Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Guide for Combustion Chambers and Flue Ducts

Share

Pakistan’s industrial backbone—cement, steel, and glass—enters 2025 under dual pressures: expand capacity and cut unit energy, all while coping with volatile fuels and stricter environmental oversight. Inside furnace combustion chambers and flue ducts, the operating reality has grown harsher. Alternating oxidizing/reducing atmospheres, dust-laden high-velocity flows, alkali–sulfur–chlorine volatiles, secondary air disturbances, and frequent start–stop cycles collide to create relentless fouling, scouring, and thermal shock. Conventional refractories or generic coatings rarely sustain performance across this spectrum. Industrial silicon carbide (SiC), engineered as dense structures with low-wettability surfaces, is redefining outcomes. Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings 10+ years of SiC customization, full-cycle manufacturing, and turnkey technology transfer to help Pakistani plants localize capability, stabilize performance, and de-risk supply.

Executive Summary: 2025 Outlook and Why Silicon Carbide Matters for Pakistan’s Combustion and Flue Assets

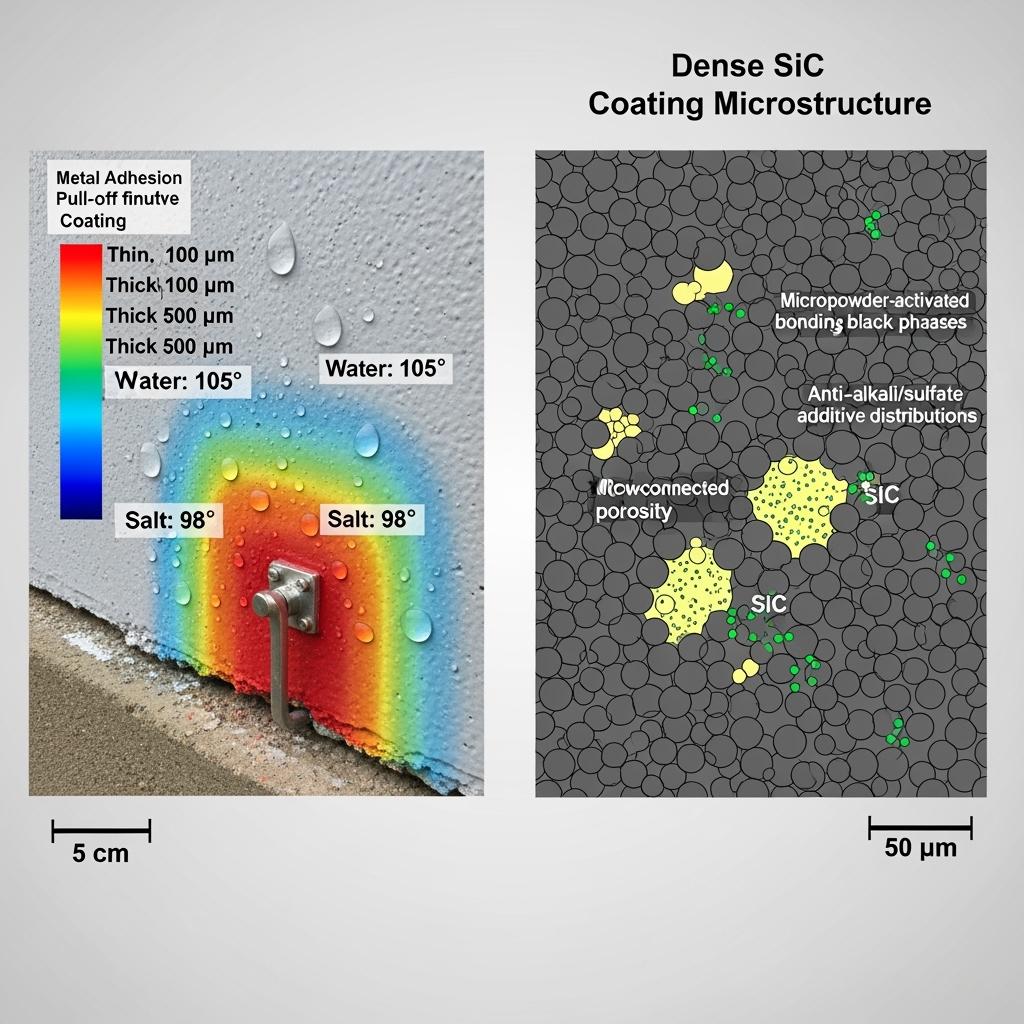

Across Pakistani clinker lines, steel reheating furnaces, and glass melters, the stakes are familiar: maintain thermal efficiency, control pressure drop, and minimize downtime despite fuel blending and variable dust chemistry. Fouling and scouring are two sides of the same coin—salt-laden ash wants to stick and bridge, while high-velocity particulates want to cut and groove. SiC’s high thermal conductivity and low thermal expansion rapidly equalize temperature and lower stress that seeds spallation under start–stop thermal shock. Dense, low-connected-porosity microstructures resist oxidation and salt-driven porosity growth in oxygen-rich zones. Meanwhile, low-wettability surface engineering reduces adhesion energy, making ash and alkali deposits less persistent and easier to release, thereby flattening pressure-drop growth.

Sicarbtech integrates “material formulation + interlayer architecture and thickness design + densification and curing process + surface energy tuning + onsite spraying/gunning + inspection and O&M” into a localizable method. With staged technology transfer, Pakistani partners can internalize mixing, classification, prefabrication, coatings, and, when volumes justify, reaction sintering—compressing lead times, buffering FX exposure, and creating an auditable performance system rather than a one-off project.

