Black SiC: Tough Abrasives for Industrial Challenges

Share

Black SiC: Tough Abrasives for Industrial Challenges

Introduction: Black Silicon Carbide – The Industrial Abrasive Powerhouse

In the realm of industrial materials, few substances command the respect and utility of black silicon carbide (SiC). Renowned for its exceptional hardness, strength, and thermal stability, black SiC has carved out an indispensable role as a high-performance abrasive. From shaping rugged metal components to finishing delicate electronics, its versatility is unparalleled. In today’s demanding industrial landscape—spanning sectors like automotive, aerospace, energy, and heavy manufacturing—the need for materials that can withstand extreme conditions and deliver precise results is paramount. Black silicon carbide abrasives rise to this challenge, offering a potent combination of aggressive material removal and fine finishing capabilities. This makes them essential for manufacturers striving for efficiency, quality, and cost-effectiveness in their operations. Whether you are an engineer designing a new manufacturing process, a procurement manager sourcing robust consumables, or a technical buyer evaluating material performance, understanding the nuances of black silicon carbide is key to unlocking significant operational advantages and tackling the toughest abrasive tasks.

Understanding Black Silicon Carbide: Key Properties and Manufacturing

Black silicon carbide is a synthetic crystalline compound of silicon and carbon, with the chemical formula SiC. It is produced through a high-temperature electrothermal process in resistance furnaces, where high-purity silica sand and petroleum coke are reacted at temperatures exceeding 2200°C (4000°F). The resulting crystalline mass is then crushed, cleaned, and meticulously graded by particle size to produce various abrasive products.

The exceptional abrasive properties of black SiC stem from its unique physical and chemical characteristics:

- Extreme Hardness: Black silicon carbide ranks very high on the Mohs scale of mineral hardness, typically around 9.0 to 9.5. This places it just below diamond, making it capable of cutting and grinding a wide array of hard materials, including metals, ceramics, and composites.

- High Thermal Conductivity: SiC exhibits excellent thermal conductivity, which helps to dissipate heat generated during abrasive processes. This reduces the risk of thermal damage to the workpiece and prolongs the life of the abrasive material itself.

- Chemical Inertness: Black SiC is highly resistant to chemical attack from acids, alkalis, and molten salts, ensuring its stability and performance in diverse chemical environments and high-temperature applications.

- Sharp, Friable Grain Structure: The crystalline structure of black SiC is characterized by sharp, angular grains. Its moderate friability means that as the abrasive wears, new sharp cutting edges are exposed. This self-sharpening characteristic maintains a consistent cutting action throughout its use.

- Electrical Conductivity: While not its primary application as an abrasive, black SiC possesses semiconducting properties, which can be relevant in specific specialized abrasive applications like electrical discharge machining (EDM) electrodes or antistatic abrasives.

The manufacturing process allows for tight control over purity and grain size distribution, enabling the production of black SiC abrasives tailored for a wide spectrum of industrial requirements, from coarse grinding to fine lapping and polishing.

Diverse Applications: Where Black SiC Abrasives Excel

The robust nature of black silicon carbide makes it a preferred abrasive across a multitude of industries. Its ability to efficiently process challenging materials translates into improved productivity and superior finishes. Here’s a look at some key sectors where black SiC abrasives are indispensable:

- Metallurgy and Foundries: Used extensively for snagging, fettling, and surface conditioning of castings and forgings. Ideal for grey iron, ductile iron, non-ferrous metals (aluminum, brass, bronze), and hard-to-grind metals. Black SiC grinding wheels and cut-off wheels are staples in these environments.

- Automotive: Critical for manufacturing engine components, transmission parts, and brake systems. Used in grinding crankshafts, camshafts, and finishing brake rotors and pads. Also employed in lapping and polishing applications for precision surfaces.

- Aerospace: Utilized for machining superalloys, composites, and ceramics used in aircraft engines and structural components. The hardness and thermal stability of SiC are crucial for working with these advanced materials.

- Power Electronics & Semiconductors: While green SiC is often preferred for its higher purity in direct semiconductor wafer processing, black SiC is used in lapping and polishing non-critical ceramic components, substrates, and for grinding consumables used in semiconductor manufacturing equipment.

