SiC Wear Parts: Significantly Extending Equipment Life

Share

SiC Wear Parts: Significantly Extending Equipment Life

In today’s demanding industrial environments, equipment uptime and longevity are paramount. Premature component failure due to wear can lead to costly downtime, increased maintenance expenses, and reduced productivity. For engineers, procurement managers, and technical buyers in sectors ranging from semiconductor manufacturing to aerospace and energy, finding robust solutions to combat wear is a critical priority. Silicon Carbide (SiC) wear parts have emerged as a game-changing technology, offering unparalleled resistance to abrasion, erosion, and corrosion, thereby significantly extending the operational life of critical machinery and components.

The Hidden Costs of Industrial Wear: Why Equipment Longevity Matters

Industrial wear is an insidious enemy that silently erodes profitability and operational efficiency. It manifests in various forms—abrasive wear from hard particles, erosive wear from fluid or particle impingement, corrosive wear from chemical attack, and adhesive or fretting wear from friction between moving parts. The consequences of unchecked wear are far-reaching:

- Increased Downtime: Unplanned equipment shutdowns for repairs or replacements are a major source of lost production and revenue.

- Skyrocketing Maintenance Costs: Frequent replacement of worn parts, along with the labor involved, can inflate maintenance budgets significantly. This includes scheduled and unscheduled maintenance activities.

- Reduced Equipment Efficiency: Worn components often lead to suboptimal performance, higher energy consumption, and compromised product quality.

- Shorter Equipment Lifespan: Persistent wear accelerates the overall degradation of machinery, necessitating premature capital reinvestment.

- Safety Risks: In some instances, component failure due to wear can lead to hazardous situations, endangering personnel and the environment.

- Supply Chain Disruptions: Failure of critical wear components can halt production lines, impacting delivery schedules and customer satisfaction for OEMs and end-users alike.

Addressing these challenges requires advanced materials that can withstand the harshest operating conditions. This is where technical ceramics, particularly silicon carbide, provide a compelling value proposition for wholesale buyers and industrial manufacturers seeking durable, long-lasting wear solutions.

Silicon Carbide (SiC): The Superior Material for Demanding Wear Applications

Silicon Carbide (SiC) stands out in the realm of advanced ceramics due to its exceptional combination of physical and chemical properties, making it an ideal material for high-performance wear parts. Its inherent characteristics directly combat the various forms of wear that plague industrial equipment:

- Extreme Hardness: SiC is one of the hardest commercially available materials, approaching diamond in hardness (Mohs hardness of 9.0-9.5, Knoop hardness ~2500-2800 kg/mm²). This makes it exceptionally resistant to abrasive wear caused by hard particles.

- High Strength and Stiffness: Silicon carbide maintains its strength at elevated temperatures, ensuring dimensional stability and resistance to deformation under mechanical stress. Its high Young’s modulus contributes to its ability to resist deflection and maintain precision.

- Excellent Thermal Shock Resistance: Many SiC grades exhibit high thermal conductivity coupled with a relatively low coefficient of thermal expansion. This combination provides outstanding resistance to thermal shock, allowing SiC parts to withstand rapid temperature fluctuations without cracking or failing—critical in applications like high-temperature furnaces and power electronics.

- Superior Chemical Inertness: SiC is highly resistant to a wide range of acids, alkalis, and molten salts, even at high temperatures. This makes it suitable for applications involving corrosive media, such as chemical processing and oil and gas exploration.

- Low Coefficient of Friction: Certain SiC grades, particularly when polished, offer a low coefficient of friction, reducing adhesive wear and energy consumption in dynamic applications like seals and bearings.

- High Wear Resistance: The combination of high hardness, strength, and chemical stability results in outstanding overall wear resistance, significantly outperforming traditional metals, alloys, and even other ceramics in many abrasive and erosive environments.

These properties translate into tangible benefits: longer service intervals, reduced maintenance interventions, and improved overall equipment effectiveness (OEE) for industries utilizing SiC wear components.

