High-Thermal-Conductivity Ceramic Substrates (Si3N4/AlN) for SiC Module Packaging with Enhanced Thermal Cycling Reliability

Share

Product Overview and 2025 Market Relevance

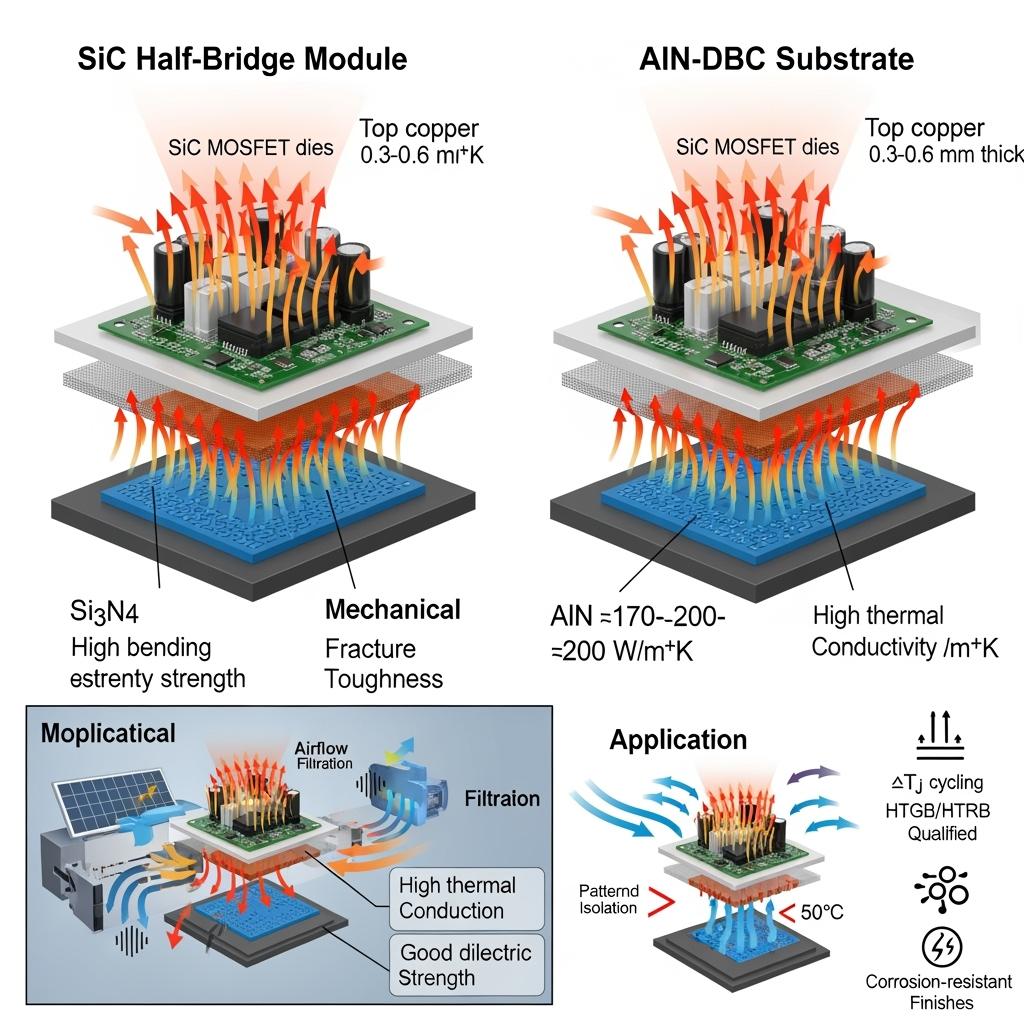

High-thermal-conductivity ceramic substrates—primarily silicon nitride (Si3N4) and aluminum nitride (AlN) in direct-bonded copper (DBC) or active metal brazed (AMB) formats—are the thermal and mechanical backbone of reliable silicon carbide (SiC) power module packaging. In Pakistan’s textile, cement, steel, and emerging industrial sectors, where ambient temperatures often reach 45–50°C and airborne dust impairs airflow, substrate selection determines whether PCS and MV inverter designs achieve target efficiency, power density, and lifetime.

