Mastering Industrial Filtration: The Power of Custom Silicon Carbide Filter Presses

Share

In the demanding landscape of modern industrial processing, the efficiency and reliability of filtration systems are paramount. From chemical manufacturing to wastewater treatment, the ability to separate solids from liquids effectively, often under harsh conditions, is critical for product quality, operational uptime, and environmental compliance. While various filtration technologies exist, silicon carbide filter presses, particularly those featuring custom SiC components, are increasingly recognized as essential for high-performance applications. These advanced ceramic systems offer unparalleled resistance to wear, corrosion, and high temperatures, making them a superior choice for engineers, procurement managers, and technical buyers in a multitude of industries. This blog post will delve into the world of silicon carbide filter presses, exploring their applications, the distinct advantages of custom SiC components, design considerations, and how to select a knowledgeable and capable supplier like Sicarb Tech.

Introduction to Silicon Carbide Filter Presses: The High-Performance Filtration Solution

A filter press is a piece of equipment used for solid/liquid separation. It works by forcing a slurry (a mixture of solids and liquids) into a series of filter chambers. Each chamber is formed by two recessed filter plates, which are lined with a filter medium (cloth or membrane). As the slurry is pumped under pressure, the liquid (filtrate) passes through the filter medium and exits the press, while the solids (filter cake) accumulate on the surface of the medium within the chambers. Once the chambers are full of solids and the filtrate flow significantly decreases, the press is opened, and the filter cake is discharged.

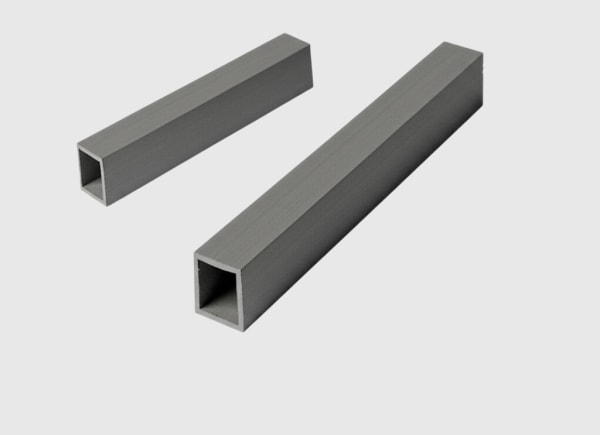

While traditional filter press plates can be made from materials like polypropylene, cast iron, or stainless steel, these materials often fall short when dealing with extremely corrosive chemicals, highly abrasive slurries, or elevated temperatures. This is where silicon carbide (SiC) emerges as a game-changing material. Silicon carbide is an advanced technical ceramic renowned for its exceptional hardness (second only to diamond), high thermal conductivity, low thermal expansion, and outstanding chemical inertness.

Silicon carbide filter presses utilize filter plates and sometimes other critical components manufactured from SiC. These presses are specifically designed to operate in environments where conventional materials would rapidly degrade, leading to frequent downtime, high maintenance costs, and compromised filtration performance. The use of SiC allows these filter presses to handle the most aggressive industrial slurries, providing longevity and consistent performance that translates into significant operational and economic benefits. For industries demanding robust industrial SiC filters, these systems represent a cutting-edge solution.

Key Industrial Applications Benefiting from SiC Filter Presses

The unique properties of silicon carbide make filter presses equipped with SiC filter plates indispensable across a wide range of demanding industrial sectors. Procurement professionals and OEMs looking for durable filter press components will find SiC to be an optimal material for challenging filtration tasks.

Here are some key applications:

- Chemical Processing: The chemical industry frequently deals with highly corrosive acids, alkalis, and solvents. SiC’s exceptional chemical inertness makes it ideal for filtering these aggressive substances without degradation. Applications include the production of specialty chemicals, pigments, agrochemicals, and pharmaceuticals where chemical resistant filters are non-negotiable. The ability to withstand a wide pH range and various oxidizing agents ensures process integrity and longevity of the equipment.

- Mining and Mineral Processing: Slurries encountered in mining and mineral extraction are often extremely abrasive due to the presence of hard, sharp particles. Wear-resistant SiC components in filter presses significantly extend the service life of filter plates, reducing the need for frequent replacements and associated downtime. This is crucial in processes like dewatering of mineral concentrates, tailings management, and clay processing.

- Wastewater Treatment: Industrial wastewater can contain a complex mixture of abrasive particles, corrosive chemicals, and high-temperature effluents. SiC filter presses provide a robust solution for dewatering industrial sludges, treating metal finishing wastewater, and handling effluents from chemical plants, ensuring compliance with environmental discharge regulations and enabling water reuse. Their durability is particularly beneficial for heavy-duty filtration systems.

