SiC Polishing Pads for Perfect Product Surfaces

Share

SiC Polishing Pads for Perfect Product Surfaces

In today’s highly demanding industrial landscape, achieving impeccable surface finishes is paramount for product performance, longevity, and reliability. From the intricate layers of a semiconductor wafer to the critical components in aerospace engines, surface quality directly impacts functionality. This is where silicon carbide (SiC) polishing pads emerge as a game-changer. Renowned for their exceptional hardness, thermal stability, and chemical inertness, SiC polishing pads are the material of choice for engineers, procurement managers, and technical buyers seeking unparalleled precision and efficiency in polishing applications across diverse industries.

The Unrivaled Role of SiC Polishing Pads in Precision Industries

Silicon carbide, a compound of silicon and carbon, boasts a unique combination of properties that make it ideal for abrasive applications. Its extreme hardness, second only to diamond, ensures efficient material removal and a superior finish. Unlike conventional abrasives, SiC retains its properties at elevated temperatures, making it suitable for high-speed and high-temperature polishing processes. Furthermore, its chemical inertness prevents unwanted reactions with workpieces, preserving material integrity.

For industries where microscopic imperfections can lead to catastrophic failures, the precision offered by SiC polishing pads is indispensable. These pads are not just abrasive tools; they are engineered solutions designed to meet the rigorous demands of advanced manufacturing.

Key Applications Across Critical Sectors

The versatility of SiC polishing pads extends across a multitude of high-tech and heavy industries, making them an essential component in modern manufacturing processes. Their ability to deliver ultra-smooth, high-precision surfaces is critical for enhancing product performance and reliability.

- Semiconductor Manufacturing: In the fabrication of microchips and integrated circuits, achieving atomically flat surfaces is crucial for device functionality. SiC polishing pads are indispensable for chemical mechanical planarization (CMP) processes, ensuring uniform wafer thickness and defect-free surfaces for optimal semiconductor performance.

- Automotive Industry: For critical engine components, braking systems, and optical elements, surface finish directly impacts efficiency, wear resistance, and safety. SiC polishing pads are used to refine surfaces, reducing friction and extending component lifespan in high-stress automotive applications.

- Aerospace and Defense: Components subjected to extreme temperatures, pressures, and corrosive environments, such as turbine blades, missile parts, and optical sensors, demand exceptional surface integrity. SiC polishing ensures optimal aerodynamic performance, reduces fatigue, and enhances the reliability of mission-critical aerospace materials.

- Power Electronics: The burgeoning field of power electronics, particularly in electric vehicles and renewable energy systems, relies heavily on SiC-based devices. Polishing pads are vital for preparing SiC wafers for power modules, ensuring efficient heat dissipation and high-power handling capabilities.

- Renewable Energy: From solar panels to wind turbine components, SiC polishing contributes to the efficiency and durability of renewable energy systems. Achieving precise surface finishes on photovoltaic cells and other critical parts optimizes energy conversion and extends operational life.

- Metallurgical Companies: In the production of high-performance alloys and specialized metals, SiC polishing pads are used for sample preparation and final finishing, ensuring material integrity and precise dimensional control for demanding metallurgical applications.

- Chemical Processing: Equipment exposed to harsh chemicals, such as pumps, valves, and reactor linings, benefits from the chemical inertness and wear resistance imparted by SiC polishing, extending their service life in corrosive environments.

- LED Manufacturing: For optoelectronic devices like LEDs, the quality of the substrate surface directly impacts light extraction efficiency. SiC polishing pads help achieve the desired flatness and smoothness for optimal LED performance.

- Industrial Equipment Manufacturing: Precision components in pumps, seals, bearings, and other industrial machinery benefit from SiC polishing to reduce friction, improve wear resistance, and extend the lifespan of critical industrial machinery.

- Telecommunications: Optical fibers and connectors require extremely smooth and precise end-faces for efficient signal transmission. SiC polishing pads are essential in achieving the necessary surface quality in telecommunications components.

- Oil and Gas: Downhole tools and drilling equipment operating in abrasive and corrosive conditions benefit from SiC polishing to enhance their wear resistance and longevity in demanding oil and gas exploration.

- Medical Devices: Implants, surgical instruments, and diagnostic equipment demand biocompatibility and ultra-smooth surfaces for hygiene and performance. SiC polishing ensures the high-quality finish required for medical device manufacturing.

- Rail Transportation: Components in rail systems, such as braking mechanisms and bearing surfaces, require durable and wear-resistant finishes, often achieved through SiC polishing for improved safety and reduced maintenance.

