Silicon Carbide Foam: Revolutionizing High-Performance Industrial Applications

Share

In the relentless pursuit of materials that can withstand extreme conditions while delivering unparalleled performance, custom silicon carbide (SiC) foam has emerged as a transformative solution across a multitude of industries. From the demanding environments of aerospace and semiconductor manufacturing to the high-temperature processes in energy and industrial sectors, SiC foam offers a unique combination of properties that traditional materials simply cannot match. This open-cell porous ceramic material, with its interconnected network of SiC struts, is not just a component; it’s an enabler of innovation, pushing the boundaries of what’s possible in high-performance applications. For engineers, procurement managers, and technical buyers seeking cutting-edge technical ceramics, understanding the capabilities of custom SiC foam is paramount.

The importance of silicon carbide foam lies in its exceptional thermal conductivity, high-temperature stability, superior mechanical strength-to-weight ratio, excellent chemical inertness, and controllable porosity. These characteristics make it an indispensable material for applications requiring efficient heat dissipation, filtration of aggressive media, lightweight structural components, or catalyst supports in harsh chemical environments. As industries strive for greater efficiency, reduced energy consumption, and enhanced process reliability, the demand for custom SiC foam components continues to grow, making it a cornerstone of advanced material science and engineering.

Diverse Applications of Custom Silicon Carbide Foam in Demanding Industries

The versatility of custom silicon carbide foam allows it to be a critical component in a wide array of industrial applications. Its unique three-dimensional porous structure and inherent SiC properties make it suitable for environments where other materials falter. Procurement professionals and OEMs are increasingly specifying industrial SiC foam applications due to its proven performance and long-term value.

Here are some key sectors and applications where SiC foam is making a significant impact:

- Molten Metal Filtration: One of the most prominent uses of reticulated SiC foam is in foundries for filtering impurities from molten ferrous and non-ferrous alloys, including cast iron, steel, aluminum, and copper. The foam’s ability to withstand extreme temperatures (up to 1650∘C) and thermal shock, coupled with its chemical resistance to molten metals and slags, ensures cleaner, higher-quality castings with reduced defects. This leads to improved mechanical properties of the final product and reduced machining costs. High-temperature SiC foam filters are essential for producing premium castings for automotive, aerospace, and heavy machinery industries.

- Diesel Particulate Filters (DPFs) and Catalyst Supports: In the automotive and emissions control sectors, porous silicon carbide is a material of choice for Diesel Particulate Filters. While often used in dense forms, SiC foam structures offer a high surface area and excellent thermal shock resistance, making them candidates for advanced DPF designs and as catalyst supports. The open-pore structure allows for efficient trapping of particulate matter, and its high thermal conductivity aids in the regeneration process (burning off trapped soot). As catalyst supports, SiC foam provides a high surface area for catalytic reactions, promoting better conversion rates and durability in exhaust gas treatment systems and industrial chemical processing. SiC foam catalyst support systems benefit from the material’s chemical inertness and thermal stability.

- Heat Exchangers and Burners: The high thermal conductivity and excellent high-temperature resistance of SiC foam make it ideal for compact, high-efficiency heat exchangers and porous burners. In heat exchangers, the large surface area-to-volume ratio enhances heat transfer rates. For burners, SiC foam allows for volumetric combustion, leading to more stable flames, lower NOx emissions, and improved energy efficiency. These are crucial for industrial furnaces, power generation, and chemical reactors.

- Aerospace and Defense: Lightweight yet robust, SiC foam components are finding applications in aerospace and defense. Their ability to withstand extreme temperatures and thermal cycling makes them suitable for thermal protection systems, lightweight mirrors, and structural components in high-speed vehicles or satellite applications. Aerospace SiC foam components offer a significant weight reduction compared to traditional materials without compromising performance.

- Semiconductor Processing: In semiconductor manufacturing, components made from high-purity SiC are valued for their thermal stability, chemical resistance to process gases, and dimensional stability at high temperatures. While solid SiC is common, semiconductor SiC foam parts could be explored for applications like gas distribution plates or wafer handling components where controlled porosity and high surface area are beneficial.

- Chemical Processing: The chemical inertness of SiC foam makes it suitable for handling corrosive fluids and gases. It can be used for filters, diffusers, and packing material in chemical reactors and distillation columns, especially in high-temperature or aggressive chemical environments.

- Acoustic Dampening: The open-cell structure of SiC foam also gives it sound absorption properties, particularly at high frequencies and elevated temperatures where conventional acoustic materials might degrade.

The broad applicability of SiC foam underscores its importance as a high-performance technical ceramic. Companies looking to source custom SiC foam are often seeking solutions for challenging operational conditions where material failure is not an option.

The Unmatched Advantages of Custom Silicon Carbide Foam

Choosing custom silicon carbide foam for demanding industrial applications offers a plethora of advantages that stem from both the inherent properties of silicon carbide and the unique open-cell, reticulated structure of the foam. For technical buyers and engineers, these benefits translate into improved process efficiency, enhanced product quality, longer service life, and often, reduced operational costs over time. The ability to tailor the foam’s properties through customization further amplifies its value proposition.

Key advantages include:

- Exceptional Thermal Properties:

- High-Temperature Stability: SiC foam can operate at extremely high temperatures (often exceeding 1500∘C in air and even higher in inert atmospheres) without significant degradation, melting, or loss of mechanical integrity. This is crucial for applications like molten metal filtration, furnace components, and high-temperature catalyst supports.

- Excellent Thermal Shock Resistance: The interconnected porous structure allows SiC foam to withstand rapid temperature changes without cracking or spalling. This is a significant advantage over many dense ceramics.