- Renewable Energy: Employed in shaping and finishing components for wind turbines, solar panel manufacturing (e.g., slicing silicon ingots, though wire sawing with SiC slurry is common), and other renewable energy systems.

- Industrial Machinery & Equipment: Used in the manufacturing and maintenance of heavy machinery, tools, and dies. Essential for grinding hardened steels, tool steels, and other durable components.

- Stone and Construction: Black SiC is used in cutting, grinding, and polishing natural stone (granite, marble), concrete, and refractories. SiC-based abrasive papers, discs, and segments are common.

- Chemical Processing: Due to its chemical inertness, SiC components, sometimes finished with SiC abrasives, are used in pumps, valves, and seals handling corrosive fluids. Abrasives are used to manufacture these parts.

- LED Manufacturing: While sapphire and purer SiC forms are key substrates, black SiC abrasives can be involved in shaping and lapping ceramic carriers or fixtures used in the LED production process.

- Rail Transportation: Used for grinding railway tracks and reconditioning wheelsets, ensuring safety and operational efficiency.

- Oil and Gas: Employed in finishing and repairing components used in drilling, extraction, and refining processes, often involving hard-wearing materials.

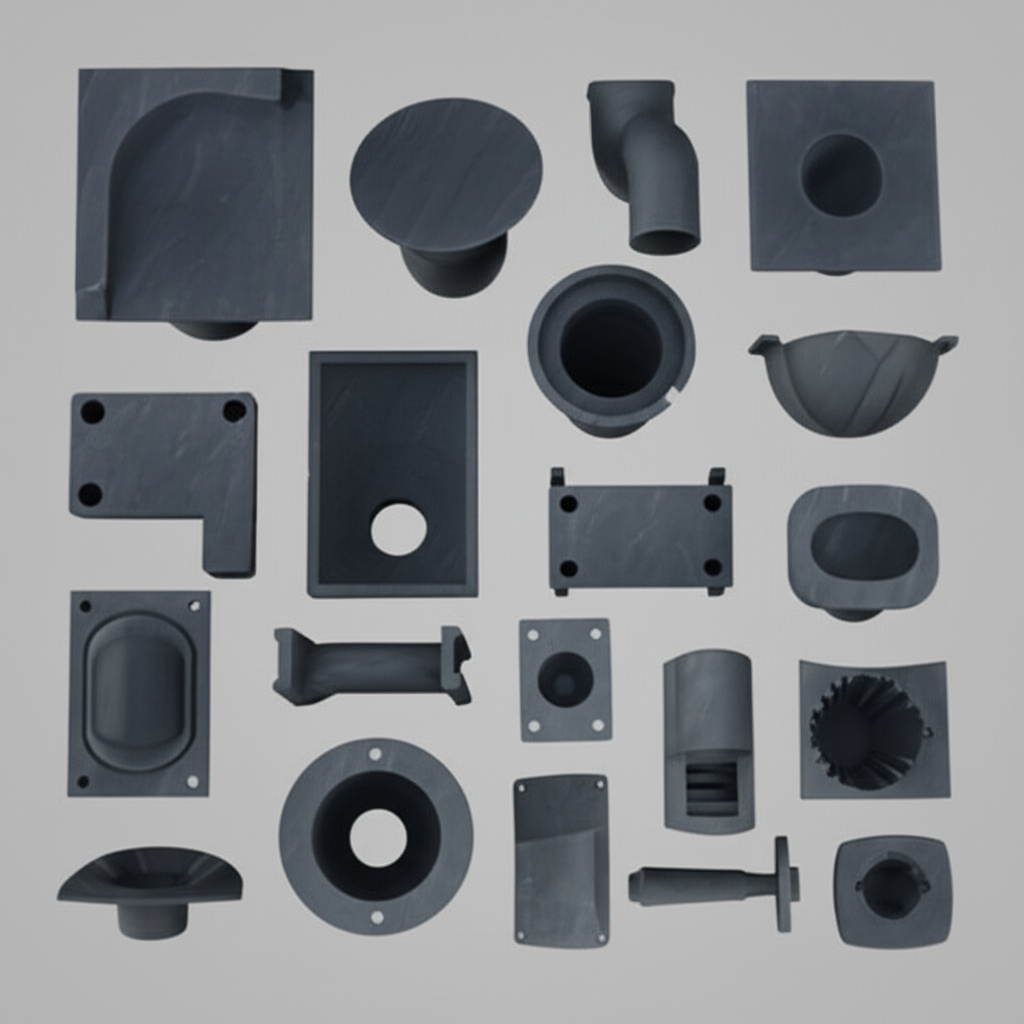

The versatility of black SiC is further enhanced by its availability in various forms, including bonded abrasives (grinding wheels, segments), coated abrasives (belts, discs, sheets), loose grains for lapping and blasting, and SiC-impregnated tools.