- Nuclear Energy: In environments requiring extreme durability and resistance to radiation, SiC components are critical. Polishing pads play a role in fabricating these components to stringent quality standards for nuclear energy applications.

Advantages of Custom Silicon Carbide Polishing Pads

While standard SiC polishing pads offer significant benefits, custom silicon carbide solutions unlock even greater potential. Tailored to specific application requirements, custom SiC pads provide a competitive edge:

- Optimized Performance: Custom geometries, grit sizes, and bonding agents ensure the polishing pad is perfectly matched to the material being processed, resulting in faster material removal, superior surface finish, and reduced defects.

- Enhanced Durability: Engineered for specific loads and operating conditions, custom SiC pads can exhibit extended lifespans, reducing replacement frequency and overall operational costs.

- Problem-Specific Solutions: For unique materials or challenging geometries, custom SiC development can overcome limitations of off-the-shelf products, providing precise solutions to complex polishing challenges.

- Cost-Effectiveness in Volume: While initial design costs may be present, custom SiC pads can be more cost-effective in large-scale production by optimizing process efficiency and reducing rework.

- Confidentiality and IP Protection: Developing custom solutions with a trusted partner ensures proprietary designs and processes remain secure.

Recommended SiC Grades and Compositions for Polishing Pads

The performance of SiC polishing pads is highly dependent on the specific grade and composition of the silicon carbide used. Understanding the different types is crucial for selecting the optimal solution for your application. Here’s a comparison of common SiC types relevant to polishing:

| SiC Grade/Type | Key Characteristics | Typical Applications in Polishing Pads |

|---|---|---|

| Reaction-Bonded SiC (RBSC) | High thermal conductivity, excellent wear resistance, good mechanical strength, cost-effective for larger components. | Aggressive stock removal, heavy-duty polishing of hard materials, large format polishing pads. |

| Sintered Alpha SiC (SSiC) | Extremely high hardness, superior wear resistance, excellent chemical resistance, high purity, fine grain structure. | Precision polishing of delicate materials, semiconductor wafer polishing, high-purity applications, achieving ultra-fine finishes. |

| Nitride-Bonded SiC (NBSC) | Good thermal shock resistance, moderate hardness, good strength, more porous than SSiC. | Intermediate polishing steps, applications requiring good thermal stability without extreme hardness. |

| Recrystallized SiC (ReSiC) | High thermal shock resistance, good creep resistance, open porosity. | Less common for polishing pads, but may be used in specific high-temperature abrasive applications where thermal cycling is a major concern. |