Transforming Industries: Applications of SiC Wear Parts

The remarkable properties of silicon carbide have led to its adoption for critical wear parts across a multitude of demanding industries. Custom SiC components are engineered to provide reliable performance where conventional materials fall short.

| Industry | Specific SiC Wear Part Applications | Key Benefits |

|---|---|---|

| Semiconductor Manufacturing | Wafer handling components (chuck tables, end effectors), plasma etch chamber components, CMP retainer rings, gas distribution plates | High purity, dimensional stability, plasma erosion resistance, thermal stability |

| Automotive | Mechanical seals for water pumps, brake disc components, diesel particulate filter (DPF) segments, turbocharger components | Wear resistance at high temperatures, lightweight, corrosion resistance |

| Aerospace & Defense | Nozzle inserts for rocket propulsion, armor plating components, bearings for high-speed applications, missile radomes, components for reconnaissance systems | High-temperature strength, lightweight, thermal shock resistance, ballistic performance |

| Power Electronics | Heat sinks, substrates for power modules, components for high-voltage switchgear | High thermal conductivity, electrical insulation, high-temperature stability |

| Renewable Energy | Bearings and seals in wind turbines, components for solar panel manufacturing equipment, parts for geothermal energy systems | Durability, resistance to harsh environmental conditions, long service life |

| Metallurgy & High-Temperature Furnaces | Burner nozzles, thermocouple protection tubes, kiln furniture (beams, rollers, plates), crucibles, radiant tubes | High-temperature strength, oxidation resistance, thermal shock resistance |

| Chemical Processing | Pump components (impellers, sleeves, shafts), valve seats and trims, mechanical seals, heat exchanger tubes, nozzles for corrosive fluids | Exceptional corrosion resistance, wear resistance in abrasive slurries |

| Mining & Mineral Processing | Cyclone liners, slurry pump liners and impellers, hydrocyclone apexes and spigots, chute liners, wear plates | Extreme abrasion resistance, impact resistance (in certain composites) |

| Oil and Gas | Downhole tool components, bearings and seals for pumps and compressors, valve components for abrasive and corrosive fluids, choke beans | Resistance to abrasion, erosion, and corrosive chemicals at high pressures and temperatures |

| Industrial Machinery | Precision shafts and bearings, cutting tool inserts (for specific applications), guide rollers, sandblasting nozzles, paper machine dewatering elements | High hardness, wear resistance, dimensional stability for precision operations |

| LED Manufacturing | Susceptors for MOCVD reactors, wafer carriers, components for crystal growth equipment | High thermal conductivity, chemical stability at high temperatures, purity |

The versatility of SiC allows for its use in an ever-expanding array of applications where longevity and reliability under harsh conditions are essential. From intricate components in telecommunications equipment to robust parts in rail transportation and nuclear energy, silicon carbide provides solutions that extend operational boundaries.

Choosing Your Shield: Understanding Silicon Carbide Grades for Wear Resistance

Not all silicon carbide is created equal. Various manufacturing processes result in different grades of SiC, each with a unique microstructure and property profile tailored for specific wear environments. Selecting the appropriate grade is crucial for optimizing performance and cost-effectiveness.

| SiC Grade | Manufacturing Process | Key Characteristics for Wear Resistance | Typical Wear Applications |

|---|---|---|---|

| Reaction-Bonded Silicon Carbide (RBSiC or SiSiC) | Infiltration of molten silicon into a porous SiC and carbon preform. | Good wear resistance, excellent thermal shock resistance, moderate cost, complex shapes possible, good thermal conductivity. Contains some free silicon (typically 8-15%). | Pump components, nozzles, kiln furniture, mechanical seals, wear liners. |

| Sintered Silicon Carbide (SSiC) | Pressureless sintering of fine SiC powder with sintering aids at high temperatures (2000-2200°C). | Extremely high hardness, excellent corrosion resistance, high strength, good wear resistance, high purity (no free silicon). | High-performance mechanical seals, bearings, valve components, semiconductor processing parts. |

| Nitride-Bonded Silicon Carbide (NBSC) | SiC grains bonded by a silicon nitride (Si₃N₄) phase. | Good thermal shock resistance, good abrasion resistance, relatively high porosity compared to SSiC. | Kiln furniture, furnace linings, thermocouple tubes, applications requiring good thermal cycling. |

