and sinterability.

- Crystal Structure: Alpha-SiC (hexagonal or rhombohedral) is the most common and stable form. Beta-SiC (cubic) can also be produced but typically transforms to alpha-SiC at high temperatures. The specific polytype (e.g., 6H, 4H) can influence electronic properties but is more critical for single-crystal SiC than for most granule applications.

A summary of quality checkpoints:

| Quality Parameter | Why It’s Critical | How It’s Measured/Specified | Potential Issues if Uncontrolled |

|---|---|---|---|

| Particle Size Distribution (PSD) | Affects packing, surface finish, reactivity | Sieve analysis, laser diffraction (D10, D50, D90) | Inconsistent product, processing difficulties |

| Chemical Purity (%SiC) | Determines thermal, electrical, chemical properties | Chemical analysis (e.g., XRF, ICP-MS) | Reduced performance, unwanted reactions, lower strength |

| Impurity Levels | Can degrade properties, cause defects | Specific limits for Fe, Al, Ca, free Si, free C | Corrosion, lower melting point, discoloration |

| Particle Morphology | Impacts cutting (abrasives), packing (ceramics) | Microscopy, friability tests | Poor abrasive action, low green density |

| Lot-to-Lot Consistency | Ensures predictable manufacturing and product quality | Statistical Process Control (SPC), Certificates of Analysis (CoA) | Process disruptions, variable product quality |

By partnering with a supplier like Sicarb Tech, which operates within Weifang’s renowned SiC industrial cluster and benefits from the advanced technological framework of the Chinese Academy of Sciences, customers gain access to silicon carbide granules that meet the highest quality benchmarks. Our rigorous quality control systems and deep material expertise ensure that you receive a product that performs reliably and consistently in your demanding applications.

Processing and Handling of Silicon Carbide Granules

Once high-quality silicon carbide granules have been procured, their effective utilization depends on proper processing and handling within the manufacturing environment. While SiC is a robust material, adhering to best practices for storage, handling, and incorporation into processes is crucial for maintaining its integrity, ensuring worker safety, and achieving optimal results in final products such as technical ceramics, abrasive tools, or refractory components.

Storage: Proper storage is fundamental to preserving the quality of SiC grit and powders.

- Environment: Store in a cool, dry, and well-ventilated area. Avoid exposure to excessive moisture, which can lead to agglomeration of fine powders or affect certain surface treatments if present.

- Containers: Keep SiC granules in their original, tightly sealed containers (e.g., woven bags, super sacks, drums) until ready for use. This prevents contamination from dust, dirt, or other airborne particles.

- Segregation: If different grades or particle sizes of SiC are stocked, ensure clear labeling and segregated storage to prevent accidental mixing, which could be detrimental to applications with precise material specifications.

- Shelf Life: While SiC itself is extremely stable and doesn’t degrade chemically under normal storage conditions, prolonged storage of very fine, high-surface-area powders might lead to some adsorption of atmospheric gases or moisture, potentially affecting dispersibility. It’s good practice to follow a first-in, first-out (FIFO) inventory system.

Handling and Worker Safety: While silicon carbide is generally considered non-toxic, the fine particulate nature of some SiC powders and the hardness of all SiC granules necessitate appropriate safety precautions.

- Dust Control: Fine SiC particles can become airborne during handling (e.g., pouring, mixing, conveying). Adequate ventilation, dust extraction systems (e.g., local exhaust ventilation – LEV), and enclosed processing equipment should be used to minimize airborne dust concentrations.

- Personal Protective Equipment (PPE):

- Respiratory Protection: NIOSH/MSHA-approved respirators (e.g., N95 dust masks for nuisance dust, or higher-rated respirators for significant exposures) should be worn when handling SiC powders or when dust levels may exceed occupational exposure limits.

- Eye Protection: Safety glasses or goggles are essential to protect eyes from abrasive particles.

- Hand Protection: Gloves can prevent skin abrasion and irritation, especially when handling coarser grits.

- Protective Clothing: Coveralls or lab coats can minimize skin contact and prevent contamination of street clothes.

- Material Safety Data Sheets (MSDS/SDS): Always consult the supplier’s SDS for specific safety information, handling recommendations, and emergency procedures. Sicarb Tech provides comprehensive SDS for all its silicon carbide granules.

- Spillage: Clean up spills promptly using methods that avoid generating dust (e.g., HEPA vacuuming or wet sweeping). Dry sweeping of fine powders should be avoided.

Incorporation into Manufacturing Processes: The method of incorporating SiC granules into a product or process depends heavily on the application.

- Mixing and Blending: For ceramic bodies, refractories, or composites, uniform dispersion of SiC granules within the matrix is crucial. Appropriate mixing equipment (e.g., V-blenders, ball mills, attritors for fine powders) and optimized mixing parameters (time, speed, media) are necessary. For dry pressing, flowability of the granule mix is key.

