Mastering the Blaze: The Essential Role of High-Temperature Furnaces and Custom Silicon Carbide Components

Share

In the demanding landscape of modern industrial processes, achieving and maintaining extreme temperatures with precision and reliability is paramount. High-temperature furnaces are the workhorses behind countless innovations, from semiconductor fabrication to aerospace engineering. Central to their performance, especially in the most challenging thermal environments, is the utilization of advanced materials like custom silicon carbide (SiC). These specialized furnaces, whether designed for SiC material production itself or incorporating SiC components for unparalleled resilience, are indispensable. This blog delves into the critical synergy between high-temperature furnaces and silicon carbide, exploring why custom SiC products are essential for high-performance industrial applications and how they drive efficiency and longevity in environments where other materials falter. For engineers, procurement managers, and technical buyers, understanding the nuances of SiC in furnace applications is key to optimizing operations and achieving superior outcomes.

The Indispensable Role of Silicon Carbide in High-Temperature Furnace Construction and Operation

Silicon carbide has carved an undeniable niche as a premier material for constructing and enhancing high-temperature furnaces. Its exceptional combination of properties makes it uniquely suited for environments where thermal stability, mechanical strength, and chemical resistance are non-negotiable. Technical ceramics like SiC are fundamental to pushing the boundaries of high-temperature processing.

At the core of its utility is SiC’s remarkable ability to withstand extreme temperatures, often exceeding 1600∘C (2912∘F) and even higher for specific grades, without significant degradation in mechanical properties. This high-temperature strength ensures that furnace components retain their structural integrity under severe thermal loads. Furthermore, silicon carbide exhibits excellent thermal shock resistance, meaning it can endure rapid temperature changes without cracking or failing. This is particularly crucial in cyclical furnace operations common in many industrial processes.

Another vital characteristic is SiC’s high thermal conductivity. This property allows for efficient and uniform heat distribution within the furnace, leading to more consistent product quality and reduced energy consumption. Whether used as heating elements, furnace linings, or kiln furniture, SiC components contribute to a more stable and predictable thermal environment.

The chemical inertness of silicon carbide is also a significant advantage. It resists corrosion and attack from a wide range of chemicals and process atmospheres, including oxidizing and reducing environments. This inertness prevents contamination of the processed materials, a critical factor in industries like semiconductor manufacturing and high-purity ceramics production.

Different forms of SiC cater to specific needs within furnace applications:

- Reaction-Bonded Silicon Carbide (RBSiC or SiSiC): Offers excellent wear resistance, high strength, and good thermal shock resistance, making it suitable for beams, nozzles, and rollers.

- Sintered Silicon Carbide (SSiC): Provides superior chemical purity, corrosion resistance, and strength at very high temperatures, ideal for critical components like semiconductor processing parts.

- Nitride-Bonded Silicon Carbide (NBSiC): Known for its exceptional thermal shock resistance and good mechanical strength, often used for kiln furniture and thermocouple protection tubes.

- Recrystallized Silicon Carbide (RSiC): Offers high porosity for applications like filters but also high temperature stability, making it suitable for setters and support structures that don’t require gas tightness.

The integration of these SiC furnace components ensures longer operational lifespans, reduced downtime for maintenance, and overall improved efficiency in high-temperature industrial furnaces.

Key Advantages of Using Custom SiC Components in High-Temperature Furnaces

While standard SiC components offer significant benefits, the ability to customize these parts unlocks a new level of performance and efficiency in high-temperature furnaces. Custom SiC fabrication allows engineers and procurement professionals to tailor components precisely to their specific operational needs, leading to a cascade of advantages that directly impact the bottom line and product quality. This is particularly beneficial for wholesale buyers and OEMs seeking optimized solutions.

The primary benefits of opting for custom silicon carbide components include:

- Enhanced Thermal Management: Custom-designed SiC parts, such as industrial heating elements SiC or bespoke furnace linings, can be optimized for specific heat distribution patterns. This leads to improved temperature uniformity within the furnace, which is critical for processes like annealing, sintering, and crystal growth. Better thermal management translates to higher product yields and reduced energy wastage.