| Recrystallized Silicon Carbide (RSiC) | High-temperature sublimation and re-deposition of SiC. | High purity, excellent thermal shock resistance, good high-temperature strength, typically porous. | High-temperature kiln furniture, setters, plates. Less common for direct wear parts unless specific properties are needed. |

| Chemically Vapor Deposited (CVD) SiC / Coated SiC | Deposition of SiC from gas phase onto a substrate. | Extremely high purity, dense, excellent corrosion and erosion resistance, can be applied as a coating. | Protective coatings on graphite or other ceramics, semiconductor components, high-performance optics. |

| Graphite-Loaded SiC (e.g., SiC-C composites) | Addition of graphite to SiC matrix. | Improved tribological properties (self-lubricating), enhanced thermal shock resistance, good electrical conductivity. | Dry running seals, bearings, applications requiring low friction. |

The choice of SiC grade will depend on factors such as the type of wear (abrasion, erosion, corrosion), operating temperature, presence of thermal shock, chemical environment, mechanical loads, and cost considerations. Consulting with experienced material scientists and suppliers is vital for making the optimal selection.

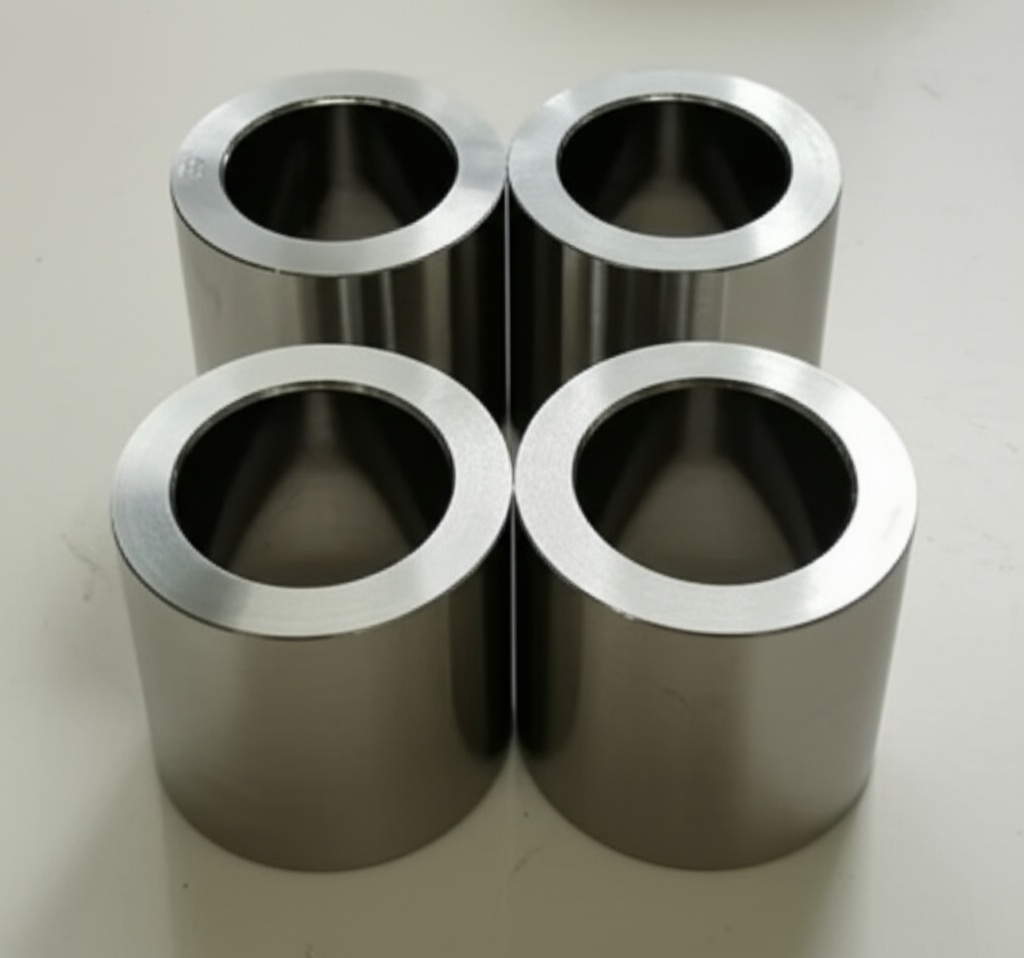

Beyond Off-the-Shelf: The Power of Custom SiC Wear Part Solutions

While standard SiC components are available, many industrial applications present unique challenges that necessitate custom-designed wear parts. Off-the-shelf solutions may not provide the optimal fit, geometry, or material grade required for maximum performance and longevity in specialized equipment. This is where the expertise of a specialized silicon carbide manufacturer becomes invaluable.

