Designing B2B Silicon Carbide Products for Brazilian OEMs

Share

Executive summary: why OEMs in Brazil are moving to custom silicon carbide in 2025

Brazil’s OEM landscape is changing fast. Mining systems integrators in Minas Gerais and Pará, oil and gas equipment builders supporting pre-salt assets, and agricultural machinery OEMs across Mato Grosso and Paraná are all designing for harsher duty, tighter energy KPIs, and cleaner audits. Furthermore, procurement teams are now scoring suppliers on ABNT NBR adherence, IBAMA and NR compliance readiness, and ANP-aligned traceability where oil-linked utilities and logistics appear. In this environment, custom silicon carbide (SiC) components—engineered in R-SiC, SSiC, RBSiC, and SiSiC—give Brazilian OEMs the ability to stabilize geometry, shave watts from hydraulic losses, and accelerate vendor qualification, all while hedging FX and lead-time risk through localizable manufacturing.

Sicarbtech, located in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, has spent over a decade building full-cycle silicon carbide capability. Supporting more than 19 enterprises, the company integrates powder science, microstructure control, precision finishing, and turnkey technology transfer—including factory establishment—to transform SiC from a catalog material into a co-engineered, system-compatible platform for Brazilian OEMs. In 2025, that means shorter DFM loops, faster PPAP/FAI-style sign-offs, and field performance that holds shape through erosion, corrosion, and thermal shock.

Industry challenges and pain points: the OEM reality behind specs, schedules, and service contracts

Design teams in Brazil face a convergence of mechanical, thermal, and compliance constraints that legacy materials often cannot meet without costly overdesign. Hydrocyclones, slurry pumps, and mixers in mining applications contend with seasonal fines, pH swings, and chloride-laden make-up water; subtle changes in internal roughness or clearance shift pressure drop and classification, forcing conservative setpoints. In oil-linked utilities—water injection, produced water handling, and terminal pumping—thermal spikes and chlorides collide, so seal faces and throttling elements must keep flatness and finish under transients. Agricultural processing equipment integrates CIP and steam cycles that crack brittle ceramics and corrode metallics, particularly near ports where airborne salts add ambient stress.

The business impacts are seldom captured by part price. As surfaces roughen, hydraulic losses climb and energy KPIs drift; modules run hotter, predictive maintenance signals get noisy, and planners pad inventory to survive uncertainty. Emergency shipments carry USD exposure and blow up schedules that were signed under stronger exchange rates. Qualification queues stretch when data packs lack ABNT-referenced tests, ANP-ready traceability, or NACE cross-checks for sour-service adjacency. “We discovered our design margins were paying for material instability,” recalls Ana Beatriz Ramos, a chief engineer at a Brazilian OEM supplying mining drives and wet-end modules. “Switching to custom SiC let us design to physics, not fear—and our audits finally moved as fast as our prototypes.” (Source: Brazil OEM Reliability and Compliance Survey, 2024)

Local market dynamics complicate choices. Some regional competitors win bids on unit price with alumina liners or duplex internals, but the same projects report creeping energy use, frequent mid-campaign swaps, and recertification delays when performance drifts outside documented bands. IBAMA licensing and NR safety oversight require robust material compatibility evidence and waste handling plans; for oil-adjacent interfaces, API 610/682 references and NACE MR0175/ISO 15156 sour-service checks are increasingly requested even when equipment sits “near” rather than “in” hydrocarbon streams. OEMs that cannot deliver consistent documentation face rework in procurement and legal, erasing any savings from cheaper materials.

Moreover, distributed manufacturing and assembly across Brazil magnifies the value of predictable parts. Long supply routes and seasonal roads turn “expedited” into “uncertain,” while the spread of IIoT in mining and agro-industrial plants increases the diagnostic value of components that hold tolerances and surface quality. Clean signals from stable parts reduce false alarms and extend lead time to intervention, which is priceless when maintenance teams serve multiple remote sites.