- Pharmaceutical and Food & Beverage Industries: While perhaps less common due to the high-performance nature often exceeding typical needs, specific niche applications in these industries that involve aggressive cleaning agents, high temperatures, or fine abrasive particles can benefit from the purity and resilience of SiC. For instance, filtering certain catalysts or dealing with abrasive natural product extracts.

- Power Generation: In flue gas desulfurization (FGD) systems, SiC components can handle the corrosive and abrasive nature of limestone/gypsum slurries. Also, in certain high-temperature filtration processes within power plants, SiC offers superior stability.

- Electronics and Semiconductor Manufacturing: The production of electronic components and semiconductors often involves aggressive chemicals and the need for high-purity filtration. Custom SiC parts can be essential in specific filtration steps where material purity and resistance to chemical attack are critical.

The table below highlights the suitability of SiC filter presses for various challenging conditions:

| Industrial Challenge | Traditional Material Limitations | SiC Advantage | Relevant Keywords |

|---|---|---|---|

| Aggressive Chemicals (Acids, Alkalis, Solvents) | Corrosion, leaching, material degradation | Excellent chemical inertness across a wide pH range, resistance to oxidation | Chemical resistant SiC filters, corrosion-proof filter plates |

| Abrasive Slurries | Rapid wear, erosion, frequent replacement | Exceptional hardness and abrasion resistance, extended service life | Wear-resistant filter components, abrasion-resistant SiC plates |

| High Temperatures | Softening, deformation, reduced mechanical strength, creep | High-temperature stability, excellent thermal shock resistance | High-temperature filtration, thermal resistant ceramics |

| High-Pressure Operation | Risk of cracking, deformation, sealing issues | High mechanical strength and rigidity, maintains dimensional stability | High-strength SiC plates, durable filter press parts |

| Need for Purity | Potential for leaching or contamination from plate material | High purity grades available, non-contaminating | High-purity SiC components, inert ceramic filters |

Export to Sheets

These applications underscore the critical role of technical ceramics in filtration, with SiC leading the charge in the most demanding scenarios.

Advantages of Custom Silicon Carbide Components in Filter Presses

Opting for custom silicon carbide components in filter presses offers a multitude of advantages over standard or alternative material options, especially when tackling challenging industrial filtration tasks. These benefits translate to improved efficiency, reduced operational costs, and enhanced reliability for wholesale SiC components buyers and technical procurement professionals.

- Unmatched Wear and Abrasion Resistance: Silicon carbide is one of the hardest commercially available materials. This inherent hardness provides exceptional resistance to the erosive action of abrasive particles found in many industrial slurries, such as those in mining, ceramics manufacturing, and pigment production.

- Benefit: Significantly longer service life of filter plates and other wetted parts compared to metallic or polymeric alternatives. This reduces the frequency of replacements, minimizes downtime, and lowers maintenance costs. For instance, in mineral concentrate dewatering, SiC plates can outlast conventional plates by a significant margin.

- Superior Chemical Inertness: SiC exhibits outstanding resistance to a wide spectrum of corrosive chemicals, including strong acids (e.g., sulfuric acid, hydrochloric acid, hydrofluoric acid – depending on SiC grade and concentration/temperature), alkalis, and organic solvents, even at elevated temperatures.

- Benefit: Enables filtration of highly aggressive media without the risk of plate degradation, corrosion, or leaching of contaminants into the filtrate or filter cake. This is crucial for maintaining product purity in chemical and pharmaceutical applications and ensures equipment longevity in harsh chemical environments. Sicarb Tech can advise on the optimal SiC grade, such as Reaction Bonded Silicon Carbide (RBSC/SiSiC) or Sintered Silicon Carbide (SSiC), based on the specific chemical environment.

- Excellent Thermal Stability and Thermal Shock Resistance: SiC components can operate at very high temperatures (up to $1380^\\circ C$ for RBSC, and even higher for SSiC in controlled atmospheres) without significant loss of mechanical properties. They also possess excellent thermal shock resistance, meaning they can withstand rapid temperature fluctuations without cracking.

- Benefit: Suitable for high-temperature filtration processes where other materials would fail. This allows for filtration of hot slurries directly, potentially streamlining processes and saving energy by eliminating the need for cooling steps.

- High Mechanical Strength and Rigidity: SiC maintains its strength and structural integrity even under high operating pressures common in filter press operations. Its high modulus of elasticity ensures dimensional stability.