The Competitive Edge: Why Choose Black SiC for Abrasive Tasks?

When faced with demanding abrasive applications, selecting the right material is crucial for achieving optimal results, efficiency, and cost-effectiveness. Black silicon carbide offers several distinct advantages that make it a superior choice for a wide range of industrial challenges:

- Exceptional Hardness and Cutting Ability: As one of the hardest synthetic abrasives available (after diamond and boron carbide), black SiC can effectively cut and grind even the toughest materials. This includes cast iron, non-ferrous metals, ceramics, stone, and hard rubber. Its sharp, angular grains provide aggressive material removal rates.

- Superior Performance on Non-Ferrous Metals and Non-Metallics: While aluminum oxide is often the go-to for ferrous metals, black SiC excels with softer, lower tensile strength materials like aluminum, brass, copper, and plastics, as well as hard, brittle materials like stone and ceramics. It tends to cut cooler and cleaner on these materials.

- Self-Sharpening Action: The moderate friability of black SiC grains means that under pressure, they fracture to expose new, sharp cutting edges. This self-sharpening characteristic ensures consistent cutting performance and extends the useful life of the abrasive product.

- Cost-Effectiveness for Tough Jobs: While premium abrasives like diamond exist, black SiC provides an excellent balance of performance and cost, especially for applications where its unique properties are a good match. It often delivers lower overall process costs through faster cycle times and longer abrasive life in suitable applications compared to less capable abrasives.

- Thermal Stability and Conductivity: Its ability to withstand high temperatures and conduct heat away from the grinding zone minimizes the risk of thermal damage to the workpiece and the abrasive tool itself. This is particularly important in high-speed or heavy-duty grinding operations.

- Versatility in Application Forms: Black SiC is available in a vast array of forms – from loose grit for blasting and lapping to bonded wheels, coated belts, and even slurries. This adaptability allows it to be integrated into virtually any abrasive process.

- Chemical Resistance: Its inherent chemical inertness makes it suitable for use in environments where other abrasives might degrade, ensuring consistent performance and longevity even when machining materials that release reactive byproducts or when coolants are chemically active.

By leveraging these advantages, industries can achieve higher material removal rates, improved surface finishes, reduced cycle times, and longer tool life, ultimately leading to enhanced productivity and lower manufacturing costs.

Navigating Black SiC Grades and Forms for Optimal Abrasion

To harness the full potential of black silicon carbide abrasives, it’s essential to select the appropriate grade and form for your specific application. Black SiC is categorized primarily by grit size and purity, with various forms available to suit different abrasive processes.

Key Grades and Classifications:

- Macrogrits (Coarse to Medium):

- Sizes: Typically range from ANSI/FEPA grit sizes 8 to 220 (e.g., F16, F36, F60, F120, F220).

- Applications: Heavy stock removal, snagging, rough grinding, cutting operations, pressure blasting. Ideal for foundries, metal fabrication, and stone cutting.

- Microgrits (Fine to Very Fine):

- Sizes: Typically range from ANSI/FEPA grit sizes 240 to 2500 and beyond (e.g., F240, F400, F800, F1200, F2000). JIS standards are also common for finer powders (e.g., JIS #3000, JIS #4000).

- Applications: Lapping, polishing, fine grinding, precision finishing. Used in automotive, electronics, optics, and applications requiring smooth surfaces and tight tolerances.

- Purity Levels:

- Standard abrasive grade black SiC typically has a SiC content of 98.5% or higher. Higher purity grades are available for specialized applications, though green SiC is often chosen when ultra-high purity is paramount.