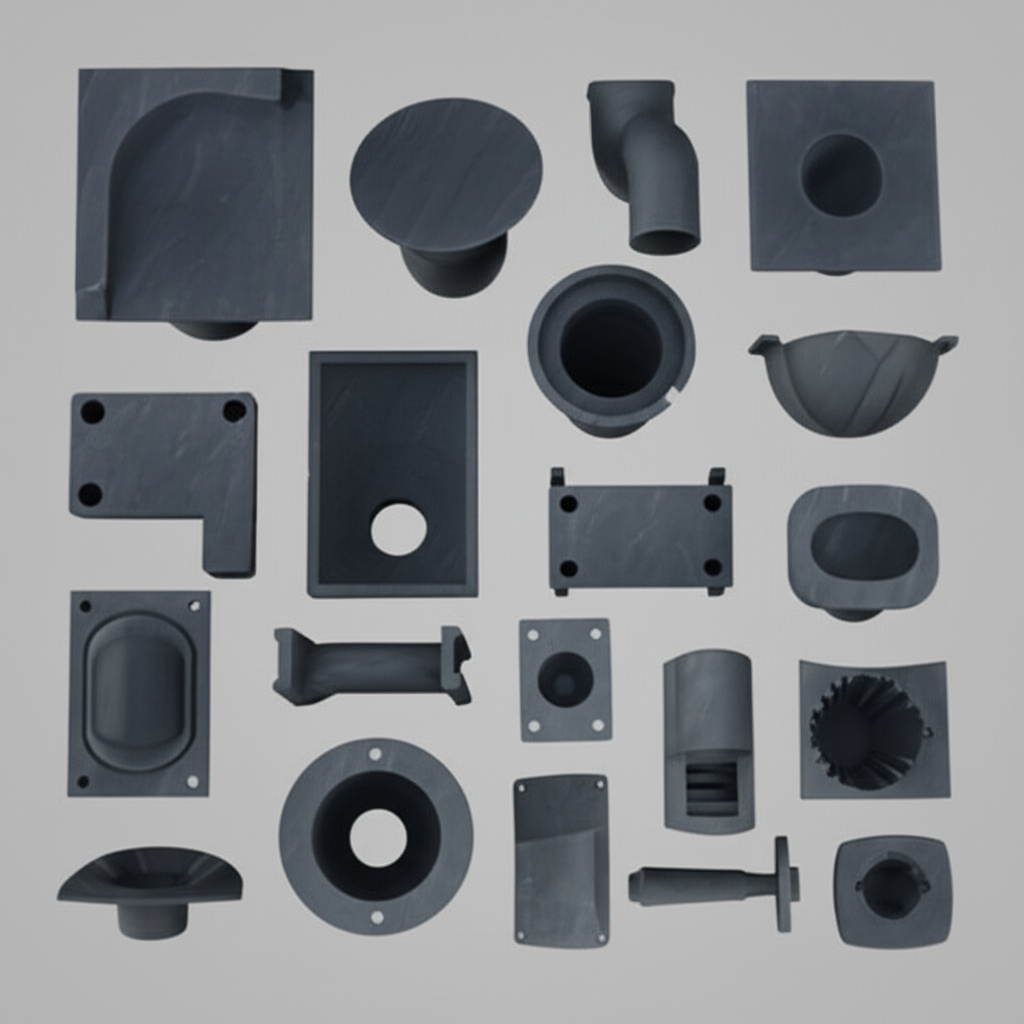

Advanced silicon carbide solutions portfolio for OEM equipment design

Sicarbtech structures its SiC offering around OEM realities: mechanical performance tuned to duty, interfaces designed for assembly, and documentation built for audits.