- Dispersion: For liquid systems (e.g., slurries for lapping, coatings), achieving stable dispersion may require dispersants and controlled pH. Surface characteristics of the SiC granules can influence this.

- Feeding and Conveying: Automated systems for feeding granules into furnaces, presses, or mixers should be designed to handle abrasive materials and prevent segregation of different particle sizes. Wear-resistant components in handling equipment are often necessary.

- Compaction (for Ceramics/Refractories): When forming green bodies, understanding the compaction behavior of the specific SiC granule batch (influenced by PSD and morphology) is important for achieving desired green density and minimizing defects.

- Sintering/Firing: For applications involving high-temperature processing, the purity and PSD of the SiC granules will directly affect the sintering kinetics, final density, and microstructure of the fired component.

Key Engineering Tips for Handling SiC Granules:

- Minimize Dust Generation: Use enclosed systems, local exhaust ventilation, and handle materials gently.

- Prevent Contamination: Dedicate tools and equipment where possible, and maintain good housekeeping.

- Ensure Homogeneity: Proper mixing is key for consistent product quality, especially when dealing with custom SiC materials blended with other powders.

- Account for Abrasiveness: Equipment in contact with SiC granules (e.g., mixers, feeders, dies) may experience wear. Select wear-resistant materials or plan for regular maintenance/replacement.

- Consult with Supplier: For specific processing challenges or optimization, a knowledgeable supplier like Sicarb Tech can provide valuable technical support based on their deep understanding of SiC material science and industrial processing.

By implementing these best practices, manufacturers can ensure the safe and efficient use of silicon carbide granules, maximizing their benefits and contributing to the production of high-quality, reliable end-products. The inherent quality of SiC granules from a trusted source like Sicarb Tech, combined with careful downstream processing, paves the way for innovation in industrial manufacturing.

Sourcing Silicon Carbide Granules: Choosing the Right Supplier – Why Sicarb Tech is Your Trusted Partner

Selecting the right supplier for silicon carbide granules is a critical decision that directly impacts the quality of your end-products, the efficiency of your manufacturing processes, and your overall competitiveness. In a market with numerous providers, identifying a partner who not only supplies materials but also offers technical expertise, reliability, and a commitment to quality is paramount. This is where Sicarb Tech distinguishes itself, particularly for wholesale buyers, technical procurement professionals, OEMs, and distributors seeking high-performance SiC grit, SiC powder, and custom SiC solutions.

Key Criteria for Evaluating a Silicon Carbide Granule Supplier:

- Material Quality and Consistency:

- What to look for: Stringent quality control processes, adherence to international standards (e.g., ISO, FEPA, ANSI, JIS), detailed Certificates of Analysis (CoA) with each shipment, narrow particle size distributions, high purity levels, and low lot-to-lot variability.

- Sicarb Tech Advantage: Our operations are rooted in Weifang City, the epicenter of China’s SiC production, which accounts for over 80% of the nation’s output. Since 2015, we’ve been instrumental in advancing local SiC production technology. Backed by the formidable scientific and technological capabilities and talent pool of the Chinese Academy of Sciences through the Chinese Academy of Sciences (Weifang) Innovation Park and the National Technology Transfer Center, we ensure a more reliable quality and supply assurance within China. Our quality control for silicon carbide granules is rigorous, benefiting from advanced analytical techniques and a deep understanding of material science.

- Technical Expertise and Support:

- What to look for: A supplier with in-depth knowledge of SiC materials, their properties, and their behavior in various applications. They should be able to provide technical guidance, assist with material selection, and offer solutions for processing challenges.

- Sicarb Tech Advantage: We boast a domestic top-tier professional team specializing in the customized production of silicon carbide products. Our expertise spans material science, process engineering, design, measurement, and evaluation technologies. This integrated approach, from raw materials to finished products, allows us to provide unparalleled technical support and assist clients in optimizing their use of SiC powder and granules. We’ve supported over 10 local enterprises with our technologies, demonstrating our capability to meet diverse customization needs.

- Range of Products and Customization Capabilities:

- What to look for: A broad portfolio of SiC grades (e.g., black, green, metallurgical, refractory, abrasive), particle sizes (from coarse grits to fine micro-powders), and the ability to provide custom SiC materials tailored to specific requirements (e.g., unique PSD, specific purity levels, surface treatments).

- Sicarb Tech Advantage: We offer a wide array of silicon carbide granules and possess the integrated process knowledge from materials to products. This enables us to meet diverse customization needs, providing higher-quality, cost-competitive customized silicon carbide components and granules in China.