Common Forms of Black SiC Abrasives:

| Form | Description | Typical Applications |

|---|---|---|

| Loose Grains/Powders | Ungraded or precisely graded SiC particles. | Lapping, polishing, ultrasonic machining, abrasive blasting, wire sawing, anti-slip flooring. |

| Bonded Abrasives | SiC grains mixed with a bonding agent (vitrified, resinoid, rubber) and pressed/fired into shapes like grinding wheels, segments, sticks. | Grinding (cylindrical, surface, centerless), cutting-off, snagging, tool sharpening. Used for non-ferrous metals, cast iron, ceramics, stone. |

| Coated Abrasives | SiC grains adhered to a backing material (paper, cloth, polyester film) using an adhesive. Forms include belts, discs, sheets, rolls. | Sanding, finishing, polishing. Widely used on wood, metal, plastics, composites, and auto bodywork. Particularly good for harder materials and between-coat sanding. |

| Abrasive Slurries | Fine SiC powders suspended in a liquid carrier (water or oil-based). | Wire sawing of silicon and sapphire wafers, lapping of precision components. |

The choice depends on the material being worked, the desired stock removal rate, the required surface finish, and the specific abrasive equipment being used. Consulting with an experienced abrasive supplier can help in selecting the optimal black SiC product for your needs.

Strategic Selection: Design Considerations for Black SiC Abrasive Products

When selecting or designing black silicon carbide abrasive products, several factors must be considered to ensure optimal performance, efficiency, and safety. These considerations apply whether you’re choosing an off-the-shelf product or seeking a custom abrasive solution.

- Workpiece Material Properties:

- Hardness: Black SiC is ideal for hard, brittle materials and non-ferrous metals. For very hard ferrous alloys, other abrasives like cubic boron nitride (CBN) might be more suitable, though SiC can still be effective.

- Tensile Strength: Materials with lower tensile strength (e.g., cast iron, aluminum, brass) are well-suited for SiC.

- Thermal Sensitivity: SiC’s good thermal conductivity helps, but for extremely heat-sensitive materials, coolants and process parameters must be carefully managed.

- Application Requirements:

- Stock Removal Rate: Coarser grit sizes and more aggressive bond types (for bonded abrasives) will yield higher stock removal but rougher finishes.

- Surface Finish: Finer grit sizes and specific lapping/polishing techniques are needed for smooth, high-precision surfaces. Microgrits are essential here.

- Dimensional Tolerances: The precision of the abrasive product itself and the process control will dictate achievable tolerances on the workpiece.

- Abrasive Product Specifications:

- Grit Size: The primary determinant of cutting speed and surface finish. A balance is often sought.

- Bond Type (for Bonded Abrasives): Vitrified bonds offer rigidity and high form holding, resin bonds provide some flexibility and shock resistance, and rubber bonds are used for fine finishing and regulating wheels.

- Concentration (for Superabrasive Wheels): Though less common for conventional SiC, it’s a factor in diamond/CBN wheels and sometimes specialized SiC tools.

- Hardness/Grade (for Bonded Abrasives): Refers to the strength of the bond holding the abrasive grains. A harder grade retains grains longer, suitable for soft materials or high-pressure applications. A softer grade releases dull grains faster, good for hard materials or preventing loading.

- Operational Parameters:

- Speed: Grinding wheels and belts are designed to operate safely and effectively within specific speed ranges.

- Pressure/Feed Rate: Excessive pressure can lead to premature abrasive wear, workpiece damage, or safety hazards. Optimal parameters depend on the abrasive, material, and machine.

- Coolant: Using coolants can improve surface finish, extend abrasive life, and prevent thermal damage, especially in high-intensity operations. The type of coolant must be compatible with the workpiece and abrasive.

- Safety: Always ensure that abrasive products are used in accordance with manufacturer recommendations and safety regulations. This includes proper machine guarding, personal protective equipment (PPE), and dust extraction.

For custom abrasive solutions, close collaboration with a knowledgeable supplier is crucial. They can assist in designing an abrasive product that is perfectly matched to your material, application, and operational setup, ensuring you achieve the desired outcomes efficiently and safely.

