SiC Precision Grinding for Ultimate Accuracy

Share

SiC Precision Grinding for Ultimate Accuracy

Introduction: The Imperative of Precision in Silicon Carbide Components

In the realm of advanced materials, silicon carbide (SiC) stands out for its exceptional hardness, thermal conductivity, and resistance to wear and chemical attack. These properties make it indispensable in high-performance industrial applications. However, harnessing the full potential of SiC often comes down to one critical factor: precision. This is where silicon carbide precision grinding becomes essential. This advanced machining process allows for the fabrication of SiC components with extremely tight tolerances and superior surface finishes, which are crucial for the reliability and efficiency of devices in sectors ranging from semiconductors to aerospace. As industries push the boundaries of technology, the demand for SiC parts with ultimate accuracy continues to grow, making precision grinding a cornerstone of modern manufacturing.

The inherent hardness of silicon carbide, while a significant advantage in end-use applications, presents considerable challenges in machining. Traditional methods often fall short, unable to achieve the required dimensional accuracy or surface quality without causing subsurface damage. Precision grinding, utilizing diamond abrasives and sophisticated machinery, is specifically designed to overcome these challenges, shaping SiC into complex geometries while maintaining its structural integrity. This blog post will delve into the intricacies of SiC precision grinding, exploring its applications, benefits, technical considerations, and how to partner with the right supplier for your custom SiC needs.

Key Applications: Where SiC Precision Grinding Drives Innovation

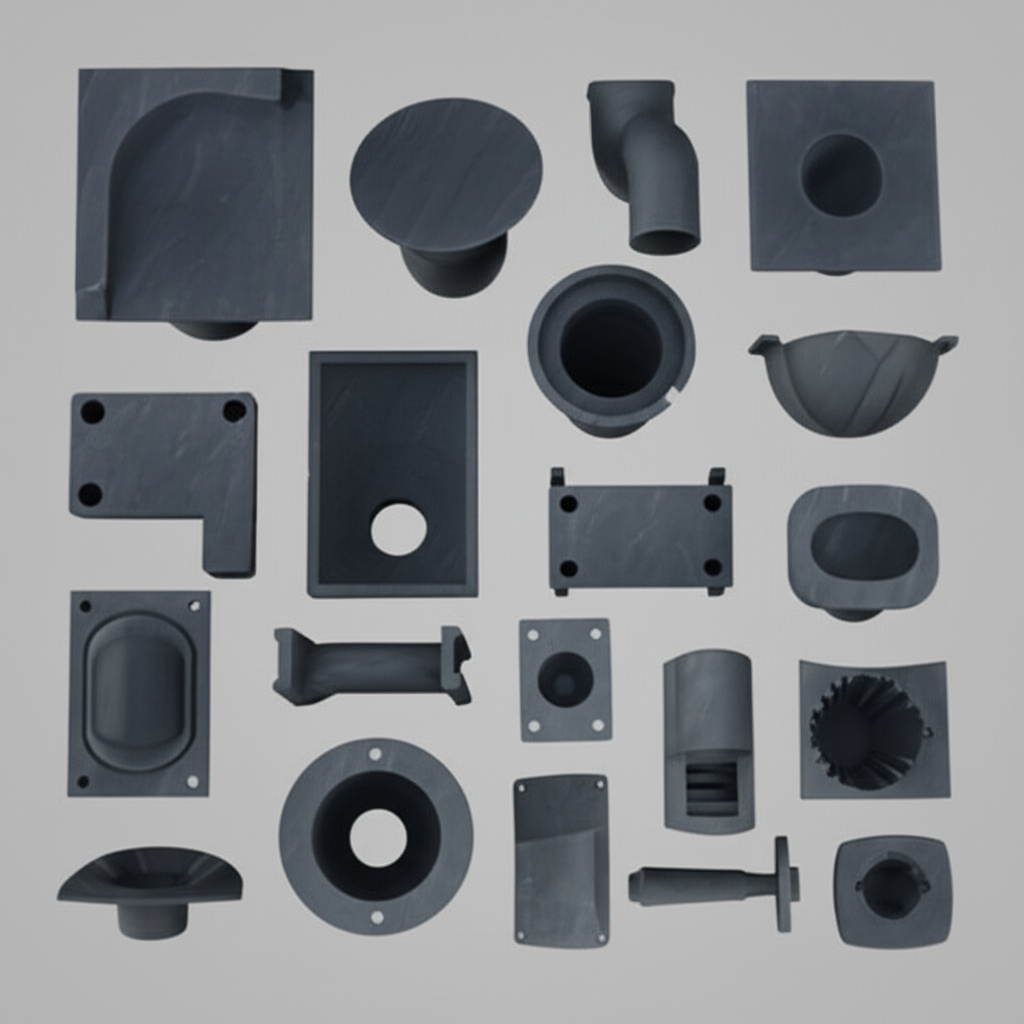

The demand for precision-ground silicon carbide components spans a multitude of high-tech industries. The unique combination of SiC’s properties, enhanced by precision grinding, allows for groundbreaking advancements in various fields. Key applications include:

- Semiconductor Manufacturing: Wafer chucks, focus rings, edge rings, and end effectors require extreme flatness, parallelism, and surface finish to minimize particle generation and ensure process uniformity. Precision ground SiC delivers these requirements.