- High Thermal Conductivity: Silicon carbide itself has high thermal conductivity. In foam structures, this property facilitates rapid and uniform heat distribution or dissipation, beneficial for heat exchangers, thermal management systems, and applications requiring quick temperature responses.

- Superior Mechanical Properties:

- High Strength-to-Weight Ratio: Despite its porous nature, SiC foam exhibits excellent mechanical strength, especially in compression. Its low density combined with good strength makes it a lightweight SiC structure, ideal for aerospace and applications where weight reduction is critical.

- Wear and Abrasion Resistance: Silicon carbide is an extremely hard material (Mohs hardness > 9), making SiC foam highly resistant to wear and abrasion, which is beneficial in applications involving abrasive particles or high-velocity flows.

- Outstanding Chemical Properties:

- Chemical Inertness: SiC foam is highly resistant to a wide range of corrosive chemicals, including acids, alkalis, and molten salts, even at elevated temperatures. This makes it suitable for chemical processing equipment, filters for aggressive media, and components exposed to harsh industrial environments.

- Oxidation Resistance: While SiC can oxidize at very high temperatures, it forms a protective silica (SiO2) layer that slows down further oxidation, allowing for extended service life in oxidizing atmospheres.

- Unique Structural Advantages:

- High Surface Area: The open-cell structure provides an exceptionally high surface area per unit volume. This is highly advantageous for applications such as catalyst supports (enhancing reaction efficiency), filters (improving capture efficiency), and heat exchangers (increasing heat transfer rates).

- Controlled Porosity and Permeability: The manufacturing process allows for control over pore size (typically measured in Pores Per Inch or PPI), porosity (void volume fraction), and cell structure. This enables the tailoring of permeability and filtration efficiency to specific application requirements. Custom SiC foam components can be designed with specific flow characteristics.

- Low Pressure Drop: For filtration and flow-through applications, the open and interconnected porosity results in a relatively low pressure drop compared to other filter media with similar efficiency, leading to energy savings.

- Customization Potential: Beyond standard grades, custom silicon carbide foam can be manufactured to specific shapes, sizes, and porosity levels. This allows engineers to optimize components for their unique applications, ensuring maximum performance and integration.

The table below summarizes some of these key advantages in relation to industrial needs:

| Feature | Advantage for Industrial Applications | Relevant Keywords |

|---|---|---|

| High-Temperature Stability | Enables use in furnaces, molten metal processing, exhaust systems without degradation. | High-temperature SiC foam filters, Industrial furnaces, Kiln furniture |

| Thermal Shock Resistance | Prevents failure during rapid heating/cooling cycles, increasing component lifetime. | Thermal cycling applications, Rapid prototyping |

| High Thermal Conductivity | Facilitates efficient heat transfer for heat exchangers, thermal management, and uniform heating. | SiC foam heat exchangers, Thermal management solutions |

| High Strength-to-Weight Ratio | Offers structural integrity with reduced mass, crucial for aerospace, automotive, and mobile equipment. | Lightweight SiC structures, Aerospace components, Automotive SiC parts |

| Wear & Abrasion Resistance | Provides durability in environments with abrasive particles or high-velocity flows, such as nozzles or filters for abrasive slurries. | Wear parts, Protective linings |

| Chemical Inertness | Ensures compatibility with corrosive substances, extending service life in chemical processing and harsh environments. | Chemical processing equipment, SiC foam catalyst support, Acid resistant SiC |

| High Surface Area | Increases efficiency in catalytic reactions, filtration, and heat exchange. | High surface area SiC foam, Catalyst carriers, Porous electrodes |

| Controlled Porosity | Allows for tailored flow rates, filtration efficiency, and pressure drop characteristics for specific applications. | Custom SiC foam components, Porous silicon carbide, Filter media |

By leveraging these advantages, industries can significantly improve their processes, develop innovative products, and achieve a competitive edge. Partnering with a knowledgeable supplier like Sicarb Tech can help unlock the full potential of custom SiC foam for your specific needs.

Understanding Silicon Carbide Foam: Grades, Properties, and Customization Potential

Silicon carbide foam is not a one-size-fits-all material. Its properties can be tailored through the selection of raw materials, manufacturing processes, and post-processing treatments. Understanding these variations is crucial for engineers and procurement specialists to select or specify the optimal porous silicon carbide for their application. Key characteristics such as porosity, permeability, thermal conductivity, and mechanical strength can vary significantly.

Common Forms and Grades:

While highly specialized grades exist, SiC foam is often characterized by its base material and pore density:

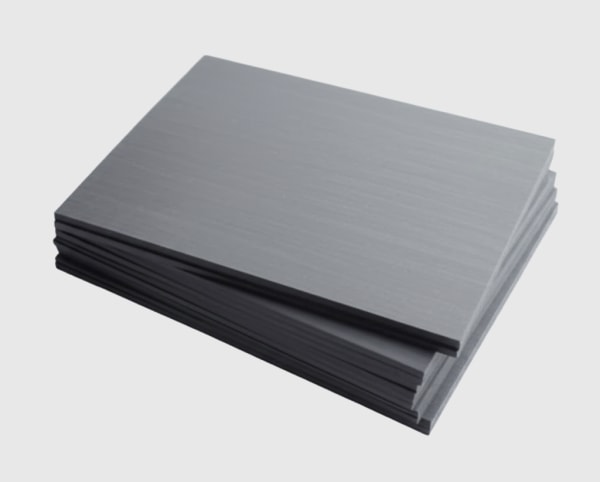

- Reaction-Bonded Silicon Carbide (RBSC or SiSiC) Foam: This type is often produced by infiltrating a carbon preform (typically a polyurethane foam replica coated with phenolic resin and pyrolyzed) with molten silicon. The silicon reacts with the carbon to form SiC, and some residual free silicon may remain in the structure (typically 10-15%). SiSiC foams generally offer good strength, excellent thermal conductivity, and wear resistance. They are widely used for molten metal filters and structural components.