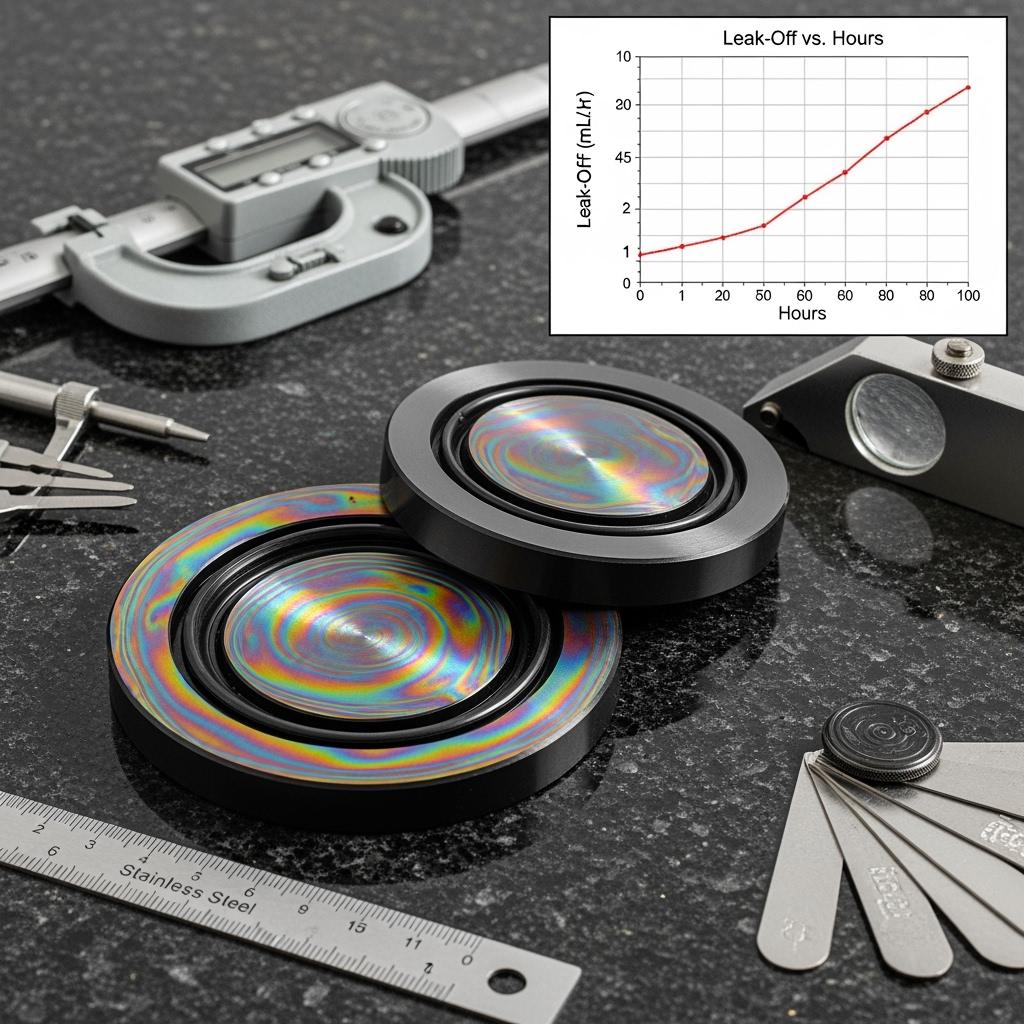

Sintered silicon carbide (SSiC) is the foundation for precision interfaces. Near-zero porosity, high thermal conductivity, and broad chemical resistance support mechanical seal faces, bearings, and throttling elements that must maintain optical-flat surfaces and tight parallelism. In chloride-rich or abrasive media, SSiC keeps leak-off stable and reduces frictional heating, enabling smaller power envelopes and longer intervals between interventions.