- Automotive: Components in electric vehicles (EVs) like power electronic modules (inverters, converters) benefit from SiC’s high thermal conductivity and electrical insulation. Precision grinding ensures optimal fit and thermal management for parts like heat sinks and substrates. Mechanical seals and bearings in high-performance engines also utilize ground SiC for its wear resistance.

- Aerospace & Defense: Lightweight mirrors for optical systems, components for missile guidance systems, turbine engine parts (nozzles, vanes), and armor benefit from SiC’s stiffness, thermal stability, and low density. Precision grinding is critical for achieving the necessary aerodynamic profiles and optical surfaces.

- Power Electronics: Substrates, insulators, and housings for high-power and high-frequency devices demand precision-ground SiC for efficient thermal dissipation and electrical insulation. This includes applications in industrial motor drives and power grid components.

- Renewable Energy: Components in solar panel manufacturing (e.g., ceramic rollers for high-temperature processing) and critical parts in wind turbines require materials that can withstand harsh environments and offer long service life. Precision-ground SiC meets these demands.

- Metallurgy: Furnace components, kiln furniture, thermocouple protection tubes, and crucibles made from SiC must endure extreme temperatures and corrosive environments. Precision grinding ensures tight seals and dimensional stability.

- Chemical Processing: Pump seals, valve components, and nozzles exposed to aggressive chemicals rely on SiC’s chemical inertness and wear resistance, with precision grinding ensuring leak-proof performance and longevity.

- LED Manufacturing: Susceptors and handling tools used in MOCVD reactors for LED production require high purity, thermal uniformity, and precise dimensions, all achievable with ground SiC.

- Industrial Machinery: Precision shafts, bearings, wear-resistant linings, and nozzles in various industrial equipment leverage the durability of SiC. Grinding ensures these parts meet exacting operational tolerances.

- Medical Devices: Biocompatible SiC components for surgical tools, implants, and diagnostic equipment require ultra-precise dimensions and smooth surfaces.

- Nuclear Energy: Components for fuel cladding and structural elements in nuclear reactors benefit from SiC’s radiation resistance and high-temperature stability, demanding precise manufacturing.

Why Choose Custom Silicon Carbide for Precision Grinding?

While standard SiC components are available, custom silicon carbide parts tailored through precision grinding offer unparalleled advantages, particularly when specific performance characteristics are paramount. Customization allows engineers to optimize designs for their unique application requirements, maximizing efficiency, longevity, and reliability.

The benefits of opting for custom, precision-ground SiC include:

- Optimized Thermal Management: Precision grinding can create intricate cooling channels or achieve specific surface profiles that enhance heat dissipation, crucial for power electronics and high-temperature applications. Custom designs ensure that thermal resistance is minimized exactly where it matters.

- Superior Wear Resistance in Specific Geometries: Components subject to abrasive wear, such as seals, nozzles, and bearings, can be custom ground to precise contours that optimize wear distribution and extend service life significantly beyond off-the-shelf parts.

- Enhanced Chemical Inertness and Purity: For applications in semiconductor and chemical processing, custom ground and polished SiC components can achieve very low surface roughness, minimizing areas where contaminants can adhere. This ensures higher purity in the process environment.

- Improved Mechanical Stability: Precision grinding allows for the creation of SiC parts with exact dimensions and tight tolerances, leading to better assembly fit, reduced vibration, and improved overall mechanical stability of the system.

- Application-Specific Geometries: Many advanced applications require complex shapes and features that are not available in standard SiC offerings. Custom precision grinding enables the production of these intricate designs, unlocking new possibilities in device performance.

- Material Grade Selection: Customization often involves selecting the optimal SiC grade (e.g., reaction-bonded, sintered) whose intrinsic properties are best suited for the application, and then further enhancing these with precision grinding for the final form and finish.

Choosing custom SiC components means not settling for “good enough” but striving for the “perfect fit” – a solution engineered to meet exact specifications and deliver maximum performance. This is where partnering with a knowledgeable supplier with robust customizing support becomes invaluable.