- Sintered Silicon Carbide (SSiC) Foam: Sintered SiC foams are made from pure SiC powders with sintering aids, fired at very high temperatures (often >2000∘C). This process results in a product with very high SiC purity (typically >98-99%), leading to superior high-temperature performance, excellent chemical resistance, and better creep resistance compared to SiSiC. SSiC foams are preferred for the most demanding applications, such as advanced catalyst supports or filters for highly corrosive environments.

- Nitride-Bonded Silicon Carbide (NBSC) Foam: In this type, SiC grains are bonded by a silicon nitride (Si3N4) phase. NBSC foams can offer good thermal shock resistance and mechanical strength.

The choice between these types often depends on the specific requirements of the application, including operating temperature, chemical environment, and mechanical stress.

Key Properties and Parameters:

When specifying custom SiC foam components, several parameters are critical:

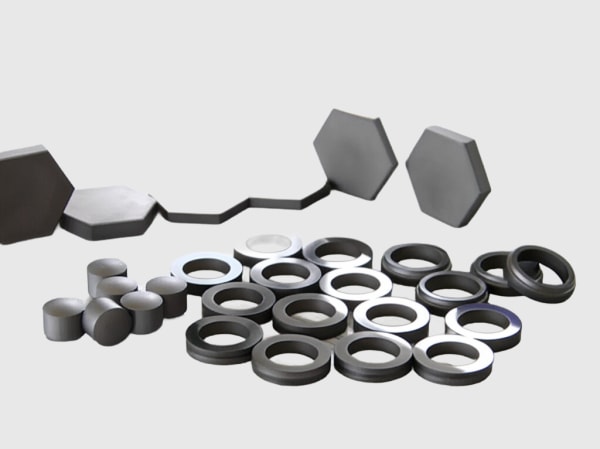

- Porosity (PPI – Pores Per Inch): This defines the coarseness or fineness of the foam structure. Common PPI values range from 10 PPI (coarse) to over 100 PPI (very fine). Higher PPI generally means smaller pores, higher surface area, and higher filtration efficiency but also increased pressure drop.

- Low PPI (10-30 PPI): Often used for molten metal filtration (e.g., aluminum, iron), applications requiring high permeability, or as flow straighteners.

- Medium PPI (45-65 PPI): Suitable for finer filtration, catalyst supports, or applications needing a balance between surface area and flow.

- High PPI (80-100+ PPI): Used for very fine particulate filtration, diesel particulate filters, or applications demanding maximum surface area.

- Relative Density / Void Volume Fraction: This indicates the percentage of open space within the foam structure. Typically, SiC foams have a high void volume, often ranging from 70% to over 90%. Higher void volume means lower density and potentially higher permeability.

- Permeability: This measures the ease with which fluids (liquids or gases) can flow through the foam. It’s influenced by pore size, interconnectivity, and overall porosity.

- Thermal Conductivity: While bulk SiC has high thermal conductivity (e.g., 100-200 W/mK), the effective thermal conductivity of SiC foam is lower due to the high porosity but still significantly better than many other porous ceramics or insulators. It’s influenced by the density of the foam and the conductivity of the base SiC material.

- Mechanical Strength: Typically characterized by compressive strength, flexural strength, and fracture toughness. Strength generally decreases with increasing porosity but is excellent for the given density.

- Maximum Use Temperature: Depends on the grade (SiSiC, SSiC) and atmosphere (oxidizing, reducing, inert). SSiC generally offers higher temperature capability.

- Chemical Resistance: SiC is inherently resistant to most acids, alkalis, and organic solvents. SSiC offers the broadest chemical resistance due to its purity.

The table below provides a general comparison, though specific values can vary significantly based on manufacturer and customization:

| Property | SiSiC Foam (Typical) | SSiC Foam (Typical) | Considerations for Customization |

|---|---|---|---|

| Max. Use Temperature | ~1350−1450∘C (with free Si) | ~1600−1700∘C (or higher) | Atmosphere (oxidizing, inert), purity requirements. |

| SiC Purity | ~85-90% SiC, residual Si | >98-99% SiC | Critical for applications sensitive to impurities (e.g., semiconductor, some catalysts). |

| Thermal Conductivity | Good to Excellent | Excellent | Higher density foam generally has higher thermal conductivity. |

| Mechanical Strength | Good | Very Good | Dependent on porosity and cell structure; can be optimized for specific load conditions. |

| Chemical Resistance | Very Good | Excellent | SSiC preferred for extremely corrosive environments. |

| Cost | Moderate | Higher | SSiC typically more expensive due to higher processing temperatures and purer raw materials. |

| Typical Porosity (PPI) | 10 – 80 PPI | 10 – 100+ PPI | Can be tailored to specific filtration efficiency or surface area needs. |

| Primary Manufacturing | Reaction Bonding | Sintering | Process influences final properties and cost. |

Customization Potential:

Beyond selecting a standard grade and PPI, true customization is where partners like Sicarb Tech excel. This includes:

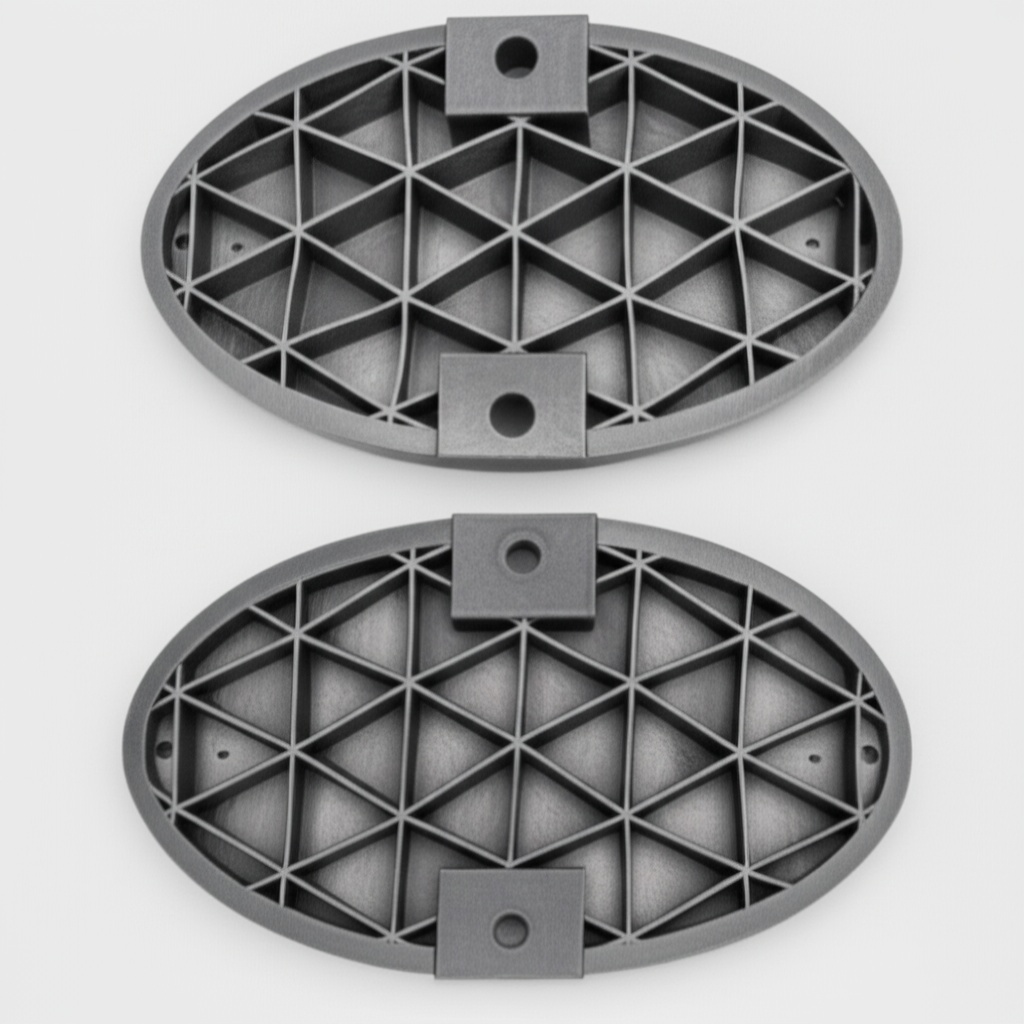

- Complex Geometries: Manufacturing SiC foam in specific shapes (blocks, discs, tubes, custom designs) to fit existing equipment or novel designs.

- Graded Porosity: Creating foams with varying pore sizes or densities within a single component for optimized performance in specific applications (e.g., multi-stage filtration).

- Surface Modifications: Applying coatings to enhance catalytic activity, improve biocompatibility, or modify surface energy.

- Hybrid Structures: Combining SiC foam with dense SiC or other materials to create components with tailored functionalities.

By leveraging these customization capabilities, engineers can move beyond off-the-shelf solutions and develop highly optimized custom SiC foam components that provide a distinct performance advantage. SicSino, with its deep expertise in silicon carbide technology and access to the Weifang manufacturing hub, is well-positioned to assist with such demanding customization projects.

Critical Design and Manufacturing Considerations for Optimal SiC Foam Performance

Developing effective custom silicon carbide foam components requires careful consideration of both the design phase and the intricacies of the manufacturing process. Engineers and designers must work closely with experienced SiC foam manufacturers to ensure the final product meets the demanding performance criteria of its intended application. Factors such as component geometry, porosity control, achievable tolerances, and potential post-processing needs are all interconnected and influence the functionality and longevity of the SiC foam part.

Design for Manufacturability (DfM):

- Geometry and Complexity: While SiC foam can be produced in various shapes, overly complex geometries with very thin walls, sharp internal corners, or large unsupported spans can be challenging and costly to manufacture reliably. Simpler, more robust designs are generally preferred. Discussing design feasibility early with the manufacturer is crucial.

- Wall Thickness: Minimum achievable wall thickness depends on the foam’s PPI and overall part size. Thicker walls generally provide greater strength but also increase material usage and weight.

- Draft Angles: For molded or cast preforms, draft angles may be necessary to facilitate demolding.

- Stress Concentration Points: Designs should aim to minimize stress concentration points, as ceramic foams, while strong, can be notch-sensitive. Rounded corners and gradual transitions in thickness are beneficial.

Porosity and Cell Size Control:

- Pores Per Inch (PPI) Selection: The choice of PPI is critical and application-dependent. For molten metal filtration SiC foam, a lower PPI (e.g., 10-30 PPI) allows for high flow rates and capture of larger inclusions, while finer filtration or catalyst support applications might require higher PPI (e.g., 45-80+ PPI) for increased surface area and capture of smaller particles.