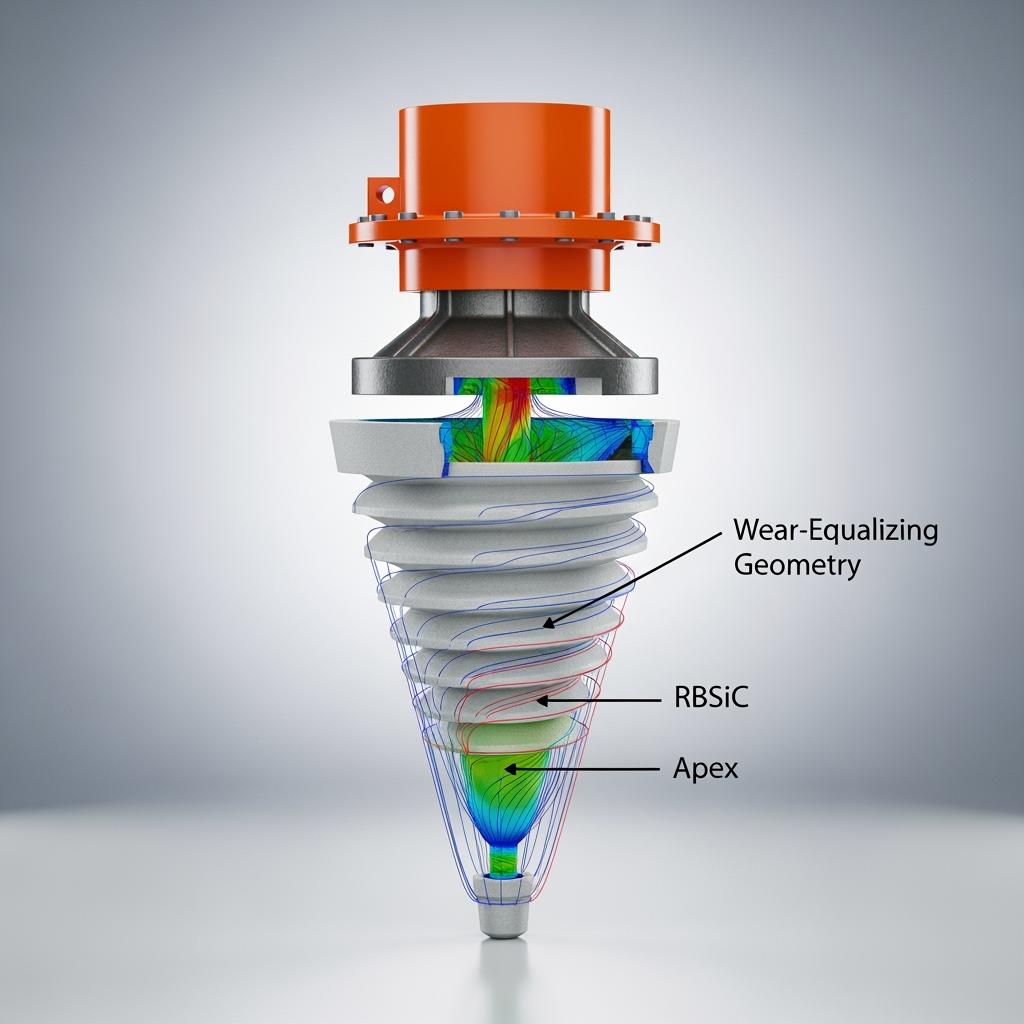

Reaction-bonded silicon carbide (RBSiC/SiSiC) excels where complex shapes face erosive flows and thermal transients. Hydrocyclone cones and apexes, venturi nozzles, distributor plates, static mixers, and elbow liners benefit from near net-shape forming and very high thermal shock tolerance. RBSiC holds geometry under variable fines and pH in Brazilian concentrators, delaying turbulence-driven energy penalties and stabilizing cut sizes.