Recommended SiC Grades and Compositions for Precision Grinding

The choice of silicon carbide grade is a critical first step before the precision grinding process. Different SiC grades offer varying properties, which influence their suitability for specific applications and their response to grinding. Here are some commonly used SiC grades that are often subjected to precision grinding:

| SiC Grade | Key Properties | Common Applications for Grinding | Grindability Notes |

|---|---|---|---|

| Reaction-Bonded SiC (RBSC / SiSiC) | High hardness, excellent wear resistance, good thermal conductivity, moderate cost, near-net-shape capability. Contains free silicon (typically 8-15%). | Mechanical seals, pump components, nozzles, kiln furniture, wear liners. | Relatively easier to grind compared to fully dense SiC due to the presence of free silicon, but diamond tooling is still essential. Can achieve good surface finishes. |

| Sintered SiC (SSiC) | Extremely high hardness, superior chemical inertness, high-temperature strength, excellent corrosion resistance. No free silicon. | Semiconductor equipment parts (chucks, rings), bearings, chemical processing components, advanced heat exchangers. | More challenging to grind due to extreme hardness. Requires optimized grinding parameters and high-quality diamond wheels. Can achieve very fine finishes and tight tolerances. |

| Nitride-Bonded SiC (NBSC) | Good thermal shock resistance, high strength, good wear resistance. Silicon nitride acts as the bonding phase. | Kiln furniture, furnace linings, crucibles, components for molten metal handling. | Grindability is moderate. Often used where complex shapes are needed, and grinding is for critical mating surfaces or tolerances. |

| Chemical Vapor Deposited SiC (CVD-SiC) | Ultra-high purity, theoretically dense, excellent surface finish capability, superior chemical resistance. | Semiconductor process chamber components, optical mirrors, high-purity applications. | Can be ground and polished to exceptionally smooth surfaces (angstrom-level roughness). Requires specialized techniques due to its purity and potential for subsurface damage if not handled correctly. |

| Recrystallized SiC (RSiC) | High porosity (typically 10-15%), excellent thermal shock resistance, high operating temperature. | Kiln furniture, setters, radiant tubes, burner nozzles. | Generally not ground for ultra-precision due to porosity, but critical dimensions can be refined. Grinding can open pores, affecting surface properties. |

| Graphite-Loaded SiC | Improved thermal shock resistance, self-lubricating properties, lower coefficient of friction. | Bearings, dynamic seals. | Grindability depends on the SiC matrix and graphite content. The presence of graphite can make achieving ultra-fine finishes more complex. |

The selection of the appropriate SiC grade should be a collaborative effort between the design engineer and the SiC component supplier. Factors such as operating temperature, chemical environment, mechanical stresses, and desired surface finish will dictate the best material choice, which in turn impacts the precision grinding strategy.

Design Considerations for SiC Products Requiring Precision Grinding

Designing silicon carbide components that are destined for precision grinding requires careful consideration of various factors to ensure manufacturability, functionality, and cost-effectiveness. SiC’s hardness and brittleness mean that design choices have a significant impact on the grinding process and the final quality of the part.

- Geometry and Complexity:

- Simplify where possible: Complex features, sharp internal corners, and intricate contours increase grinding time and tooling complexity, leading to higher costs. Radii are preferred over sharp corners to reduce stress concentrations and ease grinding.

- Accessibility: Ensure that all surfaces requiring grinding are accessible to grinding wheels and tooling. Deep pockets or internal features may be challenging or impossible to grind to high precision.

- Wall Thickness and Aspect Ratios:

- Minimum Wall Thickness: SiC is strong but brittle. Very thin walls can be prone to chipping or fracture during grinding or handling. Consult with your supplier on minimum achievable wall thicknesses for the chosen SiC grade.

- Aspect Ratios: Long, thin parts can be challenging to hold securely and grind without vibration or deflection, affecting dimensional accuracy.

- Stress Points:

- Avoid Stress Concentrators: Sharp corners, notches, and abrupt changes in cross-section can act as stress concentrators. Generous radii and smooth transitions are crucial to prevent cracking during grinding or in service.

- Material Removal: Consider the amount of material to be removed during grinding. Excessive stock removal can induce stress. Near-net-shape forming prior to grinding is often preferred.

- Tolerances and Surface Finish Callouts:

- Specify Realistically: While extremely tight tolerances and ultra-fine finishes are achievable with precision SiC grinding, they come at a cost. Specify only what is functionally necessary for the application.

- Datum Structures: Clearly define datum surfaces on drawings. These references are critical for accurate setup and measurement during the grinding process.