- Increased Component Lifespan: By tailoring the SiC grade (e.g., reaction bonded silicon carbide furnace parts for mechanical strength or sintered silicon carbide furnace components for extreme purity and corrosion resistance) and geometry to the specific stresses, chemical environment, and thermal cycling of the furnace, custom components exhibit superior durability. This results in longer service life, fewer replacements, and reduced maintenance downtime.

- Optimized Mechanical Performance: Customization allows for the reinforcement of critical stress points and the design of complex geometries that would be impossible with off-the-shelf parts. This ensures that kiln furniture SiC, such as beams, rollers, and supports, can handle specific loads at high temperatures without deformation or failure, improving process reliability.

- Reduced Contamination: For industries requiring high purity, such as semiconductor and advanced materials manufacturing, custom SiC components can be designed to minimize outgassing and particulate generation. Selecting ultra-high purity SiC grades and optimizing surface finishes contribute to a cleaner furnace environment.

- Improved Energy Efficiency: Components designed for optimal heat transfer and insulation contribute directly to lower energy consumption. Custom SiC heating elements can be designed for specific resistances and radiative properties, ensuring energy is delivered precisely where needed.

- Process-Specific Solutions: Many industrial furnaces have unique requirements based on the materials being processed or the specific thermal cycle. Custom SiC components allow for the integration of features like specific flow channels, thermocouple ports, or mounting interfaces, streamlining the overall process and improving control.

Below is a table highlighting how customization addresses common furnace challenges:

| Challenge in High-Temperature Furnaces | How Custom SiC Components Provide a Solution | Benefit for B2B Buyers |

|---|---|---|

| Non-uniform temperature distribution | Optimized design of heating elements, baffles, or radiant tubes | Improved product consistency, higher yield |

| Premature component failure | Selection of appropriate SiC grade and reinforced design features | Reduced downtime, lower replacement costs |

| Contamination of processed materials | Use of high-purity SiC, specific surface finishes | Enhanced product quality, suitable for sensitive applications |

| High energy consumption | Components designed for efficient heat transfer and insulation | Lower operational costs, improved sustainability |

| Difficulty integrating standard parts | Custom geometries and features for seamless fit and function | Easier assembly, optimized process flow |

By investing in custom silicon carbide products, businesses can significantly enhance the performance, reliability, and cost-effectiveness of their high-temperature furnace operations. This strategic approach ensures that the furnace system is not just functional but is optimized for the specific demands of the application.

Types of High-Temperature Furnaces Utilizing SiC Components

Silicon carbide’s versatility and exceptional properties make it a cornerstone material in a wide array of high-temperature furnaces across diverse industrial applications. From the production of advanced materials to the heat treatment of metals, SiC furnace components play a critical role in enabling these demanding processes. Understanding the types of furnaces that benefit most from SiC can help technical procurement professionals and engineers make informed decisions.

Here are some prominent examples of high-temperature furnaces where silicon carbide components are extensively used:

- Sintering Furnaces: Used for densifying powdered materials (ceramics, metals, cermets) at high temperatures, sintering furnaces rely on SiC for heating elements, kiln furniture (setters, plates, beams), and muffle tubes. The ability of SiC to maintain strength and provide uniform heating at temperatures often exceeding 1400∘C is crucial for producing high-quality sintered products. Sintered silicon carbide furnace components themselves are often produced in such furnaces, showcasing a full-circle application.

- Annealing Furnaces: These furnaces are used to alter the microstructure of materials like metals and glass by heating them to a specific temperature and then cooling them slowly. SiC radiant tubes and heating elements are favored for their longevity and ability to create controlled atmospheres, preventing oxidation or unwanted reactions.

- Diffusion Furnaces: Predominantly used in semiconductor manufacturing for processes like doping and oxidation of silicon wafers. These furnaces require extremely high purity and precise temperature control. SiC process tubes, wafer boats, and liners are essential because they minimize particle generation and can withstand the corrosive gases and high temperatures involved (often 800∘C to 1200∘C).