Benefits of Custom SiC Wear Parts:

- Optimized Performance: Parts are designed specifically for the application’s unique wear conditions, mechanical loads, thermal stresses, and chemical environment.

- Enhanced Equipment Life: Tailored solutions can address specific failure modes more effectively than generic parts, leading to significantly longer service life.

- Improved System Efficiency: Custom designs can contribute to better overall system performance, for example, by optimizing flow dynamics in nozzles or pump components.

- Perfect Fit and Integration: Custom parts ensure seamless integration with existing machinery, avoiding compatibility issues.

- Material Grade Selection: The precise SiC grade can be chosen and even modified to meet exact requirements, rather than being limited to standard offerings.

- Complex Geometries: Advanced manufacturing techniques allow for the creation of intricate shapes that would be impossible with standard parts, enabling innovative equipment designs.

Companies like Sicarb Tech specialize in providing customizing support for silicon carbide products. Leveraging deep material science knowledge and advanced manufacturing capabilities, they work closely with clients to develop bespoke SiC wear parts that deliver superior performance and value. This collaborative approach ensures that the final product is perfectly matched to the end-user’s specific operational needs, pushing the boundaries of equipment durability.

Precision Engineering: Critical Design Considerations for SiC Wear Components

Designing effective silicon carbide wear parts requires a thorough understanding of both the material’s properties and the application’s demands. SiC is an extremely hard and strong material, but it is also a brittle ceramic. Therefore, design considerations must aim to leverage its strengths while mitigating its inherent brittleness.

Key Design Factors:

- Load Conditions: Understand the nature and magnitude of mechanical loads (compressive, tensile, bending, impact). SiC performs best under compressive loads. Tensile stresses should be minimized.

- Impact Forces: Avoid sharp impacts. If impacts are unavoidable, consider designing for energy absorption through system design or using tougher SiC composites. Generous radii and chamfers can help distribute stress.

- Operating Temperatures and Thermal Cycling: While SiC has excellent high-temperature stability and good thermal shock resistance, extreme thermal gradients or rapid cycling can induce stress. Design should allow for uniform heating and cooling where possible. Consider the thermal expansion coefficient relative to mating parts.

- Interfacing with Other Materials: Differences in thermal expansion coefficients between SiC and metallic components need careful management, often through specialized mounting techniques (e.g., shrink fitting, brazing with compliant interlayers, mechanical clamping) to avoid stress buildup.

- Edge Geometries and Stress Concentrations: Avoid sharp internal corners, thin sections, and abrupt changes in cross-section, as these can act as stress concentrators. Use fillets and radii to distribute stress.

- Tolerances and Surface Finish: Specify realistic tolerances and surface finish requirements. Extremely tight tolerances or mirror finishes significantly increase machining costs. The required finish depends on the application (e.g., smoother for seals, potentially rougher for some liner applications if it doesn’t impede flow).

- Attachment and Assembly: Consider how the SiC part will be assembled into the larger system. Design features for secure and stress-minimized mounting.

- Chemical Environment: While SiC is highly resistant, ensure the chosen grade is optimal for the specific chemical exposures and temperatures.

- Manufacturability: Design with the manufacturing process in mind. Extremely complex geometries can be challenging and costly to produce, even with advanced forming and machining techniques. Early consultation with the SiC supplier is crucial.

A collaborative approach between the end-user’s engineering team and the SiC component manufacturer is essential to develop robust and reliable designs that maximize the benefits of silicon carbide.

Manufacturing Excellence: Tolerances, Surface Finish, and Quality Control for SiC Wear Parts

Producing high-quality silicon carbide wear parts that meet stringent performance requirements demands sophisticated manufacturing processes and rigorous quality control. The journey from SiC powder to a precision-finished component involves several critical steps:

- Powder Preparation: Starting with high-purity SiC powders, often mixed with sintering aids or binders depending on the desired SiC grade.