- Chamfers and Edge Treatment:

- Edge Chipping: Sharp edges on SiC components are prone to chipping. Specifying small chamfers or radii on edges can improve durability and safety.

- Pre-Grinding Form:

- The quality of the sintered or reaction-bonded blank significantly impacts the grinding outcome. Variations in density or initial geometry can lead to challenges in achieving uniform results.

Collaborating with experienced SiC manufacturers early in the design phase can help optimize the component for precision grinding, ensuring that the final product meets performance requirements while managing manufacturing costs. Many advanced suppliers offer design for manufacturability (DFM) assistance to guide engineers through these critical considerations.

Tolerance, Surface Finish & Dimensional Accuracy in SiC Grinding

One of the primary reasons for employing precision grinding for silicon carbide components is the ability to achieve exceptionally tight tolerances, superior surface finishes, and high dimensional accuracy. These attributes are critical for the performance of SiC parts in demanding applications.

Achievable Tolerances:

The level of tolerance achievable depends on the specific SiC grade, the complexity of the part geometry, the size of the component, and the sophistication of the grinding equipment and process control. Generally, for precision SiC grinding:

- Dimensional Tolerances: Can often be held to $pm 0.005 text{ mm}$ (5 microns) or even tighter for critical features on smaller parts. For larger or more complex components, tolerances might be in the range of $pm 0.01 text{ mm}$ to $pm 0.025 text{ mm}$.

- Geometric Tolerances:

- Flatness: Achievable down to $1-2 text{ µm}$ over significant surface areas, particularly for components like semiconductor wafer chucks or lapping plates.

- Parallelism: Can be controlled to within a few microns ($2-5 text{ µm}$) for opposing surfaces.

- Roundness (Circularity): For cylindrical parts, roundness can often be achieved within $1-2 text{ µm}$.

- Cylindricity: Can be held to $2-5 text{ µm}$ for precision shafts or bores.

It’s important to note that specifying tighter tolerances than necessary will increase manufacturing costs due to longer processing times, increased tooling wear, and higher inspection demands.

Surface Finish Options:

Surface finish, typically quantified by average roughness (Ra), is another key outcome of precision grinding. Different applications require different surface characteristics:

- Standard Ground Finish: Ra values typically range from $0.2 text{ µm}$ to $0.8 text{ µm}$. This is suitable for many industrial applications where good wear resistance and reasonable sealing surfaces are needed.

- Fine Ground Finish: Ra values can be achieved in the range of $0.1 text{ µm}$ to $0.2 text{ µm}$. This is often required for precision bearings, some seal faces, and components requiring smoother surfaces to reduce friction.

- Lapped/Polished Finish: For applications demanding ultra-smooth surfaces, such as semiconductor components, optical mirrors, or high-performance seals, grinding is often followed by lapping and polishing. These processes can achieve Ra values below $0.05 text{ µm}$ (50 nanometers), and even down to angstrom levels for CVD-SiC.

Maintaining Dimensional Accuracy:

Achieving and maintaining dimensional accuracy throughout the SiC grinding process relies on several factors:

- High-Precision Grinding Machines: Machines with rigid construction, high-resolution encoders, and advanced CNC controls are essential.

- Quality Diamond Tooling: The selection of diamond grit size, concentration, and bond type must be optimized for the specific SiC grade and desired outcome.

- Process Control: Strict control over grinding parameters such as wheel speed, feed rate, depth of cut, and coolant application is crucial.

- In-Process Metrology: Advanced systems may incorporate in-process measurement to monitor and adjust the grinding process in real-time.

- Temperature Stability: Both the workpiece and the machine environment must be temperature-controlled to prevent thermal expansion errors.

- Operator Skill: Experienced machinists with expertise in hard material grinding play a vital role.

Understanding these capabilities allows engineers and procurement managers to specify SiC components that are both functional and manufacturable, ensuring optimal performance in their final application.

Post-Processing Needs Beyond Grinding

While precision grinding is a critical step in achieving the desired shape and tolerance for silicon carbide components, some applications may require further post-processing to enhance specific properties or meet even more stringent surface requirements. These additional steps can improve performance, durability, and functionality.

Common post-processing needs for precision-ground SiC components include:

- Lapping:

- Purpose: To achieve extreme flatness, parallelism, and very fine surface finishes, often beyond what grinding alone can economically provide. Lapping uses a fine abrasive slurry between the workpiece and a lapping plate.

- Applications: Semiconductor wafer chucks, precision seal faces, metrology masters, optical components.

- Result: Can reduce Ra values significantly, often to the $0.02 text{ µm}$ to $0.05 text{ µm}$ range.