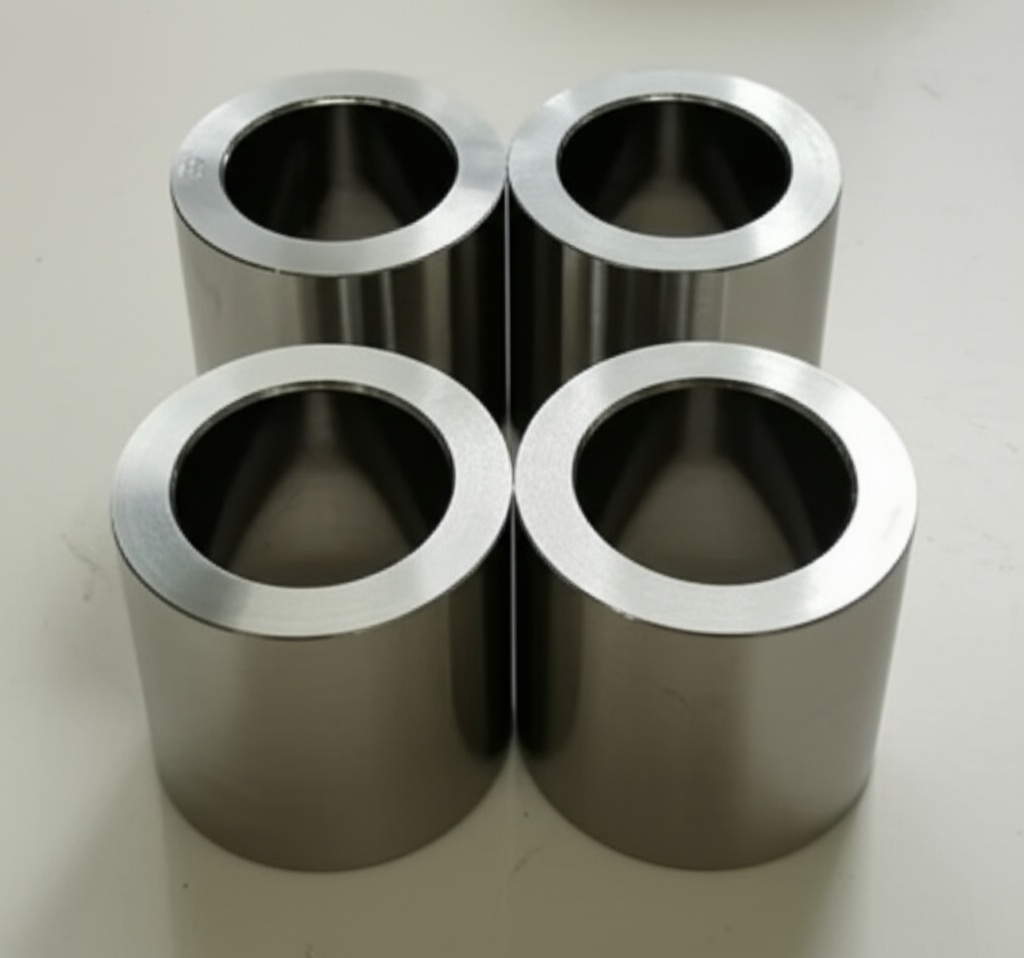

- Melting and Holding Furnaces: In the metallurgical industry, particularly for non-ferrous metals like aluminum and copper, SiC is used for crucibles, thermocouple protection tubes, and immersion heater tubes. Its resistance to molten metal attack and excellent thermal conductivity ensure efficient melting and temperature maintenance.

- Ceramic Firing Kilns: For firing a wide range of technical ceramics, pottery, and refractories, SiC kiln furniture (shelves, posts, beams) is indispensable. It offers high load-bearing capacity at elevated temperatures, allowing for efficient stacking of products and maximizing kiln throughput. Reaction bonded silicon carbide furnace parts and nitride-bonded SiC are common choices here.

- Heat Treatment Furnaces: Used for various processes like hardening, tempering, and carburizing of metals, these furnaces benefit from SiC heating elements and radiant tubes for their rapid heating capabilities and durability in harsh chemical environments.

- Laboratory and Research Furnaces: Smaller-scale furnaces used for R&D often employ SiC heating elements and tubes due to their reliability, fast ramp-up rates, and ability to achieve very high temperatures, facilitating experimentation with novel materials and processes.

- Incineration Furnaces: For waste treatment at high temperatures, SiC linings and components offer excellent resistance to corrosive byproducts and thermal shock, ensuring long operational life.