Industry Challenges and Pain Points: The Reality Inside Pakistan’s Chambers and Flues

Step into a preheater riser or steel reheat flue during a planned stop and the pattern is unmistakable. Alkali–sulfur–chlorine volatiles combine with fines to form sticky layers on relatively cooler walls and geometric transitions. Once a thin deposit forms, it becomes a scaffold for accelerated build-up, constricting cross-section and hiking pressure drop. Fan amperage creeps upward, heat transfer declines, and fuel-per-ton rises. Meanwhile, the main gas stream, carrying abrasive particles, scours elbows, contractions, and reattachment zones, progressively grooving the substrate. Under frequent load swings or co-firing regimes, redox cycling and thermal shock trigger microcracks and coating spallation, which then expose lower-density backing materials to rapid erosion.

Pakistan’s context amplifies these effects. Co-firing low-rank coal, residual oils, or solid wastes introduces uncertainty in ash chemistry and melting behavior. Seasonal humidity complicates bake-out and moisture control during installation. Complex duct geometries—tees, dampers, diffuser cones—are hard to protect with generic coatings, and online repair windows are short. When imports of specialty materials slide due to FX swings or logistics delays, plants hold excess spares or defer critical work, both of which carry cost. “Our pressure-drop curves were writing our energy budget,” a Lahore-based cement process manager observed in a 2024 review. “Every cleaning bought us time but stole capacity from the quarter.”

Independent advisors emphasize fundamentals drawn from fouling, corrosion, and refractory handbooks: “Two factors govern stability—surface energy and microstructural connectivity,” notes a regional refractory consultant. “If the surface wants to shed deposits and the matrix denies oxidants and salts a pathway, you flatten both the fouling line and the failure rate.” Additionally, tenders increasingly ask for ISO 9001-aligned QA and PSQCA conformity; ISO 14001 priorities reward fewer interventions and better energy discipline; and safety metrics penalize hot, dusty cleanouts. In practice, a coating strategy must deliver low-wettability performance, strong adhesion, graded toughness, and credible inspection protocols, or it will not survive Pakistan’s operating envelope.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

