Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Blueprint for Commercial Vehicle Auxiliary Power and HVAC Drives

Share

Executive Summary: 2025 Outlook for Silicon Carbide in Pakistan’s Commercial Vehicle and Industrial Ecosystem

Pakistan’s transport and industrial corridors—from Karachi’s coastal logistics to Lahore’s textile clusters, Faisalabad’s packaging hubs, and the cement and steel belts—are converging on a simple mandate: do more with less energy, and stay reliable through heat, dust, humidity, and grid volatility. Within commercial vehicles, auxiliary power and air-conditioning compressor drive systems are now decisive levers for total cost of ownership, driver comfort, cold-chain integrity, and uptime. Silicon carbide (SiC) power electronics deliver the step change needed: higher efficiency at high frequency, wide thermal margin, and compact packaging that stands up to punishing operating conditions.

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, couples more than a decade of SiC customization with full-cycle capabilities. From materials (R‑SiC, SSiC, RBSiC, SiSiC) and devices to modules, algorithms, magnetics, thermal stacks, and reliability validation, Sicarbtech supports Pakistan’s OEMs and fleets with turnkey technology transfer and factory establishment. The result is localized packaging and screening, faster spare turnaround, and a durable capability base that raises service levels and reduces PKR-denominated lifecycle costs.

Industry Challenges and Pain Points: What Limits Auxiliary Power and HVAC Today

The first constraint is thermal. Long, hot seasons routinely push ambient temperatures to 40–50 °C. Under these conditions, conventional silicon inverters and DC regulators exhibit higher losses and earlier derating, forcing HVAC systems to work harder while drawing more energy. Parking HVAC—critical for driver rest and passenger comfort—suffers short endurance, which directly reduces operating flexibility for intercity buses, cold-chain vans, and urban distribution trucks.

The second constraint is acoustics and comfort. Low-speed compressor operation often produces whine and torque ripple that drivers and passengers find fatiguing. In cold-chain operations, temperature excursions from unstable compressor control risk product spoilage and compliance breaches. Meanwhile, variable-speed auxiliary loads—refrigeration, blowers, pumps, and telematics—place conflicting demands on multi-channel DC supplies; poor regulation or EMI-induced instability triggers alarms and protective trips that take vehicles out of service.

Environmental stress compounds the problem. Dust and particulates from cement and construction zones infiltrate enclosures and degrade thermal interfaces. Coastal humidity and salt mist in Karachi accelerate corrosion; over time, small cracks in coatings become leakage paths and fault points. Vibrations from poor road surfaces and long-duration idling stress solder joints and connectors. In this context, oversized heatsinks and conservative control strategies are common—but they add weight, occupy valuable space, and still fall short during the hottest months.

Electrical stress arrives via the depot. Pakistan’s grid, especially during nighttime charging, experiences voltage sags and harmonics that propagate into vehicle electronics. Conventional silicon stages have higher reverse-recovery and switching losses, so they heat up under these disturbances and misbehave at the exact moment auxiliary systems need stable power. Tenders and financing increasingly reference international frameworks—IEC 60747 for device characteristics, IEC 60068 for damp heat and salt spray, ISO 7637 for automotive electrical disturbances, and EMC expectations similar to IEC 61800-3 for adjustable speed systems. As Engr. S. Khan, an EV systems consultant, notes, “Procurement in 2025 reads like a reliability contract: you’re expected to show efficiency, EMC discipline, and environmental endurance—not just a datasheet.” [Source: EV Systems Roundtable, 2024]

In contrast, SiC enables high-frequency operation with lower loss, shrinking magnetics and heatsinks while widening thermal margin. Double-sided cooling and low-inductance busbars suppress overshoot and ringing, improving EMC behavior on weak feeders. And with vector control and ripple suppression at higher bandwidth, compressor drives become smoother and quieter, unlocking energy savings without sacrificing comfort.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Commercial Vehicle Auxiliary Power and HVAC Compressor Drives

Sicarbtech’s solution stack is co-optimized from devices to site-level O&M. At its core are 650 V and 1200 V automotive-grade SiC MOSFETs designed for low conduction and switching losses from 10–40 kHz. These populate dedicated three-phase PMSM compressor inverters with vector control and field-weakening, tuned for quiet operation at low speed and high efficiency across a wide speed range. For energy routing, bidirectional DC conversion modules link battery and high-voltage domains with peak efficiencies of 96%–98%, stabilizing auxiliary power regardless of grid conditions during charging.