- Benefit: Allows for the design of thinner, yet stronger, filter plates, potentially increasing the filtration area within a given press footprint. It also ensures reliable sealing and prevents plate deformation under pressure, leading to more efficient dewatering and consistent cake formation.

- Reduced Total Cost of Ownership (TCO): While the initial investment in SiC components might be higher than for some conventional materials, their extended lifespan, reduced maintenance requirements, and improved operational efficiency often lead to a lower TCO.

- Benefit: Fewer production interruptions, lower labor costs for replacements, and reduced expenditure on spare parts contribute to significant long-term savings.

- Customization for Optimized Performance: SiC components can be manufactured to precise designs and complex geometries. Custom SiC filter plates can be engineered with optimized feed and filtrate porting, drainage surfaces, and sealing features to match specific process requirements.

- Benefit: Tailored designs ensure maximum filtration efficiency, improved cake release, and better overall performance for the specific application. Sicarb Tech specializes in providing such custom solutions, leveraging their expertise in SiC material science and manufacturing processes.

By choosing custom SiC components, industries can transform their filtration operations from a frequent maintenance headache into a reliable, high-performance process step. This strategic material selection is key for OEM SiC parts integration and for end-users seeking advanced ceramic solutions.

Recommended Silicon Carbide Grades for Filter Press Components

Selecting the appropriate grade of silicon carbide is crucial for optimizing the performance and lifespan of filter press components. Different manufacturing processes result in SiC materials with varying properties, making them suitable for different operational demands. The two primary grades often considered for filter press applications are Reaction-Bonded Silicon Carbide (RBSC, also known as Silicon Infiltrated Silicon Carbide or SiSiC) and Sintered Silicon Carbide (SSiC).

Reaction-Bonded Silicon Carbide (RBSC / SiSiC): RBSC is a composite material typically consisting of silicon carbide grains and a continuous matrix of silicon metal (usually 8-15% free silicon). It is produced by infiltrating a porous carbon-SiC preform with molten silicon. The silicon reacts with the carbon to form new SiC, which bonds the original SiC grains.

- Key Properties:

- Excellent wear and abrasion resistance.

- Good thermal shock resistance.

- High thermal conductivity.

- Good mechanical strength.

- Relatively lower manufacturing cost compared to SSiC.

- Maximum service temperature typically around $1350-1380^\\circ C$.

- Good resistance to many acids, but can be attacked by strong alkalis and certain oxidizing agents at higher temperatures due to the presence of free silicon.

- Suitability for Filter Presses: RBSC is often the workhorse material for many SiC filter plate applications due to its excellent balance of performance and cost-effectiveness. It performs exceptionally well in applications involving abrasive slurries and moderate chemical conditions. For instance, it’s a preferred choice for dewatering mineral concentrates, industrial sludges, and in many chemical processing applications where extreme chemical resistance isn’t the primary concern. Sicarb Tech has extensive experience in producing custom RBSC components tailored to specific filtration needs.

Sintered Silicon Carbide (SSiC): SSiC is a high-purity silicon carbide material (typically >98% SiC) produced by sintering fine SiC powder at very high temperatures (often above $2000^\\circ C$) with the aid of sintering additives (non-oxide or oxide). There are different types, including pressureless sintered (the most common), hot-pressed (HP-SSiC), and reaction-sintered (a distinct category from RBSC).

- Key Properties:

- Extremely high hardness and exceptional wear resistance, often superior to RBSC.

- Superior corrosion resistance across a very broad pH range, including strong acids and alkalis, even at elevated temperatures. This is due to the absence of free silicon.

- Excellent high-temperature strength and creep resistance.

- Good thermal shock resistance.

- Typically higher manufacturing cost than RBSC due to more complex processing.

- Suitability for Filter Presses: SSiC is the premium choice for the most demanding applications where extreme chemical aggression (e.g., handling concentrated hydrofluoric acid or hot caustic solutions) or very high temperatures are involved. It is also selected when the utmost purity is required, as it contains minimal secondary phases. While more expensive, its unparalleled durability in these harsh environments can justify the investment by minimizing downtime and maximizing component life.

Other SiC Variants (Less Common for Filter Press Plates):

- Nitride-Bonded Silicon Carbide (NBSC): Offers good thermal shock resistance and strength but may have limitations in certain corrosive environments compared to RBSC or SSiC.

- Recrystallized Silicon Carbide (RSiC): Known for very high operating temperatures and purity but can be more porous and less strong than RBSC or SSiC, making it less typical for high-pressure filter press plates.