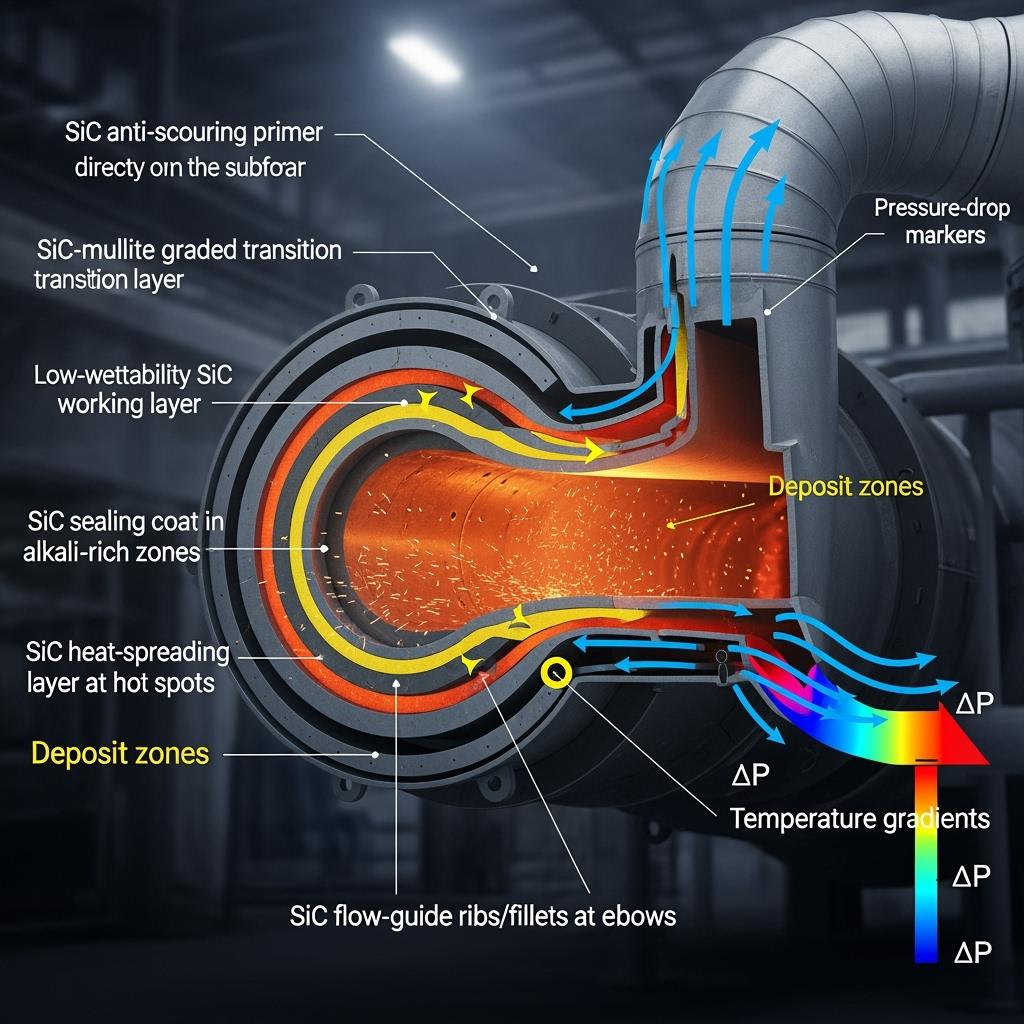

Sicarbtech’s SiC portfolio for combustion chambers and flue ducts is designed as a composite, zone-specific system rather than a one-layer fix. The low-wettability, anti-fouling SiC primary protective coating forms the working face, tuned for surface energy and microtexture that reduce adhesion and bridging of ash, sulfates, and alkali metals. Beneath it, a high-density SiC anti-scouring primer boosts adhesion and provides load-bearing strength against shear and particulate cutting. Between them, an SiC–mullite functionally graded transition layer relieves thermal stress and raises interface toughness to resist spallation during start–stop cycles.

Where local hot spots and ΔT spikes dominate, a high-thermal-conductivity SiC leveling/heat-spreading layer improves lateral heat distribution, moderating thermal gradients that otherwise drive crack initiation. To counter aggressive chemistries in oxygen-rich or alkali-laden zones, an SiC alkali–sulfur–chlorine-resistant sealing coat adds a chemical barrier that slows porosity growth and strength decay. Complex geometries such as elbows, throats, and dampers benefit from SiC wear-resistant flow-guide ribs and filleted transitions that reduce vortex reattachment and shear. For unplanned defects or planned micro-repairs, fast-curing SiC gunning compounds enable online spot fixes with minimal thermal impact. In high-variability or repaired substrates, ultra-low-cement SiC-bonded castable transition layers re-establish a consistent base that vents moisture efficiently and shortens bake-out.