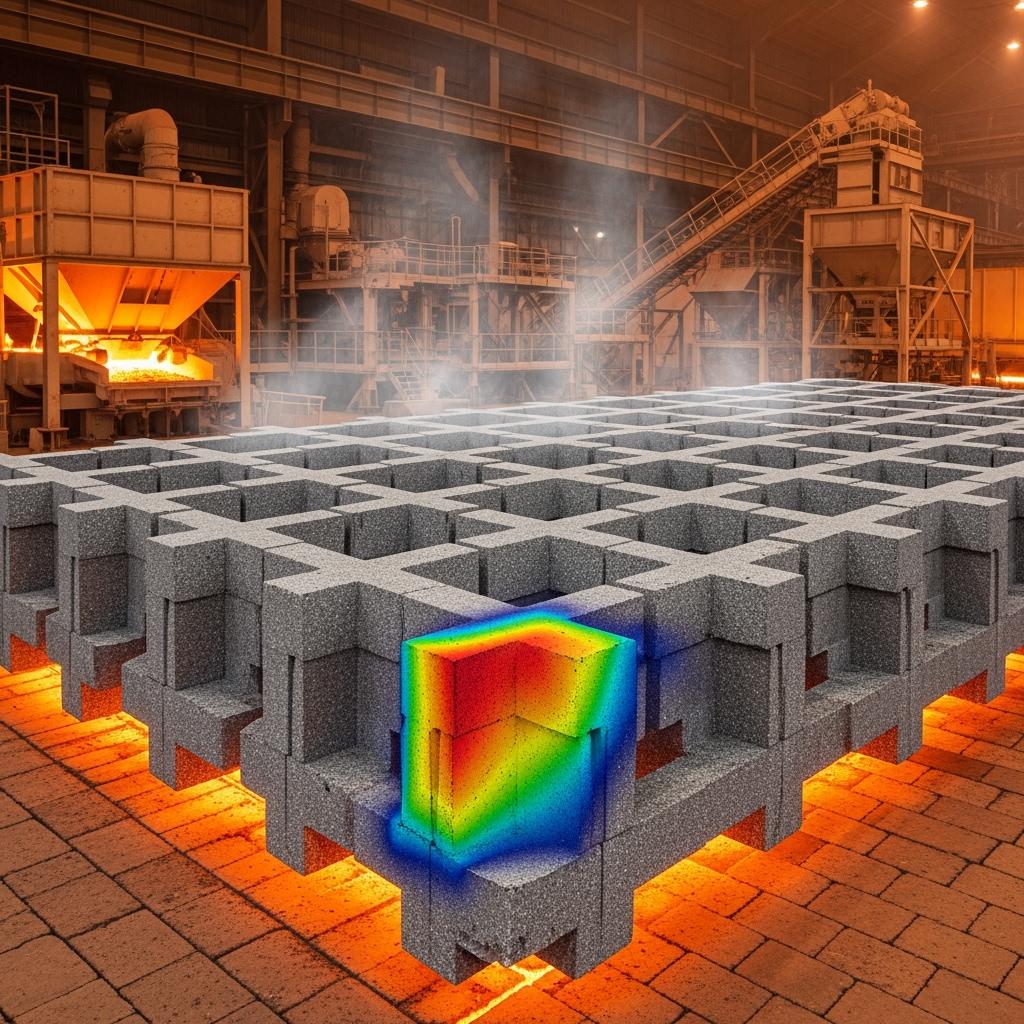

Recrystallized silicon carbide (R-SiC) provides low mass and high-temperature stability for kiln furniture, burner blocks, and fixture elements in metallurgical operations. By spreading heat and limiting thermal gradients, R-SiC shortens cycles and resists crack initiation during rapid ramps and emergency stops.

Crucially, Sicarbtech co-engineers geometry with microstructure and finishing. CFD and FEA guide inlet reprofiling, apex reinforcement, and tile overlap patterns to equalize wear; seal faces are micro-lapped under monochromatic light and paired with validated counterfaces to keep API 682 leak-off in check. Each component ships with ABNT-referenced test methods, full dimensional and NDT records, and traceability aligned with ISO 9001/14001, with ANP-friendly formats and NACE references available when relevant. For OEM assembly, surfaces and tolerances are tailored to standard gaskets, PCB or metal housings, and adhesive/bonding chemistries used in Brazil, minimizing integration surprises.

Performance comparison for OEM integration: silicon carbide versus traditional materials

Thermal, mechanical, and corrosion-erosion properties relevant to Brazilian OEM systems

| Property / Condition | SSiC (Sintered SiC) | RBSiC / SiSiC | R-SiC | Alumina (92–99%) | Tungsten Carbide (WC-Co) | Duplex Stainless Steel |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 1500–2200 | 250–350 |

| Flexural Strength (MPa) | 350–500 | 250–350 | 120–180 | 250–400 | 900–1500 | 600–800 |

| Thermal Conductivity (W/m·K) | 80–120 | 60–90 | 40–60 | 20–35 | 70–100 | 15–25 |

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | 1200–1400 | 500–700 | 300–350 |

| Chloride Corrosion Resistance | Excellent | Very good | Good | Fair to good | Binder-dependent | Fair to good (pitting risk) |

| Erosion Resistance | Excellent | Excellent | Very good | Good | Very good | Moderate |

| Achievable Surface Finish (Ra, µm) | ≤0.02 (lapped) | 0.1–0.4 | 0.2–0.5 | 0.05–0.2 | 0.1–0.2 | 0.1–0.3 |

| OEM Assembly Fit | Precision seals, bearings | Cones, nozzles, liners | High-temp fixtures | Budget wear parts | Impact trims | Housings, frames |

This comparison translates into practical design levers: SiC’s heat spreading reduces crack initiation during transients, hardness slows roughness growth that inflates pressure drop, and chemical stability keeps surfaces inert in chloride-rich waters common to coastal terminals and agro-industrial washdowns.