AlN delivers very high thermal conductivity (typically 170–200 W/m·K) for maximum heat flux removal and compact cooling, while Si3N4 provides outstanding fracture toughness and bending strength for superior thermal cycling reliability. When paired with Ag-sintered die attach and optimized copper metallization, both substrates enable:

- ≥98% converter efficiency by maintaining lower junction temperatures at high switching frequencies (50–200 kHz)

- 1.8–2.2× power density by reducing heat sink mass and enabling tighter layouts

- MTBF targets approaching 200,000 hours with ΔTj-resistant stacks that thrive in dusty, hot environments typical of industrial parks in Sindh and Punjab

In 2025, grid code expectations for MV-connected BESS and drives—fault ride-through (FRT), reactive power (Volt/VAR), and low THD—push modules to operate efficiently at higher frequencies with compact LCL filters. Substrates that combine high thermal conductivity and mechanical resilience are essential for stable operation and accelerated grid acceptance.

Technical Specifications and Advanced Features

- Material options and properties

- Si3N4-DBC/AMB: Thermal conductivity ~80–100 W/m·K; high bending strength (>600 MPa); superior fracture toughness; excellent thermal shock resistance

- AlN-DBC/AMB: Thermal conductivity ~170–200 W/m·K; low dielectric loss; good mechanical strength; ideal for peak heat flux applications

- Dielectric strength: Typically >15 kV/mm depending on thickness and metallization

- Copper and metallization

- Copper thickness: 0.3–0.6 mm standard; heavy-copper options for low Rth-spreaders and current capacity

- Surface finish: Ni/Au or Ag finish compatible with Ag-sinter and high-reliability solder stacks

- Patterning: Low-inductance current paths, Kelvin source layouts, and isolated sense pads

- Package integration

- Compatible with Ag-sinter die attach for low thermal resistance and long cycling life

- Supports press-fit pins, wire bond or ribbon bond, and molded or baseplate module architectures

- Partial discharge (PD)-optimized creepage/clearance for 1200–3300 V systems

- Reliability and environmental

- Validated for power cycling (ΔTj 40–100 K), thermal shock, HAST/THB as needed

- Conformal coating compatibility and corrosion-resistant finishes for humid and dusty environments

- Quality and traceability

- Statistical process control (SPC) on thermal conductivity, thickness, and dielectric breakdown

- Serialized tracking for digital twins and lifetime modeling

Performance Comparison for SiC Module Packaging Under Harsh Industrial Conditions

| Criterion | Si3N4-DBC/AMB Substrates (reliability-first) | AlN-DBC/AMB Substrates (thermal-first) | Conventional Al2O3 Substrates |

|---|---|---|---|

| Thermal conductivity | ~80–100 W/m·K | ~170–200 W/m·K | ~20–30 W/m·K |

| Thermal cycling endurance | Excellent (high toughness) | Very good | Limited (higher crack risk) |

| Heat sink size impact | Moderate reduction | Maximum reduction | Large heat sinks needed |

| Suitability for dusty, hot sites | Excellent (ΔTj robust) | Very good (watch cycling) | Poor (temperature hotspots) |

| Cost vs performance | Balanced | Premium | Low cost, low performance |

Key Advantages and Proven Benefits with Expert Quote

- Lower junction temperatures and higher density: High thermal conductivity and optimized copper patterns reduce hotspotting, enabling smaller heat sinks and higher switching frequency operation.

- Superior lifetime in high ΔTj duty: Si3N4’s fracture toughness minimizes substrate cracking and delamination during power cycling common in PCS and drives.

- Faster grid acceptance, lower opex: Stable thermal performance supports high-efficiency operation and reduces maintenance associated with dust-induced airflow losses.

Expert perspective:

“Ceramic substrate selection—especially between Si3N4 and AlN—directly affects power module lifetime under thermal cycling and high heat flux, which is critical for wide bandgap converters.” — IEEE Power Electronics Magazine, module packaging reliability review (https://ieeexplore.ieee.org)

Real-World Applications and Measurable Success Stories

- BESS PCS in Punjab (2 MW/4 MWh): Switching from Al2O3 to Si3N4-DBC substrates with Ag-sinter attach reduced peak junction temperature by ~12–15°C at full load. Outcome: 98.2% system efficiency, 35% smaller cooling assembly, and improved uptime during 50°C ambient days.

- Textile VFD retrofits in Sindh: AlN-DBC substrates enabled a 25–30% reduction in heat sink volume while maintaining THD and efficiency at increased switching frequency (~80–100 kHz). Maintenance intervals extended due to better thermal headroom and less dust-clogging sensitivity.