Achieving Precision: Surface Finish and Dimensional Control with Black SiC

Black silicon carbide abrasives play a critical role in achieving precise surface finishes and tight dimensional control across a wide range of materials. The ability to select specific grit sizes and employ various abrasive techniques allows manufacturers to meet demanding specifications for smoothness, flatness, and overall geometry.

Achieving Desired Surface Finishes:

The surface finish (Ra, Rz, etc.) achievable with black SiC is directly related to the grit size used and the process employed:

- Coarse Grits (e.g., F24 – F80): Primarily used for rapid stock removal. They leave a relatively rough surface, suitable for applications where finish is not critical or as a preliminary step before finer operations.

- Medium Grits (e.g., F100 – F220): Offer a balance between stock removal and finish. Used for general-purpose grinding and preparation for finer finishing or painting.

- Fine Grits (e.g., F240 – F600): Employed for pre-polishing, achieving smoother surfaces, and applications where a good visual appearance or specific Ra value is needed. Often used in coated abrasives for finishing.

- Microgrits (e.g., F800 – F2500 and finer): Essential for lapping and polishing operations. These ultra-fine powders, often used in slurries or on specialized polishing pads, can produce mirror-like finishes and achieve very low Ra values on hard materials like ceramics, metals, and even glass.

Techniques for Surface Finish Enhancement:

- Progressive Grinding/Lapping: Using a sequence of progressively finer grit sizes is key to achieving high-quality finishes. Each step removes the scratches and imperfections left by the previous, coarser grit.

- Lapping: Involves using loose SiC abrasive grains (typically microgrits) in a slurry between the workpiece and a lapping plate. This process generates very flat, smooth surfaces with high precision.

- Polishing: Often follows lapping, using even finer SiC powders or other polishing compounds on soft pads to achieve the final desired luster and surface quality.

- Controlled Application Parameters: Speed, pressure, and the type of lubricant or coolant used significantly influence the surface finish. Lower speeds and lighter pressures with finer grits generally yield better finishes.

Dimensional Control with Black SiC Abrasives:

Beyond surface texture, black SiC abrasives are instrumental in achieving precise dimensional accuracy:

- Form Holding in Bonded Abrasives: Vitrified bonded SiC wheels, for example, offer excellent form holding, crucial for precision grinding of profiles and contours.

- Precision Grinding Machines: When used in high-precision grinding machines (surface grinders, cylindrical grinders), SiC wheels can achieve tolerances in the micron range.

- Consistent Abrasive Performance: The quality and consistency of the SiC grit size and distribution within the abrasive product are vital for predictable material removal and dimensional stability.

The selection of the right SiC abrasive product, combined with optimized process parameters and appropriate machinery, enables industries to meet stringent specifications for both surface finish and dimensional accuracy, ensuring the functionality and reliability of their components.

Beyond Abrasion: Post-Processing of Workpieces Machined by SiC

While black silicon carbide abrasives are primarily used for material removal and surface finishing, consideration must also be given to the post-processing steps that workpieces may require after being machined or finished with SiC. These steps are crucial for ensuring the final component meets all functional, cleanliness, and aesthetic requirements.

Common post-processing steps for parts machined with SiC abrasives include:

- Cleaning and Degreasing:

- Purpose: To remove residual SiC particles, swarf, coolants, oils, and any other contaminants from the workpiece surface.

- Methods: Aqueous cleaning with detergents, solvent cleaning, ultrasonic cleaning, or specialized chemical cleaning depending on the workpiece material and the nature of the contaminants. Thorough cleaning is vital to prevent interference with subsequent processes or a product’s end-use.

- Deburring:

- Purpose: Grinding and cutting operations, even fine ones, can leave small burrs or sharp edges on the workpiece. Deburring removes these to improve handling safety, part fitment, and overall quality.

- Methods: Manual deburring with hand tools, tumbling, vibratory finishing (often with ceramic or plastic media, though fine SiC can be used here too for aggressive deburring), brushing, or electrochemical deburring.

- Surface Treatment or Coating:

- Purpose: Depending on the application, the SiC-machined surface might be a preparatory step for further surface treatments like plating, painting, anodizing, PVD/CVD coating, or passivation.

- Consideration: The surface roughness and cleanliness achieved by the SiC abrasive process must be compatible with the adhesion and quality requirements of the subsequent coating or treatment.