The table below summarizes common SiC components used in these furnace types:

| Furnace Type | Common SiC Components Used | Key SiC Properties Leveraged |

|---|---|---|

| Sintering Furnaces | Heating elements, kiln furniture, muffle tubes | High temperature strength, thermal conductivity, inertness |

| Annealing Furnaces | Radiant tubes, heating elements | Longevity, controlled atmosphere compatibility |

| Diffusion Furnaces | Process tubes, wafer boats, liners, paddles | High purity, thermal shock resistance, chemical inertness |

| Melting/Holding Furnaces | Crucibles, thermocouple tubes, immersion heater tubes | Molten metal resistance, thermal conductivity |

| Ceramic Firing Kilns | Kiln shelves, posts, beams, setters | High load-bearing capacity, thermal shock resistance |

| Heat Treatment Furnaces | Heating elements, radiant tubes, muffles | Rapid heating, durability, chemical resistance |

| Laboratory Furnaces | Heating elements, tubes, crucibles | High temperature capability, fast ramp rates, reliability |

| Incineration Furnaces | Linings, nozzles, burner components | Corrosion resistance, thermal shock resistance, abrasion resistance |

The widespread adoption of SiC in these varied high-temperature furnaces underscores its status as a critical enabling material for many advanced manufacturing and processing industries. Custom SiC fabrication further allows these applications to be fine-tuned for optimal performance.

Critical Design and Material Considerations for SiC Furnace Components

Designing and selecting the right silicon carbide components for high-temperature furnaces is a complex process that requires careful consideration of numerous interacting factors. The success of a furnace application hinges on choosing the appropriate SiC grade and optimizing the component design to withstand the specific operational environment. This is where collaboration with experienced SiC material suppliers who offer robust customizing support becomes invaluable.

Key considerations include:

- Operating Temperature and Thermal Cycling:

- Maximum Temperature: The SiC grade must be able to withstand the peak operating temperature without deformation, creep, or excessive oxidation. For instance, while Reaction Bonded SiC (RBSiC) is excellent up to around 1350−1380∘C, Sintered SiC (SSiC) can often perform at temperatures exceeding 1600∘C.

- Thermal Cycling: Frequent or rapid changes in temperature can induce thermal shock. Materials like Nitride Bonded SiC (NBSiC) or certain grades of RBSiC offer superior thermal shock resistance compared to SSiC. The design should also aim to minimize stress concentrations that can be exacerbated by thermal cycling.

- Furnace Atmosphere and Chemical Environment:

- Oxidizing Atmospheres: Most SiC materials form a protective silica (SiO2) layer in oxidizing environments, which slows down further oxidation. However, the stability of this layer can be affected by temperature and the presence of other elements.

- Reducing Atmospheres: In strongly reducing atmospheres (e.g., hydrogen, carbon monoxide) or vacuum at very high temperatures, active oxidation can occur, leading to material degradation. SSiC generally offers better resistance than RBSiC in such conditions due to the absence of free silicon.

- Chemical Attack: The presence of molten metals, salts, slags, or aggressive gases (e.g., halogens) requires careful selection. SSiC typically exhibits the best overall chemical resistance. Coatings can sometimes be applied to enhance protection.

- Mechanical Loads and Stresses:

- Static Loads: Kiln furniture (beams, plates, rollers) must support the weight of the products being processed at high temperatures. The flexural strength and creep resistance of the SiC material are critical. Custom designs can incorporate ribs or optimized cross-sections to enhance load-bearing capacity.

- Dynamic Loads: Components like rollers or parts subjected to vibration need good fatigue resistance.

- Stress Concentrations: Sharp corners, notches, and abrupt changes in thickness can lead to stress concentrations and premature failure. Designs should incorporate generous radii and smooth transitions.

- Component Geometry and Manufacturability:

- Complexity: While custom SiC fabrication allows for intricate shapes, there are limits imposed by the manufacturing process (e.g., pressing, slip casting, extrusion, machining of green or sintered bodies). Complex designs can increase costs and lead times.

- Wall Thickness: Minimum and maximum wall thicknesses vary by manufacturing method and SiC grade. Thin walls can be prone to damage, while overly thick sections can lead to thermal stresses or issues during firing.

- Tolerances: The achievable dimensional tolerances depend on the SiC grade and manufacturing process. Sintered SiC can often be machined to tighter tolerances after firing, but this adds to the cost.