Here’s a comparative table to summarize:

| Property | Reaction-Bonded SiC (RBSC/SiSiC) | Sintered SiC (SSiC) | Considerations for Filter Presses |

|---|---|---|---|

| SiC Purity | ~85-92% SiC, 8-15% free Si | >98% SiC | SSiC offers higher purity and better resistance to certain aggressive chemicals due to no free Si. |

| Hardness/Wear Resistance | Excellent | Exceptional | Both are excellent, SSiC often has an edge in the most severe abrasive conditions. |

| Chemical Resistance | Good (less so to strong alkalis) | Excellent (broad pH, strong acids/alkalis) | SSiC is superior for highly corrosive environments. |

| Max. Service Temp. | ~$1380^\\circ C$ | >$1600^\\circ C$ (environment dependent) | SSiC can handle higher temperatures. |

| Thermal Conductivity | High | Very High | Both offer good thermal management. |

| Mechanical Strength | Good to High | Very High | SSiC generally offers higher strength. |

| Cost | Moderate | High | RBSC is more cost-effective for many applications; SSiC is for extreme conditions. |

| Manufacturability | Good for complex shapes | More complex for large/intricate parts | Both can be custom-made; RBSC often allows for larger and more intricate designs more readily. |

Procurement professionals looking for wholesale SiC components should consult with material experts like Sicarb Tech. Their team can analyze the specific operating conditions – slurry characteristics (abrasiveness, pH, particle size), temperature, pressure, and required service life – to recommend the optimal and most cost-effective SiC grade and design for your filter press components.

Critical Design and Engineering Considerations for SiC Filter Press Plates

The successful implementation of silicon carbide filter press plates hinges not only on selecting the right SiC grade but also on meticulous design and engineering. These considerations ensure manufacturability, operational efficiency, structural integrity, and longevity of the components. Technical buyers and engineers specifying custom SiC filter plates should work closely with experienced suppliers who understand the nuances of designing with advanced ceramics.

- Plate Type and Configuration:

- Chamber Filter Plates (Recessed Plates): These are the most common type, forming a chamber between two adjacent plates where the filter cake accumulates. The design of the recess depth and overall plate thickness is critical for cake capacity and strength.

- Membrane Filter Plates: These incorporate a flexible, impermeable membrane behind the filter cloth. After the initial chamber filling, the membrane is inflated (pneumatically or hydraulically) to squeeze the filter cake, achieving higher solids content. Designing SiC plates to support membrane functionality requires careful consideration of pressure distribution and support structures.

- Plate and Frame: An older design, less common now for SiC due to the complexity and sealing challenges with hard ceramic frames.

- Flow Channel Optimization (Pips and Grooves): The surface of the filter plate features a pattern of pips (raised dimples) or grooves that support the filter cloth and create channels for the filtrate to flow towards the outlet ports.

- Design Goals: Efficient drainage, prevention of cloth blinding, uniform flow distribution, and mechanical support for the cloth under pressure.

- SiC Considerations: The design must be manufacturable using SiC forming techniques (e.g., slip casting, pressing, green machining). Sharp internal corners should be avoided to minimize stress concentrations. Sicarb Tech leverages its expertise in SiC processing to advise on optimal and manufacturable drainage patterns.

- Feed and Filtrate Porting: The location, size, and design of feed inlet(s) and filtrate outlet(s) are crucial for even slurry distribution and efficient filtrate removal.

- Common Configurations: Center feed, corner feed.

- Design Goals: Minimize pressure drop, prevent clogging, ensure complete chamber filling, and optimize flow dynamics. The hard, wear-resistant nature of SiC is advantageous for port areas which see high velocity and abrasive flow.

- Sealing Mechanisms: Achieving a reliable seal between filter plates and between the plates and the filter cloth is essential to prevent leakage, especially under high operating pressures.

- SiC Considerations: SiC is a rigid material. The flatness and surface finish of the sealing surfaces are critical. Gasket materials must be compatible with the process fluids and temperature, and the design should ensure proper gasket compression. O-ring grooves or other sealing features can be machined into the SiC plates.

- Structural Integrity and Stress Management: Filter plates are subjected to significant mechanical stresses from the hydraulic closing force of the press and the internal pressure during filtration and membrane squeezing.

- Design Analysis: Finite Element Analysis (FEA) is often employed to predict stress distributions and ensure the design can withstand operational loads without failure. This is particularly important for large plates or high-pressure applications.

- SiC Properties: While SiC has high compressive strength, its tensile strength is lower, and it is a brittle material. Designs must minimize tensile stresses and avoid stress concentrators like sharp corners or sudden changes in thickness. Generous radii and smooth transitions are essential.

- Manufacturability and Tolerances: The complexity of the design impacts manufacturing cost and feasibility.