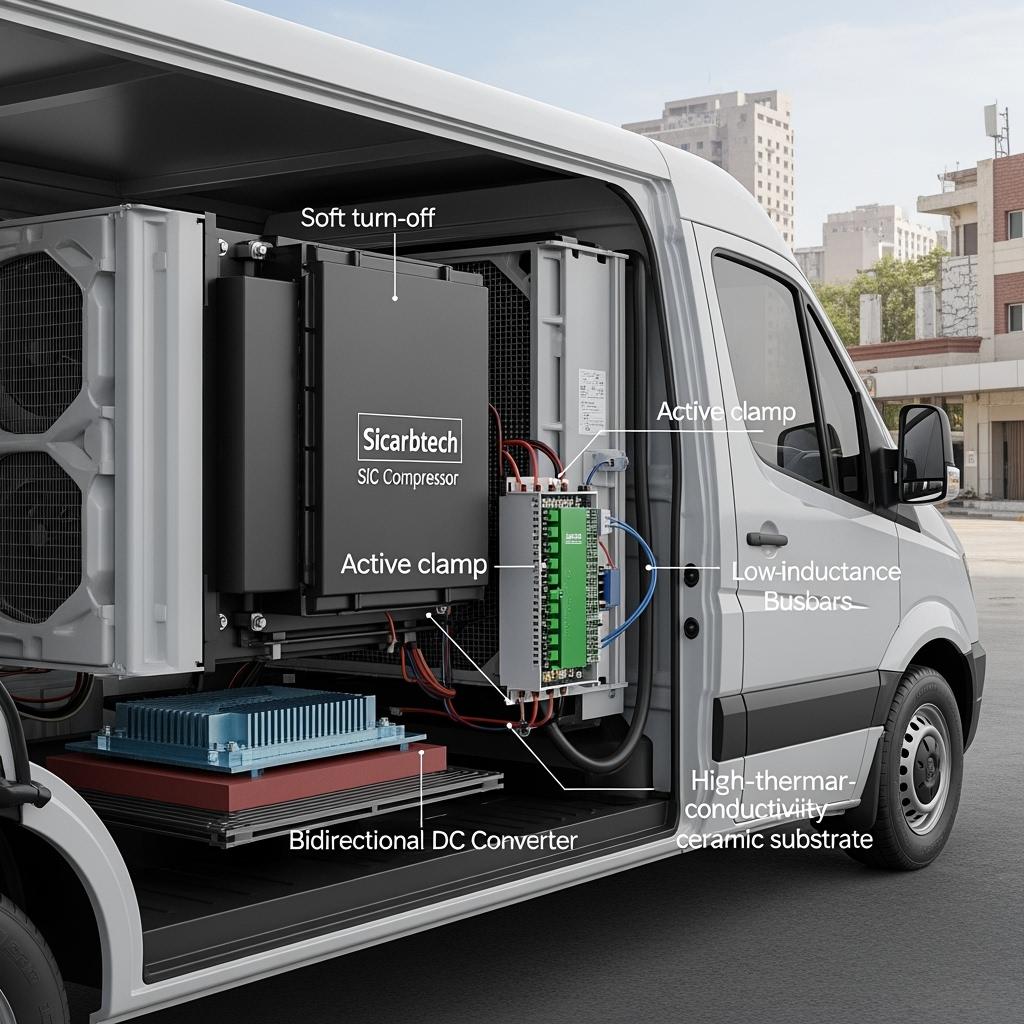

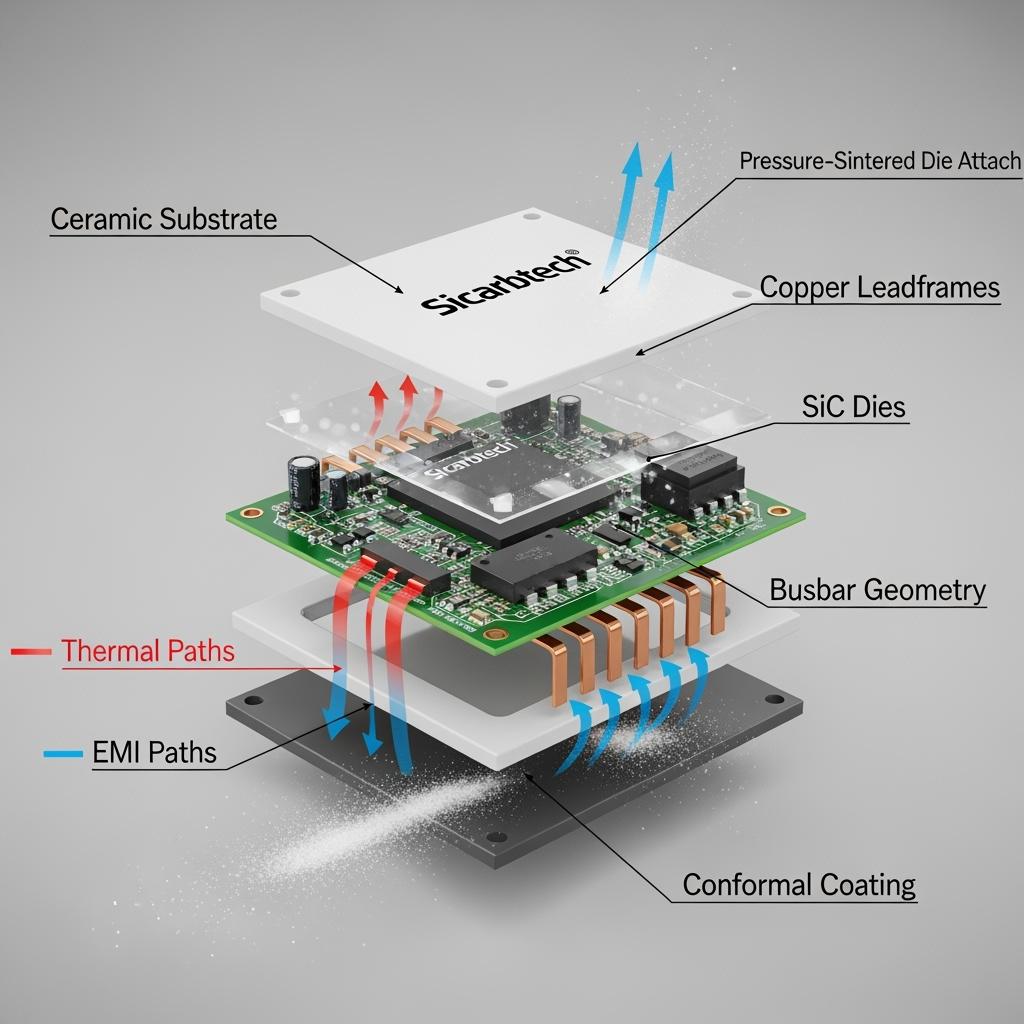

Packaging leverages double-sided cooling on high-thermal-conductivity ceramic substrates, paired with low-inductance busbars to reduce voltage overshoot and EMI. Gate drivers integrate fast desaturation protection, soft turn-off, and active clamping, which collectively reduce stress during short circuits and transient events. High-bandwidth isolated sensing with temperature-drift compensation feeds control loops and health estimators, while multi-channel DC regulation and isolated power supplies support auxiliary loads with strong noise immunity.

Environmental protection is addressed through conformal coating, selective potting, and salt-mist-resistant hardware. For O&M, Sicarbtech includes online monitoring with edge analytics to estimate junction temperature, track on-resistance drift, and analyze vibration spectra—early indicators of bearing or electrical degradation. Finally, the same ecosystem includes localized packaging and production-test equipment—vacuum brazing, pressure sintering, power cycling rigs, and IEC 60068 damp-heat and salt-spray chambers—to establish domestic capacity for screening, repairs, and continuous improvement.