- Electrical Properties (for Heating Elements):

- Resistivity: The electrical resistivity of SiC changes with temperature and material grade. This is a critical parameter for designing SiC heating elements to achieve the desired power output and temperature.

- Aging: Over time and with use, the resistivity of SiC heating elements can increase (aging). This needs to be factored into the power supply design and element lifespan predictions.

The following table outlines how different SiC grades align with some of these critical considerations:

| SiC Grade | Max. Use Temp. (approx.) | Thermal Shock Resistance | Flexural Strength (RT) | Chemical Resistance | Typical Furnace Applications |

|---|---|---|---|---|---|

| Reaction Bonded SiC (RBSiC / SiSiC) | 1380∘C | Good to Excellent | High | Good (fair in alkalis) | Beams, rollers, nozzles, plates, wear parts, burner tubes |

| Sintered SiC (SSiC) | 1600∘C+ | Fair to Good | Very High | Excellent | Process tubes, chemical processing components, advanced kiln furniture, semiconductor parts |

| Nitride Bonded SiC (NBSiC) | 1450∘C | Excellent | Moderate | Good | Kiln furniture, thermocouple tubes, crucible linings |

| Recrystallized SiC (RSiC) – (Porous) | 1650∘C | Excellent | Moderate to Low | Good | Setters, plates, supports (where gas tightness isn’t needed) |

| Clay Bonded SiC (CBSiC) – (Lower Grade) | 1300∘C | Good | Low to Moderate | Fair | Muffles, general kiln furniture (less demanding applications) |

Optimizing Performance: Post-Processing and Maintenance of SiC Furnace Parts

Ensuring the long-term, optimal performance of silicon carbide components within high-temperature furnaces goes beyond initial design and material selection. Strategic post-processing treatments and diligent maintenance practices are key to maximizing their service life, maintaining furnace efficiency, and safeguarding the quality of processed goods. For technical buyers and plant managers, understanding these aspects contributes to lower total cost of ownership and more reliable industrial furnace operations.

Post-Processing Treatments for Enhanced Performance:

After the initial shaping and firing (sintering or reaction bonding) of SiC components, several post-processing steps can be employed to meet specific application requirements:

- Grinding and Lapping: For applications demanding tight dimensional tolerances and smooth surface finishes, such as semiconductor process tubes, precision seals, or mating surfaces, SiC components can be ground or lapped. Diamond abrasives are typically used due to SiC’s extreme hardness. This can improve fit, reduce wear, and minimize particle generation.

- Polishing: Achieves even finer surface finishes than grinding or lapping, which can be critical for optical applications (though rare for furnace parts) or where ultra-smooth surfaces are needed to prevent material adhesion or contamination.

- Coatings:

- Anti-Oxidation Coatings: While SiC naturally forms a protective silica layer, specialized coatings (e.g., CVD SiO2, mullite, or proprietary ceramic coatings) can be applied to further enhance oxidation resistance, especially in very aggressive atmospheres or at the upper limits of the SiC’s temperature range. This is particularly relevant for advanced ceramics manufacturing where extended component life is crucial.

- Chemical Barrier Coatings: To improve resistance against specific chemical attacks (e.g., from certain molten metals or corrosive gases), tailored barrier coatings can be applied.

- Non-Wetting Coatings: For applications involving molten materials, coatings can be used to prevent wetting and adhesion, making cleaning easier and extending component life.

- Sealing: Some grades of SiC, like certain types of RSiC or less dense RBSiC, can have inherent porosity. If gas tightness is required (e.g., for muffle tubes or controlled atmosphere applications), a sealing treatment or glaze can be applied to close off surface porosity. SSiC is inherently non-porous.

- Edge Chamfering/Radiusing: To reduce the risk of chipping or cracking initiation at sharp edges, especially for components handled frequently or subjected to mechanical stress, edges can be chamfered or radiused.

Maintenance Practices for SiC Furnace Components:

Regular inspection and appropriate maintenance are vital for extending the life of SiC furnace components and ensuring safe, efficient furnace operation.

- Regular Visual Inspection:

- Look for signs of cracking, chipping, spalling, or excessive wear.

- Inspect for discoloration, which might indicate oxidation or chemical attack.

- Check for any warping or sagging, especially in load-bearing components like beams and shelves.

