Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability

Share

In Pakistan’s steel plants, the hidden cost of every heat often shows up at the tundish. Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability was built by Sicarbtech for the long, quiet sequences that planners demand and casters rarely enjoy. By combining high-activity SiC with precisely dosed barium microdomains and a hydrophobic, anti-oxidation coating, the modifier shapes inclusion chemistry away from stubborn alumina, encourages deformable compound formation, and protects the nozzle from progressive choking. Meanwhile, silicon and carbon synergy delivers decisive deoxidation without inviting late aluminum spikes. In the 2025 environment—higher scrap ratios, tighter EHS expectations, and relentless cost pressure—this composite route turns nozzle openness from a risk factor into a managed parameter.

Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability product overview and 2025 market relevance

The logic behind Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability is straightforward. Silicon carbide provides a fast, controllable reduction of oxygen with simultaneous silicon addition and mild exothermic support, while barium—embedded as microdomains within densified granules or pellets—acts as an inclusion modifier. Together they discourage hard, angular Al2O3 clusters and promote softer, more deformable inclusions that pass nozzles without building rings. Manufactured via carbothermal reduction synthesis, high-purity classification, and densified granulation, each particle is finished with a hydrophobic coating to resist monsoon moisture and minimize dust in enclosed feeders. For Pakistan’s EAF and converter routes, this composite reduces reliance on high aluminum wire, simplifies alloy recipes, and stabilizes continuous casting. As Dr. Nadia Rehman observed during an audit in Karachi, “Barium doesn’t win the heat by itself—it prevents you from losing it at the nozzle” (Steel Process Insights Pakistan, 2024).

Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability technical specifications and advanced features