- Polishing:

- Purpose: To achieve mirror-like finishes and the lowest possible surface roughness, often for optical or high-purity applications. Polishing typically follows lapping and uses even finer abrasives.

- Applications: SiC mirrors, windows for harsh environments, ultra-smooth substrates for semiconductor devices, components requiring minimal surface defects.

- Result: Can achieve Ra values in the nanometer or even angstrom range, especially for materials like CVD-SiC.

- Edge Honing/Radiusing:

- Purpose: To remove micro-cracks or sharp edges that can be sites for fracture initiation, thereby improving the component’s strength and resistance to chipping.

- Applications: Cutting tools (though SiC is rarely the primary cutting material, it’s used in composites), wear parts subjected to impact or high edge loads.

- Result: Improved edge toughness and reduced likelihood of chipping in handling or operation.

- Cleaning and Surface Treatment:

- Purpose: To remove any residues from grinding, lapping, or polishing, and to prepare the surface for subsequent coatings or for use in ultra-clean environments.

- Methods: Ultrasonic cleaning, precision cleaning with specialized solvents, plasma etching (for semiconductor applications).

- Result: Contaminant-free surfaces, optimized for adhesion or purity requirements.

- Sealing (for porous grades):

- Purpose: Some SiC grades, like certain types of RBSC or NBSC, might have residual porosity. Sealing can fill these pores to improve impermeability to gases or liquids, or to enhance chemical resistance.

- Materials: Glass frits, polymeric sealants, or further SiC deposition.

- Applications: Chemical pump components, heat exchanger tubes where gas tightness is critical.

- Result: Reduced permeability and improved resistance to chemical attack in porous areas.

- Coatings:

- Purpose: To add specific functionalities not inherent to the SiC substrate, such as enhanced lubricity, different electrical properties, or improved biocompatibility.

- Types: Diamond-Like Carbon (DLC), PVD/CVD coatings (e.g., TiN, AlN), specialized polymers.

- Applications: Bearings, medical implants, specialized semiconductor components.

- Result: Tailored surface properties for specific performance enhancements.

The necessity for these post-processing steps depends heavily on the application’s demands. Discussing these requirements with your SiC component supplier early in the project lifecycle will ensure that all necessary manufacturing stages are planned and quoted accurately.

Common Challenges in SiC Precision Grinding and How to Overcome Them

Silicon carbide’s exceptional hardness and brittleness, while beneficial for end-use, present significant challenges during precision grinding. Understanding these challenges and the strategies to mitigate them is key to successfully manufacturing high-quality SiC components.

| Challenge | Description | Mitigation Strategies |

|---|---|---|

| Extreme Hardness & Abrasiveness | SiC is one of the hardest commercially available materials (Mohs hardness ~9-9.5). This leads to rapid wear of grinding wheels and cutting tools. |

|

| Brittleness & Susceptibility to Fracture | SiC has low fracture toughness, making it prone to chipping, cracking, and subsurface damage if grinding parameters are not carefully controlled. |

|

| Subsurface Damage (SSD) | Grinding can introduce micro-cracks and lattice distortions beneath the machined surface, which can compromise the mechanical strength and performance of the component. |

|

| Achieving Tight Tolerances & Fine Finishes | The combination of hardness and brittleness makes it difficult to achieve ultra-precise dimensions and very smooth surfaces simultaneously without defects. |

|

| Thermal Shock Sensitivity | Localized heating during grinding, followed by rapid cooling, can induce thermal stresses leading to cracks, especially in SiC grades with lower thermal shock resistance. |

|

| Wheel Loading and Glazing | Fine SiC particles (swarf) can clog the grinding wheel (loading) or dull the abrasive grains (glazing), reducing cutting efficiency and increasing grinding forces. |

|

Overcoming these challenges requires a combination of advanced equipment, optimized processes, material science knowledge, and skilled personnel. Partnering with a supplier experienced in SiC precision grinding is crucial for mitigating these issues and ensuring high-quality outcomes.

How to Choose the Right SiC Precision Grinding Supplier

Selecting the right supplier for your custom silicon carbide precision grinding needs is a critical decision that directly impacts component quality, lead times, and overall project success. Given the specialized nature of SiC machining, not all providers are equally equipped. Here’s what to look for:

- Technical Expertise and Experience:

- Depth of Knowledge: Does the supplier have a deep understanding of different SiC grades (RBSC, SSiC, CVD-SiC, etc.) and their specific grinding character

- Depth of Knowledge: Does the supplier have a deep understanding of different SiC grades (RBSC, SSiC, CVD-SiC, etc.) and their specific grinding character

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.