- Examine heating elements for signs of overheating, thinning, or breakage.

- Cleaning:

- Periodically remove any product residue, dust, or debris from SiC components. The cleaning method will depend on the nature of the residue and the SiC grade. Avoid aggressive mechanical scraping that could damage the surface.

- For heating elements, ensure there’s no buildup that could cause localized overheating.

- Atmosphere Control: Ensure the furnace atmosphere is maintained within the specified parameters for the SiC grade in use. Deviations can accelerate degradation.

- Load Management: Avoid overloading kiln furniture beyond its design capacity, especially at peak temperatures where creep can become a factor. Ensure loads are distributed evenly.

- Monitoring Heating Element Resistance: For SiC heating elements, periodically check their electrical resistance. A significant increase can indicate aging and may signal the need for replacement or adjustment of the power supply.

- Gentle Handling: SiC is a strong but brittle ceramic. Components should be handled with care during installation, removal, and maintenance to prevent mechanical shock or impact damage.

- Record Keeping: Maintain logs of component installation dates, inspection findings, and any maintenance performed. This data can help predict service life and optimize replacement schedules.

By implementing these post-processing and maintenance strategies, users of high temperature furnaces for SiC applications can significantly enhance component durability and overall operational efficiency. Partnering with a supplier like Sicarb Tech, which understands the intricacies of custom SiC fabrication and subsequent treatments, ensures that you receive components optimized from the outset for your demanding environment. Their expertise in material, process, design, measurement & evaluation technologies supports the entire lifecycle of your SiC components.

Choosing Your Partner for High-Temperature SiC Furnace Solutions: Why Sicarb TechExcels

Selecting the right supplier for your custom silicon carbide products is as critical as the material choice itself, especially when dealing with the demanding requirements of high-temperature furnace applications. Your chosen partner should not only provide high-quality materials but also offer profound technical expertise, reliable supply chains, and comprehensive support. This is whereSicarb Tech distinguishes itself as a premier provider and a trusted partner for OEMs, distributors, technical procurement professionals, and wholesale buyers worldwide.

The Weifang SiC Hub and SicSino’s Foundational Role: Weifang City, China, stands as the epicenter of the nation’s silicon carbide customizable parts manufacturing. This region is home to over 40 SiC production enterprises, collectively responsible for more than 80% of China’s total SiC output. Sicarb Tech has been an integral part of this ecosystem since 2015, introducing and implementing advanced silicon carbide production technology. We have actively assisted local enterprises in achieving large-scale production and significant technological advancements in product processes, witnessing firsthand the growth and maturation of this vital industry. Our deep roots in this SiC heartland provide us with unparalleled access to resources and manufacturing capabilities.

Leveraging the Strength of the Chinese Academy of Sciences : Sicarb Tech operates under the umbrella of the Chinese Academy of Sciences(Weifang) Innovation Park and is closely affiliated with the National Technology Transfer Center of the Chinese Academy of Sciences. This connection is a cornerstone of our strength, providing us access to the formidable scientific, technological capabilities, and talent pool of one of the world’s leading research institutions. This backing ensures that our clients benefit from:

- Reliable Quality and Supply Assurance: We possess a domestic top-tier professional team specializing in the customized production of silicon carbide products.

- Advanced Technology Integration: We leverage a wide array of technologies, encompassing material science, process engineering, component design, and meticulous measurement & evaluation techniques.

- Comprehensive Service Ecosystem: Our operations are supported by a robust system for technology transfer and commercialization, ensuring that cutting-edge innovations are translated into practical, high-performance products.

Unmatched Customization and Technical Support: At SicSino, we understand that “one size fits all” does not apply to high-performance SiC furnace components. Our core strength lies in our ability to meet diverse customization needs.

- Integrated Process: We manage the entire process from raw materials to finished products, allowing for tight quality control and optimization at every stage.

- Expert Team: Our professional team works closely with clients to understand their specific application requirements, including operating temperatures, chemical environments, mechanical loads, and desired component lifespan.

- Tailored Solutions: We offer higher-quality, cost-competitive customized silicon carbide components designed to enhance the efficiency and longevity of your high temperature furnaces for SiC applications. To date, over 10 local enterprises have directly benefited from our technological support and expertise.