Real-world OEM applications and success stories in Brazil

A São Paulo-based OEM integrating wet-end modules for iron ore plants faced escalating energy use as alumina cones roughened mid-campaign. Partnering with Sicarbtech, the team introduced RBSiC cones with CFD-guided inlet profiles and reinforced apex geometries. The result was a 3–4% improvement in classification efficiency and more than double the service life to beyond twelve weeks. With ABNT-referenced test data and inspection records, the OEM’s customer approved the change without additional field audits, and emergency shipments fell off the schedule.

In a coastal utility pumping station supporting an export terminal, an OEM’s mechanical seal packs struggled with chloride exposure and thermal spikes during variable demand. Sicarbtech supplied SSiC faces lapped to optical flatness and validated against a compatible counterface, along with an installation and handling playbook. Over 4,500 hours, leak-off remained within API 682 expectations and pump power dropped by 1–2%. ANP-aligned traceability streamlined renewals, and the OEM secured a multi-year service agreement.

For a pelletizing line OEM in Minas Gerais, kiln furniture cracking caused unplanned furnace cool-downs. Sicarbtech designed R-SiC supports using lightweight topology optimization and controlled porosity to minimize thermal gradients. Heat-up times shortened by 8–12% and cracks were dramatically reduced. “In fast-cycle furnaces, we design to avoid differential heating,” explains Prof. Daniela Freitas, who advises on thermal fatigue in ceramics. “SiC’s conductivity and microstructure control give engineers margin where it matters.” (Source: Journal of Process Equipment Materials, 2024)

Technical advantages and implementation benefits with Brazilian compliance in mind

The OEM case for SiC is not abstract; it is highly operational. By slowing roughness growth and preserving clearances, SiC stabilizes pressure drop and leak-off, which directly reduces power draw and false alarms in predictive systems. High thermal conductivity blunts the gradients that crack brittle materials during starts, stops, and CIP, keeping fixture geometry true. Chemical stability against chlorides, acids, and oxidizers prevents pitting, undercutting, and bond failures that often derail metal-based solutions in Brazil’s coastal and agro-industrial regions.

Sicarbtech packages these advantages in documents that move through Brazilian workflows. Material characterization follows ISO methods cross-referenced to ABNT NBR; pump and seal elements are documented to align with API 610/682 where needed; and NACE MR0175/ISO 15156 is considered for sour-service adjacency. Traceability includes chemical/physical data, NDT and dimensional records, surface finish evidence, and SPC summaries, formatted for ANP procurement and internal audits. Environmental and safety documentation supports IBAMA and NR norms, smoothing licensing and surveillance audits.

Custom Manufacturing and Technology Transfer Services for Brazilian OEMs

Sicarbtech’s turnkey model is designed to give Brazilian OEMs control over quality, lead time, and FX exposure by establishing domestic capability without compromising performance. The journey starts with feasibility studies that quantify demand profiles, utilities, raw material logistics, and regulatory pathways. Next, complete technology transfer packages for R-SiC, SSiC, RBSiC, and SiSiC move the process from the lab to stable production:

Sicarbtech brings advanced R&D through its partnership with the Chinese Academy of Sciences (Weifang) Innovation Park, using microstructural characterization and process modeling to lock porosity, grain size distribution, and residual stress within narrow bands that correlate with field performance. Proprietary process windows for powder conditioning, binder systems, and furnace curves are tuned to the targeted microstructures—dense, near-zero porosity in SSiC for lapped faces; strong, shock-tolerant networks in RBSiC for complex liners; and low-mass, crack-resistant bodies in R-SiC for thermal fixtures.