- Porosity Distribution: Achieving uniform porosity throughout the component is essential for consistent performance. Non-uniformity can lead to preferential flow paths or localized stress points.

- Interconnectivity: The open-cell nature with interconnected pores is a defining feature. The degree of interconnectivity influences permeability and mechanical strength.

Achievable Tolerances, Surface Finish, and Dimensional Accuracy:

- Dimensional Tolerances: Porous silicon carbide foams inherently have a rougher surface texture than dense ceramics. As-fired tolerances are typically wider than for machined dense ceramics. Typical linear tolerances might be in the range of ±1−2% of the dimension, or a minimum of ±0.5mm to ±1mm, depending on the size and manufacturing route. Tighter tolerances often require post-machining.

- Surface Finish: The surface finish is naturally textured due to the open-pore structure. The “smoothness” is relative to the cell size (PPI). If a specific surface finish is required on certain faces (e.g., for sealing), this may necessitate machining or lapping.

- Flatness and Parallelism: For components like filter plates or substrates, flatness and parallelism are important. These can be controlled during manufacturing and, if necessary, improved by grinding.

Manufacturing Processes Overview:

The most common method for producing SiC foam involves the replication of an open-cell polymer foam (typically polyurethane) template:

- Polymer Foam Selection: A polymer foam with the desired PPI and cell structure is chosen as the template.

- Slurry Coating: The polymer foam is coated with a ceramic slurry containing SiC powder, binders, and other additives. The slurry composition is critical for the final properties of the SiC foam.

- Drying and Burnout: The coated foam is carefully dried, and then the polymer template is burned out at elevated temperatures, leaving a fragile ceramic preform that replicates the original foam structure.

- Sintering / Reaction Bonding:

- For Sintered SiC (SSiC) foam, the ceramic preform is sintered at very high temperatures (typically >2000∘C) in a controlled atmosphere. This causes the SiC particles to bond together, densifying the struts of the foam.

- For Reaction-Bonded SiC (RBSC/SiSiC) foam, the carbonaceous preform (after polymer burnout and potentially a carbonization step) is infiltrated with molten silicon. The silicon reacts with the carbon to form SiC in-situ, bonding the original SiC particles.

- Machining and Finishing (if required): After firing, the SiC foam components can be machined (e.g., cut, ground) to achieve final dimensions, tighter tolerances, or specific features. Due to the hardness of SiC, this typically involves diamond tooling.

Potential Post-Processing Needs:

Depending on the application, SiC foam components might undergo further post-processing:

- Grinding/Lapping: To achieve tight dimensional tolerances, specific surface finishes on sealing faces, or to ensure flatness/parallelism.

- Cutting/Slicing: To obtain specific shapes or sizes from larger foam blocks.

- Cleaning: To remove any residual contaminants from manufacturing or machining.

- Sealing: In some cases, portions of the foam might be selectively sealed or densified, for example, to create non-permeable edges or to attach to other components.

- Coating: Application of catalytic coatings (e.g., precious metals for catalyst supports) or protective coatings to further enhance chemical resistance or modify surface properties.

Careful consideration of these design and manufacturing aspects is vital for the successful implementation of custom SiC foam solutions. Collaborating with experienced silicon carbide foam manufacturers like Sicarb Tech, who possess a deep understanding of material science, process capabilities, and design for manufacturability, can significantly streamline the development process and ensure optimal component performance. SicSino’s connection to the Weifang SiC manufacturing hub provides access to a broad range of processing technologies and expertise.

Overcoming Challenges in SiC Foam Implementation and Partnering for Success

While custom silicon carbide foam offers a remarkable array of benefits, its implementation is not without challenges. Understanding these potential hurdles and how to mitigate them is crucial for engineers and procurement teams. Partnering with a knowledgeable and capable supplier, such as Sicarb Tech, can be instrumental in navigating these complexities and ensuring successful application outcomes.

Common Challenges Associated with SiC Foam:

- Brittleness and Handling: Like most ceramics, SiC foam is inherently brittle and has low fracture toughness compared to metals. This means it can be susceptible to damage from mechanical shock, impact, or high tensile stresses.

- Mitigation:

- Design Optimization: Designing components to minimize stress concentrations, avoid sharp corners, and ensure adequate support.

- Handling Procedures: Implementing careful handling protocols throughout manufacturing, assembly, and installation. Specialized packaging may be required for transport.

- System Integration: Designing the surrounding system to protect the SiC foam component from excessive mechanical loads or vibrations. Compressive loading is generally preferred.

- Toughening Strategies: Research into incorporating secondary phases or fiber reinforcements can improve toughness, though this may alter other properties and increase cost.

- Mitigation:

- Machining Complexity and Cost: Machining fired SiC foam is challenging due to its high hardness. This typically requires diamond tooling and specialized equipment, which can add to the overall cost and lead time, especially for complex shapes or tight tolerances.

- Mitigation:

- Near-Net Shape Manufacturing: Designing components to be as close to their final shape as possible (“near-net shape”) to minimize the need for extensive post-sintering machining. This requires precise control during the initial forming and firing stages.

- Advanced Machining Techniques: Utilizing techniques like ultrasonic machining, laser machining, or EDM (Electrical Discharge Machining) for specific features, though applicability varies.

- Supplier Expertise: Working with suppliers who have in-house machining capabilities and experience with hard ceramics. SicSino, leveraging its network in the Weifang SiC hub, can facilitate access to advanced machining resources.