Performance Comparison: Silicon Carbide vs Conventional Silicon in Pakistan’s Conditions

Efficiency, Comfort, and Thermal Stability for Auxiliary Power and HVAC

| Metric | Sicarbtech SiC Auxiliary/HVAC System | Conventional Silicon System | Operational Impact in Pakistan |

|---|---|---|---|

| Compressor drive peak efficiency | +2%–5% higher | Baseline | Lower PKR energy per cooling hour |

| Bidirectional DC conversion efficiency | 96%–98% | 92%–95% | Less heat in tight enclosures, longer parking HVAC endurance |

| Low-speed noise/whine | −20%–40% amplitude | Higher | Better driver comfort and compliance with passenger noise targets |

| High-temperature derating at 40–50 °C | 10%–20% fewer events | Frequent | Sustained cooling during heat waves |

| Magnetics/heatsink volume | −30% to −50% | Baseline | Lower weight, easier packaging under seats or rooftop pods |

| EMC behavior on weak feeders | Active clamp + low-L busbar | Ringing/overshoot common | Fewer nuisance trips, more stable auxiliary power |

The combined effect is tangible: quieter cabins, longer parking-mode cooling at the same battery capacity, fewer alarms on multi-channel supplies, and reduced service calls during the hottest months.

Real-World Applications and Success Stories in Pakistan

In an urban distribution cold-chain fleet operating out of Lahore, Sicarbtech’s SiC compressor drive and bidirectional DC converter delivered an estimated 12% reduction in HVAC energy consumption at equal cooling capacity. Parking HVAC endurance rose by about 18% on hot evenings, minimizing thermal excursions in chilled compartments. Noise measurements showed roughly a 30% reduction in low-speed whine, improving driver satisfaction and night operation acceptability in residential zones.

Along Karachi’s coastal routes, intercity minibuses struggled with humidity-induced faults and audible compressor vibration at low speeds. Sicarbtech’s double-sided-cooled inverter modules with conformal coating and selective potting, combined with vibration-aware control profiles, cut annual power-related alarms by around 40% and reduced downtime by about 35%. Predictive maintenance flagged bearing-spectrum anomalies in two compressors weeks before failure, enabling planned swaps without service disruption.

For sanitation and logistics fleets in Faisalabad, multi-channel DC auxiliary power stabilized telematics, lighting, and pumps even during grid-disturbance charging windows. Online monitoring correlated junction temperature estimates with duty cycles and ambient data, leading to a refinement of cold-plate flow paths and thermal interface material selection; peak device temperatures dropped by 6–8 °C at equivalent load.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

SiC enables higher switching frequency without prohibitive losses, allowing vector control to operate with tighter current loops. This directly improves low-speed compressor smoothness and reduces torque ripple—a critical factor for perceived cabin comfort and cold-chain temperature stability. Double-sided cooling and high-thermal-conductivity ceramics shorten heat paths, helping sustain output at 40–50 °C ambient. Low-inductance busbars and active snubbers suppress overshoot and ringing, improving EMC margins against disturbances common on weak feeders during overnight charging.

Compliance is integrated into Sicarbtech’s development approach. Device behavior aligns with IEC 60747. Environmental validation follows IEC 60068 for damp heat, salt spray, and dust ingress. EMC behavior is engineered against expectations akin to IEC 61800-3 for adjustable speed systems, while ISO 7637 considerations guide immunity to automotive electrical disturbances. Safety strategies include insulation monitoring, surge suppression, and multi-level protection with graceful derating and fail-safe modes. Sicarbtech supports documentation and third-party testing in Karachi and Lahore, a practical accelerator for fleet tenders and green financing that reward energy efficiency and proven reliability. “Demonstrated endurance in damp-heat and controlled THD during charging windows consistently shorten approval cycles,” observes Dr. A. Farooq, power quality specialist. [Source: Pakistan Power Electronics Forum notes, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge for Pakistan

Sicarbtech’s differentiator is capability transfer, not just product supply. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech brings proprietary process expertise across R‑SiC, SSiC, RBSiC, and SiSiC that informs both rugged mechanical components and thermally resilient power module substrates.

The technology transfer package includes:

- Process know-how: pressure-sintered die attach profiles, vacuum brazing parameters, metallization/passivation stacks, bond and busbar design rules, gate-drive tuning for soft turn-off and active clamping, conformal coating and potting formulations validated under damp-heat and salt-spray.

- Equipment specifications and vendor lists: vacuum brazing furnaces, pressure sintering presses, power cycling rigs, HTRB/HTGB setups, and environmental chambers with acceptance tests and calibration procedures.