- Forming Methods: Common methods for SiC include slip casting for complex shapes, uniaxial or isostatic pressing for simpler geometries, and green machining before sintering.

- Dimensional Accuracy & Tolerances: SiC components undergo shrinkage during sintering. Achieving tight tolerances requires precise control over the manufacturing process and may involve post-sintering grinding or machining, which adds to the cost. Understanding achievable tolerances for features like flatness, parallelism, and port dimensions is crucial. Sicarb Tech has a deep understanding of these manufacturing constraints and can guide designs for optimal manufacturability and cost-effectiveness.

- Cake Discharge: The design should facilitate easy and complete discharge of the filter cake. Smooth plate surfaces (achievable with SiC) and appropriate chamber design can help.

- Weight Considerations: SiC is denser than some plastics but lighter than many metals. For very large plates, the overall weight can be a factor in handling and press design. Optimized SiC plate designs can minimize weight while maintaining strength.

Engineering Tips for SiC Filter Plate Design:

- Engage Early with Supplier: Collaborate with your SiC component supplier, like Sicarb Tech, from the early design stages. Their material and manufacturing expertise is invaluable.

- Simplify Where Possible: While SiC allows for complex shapes, unnecessary complexity increases cost.

- Consider Assembly and Maintenance: Design for ease of installation, cloth replacement, and cleaning.

- Specify Surface Finish: Determine the required surface finish for sealing surfaces and areas in contact with the filter cloth. SiC can be ground and lapped to very fine finishes if needed.

By carefully addressing these design and engineering aspects, companies can fully leverage the exceptional properties of silicon carbide to create filter press systems that deliver superior performance and longevity in the most challenging industrial applications. This focus on robust design is critical for OEMs integrating SiC parts and for end-users seeking reliable, high-performance ceramic filter components.

Operational Best Practices and Maintenance of SiC Filter Presses

While silicon carbide filter press components are renowned for their durability and long service life, adopting proper operational best practices and a consistent maintenance schedule is crucial to maximize their performance, prevent premature failures, and ensure the overall efficiency of the filtration system. Engineers and operators responsible for industrial SiC filters should be well-versed in these procedures.

Operational Best Practices:

- Proper Installation and Alignment:

- Ensure the filter press frame is level and stable.

- Install SiC filter plates carefully, ensuring they are correctly aligned and seated in the press. Misalignment can cause uneven pressure distribution and damage the plates or sealing surfaces.

- Verify that filter cloths are installed correctly, without wrinkles or damage, and that they provide an effective seal against the SiC plates.

- Slurry Conditioning:

- Pre-treat the slurry if necessary (e.g., pH adjustment, flocculant/coagulant addition) to optimize filterability and cake formation. This can reduce filtration cycle times and improve dewatering efficiency.

- Control the solids concentration in the feed. Excessively thick or thin slurries can impact performance.

- Optimal Operating Pressures and Flow Rates:

- Gradually increase the feed pressure to the recommended operating level. Avoid sudden pressure shocks, which can stress components, even robust SiC.

- Operate within the designed pressure limits for the SiC plates and the filter press. Overpressure can lead to plate damage or failure.

- Monitor flow rates. A sudden drop might indicate cloth blinding or other issues.

- Controlled Cake Formation and Discharge:

- Ensure even cake formation across all chambers. Uneven cake can lead to inefficient washing (if applicable) and mechanical stress on plates.

- Follow recommended procedures for cake discharge. If mechanical aids are used (e.g., vibrators, spatulas), ensure they do not damage the SiC plates or filter cloths. SiC’s hardness protects against incidental contact, but direct, forceful impact should be avoided.

- Filter Cloth Management:

- Select filter cloths appropriate for the slurry characteristics and compatible with SiC plates.

- Regularly inspect filter cloths for wear, tears, or blinding. Damaged cloths can lead to poor filtrate quality and can affect the SiC plates if particulate matter gets trapped.

- Clean filter cloths according to manufacturer recommendations to maintain permeability.

Maintenance Schedule and Procedures:

- Regular Inspections:

- Daily/Per Shift: Visually inspect for leaks, abnormal noises, or changes in performance. Check pressure gauges and flow meters.

- Weekly/Monthly (or as per process demands):

- Inspect SiC filter plates for any signs of chipping (especially around edges or ports, often due to mishandling rather than operational wear), cracking, or unusual wear patterns. While SiC is extremely wear-resistant, severe, unexpected abrasion sources should be investigated.

- Examine sealing surfaces on the plates and gaskets/O-rings for wear or damage.

- Check filter cloths thoroughly.

- Inspect the press frame, hydraulic system, and other mechanical components.