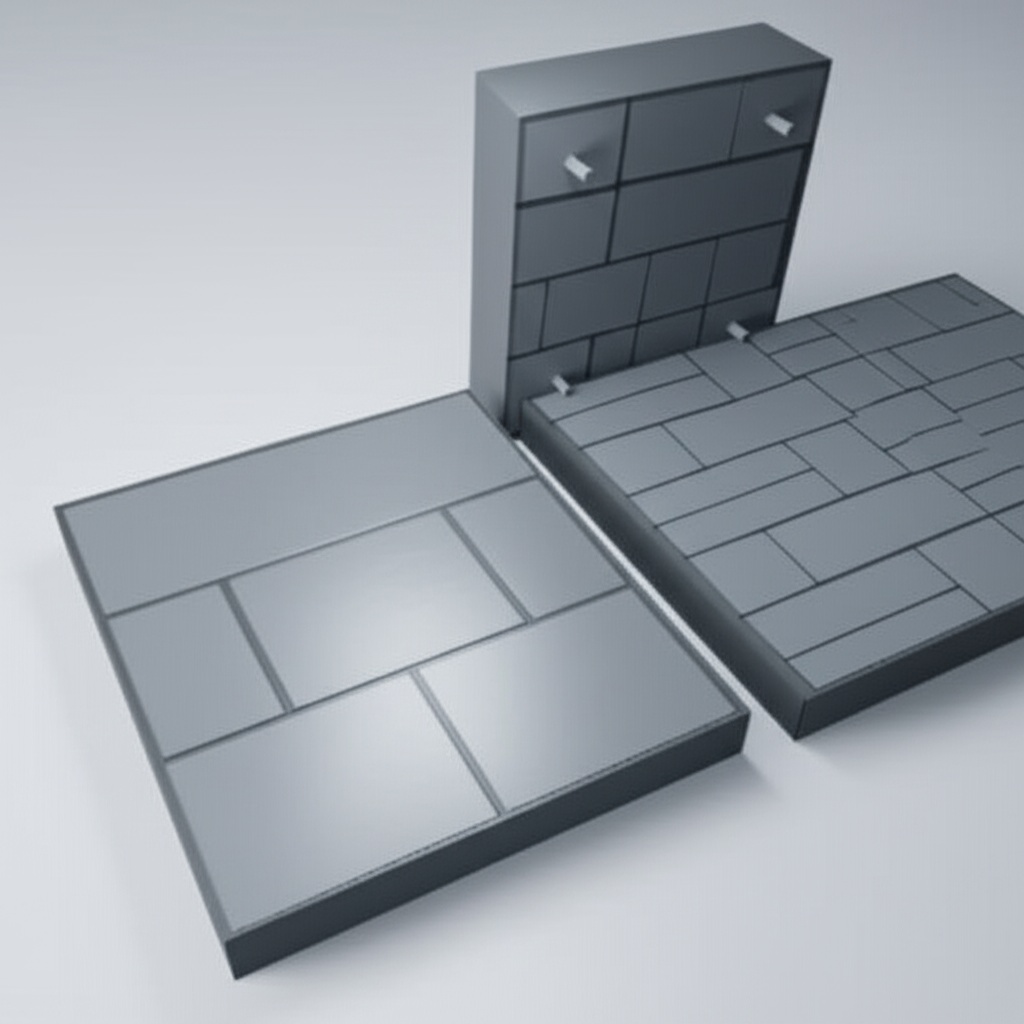

Design Considerations for SiC Polishing Pads

Effective SiC polishing pad design goes beyond simply choosing a material. It involves a holistic approach to geometry, mounting, and interface with the workpiece.

- Pad Geometry: The shape and size of the polishing pad must be tailored to the workpiece. This includes considerations for flat pads, contoured pads, or specialized geometries for internal diameters or complex surfaces.

- Groove Patterns: Designing specific groove patterns on the pad surface can enhance slurry distribution, remove debris more effectively, and improve cooling, leading to more consistent and efficient polishing.

- Bonding and Mounting: The method of bonding the SiC abrasive to a backing material or mounting the pad to the polishing equipment is crucial for stability and consistent performance. This could involve adhesive bonding, mechanical clamping, or integrated designs.

- Material Thickness: Appropriate pad thickness ensures structural integrity and allows for sufficient material to wear down over time without compromising performance.

- Cooling Channels: For high-speed or high-pressure polishing, integrating cooling channels within the pad design can prevent localized heating and thermal damage to both the pad and the workpiece.

- Weight and Balance: Especially for rotating pads, proper weight distribution and balance are essential to minimize vibration and ensure uniform polishing pressure.

Tolerance, Surface Finish & Dimensional Accuracy with SiC Polishing

The primary advantage of SiC polishing pads lies in their ability to achieve exceptional levels of precision. Understanding the achievable tolerances, surface finish options, and dimensional accuracy is crucial for engineers and buyers.

- Dimensional Tolerances: With advanced machining and polishing techniques, SiC polishing pads themselves can be manufactured to extremely tight dimensional tolerances, often in the micron range (e.g., ±5-10 microns for critical features). This precision in the tool directly translates to the precision of the polished workpiece.

- Surface Finish (Roughness): SiC polishing pads are capable of achieving very low surface roughness values. Depending on the abrasive grit size and process parameters, surface finishes of Ra (arithmetic average roughness) less than 0.1 µm, and even down to a few nanometers, are achievable, particularly with fine-grit SSiC pads in CMP applications.

- Flatness and Parallelism: For flat components, SiC polishing pads can achieve exceptional flatness (e.g., within 1-2 light bands or better for optical components) and parallelism, which are critical for semiconductor wafers, optical windows, and sealing surfaces.

- Edge Quality: SiC polishing can produce very clean and sharp edges, or precisely radiused edges, depending on the application requirements.

Post-Processing Needs for Optimal SiC Performance

While SiC polishing pads are designed for high performance, certain post-processing steps can further enhance their longevity, specific functionalities, or overall effectiveness in specialized applications:

- Cleaning: Thorough cleaning is essential to remove any residual polishing slurry or debris from the pad, preventing contamination in subsequent polishing cycles.

- Dressing and Conditioning: Over time, polishing pads can become glazed or loaded with workpiece material. Dressing and conditioning techniques, such as mechanical brushing or chemical treatments, restore the pad’s abrasive efficiency.

- Surface Treatments/Coatings: In some highly specialized applications, a thin coating (e.g., diamond-like carbon, specific polymers) might be applied to the SiC polishing pad to modify its tribological properties, improve lubricity, or enhance its resistance to specific chemicals.