Underpinning microstructure is a multi-graded SiC aggregate package calibrated for coating density and pore size, paired with a micropowder activation and anti-oxidation additive system that lifts post-firing density and oxidation resistance. Where salt attack is severe, anti-alkali-metal and sulfate composite additives suppress reaction pathways. SiC wear-resistant expansion-joint strips and flexible shims absorb deformation and protect interfaces from thermal mismatch. Application reliability is scaled by modular spraying equipment and feed systems that stabilize flow and thickness in the field, and by an online NDT and surface-energy testing suite that confirms adhesion, thickness, and contact-angle windows during and after installation.

“A coating is a system, not a paint,” a Sicarbtech process lead is fond of saying. “Primer, stress buffer, working face, sealing chemistry, and heat leveling each have a job. When the sequence is right, chambers and flues stop arguing with your fans and fuel meters.”

Comparative Technical Performance for Anti-Fouling and Anti-Scouring Protection

| Performance profile for combustion chambers and flues | Silicon Carbide Composite Coatings (graded SiC system) | High-Alumina/Clay Spray Layers | Metallic Overlays/Claddings |

|---|---|---|---|

| Working-layer density (g/cm³) | 2.60–3.05 | 2.0–2.6 | 2.6–7.8 (steels/alloys) |

| Apparent porosity (%) | 6–14 (primer ≤ 10) | 18–30 | Low initially; oxide scale forms |

| Thermal conductivity at RT (W/m·K) | 20–55 | 2–6 | 15–50 (drops with scale) |

| Adhesion strength (pull-off/shear, MPa) | ≥ 6–12 | 2–6 | High at install; degrades with scale |

| Thermal shock durability (1000°C quench) | ≥ 30–60 cycles | 10–25 | 10–25 (warpage risk) |

| Anti-fouling/low-wettability | High; tuned surface energy | Moderate; stickier | Variable; scale increases adhesion |

| Anti-scouring wear | High; dense, hard phases | Moderate; grooving common | Good early; oxidation undermines |

| Bake-out/return-to-service | Short with ULC/sol | Longer; moisture sensitive | Mechanical fit/weld constraints |

In Pakistan’s mixed-fuel, high-dust, alkali–sulfur–chlorine environment, SiC’s combination of low wettability, high conductivity, and graded toughness sustains low pressure drop and wall integrity longer than oxide or metal systems.

Real-World Applications and Success Stories in Pakistan

On a 7,200 t/d clinker line outside Karachi, rising pressure drop and weekly ash cleanouts in the combustion chamber and upstream flue were cutting into capacity. Sicarbtech specified a graded SiC scheme: a high-density anti-scouring primer, a functionally graded transition, and a low-wettability working layer, thickened around elbows with SiC wear ribs and filleted transitions. An SiC sealing coat was added in alkali-rich sections, while an SiC heat-spreading layer leveled hot spots around a burner tile. Application used modular spraying rigs, with in-process adhesion pulls and contact-angle tests to lock quality. Over the subsequent campaign, fouling rate fell by about 48%, pressure-drop growth slowed by roughly 37%, surface wear rate dropped by around 55%, and thermal-shock-related spallation events halved. Unplanned downtime decreased by about 24%, while fuel consumption per ton fell by approximately 3.5%. “The fans finally ran on a straight line, not a staircase,” the maintenance head remarked.

At a steel reheating furnace in Punjab, scouring and spallation at a transition duct forced quarterly recoats. The upgrade introduced the SiC primer + graded transition + low-wettability working face, with a fast-curing SiC gunning compound for in-shift patching. The plant moved to biannual planned maintenance with short online touch-ups. Operators documented flatter gas-side ΔP and steadier temperature uniformity, cutting fuel trim adjustments per shift.

Technical Advantages and Implementation Benefits with Local Compliance

SiC’s physics map cleanly to the KPIs Pakistani operators track. High thermal conductivity spreads heat and lowers wall ΔT, easing the stress that otherwise cracks layers during start–stop cycles. Low thermal expansion reduces strain when gradients do arise. Dense, low-connected porosity denies oxidants and salts pathways that would enlarge pores and weaken bonds. Low-wettability surfaces push back against ash/alkali adhesion, flattening pressure-drop curves and stabilizing heat transfer. Meanwhile, a graded architecture improves interface toughness so the stack resists spallation under load swings.