- Forming (Green Body Shaping):

- Pressing (Uniaxial, Isostatic): Compacting powder in a die to form basic shapes.

- Slip Casting: Pouring a SiC slurry into a porous mold. Good for complex shapes.

- Extrusion: Forcing SiC paste through a die to create long, uniform profiles like tubes and rods.

- Injection Molding: Suitable for high-volume production of small, complex parts.

- Additive Manufacturing (3D Printing): An emerging technology for creating highly complex SiC geometries directly from a digital model.

- Binder Burnout (Debinding): If binders were used in forming, they are carefully removed by heating the green body in a controlled atmosphere.

- Sintering/Reaction Bonding:

- Sintering (e.g., SSiC): Heating the green body to very high temperatures (often >2000°C) in a controlled atmosphere, causing the SiC particles to bond and densify.

- Reaction Bonding (RBSiC): Infiltrating a porous SiC/carbon preform with molten silicon, which reacts with the carbon to form new SiC, bonding the original grains.

- Diamond Machining (Hard Machining): Since sintered SiC is extremely hard, final shaping and achieving tight tolerances require diamond grinding, lapping, and polishing.

- Grinding: To achieve precise dimensions and initial surface finish.

- Lapping: To achieve very flat surfaces and improved finishes.

- Polishing: To achieve mirror-like finishes, crucial for applications like mechanical seals or semiconductor components.

Tolerances and Surface Finish:

Achievable tolerances for SiC parts depend on the size, complexity, and manufacturing process. Precision grinding can typically achieve tolerances in the range of micrometers (e.g., ±0.005 mm to ±0.025 mm). Surface finishes (Ra) can range from several microns after initial grinding down to nanometer-scale roughness (e.g., <0.02 µm Ra) after extensive lapping and polishing.

Quality Control:

Rigorous quality control is essential throughout the manufacturing process. This includes:

- Raw material inspection and characterization.

- In-process dimensional checks.

- Density and porosity measurements.

- Microstructural analysis (grain size, phase distribution).

- Non-destructive testing (NDT) such as ultrasonic inspection or X-ray to detect internal flaws.

- Final dimensional and surface finish verification using advanced metrology equipment (CMMs, profilometers, interferometers).

Leading manufacturers of technical ceramics invest heavily in state-of-the-art manufacturing equipment and comprehensive quality assurance systems to deliver SiC wear parts that consistently meet or exceed customer specifications.

Navigating Challenges: Practical Solutions in Implementing SiC Wear Parts

While silicon carbide offers exceptional wear resistance, its implementation is not without challenges. Understanding these potential hurdles and their solutions is key to successfully leveraging SiC technology.

- Brittleness:

- Challenge: SiC is a ceramic and thus inherently brittle compared to metals. It has low fracture toughness, meaning it is susceptible to catastrophic failure if subjected to high impact loads or excessive tensile stress.

- Solution:

- Design Optimization: Minimize stress concentrations by using generous radii, avoiding sharp corners, and designing for compressive loading.

- System Design: Protect SiC components from direct impact or shock loading through careful system integration and damping mechanisms.

- Material Selection: Certain SiC grades or composites (e.g., toughened SiC) offer slightly improved fracture toughness.

- Proper Handling: Implement careful handling and installation procedures to prevent accidental damage.

- Machining Complexity and Cost:

- Challenge: The extreme hardness of SiC makes it difficult and time-consuming to machine after sintering. This requires specialized diamond tooling and techniques, contributing to higher manufacturing costs compared to metals.

- Solution:

- Near-Net Shape Forming: Utilize forming techniques that produce parts as close to the final dimensions as possible to minimize subsequent machining.

- Design for Manufacturability (DFM): Simplify designs where possible and consult with SiC manufacturers early in the design process to optimize for cost-effective production.

- Volume Production: For higher volumes, economies of scale can help reduce per-unit costs.

- Thermal Expansion Mismatch:

- Challenge: SiC generally has a lower coefficient of thermal expansion (CTE) than most metals. When SiC parts are assembled with metallic components and subjected to temperature changes, differential expansion can induce significant stresses.