- Sealing/Impregnation: For porous SiC grades, impregnation with resins or other materials can reduce porosity, improve mechanical strength, or prevent absorption of polishing fluids.

- Inspection and Quality Control: Post-processing always includes rigorous inspection, often using advanced metrology tools, to verify dimensional accuracy, surface finish, and overall quality before deployment.

Common Challenges and How to Overcome Them in SiC Polishing

Despite their superior properties, working with SiC polishing pads can present certain challenges. However, with proper understanding and techniques, these can be effectively mitigated.

| Challenge | Description | Mitigation Strategy |

|---|---|---|

| Brittleness | SiC is a hard, brittle material, making it susceptible to chipping or cracking under impact or excessive localized stress. | Careful handling during installation and operation. Optimize clamping mechanisms to distribute stress evenly. Employ proper feed rates and pressures during polishing to avoid sudden impacts. |

| Machining Complexity | Due to its hardness, SiC is difficult to machine into complex shapes, requiring specialized diamond tooling and techniques. | Partner with suppliers possessing advanced machining capabilities (e.g., diamond grinding, EDM, laser machining). Design for manufacturability to simplify geometries where possible. |

| Thermal Shock | Rapid temperature changes can induce thermal stress, potentially leading to cracking, especially in certain SiC grades. | Implement controlled heating and cooling cycles. Ensure consistent slurry temperature. Utilize SiC grades with higher thermal shock resistance where applicable. |

| Slurry Management | Proper selection and management of polishing slurries (abrasive type, concentration, pH) are critical for effective SiC polishing. | Work closely with slurry manufacturers or experienced SiC suppliers to optimize slurry chemistry for specific materials and desired finishes. Implement filtration and recirculation systems. |

| Pad Wear | While highly wear-resistant, SiC polishing pads will eventually wear down. Uneven wear can lead to inconsistencies. | Regular pad dressing and conditioning. Implement precise pad wear monitoring systems. Optimize polishing parameters to minimize excessive localized wear. |

How to Choose the Right SiC Polishing Pad Supplier

Selecting the right supplier for your custom silicon carbide polishing pads is a critical decision that impacts product quality, cost, and lead time. Look for a partner who offers more than just products; seek a comprehensive solution provider.

- Technical Expertise: The supplier should demonstrate deep knowledge of SiC material science, polishing processes, and relevant industry applications. They should be able to provide expert guidance on material selection, design optimization, and process parameters.

- Customization Capabilities: Ensure they have the engineering and manufacturing capabilities to produce custom SiC polishing pads tailored to your exact specifications, including complex geometries, specialized bonding, and precise surface finishes.

- Quality Control and Certifications: A reputable supplier will have robust quality management systems (e.g., ISO 9001) and a commitment to consistently high-quality products. Ask for material certifications and performance data.

- Material Portfolio: A diverse range of SiC grades (e.g., SSiC, RBSC) and bonding options indicates a broader capability to meet varied application needs.

- R&D and Innovation: A supplier actively engaged in research and development is more likely to offer cutting-edge solutions and adapt to evolving industry demands.

- Customer Support and Collaboration: Look for a partner who emphasizes collaborative problem-solving, responsive communication, and strong after-sales support.

- Geographic Advantage: For global procurement, consider suppliers with strategic manufacturing hubs that can offer competitive pricing and reliable supply chains.

When considering a reliable and high-quality source for custom silicon carbide products, including advanced polishing pads, it is worth noting the unique capabilities emerging from Weifang City, China. This region has become the hub of China’s silicon carbide customizable parts factories, home to over 40 silicon carbide production enterprises, collectively accounting for more than 80% of the nation’s total SiC output.

We, Sicarb Tech, have been instrumental in this development, introducing and implementing silicon carbide production technology since 2015. We have assisted local enterprises in achieving large-scale production and significant technological advancements. As a witness to the emergence and ongoing development of this industry, our roots are deeply intertwined with this thriving ecosystem.

Sicarb Tech operates under the umbrella of Chinese Academy of Sciences (Weifang) Innovation Park, a national-level innovation and entrepreneurship service platform that collaborates closely with the National Technology Transfer Center of the Chinese Academy of Sciences . This unique affiliation allows us to capitalize on the robust scientific, technological capabilities, and talent pool of Chinese Academy of Sciences, serving as a bridge for the transfer and commercialization of scientific and technological achievements.