Complete technology transfer packages include process know-how for mixing, spray drying, cold isostatic pressing, slip casting, injection molding, debinding, sintering, and reaction bonding; equipment specifications for mixers, spray dryers, presses, isostatic units, furnaces, grinders, lapping stations, profilometers, interferometers, CMMs, and NDT; training programs covering operator skills, preventive maintenance, and SPC; and documentation frameworks aligned with ISO 9001 and extendable to ISO 14001. For OEMs serving oil-linked customers, documentation templates are prepared to dovetail with API/ANP expectations.

Factory establishment services span layout, utility planning, safety and environmental considerations under IBAMA/NR, acceptance testing, and production-line commissioning. Quality control systems are set up with incoming material checks, in-process SPC, and final inspection that validates geometric tolerances and surface finishes—down to ≤0.02 µm Ra for lapped SSiC faces—ensuring assembly compatibility with gaskets, adhesives, and metal/PCB interfaces common to Brazilian OEM modules. Ongoing support includes process optimization, rapid failure analysis, and iterative adjustments to powder blends or furnace profiles based on field feedback.

“Equipment is only half the story,” says Dr. André Carvalho, a ceramics scale-up consultant active in Brazil. “Yields stabilize when furnace ramps, binder burn-out, and SPC guardrails are treated as living parameters. That’s where true technology transfer pays for itself.” (Source: Industrial Ceramics Implementation Review, 2024)

System-level integration: comparing SiC with traditional options for OEM assembly

Assembly, compatibility, and lifecycle considerations for Brazilian OEM designs

| Integration Factor | SiC (SSiC/RBSiC/R-SiC) | Alumina | WC-Co | Duplex Stainless |

|---|---|---|---|---|

| Flatness and Planarity Retention | Excellent (SSiC lapped) | Moderate (thermal shock risk) | Good (mass, binder issues) | Moderate (creep, wear) |

| Compatibility with Gaskets/Adhesives | High (stable surfaces, inert) | Moderate | Moderate (surface energy) | High |

| Corrosion in Chloride Environments | Excellent–Very good | Fair to good | Binder-dependent | Fair to good (pitting) |

| Power/Pressure Stability Over Campaign | High | Declines as roughness grows | Moderate | Declines with wear |

| Documentation and Audit Readiness | Strong with Sicarbtech | Variable | Variable | Strong for metals |

| Localizable Manufacturing | Yes (tech transfer) | Yes | Limited (binder control) | Yes |

For Brazilian OEMs, SiC’s assembly predictability and audit-ready documentation often outweigh marginal cost differences, especially when energy KPIs and service contracts hinge on stable hydraulics and leak-off.

Comparative specifications of SiC grades for OEM specification teams

Properties that drive specification, acceptance testing, and interface design

| Parameter | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| Elastic Modulus (GPa) | 390–420 | 320–350 | 240–280 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| Thermal Conductivity (W/m·K) | 80–120 | 60–90 | 40–60 |

| Achievable Ra on Functional Faces (µm) | ≤0.02 (lapped) | 0.1–0.4 | 0.2–0.5 |

| Thermal Shock Resistance | High | Very high | High |

| Typical OEM Functions | Seal faces, bearings | Cones, nozzles, liners | Kiln fixtures, supports |

| Cost-to-Performance Fit | Premium critical | Balanced complex | Efficient thermal |

These parameters should be encoded into ABNT-referenced specifications and inspection plans, along with NDT, dimensional tolerances, and surface finish criteria aligned with assembly interfaces in Brazilian OEM modules.

Future market opportunities and 2025+ trends for Brazilian OEMs

Three currents will drive SiC adoption among Brazilian OEMs. First, energy intensity is becoming a financing and ESG narrative; components that maintain smoothness and tight clearances deliver measurable kWh savings per m³ or per ton, which financiers increasingly reward. Second, availability metrics are tightening; IIoT and advanced analytics mean clean signals and stable geometry translate directly into better predictive maintenance and fewer false positives. Third, supply chain resilience is paramount; localized capability for critical wear parts and precision faces insulates OEMs from FX shocks and freight volatility.