- Mitigation:

- Thermal Shock Limitations (Relative to Metals): While SiC foam has excellent thermal shock resistance compared to many other ceramics, extreme thermal gradients or very rapid cycling can still pose a risk, particularly for larger or more complex components.

- Mitigation:

- Material Selection: Sintered SiC (SSiC) foam generally offers better thermal shock resistance than Reaction-Bonded SiC (RBSC) due to its higher purity and microstructure.

- Porosity Control: Higher porosity can sometimes improve thermal shock resistance by accommodating thermal expansion differences more effectively.

- Gradual Heating/Cooling: Where possible, implementing controlled heating and cooling rates in the application.

- Mitigation:

- Cost: Custom SiC foam components can be more expensive upfront compared to traditional materials like metals or some other ceramics (e.g., alumina foam). The cost is influenced by raw material purity, manufacturing complexity, energy-intensive firing processes, and any required machining.

- Mitigation:

- Total Cost of Ownership (TCO) Analysis: Considering the longer service life, improved process efficiency, reduced downtime, and enhanced product quality that SiC foam can provide. Often, the higher initial investment is offset by long-term savings.

- Volume Production: Costs can decrease with larger production volumes.

- Optimized Design: Efficient design that minimizes material usage and complex features can help manage costs.

- Strategic Sourcing: Partnering with a supplier like SicSino, which has direct access to the Weifang manufacturing cluster known for its cost-effective SiC production, can offer competitive pricing without compromising quality.

- Mitigation:

- Joining and Sealing: Effectively joining SiC foam to other components (ceramic or metallic) or achieving gas-tight seals can be challenging due to its porous nature and thermal expansion mismatch with other materials.

- Mitigation:

- Specialized Brazing/Bonding Techniques: Using active metal brazes or ceramic adhesives specifically designed for SiC.

- Mechanical Clamping with Gaskets: Employing high-temperature gasket materials (e.g., graphite, ceramic fiber) and mechanical clamping designs.

- Integrated Design: Designing components with integral flanges or features that facilitate sealing.

- Surface Densification: Selectively densifying or coating mating surfaces to improve seal integrity.

- Mitigation:

Partnering for Success with Sicarb Tech:

Overcoming these challenges often requires more than just a product; it requires a partnership. This is where Sicarb Tech, backed by the formidable scientific and technological capabilities of the Chinese Academy of Sciences , becomes a vital asset.

- Technical Expertise: SicSino’s team possesses deep knowledge in SiC materials science, process engineering, and application development. They can provide expert guidance on material selection, design optimization, and manufacturing feasibility.

- Customization Capabilities: With strong ties to the Weifang SiC production hub – home to over 80% of China’s SiC output – SicSino offers extensive customization options, from material grades and porosity to complex geometries, ensuring that the SiC foam components are tailored to your exact requirements.

- Problem Solving: Faced with a challenging application? SicSino’s engineers can collaborate with your team to develop innovative solutions, leveraging their integrated process knowledge from materials to final products.

- Quality Assurance and Supply Chain Reliability: Operating under the umbrella of the Chinese Academy of Sciences (Weifang) Innovation Park and the National Technology Transfer Center, SicSino is committed to high-quality standards and reliable supply chains, offering more reliable quality and supply assurance within China.

- Cost-Effectiveness: By leveraging the economies of scale and specialized expertise within the Weifang cluster, SicSino can offer higher-quality, cost-competitive customized silicon carbide components.

For companies seeking not just a supplier but a strategic partner in advanced ceramics, SicSino offers a unique value proposition, transforming potential challenges into successful, high-performance solutions. Their ability to support clients from initial design through to large-scale production makes them an ideal choice for OEMs and technical buyers in the wholesale silicon carbide foam market.

Choosing Your Silicon Carbide Foam Partner: Key Factors for Procurement and Engineering Teams

Selecting the right supplier for custom silicon carbide foam is a critical decision that can significantly impact the success of your project, the performance of your products, and your overall operational efficiency. For procurement managers, engineers, and technical buyers, this goes beyond simply finding the lowest silicon carbide foam cost. It involves evaluating a potential partner’s technical capabilities, material expertise, quality systems, customization support, and supply chain reliability.

Here are key factors to consider when choosing a silicon carbide foam manufacturer or supplier:

- Technical Expertise and R&D Capabilities:

- Material Science Knowledge: Does the supplier possess in-depth knowledge of different SiC grades (SiSiC, SSiC, etc.), their properties, and suitability for various applications? Can they advise on the optimal material for your specific operating conditions (temperature, chemical exposure, mechanical stress)?

- Design and Engineering Support: Can they offer design assistance, DfM (Design for Manufacturability) reviews, and Finite Element Analysis (FEA) if needed? Do they understand how porosity, cell size, and geometry affect performance?

- Innovation and Problem-Solving: Look for a partner who can co-engineer solutions and isn’t afraid to tackle challenging or novel applications.

- Manufacturing Capabilities and Customization:

- Range of Products: Can they produce foam with a wide range of PPI values, densities, and in various SiC grades?

- Custom Shapes and Sizes: What are their capabilities for producing complex geometries and meeting specific dimensional requirements? Do they offer near-net-shape manufacturing?

- Machining and Finishing: Do they have in-house or reliable outsourced capabilities for precision machining (cutting, grinding, lapping) of SiC foam?

- Post-Processing Options: Can they provide or manage services like coating, sealing, or specialized cleaning if required?