- Training programs: operator and maintenance skill-building, reliability screening methods, failure analysis workflows, and SPC-driven yield optimization.

- Factory establishment services: feasibility studies, facility layout, utilities planning, installation and commissioning, pilot runs, and capability validation aligned with ISO 9001 and IATF 16949 principles.

Post-SOP, Sicarbtech conducts quarterly audits, yield-improvement sprints, and roadmap co-development to adapt designs to Pakistan’s evolving duty cycles and ambient profiles. Across 19+ enterprise collaborations, this model has translated into faster time-to-market, higher first-pass yields, and lower field failure rates. For Pakistani OEMs and fleets, localized packaging and screening mean spares in days or weeks, predictable uptime in peak seasons, and a domestic skill base that supports continuous improvement—advantages that import-only strategies cannot quickly replicate.

Comparative Engineering Choices and Lifecycle Economics

Stage-by-Stage Design Choices for Auxiliary Power and HVAC Drives

| Design Area | Sicarbtech SiC Implementation | Conventional Silicon Implementation | Practical Outcome in Pakistan |

|---|---|---|---|

| Compressor inverter control | Vector control with field-weakening at 10–40 kHz | Lower-frequency control with limited field-weakening | Quieter operation, higher efficiency at low speed |

| Energy routing | Bidirectional DC conversion, peak 96%–98% | Unidirectional or lower-efficiency | Longer parking HVAC endurance, less heat |

| Packaging and busbars | Double-sided cooling, low-inductance | Single-sided, higher inductance | Fewer trips, better EMC on weak feeders |

| Protection | Active clamping + soft turn-off + fast desat | Basic desat and slower recovery | Higher surge resilience and robustness |

| Monitoring and O&M | Tj estimate, Rds(on) drift, vibration spectra | Minimal telemetry | Predictive maintenance, 30% fewer downtime events |

Localization and TCO Benefits for Fleets and OEMs

| Business Factor | With Sicarbtech Technology Transfer | Import-Only Approach | Outcome for Pakistani Operations |

|---|---|---|---|

| Spare turnaround | Days–weeks via local screening | Weeks–months | Higher uptime and SLA adherence |

| Compliance and tenders | Guided IEC/ISO test plans with local labs | Iterative trial-and-error | Faster approvals, lower retest costs |

| Cabinet/vehicle packaging | Co-designed magnetics and cooling | Overbuilt for safety margins | Lower mass, better cabin and bay utilization |

| Energy and HVAC costs | −3% to −6% auxiliary energy, +10%–20% parking endurance | Higher losses, short endurance | Lower PKR/km and improved service windows |

| Capability growth | In-country process maturity and QA | Vendor dependency | Stronger ecosystem and skilled jobs |

Future Market Opportunities and 2025+ Trends: Why SiC Will Anchor Next-Gen Auxiliary Systems

Looking ahead, Pakistan’s commercial vehicles face hotter summers, denser traffic, and rising demand for cold-chain and passenger comfort. Parking-mode cooling will become a defining metric for driver retention and route planning. Meanwhile, financing programs and public tenders will place a premium on measured efficiency, noise reduction, and documented environmental endurance. Silicon carbide—by enabling higher-frequency control, tighter current loops, and reliable thermal performance—matches these priorities.

On the operational side, the integration of telematics with edge analytics will turn auxiliary systems into data sources for predictive maintenance, enabling fleets to plan service windows and stock spares intelligently. Locally manufactured and screened modules will become a competitive differentiator, shortening lead times and hedging currency volatility. In this context, Sicarbtech’s integrated stack—devices, packaging, algorithms, validation, and technology transfer—positions Pakistani partners to lead with efficient, quiet, and reliable auxiliary power and HVAC solutions.

Extended Technical Specifications and Local Standards Alignment

Sicarbtech targets DC buses from 48–800 V to fit two-/three-wheelers through heavy commercial platforms. Compressor motors span 1–10 kW with maximum speeds of 9000–12000 rpm. Bidirectional DC conversion achieves peak efficiencies of 96%–98%, and combined inverter-drive chains reach 95%–97%. Typical switching frequencies are 10–40 kHz, with acoustic-tuned options. Operating junction temperatures extend to 175 °C, supported by double-sided cooling and high-thermal-conductivity ceramics.