- Cleaning of SiC Filter Plates:

- SiC plates generally offer good cake release due to their smooth surface. However, some residues may occasionally adhere.

- Mechanical Cleaning: Use soft tools (e.g., plastic or rubber scrapers) if manual cleaning is required. Avoid using hard metal tools directly on the SiC surface to prevent chipping, though SiC is very resistant.

- Chemical Cleaning (CIP): SiC’s excellent chemical resistance allows for aggressive chemical cleaning if necessary. Select cleaning agents compatible with both the SiC (most inorganic acids and bases are fine, but consult with Sicarb Tech for specific grade compatibility with extreme chemicals like hot concentrated HF or strong oxidizing agents at high temperatures) and other press components (cloths, gaskets, frame). Ensure thorough rinsing after chemical cleaning.

- Handling and Storage of Spare Plates:

- SiC is hard but also brittle. Handle plates with care to avoid impact or dropping, which can cause chipping or cracking.

- Store spare plates in a safe, protected area where they won’t be subjected to mechanical shock. Store them flat or in appropriate racking.

- Record Keeping:

- Maintain a logbook of operations, including cycle times, pressures, throughput, maintenance activities, cloth changes, and any issues encountered. This data is valuable for troubleshooting and optimizing performance.

Troubleshooting Common Issues:

| Issue | Potential Causes | Corrective Actions |

|---|---|---|

| Leaks between plates | Damaged/worn gaskets or O-rings; misaligned plates; damaged sealing surface on SiC plate; incorrect closing pressure; damaged filter cloth. | Inspect and replace seals; realign plates; inspect SiC plate (consult supplier if damaged); adjust pressure; replace cloth. |

| Poor filtrate quality | Damaged filter cloth (holes, tears); incorrect cloth type; poor sealing. | Replace/repair cloth; select appropriate cloth; check seals and plate alignment. |

| Blinded filter cloth | Fine particles clogging cloth pores; sticky solids; incorrect slurry conditioning. | Clean or replace cloth; optimize pre-treatment (flocculants); adjust slurry properties. |

| Difficulty in cake discharge | Cake too wet or sticky; incorrect cloth type; plate surface issues (rare with SiC). | Optimize dewatering cycle (e.g., air blow, membrane squeeze); use appropriate cloth; ensure SiC surface is clean. |

| Chipping/Cracking of SiC Plates | Mechanical impact (mishandling, foreign objects); severe thermal shock (beyond design); overpressure; incorrect installation. | Handle with care; ensure proper screening of feed; operate within thermal limits; verify pressure settings; ensure correct installation. |

By adhering to these operational and maintenance guidelines, users of silicon carbide filter presses can ensure a long, efficient, and reliable service life from these high-performance systems, maximizing their return on investment. Regular consultation with suppliers like Sicarb Tech can also provide valuable insights for optimizing specific filtration processes.

Choosing the Right Supplier for Custom SiC Filter Press Components: Why Sicarb Tech Excels

Selecting the right supplier for custom silicon carbide filter press components is a critical decision that directly impacts the performance, reliability, and cost-effectiveness of your filtration operations. Procurement managers, engineers, and OEMs need a partner with deep material expertise, robust manufacturing capabilities, a commitment to quality, and the ability to provide tailored solutions. Sicarb Tech stands out as a premier provider in this specialized field, deeply rooted in the heart of China’s SiC manufacturing hub.

Key Criteria for Evaluating a SiC Component Supplier:

- Material Expertise and Range:

- Does the supplier have in-depth knowledge of different SiC grades (RBSC/SiSiC, SSiC, etc.) and their suitability for various applications?

- Can they advise on the optimal material selection based on your specific process conditions (chemical environment, temperature, abrasiveness)?

- Customization Capabilities:

- Can the supplier manufacture components to your precise design specifications and drawings?

- Do they offer design assistance or DFM (Design for Manufacturability) support to optimize your components for SiC production?

- Are they equipped to produce complex geometries and achieve tight tolerances?

- Manufacturing Prowess and Quality Control:

- What manufacturing processes do they employ (e.g., slip casting, pressing, green machining, sintering, finishing)?

- What quality management systems (e.g., ISO certification) are in place?

- What are their testing and inspection capabilities to ensure material properties and dimensional accuracy?

- Technical Support and Collaboration:

- Is the supplier responsive and willing to collaborate closely with your technical team?

- Can they provide application engineering support and troubleshooting assistance?

- Track Record and Reliability:

- What is their experience in supplying SiC components for similar applications or industries?

- Can they provide case studies or references?

- What is their reputation for on-time delivery and consistent product quality?