This integration ensures more reliable quality and supply assurance. We possess a domestic top-tier professional team specializing in customized production of silicon carbide products. Under our support, 354+ local enterprises have benefited from our technologies. Our extensive expertise spans material, process, design, measurement, and evaluation technologies, offering an integrated approach from raw materials to finished products. This enables us to meet diverse customization needs and offer you higher-quality, cost-competitive customized silicon carbide components in China.

Beyond supplying custom components, Sicarb Tech is also committed to assisting you in establishing your own specialized factory. If you need to build a professional silicon carbide products manufacturing plant in your country, we can provide technology transfer for professional SiC production, along with a full range of services (turnkey project) including factory design, procurement of specialized equipment, installation and commissioning, and trial production. This ensures a more effective investment, reliable technology transformation, and a guaranteed input-output ratio. Explore our technology transfer solutions for building your own SiC production facility.

For inquiries about our products or partnership opportunities, please contact us. You can also review our successful case studies to see how we’ve helped other businesses achieve their goals. We are dedicated to providing cutting-edge SiC solutions tailored to your specific requirements.

Cost Drivers and Lead Time Considerations for SiC Polishing Pads

Understanding the factors that influence the cost and lead time of custom SiC polishing pads is essential for effective procurement and project planning.

| Cost Driver | Description | Impact on Cost |

|---|---|---|

| Material Grade | Sintered SiC (SSiC) is generally more expensive than Reaction-Bonded SiC (RBSC) due to higher purity and more complex manufacturing processes. | Higher material cost for SSiC, lower for RBSC. |

| Design Complexity | Intricate geometries, tight tolerances, and fine surface finishes require more advanced machining and polishing techniques. | Increased manufacturing cost, especially for complex designs. |

| Size and Volume | Larger pads require more material. Higher production volumes often lead to economies of scale. | Larger sizes increase cost. Higher volumes reduce per-unit cost. |

| Post-Processing Needs | Additional steps like specialized coatings, impregnation, or ultra-fine lapping add to the production cost. | Increased cost for additional processing steps. |

| Tooling and Molds | For custom designs, initial tooling or mold costs may be incurred, which are amortized over the production run. | Upfront cost for new tooling/molds, can be significant for low volumes. |

Lead Time Considerations:

- Design and Prototyping: Initial custom designs often require prototyping and testing, adding to the lead time.

- Material Availability: The availability of specific SiC grades and forms can influence the overall lead time.

- Manufacturing Capacity: Supplier’s current production load and available machinery will impact lead times.

- Complexity of Fabrication: Highly complex parts with demanding tolerances will naturally require longer production times.

- Shipping and Logistics: International shipping and customs processes can add significant time, especially for overseas suppliers.

Frequently Asked Questions (FAQ)

- Q1: What is the typical lifespan of a SiC polishing pad?

- A1: The lifespan of a SiC polishing pad varies significantly depending on the SiC grade, the material being polished, the process parameters (pressure, speed, slurry type), and proper maintenance. With appropriate dressing and conditioning, SiC pads can offer extended service life compared to conventional abrasives, often lasting for hundreds or thousands of operational hours.

- Q2: Can SiC polishing pads be reconditioned or refurbished?

- A2: Yes, many SiC polishing pads can be reconditioned through techniques like dressing, grinding, or re-texturing to restore their abrasive properties and flatness. The feasibility and effectiveness of refurbishment depend on the extent of wear and the original pad design. It’s best to consult with your supplier for specific recommendations.

- Q3: Are custom SiC polishing pads more cost-effective than standard options?

- A3: For high-volume production or highly specialized applications, custom SiC polishing pads can be significantly more cost-effective in the long run. While they may have a higher initial design and tooling cost, their optimized performance leads to faster processing times, fewer defects, reduced material waste, and extended pad lifespan, resulting in lower overall operational costs. For smaller, less demanding applications, standard pads might be more economical.

Conclusion: The Future is Polished with Custom SiC

In an industrial landscape where precision, durability, and efficiency are non-negotiable, custom silicon carbide polishing pads stand as a testament to advanced material engineering. From achieving ultra-flat surfaces in semiconductor manufacturing to enhancing the wear resistance of aerospace components, SiC polishing pads are critical enablers of high-performance products across a vast array of industries.

For engineers, procurement managers, and technical buyers, investing in custom SiC polishing solutions represents a strategic move towards optimizing production processes, improving product quality, and securing a competitive edge. By partnering with a knowledgeable and capable supplier like Sicarb Tech, you gain access to not only cutting-edge SiC technology but also a deep well of expertise and a commitment to collaborative innovation. Embrace the power of precision with custom silicon carbide polishing pads and elevate your products to a new standard of excellence. Visit our website to learn more about our comprehensive custom SiC solutions.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.