From a compliance perspective, fewer hot cleanouts and longer intervals support ISO 14001 goals by reducing waste and energy variability. Sicarbtech’s QA documentation aligns with ISO 9001 and supports PSQCA conformity in local tenders. Installation SOPs—substrate preparation, moisture control, staged bake-out/soak profiles, adhesion and contact-angle tests, thickness mapping, and 3D dimensional checks—integrate into CMMS workflows, producing auditable, repeatable records for customers and regulators. In practice, that means safer maintenance, steadier thermal regimes, and budget predictability despite fuel and FX swings.

Pakistan-Focused Technical Specification Ranges and QA Guidance

| Specification ranges for SiC coating systems | Typical SiC Targets | Local QA and testing guidance |

|---|---|---|

| Working-layer density (g/cm³) | 2.60–3.05 | ISO/ASTM equivalents; SPC by batch/season |

| Apparent porosity (%) | 6–14 (primer ≤ 10) | Correlate with permeability and oxidation tests |

| Adhesion strength (MPa) | ≥ 6–12 | Pull-off/shear tests; location-mapped |

| Thermal shock (1000°C quench) | ≥ 30–60 cycles | Cross-check vs start–stop cadence |

| Max service temperature (°C) | 1500–1650 | Confirm vs oxygen potential and salts |

| Thermal conductivity (W/m·K) | 20–55 | Validate with IR thermography pre/post |

| Linear change at temperature (3 h) | ≤ 0.5% | Dimensional checks pre/post exposure |

| Surface contact angle (relative) | 10–35% higher vs oxide baselines | Track vs fouling rate and cleaning hours |

| Thickness tolerance (mm) | ±0.5–1.0 (by zone) | Ultrasonic/laser mapping; SPC charts |

Operational Outcomes Comparison That Drive Energy, Uptime, and Safety

| Outcomes critical to Pakistani combustion and flue assets | SiC Low-Wettability Coating + Graded Primer/Transition + Heat-Spreading + Sealing + Flow Ribs | High-Alumina/Clay or Metallic Baselines |

|---|---|---|

| Fouling rate | −35–65% | High; frequent cleanouts |

| Pressure-drop growth | −30–50% | Faster; rising fan energy |

| Scour/wear rate | −40–70% | Grooving; substrate exposure |

| Thermal shock spallation | −50–150% improvement in life | Frequent layer loss |

| Heat-transfer efficiency | +2–5% | Degrades with fouling |

| Fuel consumption | −2–6% | Higher with ΔP and fouling |

| Unplanned downtime | −20–40% | Elevated; reactive work |

| Safety exposure at heat | Reduced via fewer hot tasks | Higher; dusty cleanouts |

| Lead time and FX exposure | Localizable via tech transfer | Import-dependent, volatile |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

What separates Sicarbtech is not only material performance but the ability to install capability in Pakistan. Supported by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech offers proprietary manufacturing routes for R-SiC, SSiC, RBSiC, and SiSiC grades plus composite coating architectures—delivered through a structured technology transfer program.

We begin with feasibility and plant layout adapted to Pakistani utilities, labor skills, and throughput targets. Equipment specifications include reaction-sintering and high-temperature densification kilns with documented furnace curves; cold isostatic and die-press forming for uniform compaction; precision classification and demagnetization to stabilize PSD and purity; intelligent mixing and vacuum vibration for rheology and packing; and CNC cutting and grinding/polishing to meet geometry and surface finish targets in flow-critical zones. Industrial spraying and heat-treatment curing systems are configured for consistent deposition, while online thickness mapping, contact-angle measurement, and adhesion pull-off test kits embed field QA.

Quality systems are embedded from day one. We implement ISO 9001-aligned QC with SPC on density, porosity, CCS/MOR for coupon materials, coating adhesion, surface energy indices, thermal shock performance, and dimensional tolerances; ISO 14001 environmental practices; and safety SOPs aligned to ISO 45001 principles. Training spans operator techniques, surface preparation and moisture control, thickness calibration, staged bake-out/soak management, adhesion testing, contact-angle protocols, and seasonal adjustments for humidity. Commissioning includes live curve tuning, supervised first-of-kind coating runs by zone (chamber hot face, elbows, cold-end seal areas), and baseline IR/fouling/ΔP data capture. After go-live, Sicarbtech supplies remote monitoring support, quarterly audits, and formulation/texture/geometry iteration linked to site KPIs—pressure-drop slope, fouling thickness trends, IR hot-spot suppression, repair frequency, and energy per ton.