- Heat Treatment:

- Purpose: Some materials may undergo stress relief or other heat treatments after machining to optimize their mechanical properties.

- Consideration: The machining process itself should not have introduced excessive stress or micro-cracks that could be exacerbated by heat treatment.

- Inspection and Quality Control:

- Purpose: To verify that the workpiece meets all dimensional specifications, surface finish requirements, and is free from defects.

- Methods: Dimensional measurement (calipers, micrometers, CMMs), surface roughness testing (profilometers), visual inspection, non-destructive testing (NDT) if required.

- Assembly:

- Purpose: If the machined component is part of a larger assembly, it must be clean and dimensionally accurate to ensure proper fit and function.

The choice and extent of post-processing will depend heavily on the workpiece material, its intended application, and the quality standards required. Effective planning for these steps is integral to the overall manufacturing process, ensuring that the benefits of using high-performance SiC abrasives translate into a high-quality final product.

Overcoming Challenges: Best Practices for Using Black SiC Abrasives

While black silicon carbide abrasives offer significant advantages, users may encounter certain challenges. Understanding these potential issues and implementing best practices can help mitigate them, ensuring optimal performance, safety, and efficiency.

Common Challenges & Mitigation Strategies:

- Abrasive Loading or Glazing:

- Challenge: The abrasive surface becomes clogged with workpiece material (loading) or the grains become dull (glazing), reducing cutting efficiency. This is more common with softer, ductile materials or improper wheel/belt specifications.

- Mitigation:

- Use appropriate coolants or lubricants to flush away swarf.

- Select a softer grade or more open coat abrasive (for coated abrasives) to allow better chip clearance.

- Dress bonded abrasives regularly to expose fresh cutting edges.

- Adjust speeds and feeds – sometimes reducing pressure or increasing speed can help.

- Workpiece Burn or Thermal Damage:

- Challenge: Excessive heat generation during grinding can lead to discoloration, metallurgical changes, or warping of the workpiece.

- Mitigation:

- Utilize effective cooling systems and ensure proper coolant application.

- Use sharper abrasives (dress wheels frequently) and avoid excessive pressure.

- Consider SiC abrasives with higher thermal conductivity or specialized bonds.

- Optimize cutting speeds and feed rates to reduce heat buildup.

- Premature Abrasive Wear:

- Challenge: Abrasive tools wear out too quickly, increasing costs and downtime.

- Mitigation:

- Ensure the SiC abrasive type and grade are correctly matched to the workpiece material and application. Using SiC on hard ferrous alloys where CBN might be better, for instance, can lead to rapid wear.

- Operate within recommended speed and pressure parameters.

- Check machine stability and spindle condition; vibrations can accelerate wear.

- Use high-quality abrasives from reputable suppliers.

- Achieving Consistent Surface Finish:

- Challenge: Difficulty in obtaining the desired surface roughness or consistency across multiple parts.

- Mitigation:

- Maintain consistent process parameters (speed, feed, pressure, coolant flow).

- Use SiC abrasives from batches with consistent grit size and quality.

- Implement a progressive fining sequence if very smooth finishes are required.

- Regularly dress and true grinding wheels.

- Dust Generation and Safety:

- Challenge: Abrasive processes generate dust (SiC particles and workpiece material), which can be a respiratory hazard and an environmental concern.

- Mitigation:

- Implement effective dust extraction systems at the source.

- Ensure operators use appropriate Personal Protective Equipment (PPE), including respiratory protection, eye protection, and gloves.

- Follow safety data sheet (SDS) recommendations for handling SiC.

- Maintain good housekeeping in the work area.

- Choosing the Right Abrasive Specification:

- Challenge: With numerous grades, grit sizes, and bond types, selecting the optimal SiC abrasive can be complex.

- Mitigation:

- Consult with experienced abrasive suppliers or application engineers.

- Conduct trials to evaluate performance for specific applications.

- Refer to abrasive manufacturers’ catalogs and technical data.

By proactively addressing these common challenges, users can maximize the benefits of black silicon carbide abrasives, leading to improved productivity, higher quality parts, and a safer working environment.

Sourcing Excellence: Choosing Your Black Silicon Carbide Supplier

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.