Beyond Components: Technology Transfer and Turnkey Projects: Sicarb Tech is also committed to fostering global advancements in SiC production. For clients looking to establish their own specialized silicon carbide product manufacturing plants, we offer comprehensive technology transfer services. This includes:

- Factory design and layout

- Procurement of specialized equipment

- Installation and commissioning

- Trial production support

- Full-range services (turnkey projects)

This unique offering enables international partners to build their own professional SiC manufacturing capabilities with a more effective investment, reliable technology transformation, and a guaranteed input-output ratio.

The table below summarizes the key advantages of partnering with Sicarb Tech:

| Feature | Benefit for B2B Customers |

|---|---|

| Location in Weifang SiC Hub | Access to extensive manufacturing capacity and a mature supply chain. |

| Backed by Chinese Academy of Sciences | Assurance of cutting-edge technology, high-quality standards, and reliable innovation. |

| Domestic Top-Tier Professional Team | Deep expertise in SiC material science, design, and manufacturing for optimal component performance. |

| Wide Array of Integrated Technologies | Comprehensive solutions from material selection to final product evaluation, meeting diverse and complex customization needs. |

| Cost-Competitive, High-Quality Custom Parts | Optimized value proposition, ensuring superior performance without excessive costs for your industrial applications. |

| Technology Transfer & Turnkey Project Capability | Unique opportunity for partners to develop their own SiC production facilities with expert guidance and proven technology. |

Choosing Sicarb Tech means partnering with a leader in the silicon carbide industry, one that combines the vast resources of China’s SiC manufacturing heartland with the unparalleled scientific prowess of the Chinese Academy of Sciences. We are dedicated to providing not just components, but complete, reliable, and technologically advanced solutions for your high-temperature furnace needs.

Frequently Asked Questions (FAQ)

Navigating the selection and implementation of silicon carbide components for high-temperature furnaces often brings up specific questions for engineers, procurement managers, and technical buyers. Here are some common queries with concise, practical answers:

- What is the typical maximum operating temperature for silicon carbide components in a high-temperature furnace? The maximum operating temperature for SiC components varies significantly depending on the specific grade of silicon carbide and the furnace atmosphere.

- Reaction-Bonded Silicon Carbide (RBSiC or SiSiC): Generally suitable for continuous use up to approximately 1350∘C to 1380∘C (2462∘F to 2516∘F). Above this, the free silicon within the matrix can begin to soften or melt.

- Sintered Silicon Carbide (SSiC): Can often be used at temperatures exceeding 1600∘C (2912∘F), with some grades performing well up to 1800∘C (3272∘F) or even higher in controlled, non-oxidizing atmospheres. SSiC’s purity and lack of a secondary bonding phase contribute to its superior high-temperature stability.

- Nitride-Bonded Silicon Carbide (NBSiC): Typically used up to around 1450∘C (2642∘F).

- Recrystallized Silicon Carbide (RSiC): Can withstand temperatures up to 1650∘C (3002∘F). It’s crucial to consider the furnace atmosphere (oxidizing, reducing, vacuum) as this can also impact the effective maximum use temperature and lifespan of the SiC furnace components. Always consult with your SiC material supplier, like Sicarb Tech, to select the optimal grade for your specific temperature and atmospheric conditions.

- How does silicon carbide compare to other refractory materials like alumina or molybdenum disilicide for high-temperature furnace applications? Silicon carbide offers a unique balance of properties that make it advantageous over other refractories in many situations, but the best choice depends on the specific application requirements. | Feature | Silicon Carbide (SiC) | High-Purity Alumina (Al2O3) | Molybdenum Disilicide (MoSi2) (Heating Elements) | | :———————- | :———————————————————- | :———————————————————– | :————————————————————– | | Max. Temperature | Up to 1600∘C+ (SSiC), lower for other grades | Up to 1700−1800∘C | Up to 1800∘C (in oxidizing atm.) | | Thermal Shock Res. | Good to Excellent (especially NBSiC, RSiC, some RBSiC) | Fair to Poor (can be improved with specific formulations) | Good | | Thermal Conductivity| High | Moderate | Moderate to High | | Mechanical Strength | Very High (especially at elevated temperatures) | Good (strength decreases significantly at high temps) | Brittle at RT, becomes ductile at high temps, good hot strength | | Chemical Resistance | Good to Excellent (especially SSiC) | Excellent against many chemicals, but susceptible to some fluxes | Excellent oxidation resistance, but attacked by reducing atm. & some contaminants | | Electrical Props. | Semiconductor (used for heating elements & structural parts) | Insulator (primarily structural/lining) | Conductor (primarily heating elements) | | Cost | Moderate to High | Moderate | High |

- SiC vs. Alumina: SiC generally offers better thermal shock resistance, higher thermal conductivity, and superior strength at very high temperatures compared to alumina. Alumina might be preferred for its electrical insulation properties or in certain chemical environments where it offers better resistance.