- Location and Supply Chain:

- Proximity to manufacturing hubs can offer advantages in terms of expertise and supply chain efficiency.

- What are their capabilities for ensuring reliable supply, especially for wholesale SiC components or OEM SiC parts?

Why Sicarb Tech is Your Trusted Partner:

Sicarb Tech is uniquely positioned to meet and exceed these criteria, offering compelling advantages for businesses seeking high-quality, custom SiC filter press components.

- Located in the Epicenter of SiC Manufacturing: Weifang City, China, is the recognized hub for silicon carbide customizable parts manufacturing, accounting for over 80% of the nation’s total SiC output. Sicarb Tech has been instrumental in this region since 2015, introducing and implementing advanced SiC production technology and fostering large-scale production and technological advancements among local enterprises. We are not just a supplier; we are a witness to and a key player in the development of this industry.

- Strong Backing and Technological Prowess: As part of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarb Tech collaborates closely with the National Technology Transfer Center of the Chinese Academy of Sciences. This national-level innovation platform provides us with access to the robust scientific and technological capabilities and talent pool of the Chinese Academy of Sciences. This backing ensures more reliable quality and supply assurance within China.

- Comprehensive In-House Expertise: We possess a domestic top-tier professional team specializing in the customized production of silicon carbide products. Our integrated expertise spans:

- Material Technology: Deep understanding of various SiC grades and their properties.

- Process Technology: Advanced manufacturing techniques for forming, sintering, and finishing SiC.

- Design Technology: Capability to assist with component design and optimization for manufacturability and performance.

- Measurement & Evaluation Technology: Rigorous quality control and testing to ensure components meet specifications. This integrated process, from materials to finished products, enables us to meet diverse customization needs effectively.

- Proven Impact and Collaboration: We have successfully supported over 10 local enterprises by leveraging our technologies, enhancing their production capabilities and product quality. This collaborative approach underscores our commitment to advancing the SiC industry.

- High-Quality, Cost-Competitive Solutions: Our technological advantages and strategic location within China’s SiC hub allow us to offer higher-quality, cost-competitive customized silicon carbide components. We are dedicated to providing solutions that deliver both performance and value.

- Beyond Components – Turnkey Solutions: For clients looking to establish their own specialized SiC production, Sicarb Tech offers technology transfer for professional silicon carbide production. This includes a full range of turnkey project services, such as factory design, procurement of specialized equipment, installation and commissioning, and trial production. This comprehensive offering empowers you to own a professional SiC products manufacturing plant with a more effective investment, reliable technology transformation, and guaranteed input-output ratio.

The following table provides a quick comparison of supplier attributes:

| Attribute | Generic Supplier | Sicarb Tech |

|---|---|---|

| Location & Industry Access | Variable | Located in Weifang, China’s SiC manufacturing hub (80% of national output) |

| Technical Backing | Often relies on internal R&D | Backed by Chinese Academy of Sciences National Technology Transfer Center, leveraging Chinese Academy of Sciences expertise |

| Customization Focus | May offer standard parts, limited customization | Specializes in custom SiC products; strong design, material, and process technology |

| Industry Development Role | Primarily a manufacturer | Actively involved in local SiC industry development and technological advancement since 2015 |

| Quality & Cost | Variable | Higher-quality, cost-competitive customized components due to integrated expertise and strategic location |

| Turnkey Plant Solutions | Typically not offered | Offers technology transfer and full turnkey services for establishing SiC production plants |

| Reliability & Support | Dependent on individual company | Enhanced reliability through Chinese Academy of Sciences backing and a dedicated professional team; strong focus on collaborative support |

Choosing Sicarb Tech means partnering with a leader in the silicon carbide industry, one that combines cutting-edge technology, deep material science knowledge, and a commitment to customer success. Whether you are an OEM seeking reliable OEM SiC parts, a distributor looking for wholesale SiC components, or an end-user in need of custom SiC filter plates, we are equipped to deliver solutions that meet your most demanding requirements.

Frequently Asked Questions (FAQ)

Q1: What are the primary advantages of using silicon carbide filter plates over traditional materials like polypropylene or stainless steel in filter presses?