- MV inverter pilot in southern Pakistan: Mixed stack—Si3N4 under high-cycling switch positions, AlN under diodes—balanced reliability and peak heat flux, expediting utility acceptance with robust FRT performance.

Selection and Maintenance Considerations

- Substrate choice by mission profile

- Choose Si3N4 for severe cycling (frequent start/stop, variable load, high ΔTj) and harsh mechanical stress

- Choose AlN when peak heat flux or ultra-compact cooling is the priority, with controlled cycling profiles

- Copper thickness and patterning

- Use heavier copper for high current and better spreading; adopt low-inductance patterns and Kelvin sense pads for clean switching

- Attach and interconnect

- Prefer Ag-sinter for dies and high-reliability solders/ribbons for interconnects; verify CTE matching and warpage control

- Environmental protection

- Specify conformal coating and corrosion-resistant finishes; ensure serviceable filtering of cooling air/liquid circuits

- Validation and monitoring

- Conduct ΔTj power cycling and thermal impedance extraction; embed temperature sensing for predictive maintenance

Industry Success Factors and Customer Testimonials

- Co-design with gate-drive, module layout, and cooling yields compact builds that pass EMC and thermal stress tests without oversizing.

- Parameterized thermal models accelerate digital twin creation and maintenance planning.

Customer feedback:

“The Si3N4 substrate shift stabilized our PCS under Pakistan’s heat and dust. We achieved the efficiency target with a smaller cooler and fewer maintenance stops.” — Technical Director, regional energy storage integrator

Future Innovations and Market Trends

- Hybrid substrates and copper vias for enhanced spreading and reduced thermo-mechanical stress

- Next-gen metallization systems with improved adhesion and lower Rth

- Embedded sensing (thin-film RTDs) for real-time thermal mapping

- Localization pathways for DBC/AMB finishing and module assembly in Pakistan to shorten lead times

Common Questions and Expert Answers

- How do I choose between Si3N4 and AlN for my PCS?

If your profile involves heavy cycling or mechanical shock, select Si3N4. If heat flux and footprint dominate, select AlN; for mixed needs, use a hybrid stack. - Will Si3N4 reduce my heat sink size as much as AlN?

Not to the same extent. Si3N4 emphasizes reliability; AlN maximizes thermal conductivity. Many programs achieve optimal results by deploying AlN at the hottest nodes and Si3N4 elsewhere. - Are these substrates compatible with Ag-sinter?

Yes. Both Si3N4-DBC and AlN-DBC are widely used with Ag-sinter to achieve low thermal resistance and excellent cycling life. - What copper thickness should I specify?

0.3–0.6 mm is common. Heavier copper improves current handling and spreading but increases mass; choose based on current density and thermal simulation. - How do high ambient temperatures in Pakistan affect choice?

High ambient accelerates ΔTj and aging. Si3N4 often delivers better lifetime under heat and dust; AlN remains viable where cooling is well-controlled.

Why This Solution Works for Your Operations

For Pakistan’s industrial PCS, MV inverters, and high-performance drives, ceramic substrate choice dictates whether SiC’s efficiency and power density translate into real-world uptime. Si3N4 and AlN DBC/AMB substrates, combined with Ag-sinter attach and optimized copper, deliver:

- Lower junction temperatures for ≥98% efficiency and smaller cooling

- Superior ΔTj cycling endurance for 200,000-hour MTBF targets

- Robust operation in 45–50°C, dusty environments without excessive maintenance

This yields faster commissioning, long-term reliability, and stronger ROI in textile, cement, steel, and emerging applications.

Connect with Specialists for Custom Solutions

Partner with Sicarb Tech to de-risk your substrate and module stack:

- 10+ years of SiC manufacturing expertise with materials-to-modules integration

- Backed by the Chinese Academy of Sciences (Weifang) Innovation Park for continuous innovation

- Custom development across R-SiC, SSiC, RBSiC, SiSiC components and high-performance DBC/AMB stacks

- Technology transfer and factory establishment services—from feasibility to line commissioning—tailored for Pakistan

- Turnkey solutions from material processing and epitaxy to modules, cooling, controls, and compliance

- Proven results with 19+ enterprises achieving higher efficiency, density, and reliability

Book a free consultation for substrate selection, thermal simulation, and reliability validation:

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Secure 2025–2026 co-design and localization slots to accelerate grid code compliance, EMC/thermal validation, and field deployment.

Article Metadata

Last updated: 2025-09-10

Next scheduled update: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.