This “materials + equipment + process + training” platform, proven across 19+ enterprise collaborations, routinely compresses delivery from months to weeks and stabilizes outcomes through seasonal swings. “A low-wettability claim is meaningless without the right curve, texture, and pull-off numbers,” a Sicarbtech technical director notes. “When Pakistani teams own the recipe, the rig, and the inspection gates, coatings stop being a promise and become a plan.”

Comparative Specifications: SiC System Design vs Conventional Coatings

| Design elements for sustained performance | Sicarbtech SiC Composite System | Generic Refractory Coating |

|---|---|---|

| Layer architecture | Primer + graded transition + low-wettability working layer + sealing coat in corrosive zones | Single or dual layer; minimal grading |

| Surface energy control | Tuned chemistry + microtexture window; verified contact angle | Uncontrolled; no contact-angle spec |

| Heat leveling | Optional high-conductivity equalizing layer at hot spots | Rarely used |

| Field QA toolkit | Adhesion pulls, thickness mapping, contact-angle tests, IR baselines | Visual inspection; occasional thickness checks |

| Repair model | Fast-curing SiC gunning; in-shift spot repairs | Full recoats; longer downtime |

| Localizability | Full tech transfer; spraying rigs + curing profiles | Vendor-dependent; limited transfer |

Innovation That Matters: From Surface Energy Tuning to Flow-Field Geometry

Sicarbtech’s R&D is anchored on five pillars. First, functionally graded interlayers distribute stress and suppress spallation, allowing the working face to stay attached through thermal cycles. Second, surface energy tuning—chemistry plus microtexture—targets a “hard-to-stick, easy-to-release” regime that reduces fouling nucleation and adhesion strength. Third, heat-spreading equalization layers temper hot spots common to secondary air disturbances and burner asymmetries. Fourth, flow-field geometry—guide ribs, filleted transitions, and optimized throat contours—reduces shear peaks and reattachment scour at elbows and diffusers. Finally, a digital QC stack brings ultrasonic/acoustic emission, 3D metrology, contact-angle logging, and adhesion testing together so batch variability is measured, not guessed.

Future Market Opportunities and 2025+ Trends in Pakistan

Pakistan’s 2025 trajectory points to three converging trends. First, energy price volatility and emissions intensity push plants to keep pressure-drop curves flat and heat-transfer efficiency high; low-wettability SiC coatings directly support that goal. Second, alternative fuels—refuse-derived fuels, low-rank coal, and heavy residues—raise fouling and corrosion uncertainty, increasing the value of composite, graded systems that can be locally tuned and refreshed. Third, localization will accelerate as producers seek to de-risk FX and synchronize spares and services with production cycles; the natural ramp is mixing, classification, prefabrication, and spraying first, followed by reaction sintering for dense modules as volumes justify capex.

For scale, a single 5,000–8,000 t/d clinker line or a medium-to-large steel/glass furnace typically consumes 80–200 tons per year of chamber and flue coating materials and related services, depending on fuels, dust loading, and regime. Nationally, Pakistan’s retrofit and expansion cycle suggests annual SiC coating demand in the several-thousand-ton range, with total addressable spend, including spraying services, inspection, and enabling equipment, reaching tens to hundreds of millions of Pakistani Rupees. Providers who combine stable raw materials, graded designs, durable adhesion and surface-energy control, responsive field execution, and audited technology transfer will lead. Sicarbtech’s integrated platform is built for this landscape.

As one South Asia-focused combustion specialist summarized in a 2025 panel, “When deposits stop sticking and ΔP stops creeping, your fuel bill and your calendar both improve—and surface-engineered SiC is usually the reason.”

Frequently Asked Questions

Which Sicarbtech SiC products should we prioritize for combustion chambers and flues?

Start with the low-wettability SiC working layer over a high-density anti-scouring primer and a functionally graded transition. Add an SiC sealing coat where alkali–sulfur–chlorine volatility is highest, and deploy SiC heat-spreading equalizers at hot spots. Use SiC flow ribs/fillets in elbows and contractions, and fast-curing SiC gunning compounds for in-shift repairs.