- Solution:

- Compliant Interlayers: Use materials like graphite foils or specialized brazing alloys that can accommodate differential expansion.

- Mechanical Design: Employ mounting techniques (e.g., spring loading, shrink fitting with precise interference control) that allow for some movement or manage stresses effectively.

- Material Matching: Where possible, select mating materials with CTEs closer to that of SiC, though this is often constrained by other application requirements.

- Initial Cost:

- Challenge: The initial procurement cost of SiC components can be higher than that of traditional metallic or polymeric parts.

- Solution:

- Total Cost of Ownership (TCO) Analysis: Focus on the long-term savings achieved through significantly extended service life, reduced downtime, lower maintenance frequency, and improved productivity. SiC often provides a much lower TCO.

- Value Engineering: Work with suppliers to optimize design and material grade to achieve the required performance at the best possible cost.

By proactively addressing these challenges through careful design, material selection, and collaboration with experienced SiC suppliers, industries can fully realize the profound benefits of incorporating silicon carbide wear parts into their critical equipment.

Partnering for Performance: Selecting the Right SiC Wear Part Supplier

Choosing the right supplier for your custom silicon carbide wear parts is as critical as selecting the material itself. A knowledgeable and capable supplier acts as a partner, contributing to the success of your application. Key factors to consider when evaluating potential SiC component manufacturers include:

- Technical Expertise and Material Knowledge: The supplier should have a deep understanding of various SiC grades, their properties, and their suitability for different wear applications. Look for in-house material scientists and engineers who can provide expert advice.

- Customization Capabilities: Ensure the supplier can manufacture parts to your specific designs, tolerances, and surface finish requirements. Inquire about their experience with complex geometries and their customizing support processes.

- Manufacturing Capabilities and Technology: Assess their forming, sintering, and precision machining capabilities. Do they invest in modern equipment and advanced manufacturing techniques?

- Quality Management Systems: Look for robust quality control procedures at every stage of production, from raw material inspection to final product verification. Certifications like ISO 9001 can be an indicator of commitment to quality.

- Industry Experience and Case Studies: A supplier with a proven track record in your industry or similar demanding applications is more likely to understand your challenges and deliver effective solutions. Ask for case studies or references.

- Research and Development Focus: A supplier committed to R&D is more likely to offer innovative materials and solutions, staying at the forefront of SiC technology.

- Supply Chain Reliability and Lead Times: Discuss their capacity, typical lead times for custom parts, and their ability to manage the supply chain effectively, especially for critical OEM components.

- Communication and Support: Choose a supplier that is responsive, communicative, and willing to collaborate closely throughout the design, manufacturing, and implementation process.

A strong partnership with a reputable SiC supplier like Sicarb Tech ensures not only high-quality components but also access to valuable expertise that can optimize your equipment’s performance and longevity.

The Weifang Advantage: Accessing China’s Premier SiC Hub with Sicarb Tech

For businesses seeking high-quality, customizable silicon carbide parts, understanding the global manufacturing landscape is crucial. As you may be aware, the hub of China’s silicon carbide customizable parts manufacturing is situated in Weifang City. This region has become a powerhouse, home to over 40 silicon carbide production enterprises of various sizes, collectively accounting for more than 80% of China’s total silicon carbide output.

Within this vibrant ecosystem, Sicarb Tech plays a pivotal role. Since 2015, we have been instrumental in introducing and implementing advanced silicon carbide production technology, assisting local enterprises in achieving large-scale production and significant technological advancements in their product processes. We have proudly witnessed and contributed to the emergence and ongoing development of this leading SiC industrial cluster.

Sicarb Tech is an integral part of the Chinese Academy of Sciences (Weifang) Innovation Park, an entrepreneurial park that collaborates closely with the National Technology Transfer Center of the Chinese Academy of Sciences. This positions us as a national-level innovation and entrepreneurship service platform, integrating innovation, entrepreneurship, technology transfer, venture capital, incubation, acceleration, and scientific and technological services. We capitalize on the robust scientific, technological capabilities, and talent pool of the Chinese Academy of Sciences . Backed by the Chinese Academy of Sciences National Technology Transfer Center, Sicarb Tech serves as a vital bridge, facilitating the integration and collaboration of crucial elements in the transfer and commercialization

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.