- Quality Management Systems and Certifications:

- Quality Control Processes: What quality checks are performed throughout the manufacturing process, from raw material inspection to final product verification? Ask about their testing capabilities (e.g., porosity measurement, strength testing, dimensional checks).

- Certifications: Are they ISO 9001 certified or do they hold other relevant industry-specific certifications? This indicates a commitment to quality and process control.

- Traceability: Can they provide material traceability and certificates of conformity?

- Supply Chain and Logistics:

- Lead Times: What are their typical lead times for samples, prototypes, and production volumes? Are they transparent about factors that can affect lead times?

- Production Capacity: Can they handle your current and projected future volume requirements?

- Reliability: Do they have a track record of on-time delivery and consistent supply?

- Location and Shipping: Consider their location and ability to ship reliably to your facilities.

- Cost-Effectiveness and Total Cost of Ownership (TCO):

- Transparent Pricing: Is their pricing structure clear and competitive? While initial cost is a factor, also evaluate the TCO. A slightly more expensive but higher-quality, longer-lasting component from a reliable supplier can be more cost-effective in the long run.

- Value-Added Services: Consider the value of technical support, design assistance, and problem-solving capabilities, which may not be reflected in the per-unit price but can save significant costs elsewhere.

- Customer Service and Communication:

- Responsiveness: How quickly do they respond to inquiries and technical questions?

- Technical Support: Is knowledgeable technical support readily available?

- Collaboration: Are they willing to work collaboratively with your team throughout the project lifecycle?

Why Sicarb Tech Stands Out:

When evaluating potential partners against these criteria, Sicarb Tech presents a compelling case, particularly for businesses seeking high-quality, customized SiC foam solutions from a reliable source in China.

- Deep Technical Roots: As part of the Chinese Academy of Sciences(Weifang) Innovation Park and backed by the National Technology Transfer Center of the Chinese Academy of Sciences, SicSino leverages world-class scientific and technological capabilities. Their domestic top-tier professional team specializes in the customized production of silicon carbide products, possessing extensive technologies in materials, processes, design, measurement, and evaluation.

- Hub of SiC Manufacturing: Located in Weifang City, the heart of China’s silicon carbide customizable parts manufacturing (accounting for over 80% of the nation’s SiC output), SicSino has unparalleled access to a vast network of specialized production enterprises. They have been instrumental in introducing and implementing advanced SiC production technology since 2015, fostering technological advancements within this industrial cluster. This means they can source or facilitate the production of a wide variety of custom SiC foam components efficiently and cost-effectively.

- Comprehensive Customization: SicSino’s strength lies in its integrated process from materials to products, enabling them to meet diverse customization needs for wholesale silicon carbide foam and specialized OEM parts. They understand that each application is unique and work closely with clients to develop tailored solutions.

- Quality and Reliability: SicSino is committed to delivering higher-quality, cost-competitive customized silicon carbide components. Their robust quality assurance processes and the backing of the Chinese Academy of Sciences ensure a level of reliability that is crucial for demanding industrial applications.

- Technology Transfer Services: Uniquely, if you are considering establishing your own specialized SiC products manufacturing plant, SicSino can provide technology transfer for professional silicon carbide production. This includes a full range of turnkey project services, from factory design and equipment procurement to installation, commissioning, and trial production, ensuring a more effective investment and reliable technology transformation.

The following table highlights key considerations when selecting a SiC foam supplier and how SicSino addresses them:

| Factor | General Consideration | Sicarb Tech Advantage |

|---|---|---|

| Technical Expertise | Deep material science knowledge, design support. | Backed by Chinese Academy of Sciences; top-tier professional team; comprehensive material & process technologies. |

| Customization | Ability to produce varied PPI, grades, complex shapes. | Extensive customization capabilities; integrated process from material to product; access to Weifang SiC cluster. |

| Quality Assurance | Robust QC processes, certifications, traceability. | Commitment to high quality; reliable supply assurance; Chinese Academy of Sciences backing ensures rigorous standards. |

| Manufacturing Access | In-house capabilities or strong network. | Situated in Weifang, hub of China’s SiC manufacturing; supports 10+ local enterprises with their technologies. |

| Cost & Lead Time | Competitive pricing, reasonable lead times, TCO focus. | Offers cost-competitive components due to Weifang cluster efficiencies; transparent communication on lead times. |

| Partnership Approach | Collaborative, responsive, problem-solving. | Acts as a bridge for technology transfer and commercialization; dedicated to client success from design to production and beyond. |

| Advanced Services | R&D, technology transfer. | Offers technology transfer for turnkey SiC plant setup; continuous innovation through Chinese Academy of Sciences connection. |

Choosing the right SiC foam supplier is a strategic decision. By prioritizing technical competence, customization capabilities, quality assurance, and a partnership approach, companies can unlock the full potential of this advanced material. Sicarb Tech embodies these qualities, making them a trusted partner for businesses worldwide.

Frequently Asked Questions (FAQ) about Silicon Carbide Foam

Engineers, designers, and procurement professionals often have specific questions when considering silicon carbide foam for their applications. Here are answers to some common queries:

- What are the typical pore sizes (PPI) available for SiC foam, and how do I choose the right one? Silicon carbide foam is available in a wide range of pore sizes, typically specified as Pores Per Inch (PPI). Common ranges include 10, 20, 30, 45, 60, 80, and 100 PPI, with custom options sometimes available.

- Lower PPI (e.g., 10-30 PPI): Larger, more open pores. These are often used for applications like molten metal filtration (especially for larger inclusion removal in aluminum or iron casting), applications requiring very high permeability and low pressure drop, or as flow straighteners.