- Reliability of Supply and Lead Times:

- What to look for: Consistent availability of materials, transparent communication regarding lead times, and robust supply chain management to prevent disruptions.

- Sicarb Tech Advantage: Our strategic location in Weifang’s SiC hub and our close relationships with numerous production enterprises (many of whom benefit from our technology) provide a strong and reliable supply base. We are committed to meeting agreed-upon delivery schedules for our industrial raw materials.

- Competitive Pricing and Value:

- What to look for: While cost is a factor, the focus should be on overall value, considering material quality, consistency, technical support, and supplier reliability. The cheapest option may not always be the most cost-effective in the long run if it leads to production issues or product failures.

- Sicarb Tech Advantage: Our technological advancements and efficient processes allow us to offer cost-competitive silicon carbide granules without compromising on quality. We aim to provide the best value proposition for industrial procurement professionals seeking high-performance materials.

- Commitment to Innovation and Development:

- What to look for: A supplier invested in R&D, staying abreast of new SiC applications and processing technologies, and capable of collaborating on developing new material solutions.

- Sicarb Tech Advantage: As part of the Chinese Academy of Sciences (Weifang) Innovation Park, a national-level innovation and entrepreneurship service platform, we are at the forefront of technology transfer and commercialization. This environment fosters continuous innovation, ensuring our clients benefit from the latest advancements in advanced ceramics and SiC technology.

Why Sicarb Tech is Your Ideal Partner for SiC Granules:

- Deep Industry Roots: We are not just suppliers; we are enablers of the SiC industry in Weifang, having played a key role in its technological advancement.

- Chinese Academy of Sciences Backing: The scientific and technological might of the Chinese Academy of Sciences underpins our quality, reliability, and innovation.

- Comprehensive Solutions: From standard SiC grit to highly customized powders and even technology transfer for establishing your own SiC production plant (turnkey projects), we offer a full spectrum of services.

- Focus on B2B Needs: We understand the requirements of OEMs, distributors, and wholesale buyers for consistent quality, reliable supply, and expert support.

The table below outlines how Sicarb Tech addresses key supplier selection criteria:

| Supplier Selection Criterion | Sicarb Tech Strength | Benefit to B2B Buyers |

|---|---|---|

| Material Quality | Chinese Academy of Sciences-backed technology, stringent QC, Weifang hub advantage | Reliable, high-performance SiC granules, consistent product output. |

| Technical Expertise | Top-tier professional team, integrated process knowledge (materials to products) | Expert advice, problem-solving, optimized material selection for technical ceramics. |

| Product Range | Wide array of SiC types, grades, sizes; strong custom SiC material capabilities | One-stop solution for diverse SiC needs, materials tailored to specific industrial applications. |

| Supply Reliability | Strategic location, strong local partnerships, efficient supply chain | Reduced risk of supply disruption, dependable delivery schedules for industrial raw materials. |

| Cost-Effectiveness | Advanced technology, process efficiency | Competitive pricing without compromising quality, enhanced ROI. |

| Innovation | Part of Chinese Academy of Sciences Innovation Park, focus on technology transfer | Access to cutting-edge SiC solutions and potential for collaborative development. |

| Technology Transfer | Full turnkey project services for establishing SiC plants | Unique opportunity for clients to build their own specialized SiC production capabilities. |

Choosing Sicarb Tech as your supplier for silicon carbide granules means partnering with an organization that is deeply embedded in the SiC industry’s technological core, committed to quality, and equipped to support your most demanding applications. We are more than a material provider; we are your strategic partner in harnessing the power of silicon carbide.

Frequently Asked Questions (FAQ) about Silicon Carbide Granules

Navigating the specifics of silicon carbide granules can often lead to questions from engineers, procurement specialists, and technical buyers. Here are some common queries with concise, practical answers to help clarify key aspects of this versatile material.

What is the primary difference between black silicon carbide granules and green silicon carbide granules, and how do I choose between them?

The primary differences lie in their purity, hardness, friability, and typical applications.

- Black Silicon Carbide (Black SiC): Typically contains 98.5% to 99%+ SiC. It is generally tougher and more economical than green SiC. It excels in applications like grinding softer metals (e.g., cast iron, brass, aluminum), non-metals (stone, leather, rubber), and is widely used in refractories and as a metallurgical additive. If you need a robust, cost-effective abrasive for general-purpose grinding or a durable material for high-temperature structural components where extreme purity isn’t the foremost concern, black SiC is often a suitable choice.

- Green Silicon Carbide (Green SiC): Has a higher purity, usually >99% to 99.5%+ SiC. It is harder but also more friable than black SiC, meaning it breaks down to expose new, sharp cutting edges during use. This makes it ideal for precision grinding of very hard and brittle materials such as cemented carbides, optical glass, technical ceramics, and titanium alloys. It’s also preferred for wire sawing silicon wafers and in applications requiring high electrical purity or specific thermal properties, such as fine ceramics or some electronic components.