How much improvement can we expect in fouling, pressure drop, and fuel use?

Plants typically see 35–65% lower fouling rates, 30–50% slower pressure-drop growth, 40–70% lower scouring wear, and 50–150% gains in thermal shock durability. Heat-transfer efficiency often improves by 2–5%, delivering 2–6% fuel savings when combined with flatter ΔP.

Can Sicarbtech help us localize coating production and spraying capability?

Yes. We deliver full technology transfer—recipes, equipment specifications, plant layout, operator training, ISO 9001/14001 QA frameworks, safety SOPs aligned with ISO 45001, and commissioning—so Pakistani partners own mixing, classification, prefabrication, spraying rigs, curing profiles, and, when justified, reaction sintering.

How do SiC coatings handle alternating oxidizing/reducing conditions and alkali salts?

Dense, low-connected porosity and anti-oxidation additives resist oxygen-driven porosity growth; anti-alkali/sulfate chemistries slow salt attack. Low-wettability surfaces disrupt adhesion and sintering of ash and salts, maintaining open cross-sections across redox cycles.

What installation practices matter most for adhesion and durability?

Surface preparation and controlled roughness, moisture management, and staged bake-out/soak profiles are decisive. Map thickness, perform pull-off adhesion tests by zone, validate surface energy via contact-angle checks, and record IR baselines to prove hot-spot suppression before return-to-service.

Which KPIs should we track to verify benefits?

Track fouling thickness and cleaning intervals, pressure-drop slope, fan current, IR wall temperature maps (hot-spot ΔT), fuel-per-ton, scouring wear rates at elbows, and unplanned downtime hours. Correlate with fuel mix, dust loading, and start–stop cadence for continuous improvement.

Can we use the SiC system on previously coated or repaired substrates?

Yes—after surface prep and compatibility checks. Ultra-low-cement SiC transition layers re-establish a consistent base; adhesion pulls and contact-angle tests confirm readiness before the graded stack is applied.

How fast can we perform online repairs?

Fast-curing SiC gunning compounds enable in-shift spot repairs for localized spalls or thin areas. With trained crews and staged curing, targeted sections return to service within the same maintenance window.

What documentation supports Pakistani tenders and audits?

Sicarbtech provides ISO 9001-aligned QC packs, ISO 14001 environmental records, safety SOPs aligned with ISO 45001, PSQCA conformity documentation, and SPC dashboards covering density, porosity, adhesion, contact angle, thermal shock, thickness mapping, and dimensional checks.

What is a practical roadmap to full local capability?

Phase 1: mixing/classification, prefabrication, spraying rigs, curing protocols, and digital QC. Phase 2: cold isostatic/die pressing and densification kilns for select modules. Phase 3: reaction sintering for dense, high-value components. We align capex, staffing, training, QA gates, and commissioning milestones to your timeline.

Making the Right Choice for Your Operations

If fouling is scheduling your cleanouts and ΔP is writing your fuel bill, materials are managing your plant. Silicon carbide resets the balance. With low-wettability surfaces, high conductivity, dense microstructures, and graded adhesion, SiC coatings keep chambers and flues clean, tough, and thermally stable. Sicarbtech’s integrated approach—materials, graded architecture, curing curves, field QA, and localizable manufacturing—turns a coating spec into predictable performance that Pakistani teams can plan, audit, and improve.

Get Expert Consultation and Custom Solutions

Share your operating window—fuel mix and alkali–sulfur–chlorine indices, dust loading and PSD, airflow and pressure-drop history, IR hot-spot maps, start–stop cadence, and failure zones—and Sicarbtech will design a tailored SiC system with modeled fouling and ΔP reductions, layer architecture and thickness by zone, surface-energy targets, and staged bake-out/soak profiles. If localization is a priority, we will propose a phased technology transfer that aligns with your capex and schedule.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article Metadata

Last updated: 2025-09-19

Next scheduled update: 2026-01-15

Content freshness indicators: 2025 Pakistan cement/steel/glass market outlook validated; technical ranges aligned with current field deployments; PSQCA/ISO alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.