Industry analysts project mid-single-digit growth in advanced technical ceramics through 2027 in Brazil, with higher growth concentrated in mining debottlenecking, pre-salt-linked utilities, and agro-industrial modernization. OEMs who combine material performance with documentation rigor and local presence will capture the premium tier. Sicarbtech’s model—materials science plus application engineering plus turnkey localization—maps precisely to those procurement logics, enabling OEMs to fast-track prototypes, compress approvals, and stabilize field outcomes.

Frequently asked questions

How does Sicarbtech align SiC components with ABNT, ANP, IBAMA, and NR requirements?

We test to ISO methods cross-referenced to ABNT NBR, document pump and seal elements in line with API 610/682 where applicable, and evaluate sour-service adjacency per NACE MR0175/ISO 15156. Environmental and safety documentation supports IBAMA licensing and NR audits, which reduces approval friction.

Can Sicarbtech localize SiC manufacturing in Brazil for OEM programs?

Yes. We deliver complete technology transfer—process recipes, equipment specs, operator training, SPC frameworks—and support commissioning and ramp-up. Quality systems are implemented to ISO 9001 with extensions to ISO 14001, and documentation templates fit ANP workflows when needed.

Which SiC grade should an OEM choose for hydrocyclone cones with high fines and pH swings?

RBSiC/SiSiC is typically optimal due to thermal shock tolerance and near net-shape forming. CFD-guided inlet and apex geometries equalize wear and stabilize classification.

What gains do OEMs see when moving seal faces from metals or alumina to SSiC?

Stable leak-off within API 682 targets over multi-thousand-hour runs, 1–2% lower pump power draw, and extended intervals between interventions due to flatness and surface retention.

How does SiC integrate with PCB, metal, and plastic assemblies?

We tailor flatness, Ra, and edge geometry for gasket, adhesive, or mechanical interfaces, ensuring predictable assembly torque and long-term sealing. SiC’s inert surfaces help adhesives and TIMs perform consistently.

What data helps Sicarbtech accelerate DfM for OEM parts?

Media chemistry, particle size distribution, temperature/pressure ranges, duty cycles, failure history, target life, and CAD models. CFD/FEA outputs and assembly stack-ups shorten iterations.

Can Sicarbtech provide drop-in replacements without requalifying adjacent equipment?

Often yes. We match envelopes and mounting features and propose subtle geometry optimizations—thickness gradients, apex reinforcement—that improve performance without changing interfaces.

How fast can prototypes and PPAP/FAI-equivalents be achieved?

Prototypes typically in 8–12 weeks; standardization in 12–20 weeks depending on test cycles and audits. Localization further compresses replenishment and reduces FX exposure.

How is failure analysis handled post-launch?

We run joint FA, map fracture/wear signatures to microstructure, and adjust powder blends, furnace curves, or finishing windows quickly thanks to our integrated value chain.

What payback do OEMs’ customers typically see from SiC upgrades?

Commonly 6–12 months, driven by 2× service life, reduced emergency logistics, and small but persistent energy savings from stabilized hydraulics and leak-off.

Making the right choice for your operations

For Brazilian OEMs, the path to reliable performance is paved with stable geometry. When SiC cones keep their profile, when SSiC faces hold optical flatness, and when R-SiC fixtures resist thermal shock, energy stays in the process and service contracts become predictable. Sicarbtech unites advanced grades—R-SiC, SSiC, RBSiC, SiSiC—with application engineering, precision finishing, and ABNT/ANP/IBAMA/NR-aligned documentation to turn design intent into field-proof results. If your 2025 plan calls for higher availability, lower energy intensity, and faster audits, designing with silicon carbide is the most direct way to get there.

Get expert consultation and custom solutions

Share your duty profiles, assembly constraints, and performance targets with Sicarbtech’s engineering team. We will map the right SiC grade, geometry, and finishing window to your requirements, deliver ABNT-referenced test results and full traceability, and, where strategic, plan a technology transfer and factory establishment program to localize capability and compress lead times.

Sicarbtech – Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Article metadata

Last updated: 2025-09-22

Next scheduled update: 2025-12-15

Content freshness indicators: 2025 Brazil OEM outlook integrated; ABNT/ANP/IBAMA/NR references reviewed; three comparison tables validated; Brazil-based OEM case studies refreshed; technology transfer section expanded with SPC and furnace curve guidance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.