How does the particle size (grit size) of silicon carbide granules affect their application?

Particle size, or grit size, is a crucial parameter that dictates how SiC granules will perform:

- Coarser Grits (e.g., FEPA F16-F36): These larger particles are used for heavy stock removal, aggressive grinding, and in applications where a rougher surface finish is acceptable or desired, such as snagging castings or in coarse abrasive blasting. In refractories, coarser grits contribute to the structural integrity and porosity of the material.

- Medium Grits (e.g., FEPA F40-F100): Offer a balance between material removal rate and surface finish. Used for general-purpose grinding, shaping, and in some bonded abrasive tools.

- Finer Grits (e.g., FEPA F120-F220 and finer, including microgrits P240-P2500 or JIS #240-#8000): Used for finishing, lapping, polishing, and applications requiring smooth surfaces and high precision. Finer SiC powders (micron and sub-micron sizes) are essential for manufacturing sintered SiC components, where small particle sizes promote better packing and densification during sintering. The choice of grit size directly impacts cutting speed, surface roughness, and the integrity of the material being processed. Always match the grit size to the specific requirements of your application and the material you are working with. Sicarb Tech can provide silicon carbide granules across a full spectrum of grit sizes and offer guidance on selecting the appropriate particle size distribution.

Can Sicarb Tech provide custom silicon carbide granules if our application has unique requirements?

Yes, absolutely. Sicarb Tech specializes in providing custom SiC solutions, including tailored silicon carbide granules and powders. We understand that standard off-the-shelf products may not always meet the specific demands of advanced industrial applications. Leveraging our deep technical expertise rooted in the Chinese Academy of Sciences and our flexible manufacturing partnerships within the Weifang SiC hub, we can work with you to develop SiC granules with:

- Specific Particle Size Distributions (PSD): We can provide custom sieve cuts or engineered PSDs to optimize packing density, flowability, or surface finish.

- Controlled Purity Levels: If your application requires higher purity than standard grades or specific limits on certain trace elements, we can often accommodate these needs.

- Modified Particle Morphology: While more complex, discussions around particle shape characteristics can be had for certain applications.

- Special Blends: We can potentially create blends of different SiC types or sizes if required.

Our team of experts in material science, process engineering, and design is equipped to understand your unique challenges and collaborate on developing a custom SiC material that delivers optimal performance. We pride ourselves on our ability to go beyond standard offerings and provide true value-added solutions to our B2B clients, including OEMs, technical procurement professionals, and distributors in need of specialized advanced ceramics raw materials.

Conclusion: The Enduring Value of Quality Silicon Carbide Granules

Silicon carbide granules, in their various forms and grades, are undeniably a cornerstone material in the landscape of modern industry. From shaping the hardest alloys as abrasives to enduring extreme temperatures in refractories, and forming the basis of sophisticated technical ceramics used in semiconductor and aerospace sectors, their impact is profound and far-reaching. The exceptional hardness, high-temperature resilience, superior thermal conductivity, and chemical inertness of SiC granules make them an indispensable industrial raw material for applications that demand peak performance and unwavering reliability.

As we’ve explored, the journey to harnessing these benefits begins with selecting the right type, grade, and, most importantly, quality of SiC granules. Factors such as particle size distribution, purity, morphology, and consistency are not mere details but critical determinants of end-product success. For engineers, procurement managers, and OEMs, partnering with a knowledgeable and reliable supplier is therefore not just a transactional necessity but a strategic imperative.

Sicarb Tech stands ready to be that strategic partner. Situated in Weifang City, the vibrant hub of China’s silicon carbide industry, and empowered by the robust scientific and technological capabilities of the Chinese Academy of Sciences , we offer more than just SiC grit and SiC powder. We provide access to a legacy of innovation, a commitment to uncompromising quality, and the expertise to deliver custom SiC solutions tailored to your unique industrial challenges. Our deep understanding of the integrated process, from material science to final product application, ensures that you receive silicon carbide granules that are not only cost-competitive but also of the highest caliber, enabling you to push the boundaries of performance in your respective fields.

Whether your focus is on enhancing manufacturing efficiency, improving product durability, or pioneering new technologies, the quality of your foundational materials is key. Choose Sicarb Tech for your silicon carbide granule needs, and invest in a partnership that delivers reliability, expertise, and the advanced materials necessary to thrive in today’s demanding industrial environments. We are also uniquely positioned to assist you in establishing your own specialized SiC production facility through our comprehensive technology transfer and turnkey project services, further underscoring our commitment to the global advancement of silicon carbide applications.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.