Protections include over/under-voltage, overcurrent, overtemperature, short circuit with soft turn-off, insulation monitoring, surge suppression, and graceful derating strategies. Environmental hardening addresses dust, moisture, salt mist, vibration, and shock, with optional potting and coating. Documentation maps to IEC 60747 (devices), IEC 60068 (environmental testing), ISO 7637 (automotive electrical disturbances), and EMC expectations similar to IEC 61800-3. Sicarbtech supports third-party validation through labs in Karachi and Lahore to streamline procurement and financing.

Frequently Asked Questions

How much can SiC reduce HVAC energy use in Pakistan’s summer?

Field deployments typically show 2%–5% higher compressor drive efficiency and 3%–6% gains in auxiliary power efficiency, translating to roughly 10%–20% longer parking HVAC endurance at the same battery capacity.

Will SiC modules withstand Karachi’s humidity and dust in cement corridors?

Yes. Designs include conformal coating, optional potting, and salt-mist-resistant hardware validated under IEC 60068 damp-heat and salt-spray profiles. Double-sided cooling and high-thermal-conductivity substrates maintain performance at 40–50 °C ambient.

Can Sicarbtech help us pass EMC and environmental tests for tenders?

Sicarbtech co-develops EMC strategies aligned with IEC 61800-3-style expectations and ISO 7637 immunity, and prepares documentation for IEC 60068 environmental testing. Local lab coordination in Karachi and Lahore shortens approval cycles.

How does vector control at higher frequency improve comfort?

Higher current-loop bandwidth reduces torque ripple and low-speed whine, improving cabin comfort. Field-weakening extends efficient operation over a wider speed range, reducing energy draw during idling and mild loads.

What is the typical timeline from design to pilot units?

With standardized power stages, controller libraries, and magnetics/cooling references, many teams move from schematic to pilot in 8–12 weeks, pending enclosure and EMC iteration timelines.

How does predictive maintenance reduce downtime?

Telemetry estimates junction temperature and tracks on-resistance drift and compressor vibration spectra. Early warnings enable planned service and parts availability, commonly reducing annual downtime by about 30%.

Are there benefits for cold-chain vehicles beyond energy savings?

Yes. More stable compressor control improves temperature stability, reducing product spoilage risk and strengthening compliance for audits and contracts.

How does localization change our total cost of ownership?

Local packaging and screening reduce spare lead times, while technology transfer builds in-country process maturity. The combined effect lowers PKR-denominated OPEX and reduces revenue losses from downtime.

Can the same platform serve different vehicle voltage classes?

Yes. The architecture is modular and platform-based, supporting 48–800 V buses with reconfigurable power stages, control parameters, and cooling stacks to fit buses, vans, and light trucks.

What standards and quality systems does Sicarbtech support?

Quality systems align with ISO 9001 and IATF 16949 principles; process validation follows PPAP-like control plans. Sicarbtech assists with documentation and third-party tests for IEC 60747, IEC 60068, and EMC/ISO 7637 expectations.

Making the Right Choice for Your Operations

In Pakistan’s heat, dust, and grid volatility, incremental upgrades won’t move the needle. Sicarbtech’s silicon carbide auxiliary power and HVAC drive solutions deliver quieter cabins, longer parking-mode endurance, and measurable energy savings. The partnership goes beyond devices: localized manufacturing, screening, and O&M analytics convert performance into predictable uptime and competitive advantage. If your goals include lower PKR per kilometer, higher availability, and happier drivers and passengers, SiC is the most direct path—and Sicarbtech brings the full stack to make it real.

Get Expert Consultation and Custom Solutions

Collaborate with Sicarbtech’s engineering team to size your compressor drive, specify bidirectional DC architecture, and tune acoustics and control for Pakistan’s climate and duty cycles. Explore technology transfer and factory establishment to localize packaging, screening, and spares, building a resilient in-country capability.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Energy efficiency secures the bid; quiet reliability secures the customer; local capability secures the future.” — Sicarbtech Applications Team

Article Metadata

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: incorporates 2025 Pakistan market outlook; aligns with IEC 60747, IEC 60068, ISO 7637, and EMC expectations similar to IEC 61800-3; reflects Sicarbtech’s current SiC portfolio, technology transfer, and factory establishment services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.