A1: Silicon carbide (SiC) filter plates offer several significant advantages over traditional materials, especially in demanding industrial applications: * Exceptional Wear and Abrasion Resistance: SiC is extremely hard, making it highly resistant to abrasive slurries that would quickly wear down polypropylene or even stainless steel plates. This leads to a much longer service life. * Superior Chemical Resistance: SiC is inert to a wide range of aggressive chemicals, including strong acids and bases, where polypropylene might degrade or stainless steel would corrode. This is crucial for maintaining process purity and equipment longevity in chemical processing. * High-Temperature Stability: SiC can withstand very high operating temperatures (e.g., RBSC up to ~$1380^\\circ C$) without losing its mechanical properties, unlike plastics which have low melting points or metals that can soften or corrode more rapidly at high temperatures. * High Mechanical Strength: SiC plates maintain their rigidity and strength under high filtration pressures, preventing deformation and ensuring efficient operation. * Reduced Downtime and Lower Total Cost of Ownership: While the initial cost of SiC plates may be higher, their extended lifespan and reduced need for replacement and maintenance often result in a lower total cost of ownership.

Q2: How do I determine the right grade of silicon carbide (e.g., RBSC/SiSiC vs. SSiC) for my specific filter press application?

A2: The choice between Reaction-Bonded Silicon Carbide (RBSC or SiSiC) and Sintered Silicon Carbide (SSiC) depends primarily on the severity of your operating conditions: * RBSC/SiSiC: This is often the more cost-effective choice and performs excellently in many applications involving abrasive slurries and moderately corrosive chemicals. It contains a small percentage of free silicon, which might be a limiting factor in the presence of extremely aggressive chemicals (like strong hot alkalis or hydrofluoric acid). It’s a robust workhorse for general industrial filtration. * SSiC: This is a higher purity SiC with no free silicon, offering superior chemical resistance across the entire pH range and to very aggressive media. It also generally has slightly better wear resistance and can withstand higher temperatures. SSiC is the premium choice for the most extreme chemical environments or when utmost purity is paramount. We recommend consulting with material experts, such as the team at Sicarb Tech. By understanding your specific process parameters (slurry composition, pH, temperature, pressure, abrasiveness), we can help you select the optimal and most economical SiC grade.

Q3: Can custom features be incorporated into the design of SiC filter plates, and what are the typical lead times?

A3: Yes, absolutely. One of the key strengths of working with a specialized supplier like Sicarb Tech is the ability to obtain custom SiC filter plates tailored to your exact requirements. Custom features can include: * Specific plate dimensions and thickness. * Optimized drainage patterns (pips, grooves). * Customized feed and filtrate port designs and locations. * Specific sealing surface requirements and O-ring grooves. * Features for membrane support, if applicable. * Special surface finishes.

Lead times for custom SiC filter plates can vary significantly based on several factors:

* **Complexity of the Design:** More intricate designs or those requiring very tight tolerances may take longer.

* **Size of the Plates:** Larger plates require larger molds and longer processing times.

* **SiC Grade Selected:** Some grades may have slightly different processing requirements.

* **Quantity Ordered:** Larger orders might have phased deliveries.

* **Current Order Backlog:** Supplier capacity at the time of order.

Typically, lead times can range from several weeks to a few months. It is always best to discuss your specific needs and timeline with your supplier early in the project planning phase. **CAS new materials (SicSino)** strives to provide realistic and competitive lead times, leveraging our efficient manufacturing processes and expertise in producing **custom SiC components**.

Conclusion: Elevating Industrial Filtration with Custom Silicon Carbide

In the relentless pursuit of efficiency, durability, and performance in industrial filtration, custom silicon carbide filter presses and their components stand out as a superior solution for the most challenging environments. The inherent properties of SiC – its remarkable hardness, chemical inertness, thermal stability, and mechanical strength – translate directly into tangible benefits: extended equipment life, reduced downtime, lower maintenance burdens, and ultimately, a significantly improved total cost of ownership.

From handling fiercely abrasive mining slurries to withstanding highly corrosive chemical streams and high-temperature processes, SiC filter plates offer a level of reliability that conventional materials simply cannot match. The ability to customize these components further empowers industries to optimize their filtration systems for specific operational needs, ensuring maximum throughput and separation efficiency.

Choosing the right partner for your custom SiC requirements is paramount. Sicarb Tech, with its deep roots in Weifang City – the nucleus of China’s SiC innovation – and its backing by the prestigious Chinese Academy of Sciences, offers unparalleled expertise. Our comprehensive understanding of SiC materials, advanced manufacturing capabilities, and commitment to collaborative innovation make us an ideal supplier for engineers, procurement managers, and OEMs seeking high-quality, cost-effective custom silicon carbide solutions. We not only provide superior components but also offer the technological know-how to help you establish your own SiC production facilities if desired.

By embracing the advanced capabilities of silicon carbide and partnering with a knowledgeable supplier like Sicarb Tech, industries can overcome their toughest filtration challenges, enhance operational excellence, and secure a competitive edge in today’s demanding global market. Invest in the future of your filtration processes; invest in custom silicon carbide.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.