- Medium PPI (e.g., 45-65 PPI): A balance between surface area, filtration efficiency, and permeability. Suitable for finer molten metal filtration (e.g., steel, superalloys), catalyst supports where moderate surface area is needed, or some heat exchanger applications.

- Higher PPI (e.g., 80-100+ PPI): Smaller pores, leading to higher surface area and finer filtration capabilities. Used for applications like diesel particulate filters (DPFs), fine particle filtration in gases or liquids, or catalyst supports requiring maximum surface area. The choice depends on your specific application:

- For filtration: Consider the size of particles you need to remove and the acceptable pressure drop. Finer PPI offers better efficiency for smaller particles but higher pressure drop.

- For catalyst supports: Higher PPI generally means more surface area for catalyst loading and reaction.

- For heat exchangers: The PPI will influence the heat transfer coefficient and pressure drop. It’s often best to discuss your application requirements with an experienced supplier like Sicarb Tech to determine the optimal PPI.

- How does the cost of SiC foam compare to other ceramic foams or traditional materials? The silicon carbide foam cost is generally higher than some other ceramic foams (like alumina or zirconia foams) and significantly higher than many traditional materials (like polymer foams or some metals used in filtration or structural applications). Several factors contribute to this:

- Raw Material Cost: High-purity silicon carbide powder is more expensive than raw materials for many other ceramics.

- Manufacturing Process: The process of creating SiC foam, especially sintered SiC (SSiC), involves very high temperatures (often >2000∘C) and controlled atmospheres, which are energy-intensive and require specialized equipment.

- Machining: If tight tolerances or complex shapes require machining, the hardness of SiC makes this a costly operation, requiring diamond tooling.

- Customization: Highly customized shapes, porosities, or grades will also influence the price. However, it’s crucial to consider the Total Cost of Ownership (TCO) rather than just the upfront price. SiC foam often provides:

- Longer service life due to its superior thermal, chemical, and wear resistance.

- Improved process efficiency (e.g., better filtration, higher catalyst activity, enhanced heat transfer).

- Reduced downtime and maintenance costs. In many demanding applications, the superior performance and longevity of SiC foam justify the higher initial investment. Wholesale silicon carbide foam purchases or optimized designs in collaboration with suppliers like SicSino can help manage costs.

- Can silicon carbide foam be machined or joined to other components? Yes, but with specific considerations:

- Machining: Fired silicon carbide foam is extremely hard and can be machined using diamond grinding, cutting, or lapping techniques. It is also possible to use Electrical Discharge Machining (EDM) or ultrasonic machining for certain features. However, machining is a slow and potentially expensive process. It’s often preferred to design the component for near-net-shape manufacturing to minimize machining. Green machining (machining the ceramic preform before final firing) is sometimes possible and can be easier, but tolerances are less precise due to shrinkage during firing.

- Joining: Joining SiC foam to other components (SiC foam, dense SiC, or metals) can be challenging due to its porous nature and the thermal expansion mismatch that often exists with other materials. Common methods include:

- Ceramic Adhesives/Cements: High-temperature ceramic adhesives or cements can be used, especially for SiC-to-SiC joints.

- Brazing: Active metal brazing is a common technique for joining SiC to metals or other ceramics. This involves using a braze alloy that contains an active element (like titanium) that reacts with the SiC surface to promote wetting and bonding.

- Mechanical Fastening: Designing flanges or using clamps with high-temperature gaskets (e.g., graphite, ceramic fiber paper) can create mechanical joints.

- Diffusion Bonding: Under specific conditions of high temperature and pressure, direct bonding can be achieved. When designing components that require joining, it’s essential to consult with your SiC foam supplier, such as Sicarb Tech. Their expertise can guide you in selecting appropriate joining methods and designing features that facilitate robust connections for your custom SiC foam components.

Conclusion: Embracing the Future with Custom Silicon Carbide Foam

Custom silicon carbide foam stands as a testament to the advancements in material science, offering a unique and powerful solution for industries facing the most extreme operational challenges. Its remarkable combination of high-temperature stability, exceptional thermal shock resistance, high strength-to-weight ratio, chemical inertness, and tailorable porosity makes it an indispensable material for applications ranging from molten metal filtration SiC foam and SiC foam catalyst supports to advanced SiC foam heat exchangers and aerospace SiC foam components.

While the inherent properties of silicon carbide are impressive, the true value for engineers, procurement managers, and OEMs lies in the “custom” aspect. The ability to tailor porosity, geometry, and even the base SiC grade allows for the optimization of components to meet precise application requirements, leading to enhanced performance, increased efficiency, and longer service life. Though challenges such as brittleness and machining complexity exist, they can be effectively managed through intelligent design and collaboration with experienced manufacturers.

Choosing the right partner is paramount to harnessing the full potential of this advanced ceramic.Sicarb Tech. with its deep technical expertise rooted in the Chinese Academy of Sciences and its strategic position within Weifang – the hub of China’s SiC industry – offers more than just components. SicSino provides a collaborative partnership, offering comprehensive support from design and material selection through to manufacturing and even technology transfer for establishing your own SiC production facilities. Their commitment to quality, cost-effectiveness, and reliable supply makes them an ideal choice for businesses seeking to integrate high-performance SiC foam into their products and processes.

As industries continue to push the boundaries of temperature, pressure, and chemical exposure, the demand for materials like custom silicon carbide foam will only intensify. By embracing this innovative technology and partnering with knowledgeable suppliers, businesses can unlock new levels of performance, drive innovation, and secure a competitive advantage in the demanding industrial environments of today and tomorrow.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.