- SiC vs. MoSi2 (for heating elements): MoSi2 elements can reach higher temperatures than most SiC elements and have excellent oxidation resistance. However, MoSi2 is very brittle at room temperature and can be susceptible to “pesting” (disintegration) at intermediate temperatures in certain atmospheres. SiC elements are generally more robust mechanically and can operate in a wider range of atmospheres, often at a lower cost point for comparable power. The choice involves a trade-off between performance, lifespan, and cost, tailored to the specific industrial furnace environment and process.

- What information is essential to provide to a supplier like Sicarb Tech when requesting a quote for custom SiC furnace components? To receive an accurate and timely quote for custom silicon carbide products, and to ensure the components are perfectly suited for your application, providing comprehensive information is key. Essential details include:

- Detailed Drawings or 3D Models: Precise dimensions, tolerances, surface finish requirements, and any special features (holes, slots, chamfers).SiC Grade Preference (if known): If you have a specific grade in mind (e.g., RBSiC, SSiC) or performance requirements that point to a certain grade. If unsure, describe the application in detail.Operating Conditions:

- Maximum and typical operating temperatures.Rate of temperature change (heating/cooling rates, frequency of cycling).Furnace atmosphere (e.g., air, nitrogen, argon, vacuum, reactive gases with concentrations).Description of materials being processed in the furnace.

- Loads or stresses the component will experience (e.g., weight of products on kiln furniture).Points of contact or support.

- Detailed Drawings or 3D Models: Precise dimensions, tolerances, surface finish requirements, and any special features (holes, slots, chamfers).SiC Grade Preference (if known): If you have a specific grade in mind (e.g., RBSiC, SSiC) or performance requirements that point to a certain grade. If unsure, describe the application in detail.Operating Conditions:

Conclusion: The Enduring Value of Custom Silicon Carbide in Demanding Industrial Environments

The journey through the world of high-temperature furnaces and the critical role of silicon carbide underscores a fundamental truth: in the face of extreme conditions, material excellence is not just an advantage, it’s a necessity. Custom silicon carbide products stand out as a cornerstone of reliability, efficiency, and innovation in a multitude of industrial applications, from semiconductor processing to advanced ceramics manufacturing. Their unparalleled thermal resistance, superior mechanical strength at elevated temperatures, exceptional thermal shock resistance, and robust chemical inertness make them the material of choice for components that must perform flawlessly when the heat is on.

By opting for custom-designed SiC components, engineers and procurement managers can unlock significant benefits: extended component lifespan, improved temperature uniformity leading to higher product quality, enhanced energy efficiency, and reduced furnace downtime. These advantages translate directly into lower operational costs and a stronger competitive edge for OEMs, wholesale buyers, and end-users alike.

Choosing the right partner for these critical components is paramount. Sicarb Tech, strategically positioned in Weifang, the heart of China’s SiC industry, and backed by the scientific prowess of the Chinese Academy of Sciences, offers an unmatched combination of expertise, quality, and customization. Our deep understanding of SiC furnace components, from reaction bonded silicon carbide furnace parts to high-purity sintered silicon carbide furnace solutions, coupled with our comprehensive design and manufacturing capabilities, ensures that our clients receive components perfectly tailored to their demanding environments. Furthermore, our commitment extends to technology transfer, empowering global partners to establish their own advanced SiC production facilities.

In conclusion, as industries continue to push the boundaries of temperature and performance, the demand for sophisticated materials like silicon carbide will only grow. Investing in high-quality, custom SiC solutions from a trusted supplier like Sicarb Tech is an investment in the future of your high-temperature operations—a future characterized by greater efficiency, enhanced reliability, and superior outcomes.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.