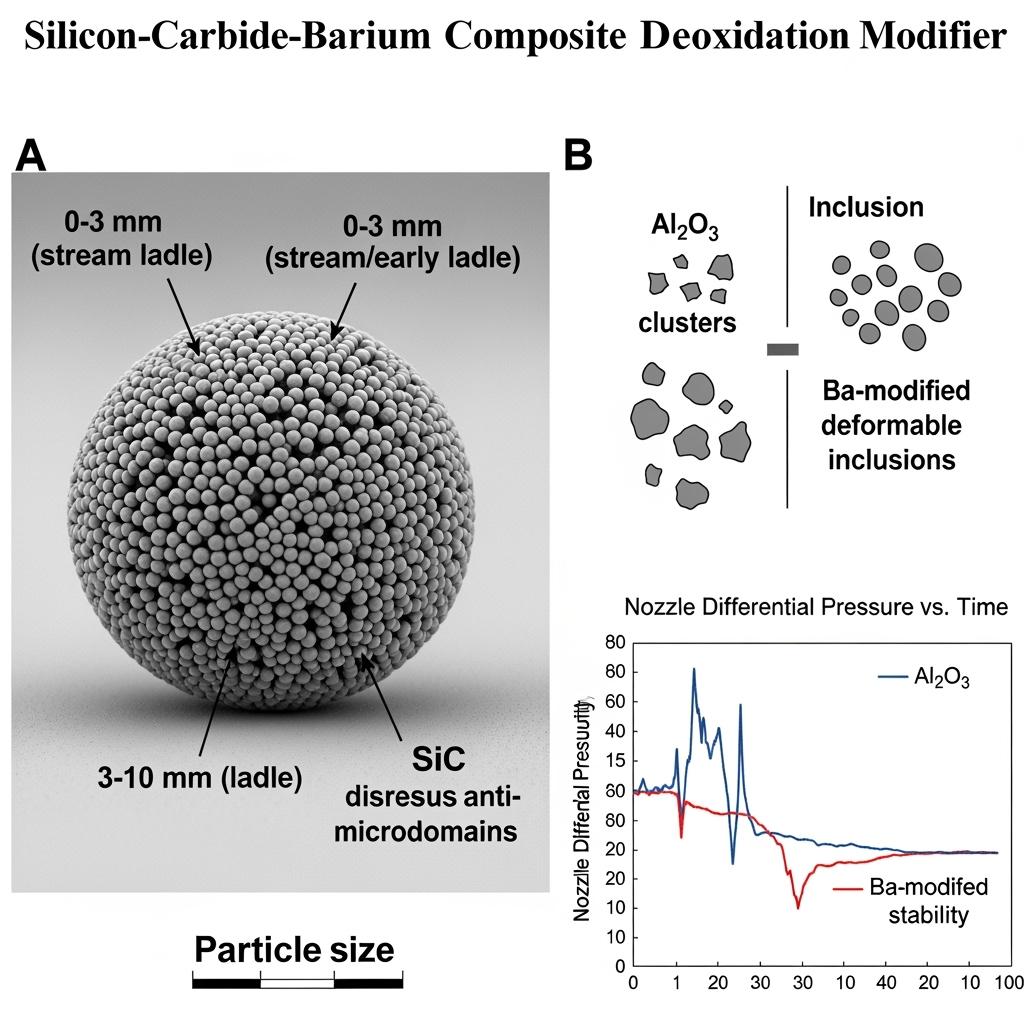

Sicarbtech formulates Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability with tight controls aligned to Pakistani practice. The SiC matrix typically ranges from eighty-eight to ninety-six percent, with free carbon between one and six percent for dual deoxidation and thermal balance. Free silicon is held around 0.5 to 1.5 percent to limit secondary oxidation during refining. Barium content is tuned in narrow bands—commonly 0.3 to 1.2 percent of the granule mass—sufficient to modify inclusion populations without destabilizing slag regimes. Sulfur and phosphorus are each capped at or below 0.02 percent to uphold cleanliness targets. Particle size distributions are engineered to the addition point: 0–3 mm for the teeming stream or early ladle when fast kinetics are essential, and 3–10 mm for sustained release in calmer ladles. A hydrophobic, anti-oxidation coating preserves activity during transport and enables low-dust, accurate metering in sealed feeders and pneumatic transfers. Reactivity indices are lab- and site-calibrated to link dissolution profiles with tapping temperatures typical of local EAF and converter operations.

Casting and cleanliness outcomes with Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability

| Deoxidation and casting KPIs | Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability | Low-Al SiC additive (no Ba) | Al-heavy deoxidation route |

|---|---|---|---|

| Silicon absorption vs baseline | +4–8 percentage points | +3–8 percentage points | Variable with late wire |

| Inclusion morphology (SEM) | More deformable, Ba-modified phases | Finer, floatable; fewer alumina clusters | Al2O3 clusters frequent |

| Nozzle clogging incidents per 100 heats | -25–45% | -20–40% | Reference/higher |

| Sequence length stability | Higher; DP slope flattened | Higher; improved | Lower; frequent interventions |

| Total oxygen after refining (ppm) | -6 to -15 | -5 to -15 | Variable; spikes possible |

Material and logistics attributes of Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability

| Attribute | Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability | Operational significance in Pakistan |

|---|---|---|

| SiC matrix | 88–96% | High-activity silicon with carbon synergy |

| Free carbon | 1–6% | Dual deoxidation and thermal support |

| Free silicon | 0.5–1.5% | Controls reoxidation risk |

| Barium microdomains | 0.3–1.2% | Inclusion modification for nozzle openness |

| S, P (each) | ≤0.02% | Clean steel/export compliance |

| Particle sizes | 0–3 mm; 3–10 mm | Stream and ladle flexibility |

| Coating | Hydrophobic, anti-oxidation, anti-powdering | Monsoon-ready, low dust |

| Storage stability | ≥6 months | Karachi-to-upcountry logistics resilience |

Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability performance comparison with alternatives

| Cost, energy, and risk profile | Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability | Low-Al SiC route (no Ba) | FeSi + high Al wire |

|---|---|---|---|

| Alloy cost per ton of steel | -1–4% vs Al-heavy | -1–5% vs Al-heavy | Baseline; FX-sensitive |

| Heat time impact | -0.5–1.5% | -0.5–2% | Reference |

| Nozzle deposit growth rate (proxy) | Low; stable DP | Low–moderate | Higher; Al2O3 deposition |

| Recipe complexity | Simplified; single composite | Simplified | Higher; wire timing critical |

| EHS/housekeeping | Low dust; enclosed metering | Low dust | Wire dust; manual handling |

Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability advantages and proven benefits with expert quote

The standout benefit of Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability is its ability to defend the caster while delivering predictable silicon pickup. By introducing barium at controlled microdomain levels, the inclusion landscape shifts away from rigid alumina toward phases that deform and pass, flattening the nozzle differential pressure curve and extending sequence lengths. Furthermore, because SiC handles the heavy lifting on deoxidation, mills can trim aluminum wire without risking oxygen rebounds. Prof. Li Wei of CAS Weifang Innovation Park summarized it succinctly: “If you fix inclusions at the ladle, you won’t fight them at the nozzle. Barium-modified SiC does that elegantly” (CAS Materials Review, 2023).

Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability real-world applications and measurable success stories

A Karachi-area EAF billet plant piloted Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability at the teeming stream with a 0–3 mm grade. Over six weeks, silicon absorption improved by five percentage points, total oxygen fell by eight ppm on average, and nozzle clogging events dropped by thirty-six percent per hundred heats. Casting cameras showed fewer strand slowdowns, and operators reduced reliance on mid-sequence wire corrections. In Punjab, a converter facility applied early ladle additions using a 3–10 mm grade tailored with 0.7 percent barium. The site reported a one percent reduction in average heat time and a three-degree Celsius improvement in tapping temperature drop. SEM analyses revealed a marked reduction in compact alumina clusters and a rise in Ba-bearing, deformable inclusions, which aligned with visibly steadier nozzle differential pressure traces during long sequences.

Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability selection and maintenance considerations

Success begins by aligning barium level and particle size with steel grade, slag chemistry, and dosing timing. For heats sensitive to nozzle openness in long sequences, a mid-range barium content around 0.6–0.9 percent paired with 0–3 mm dosing in the stream provides quick inclusion modification without overfeeding. Grades with longer ladle residence times often benefit from 3–10 mm to sustain dissolution and maintain modification throughout refining. Slag practice matters; coordinating basicity and viscosity ensures modified inclusions float or remain deformable enough to pass. The coating’s hydrophobic behavior preserves flowability under monsoon humidity, but enclosed silos and dry purge lines remain best practice. Finally, integrating with Sicarbtech’s in-situ QC and traceability allows feeders to read batch tags—PSDs, moisture, and reactivity index—so dosing curves reflect the exact material on hand.

Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability industry success factors and customer testimonials

Where plants win with Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability, they treat aluminum wire as a trim tool and let the composite set the inclusion stage early. A QA superintendent from a North Region caster put it plainly: “We stopped praying at the nozzle. Sequences got longer, and the radio went quiet.” That calm is underwritten by data—stable oxygen, flatter nozzle DP slopes, and fewer manual interventions—freeing crews to focus on throughput rather than firefighting.

Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability future innovations and market trends

Looking ahead, Sicarbtech is extending Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability with microstructured granules that deliver two-stage release: an initial pulse for early inclusion modification, followed by a controlled tail for long sequences. Coatings are being refined to react selectively under varied slag carry-over, ensuring the Ba effect lands exactly when needed. Moreover, technology transfer for localized powder synthesis, classification, and granulation will allow Pakistani mills to iterate particle size distributions and barium levels quickly, shortening learning cycles and anchoring supply independent of import volatility.

Common questions and expert answers

How does Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability differ from standard low-Al SiC additives?

Both reduce oxygen with silicon and carbon synergy, but Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability adds barium microdomains that modify inclusions into more deformable phases, directly defending nozzle openness in long sequences.

What addition point is best for Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability?

Teeming stream dosing with 0–3 mm gives fast inclusion modification. Early ladle additions with 3–10 mm sustain the effect when residence time allows. Sicarbtech will align PSD and barium level to your tapping temperatures and slag practice.

Will Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability change slag stability?

When tuned properly, slag remains stable. The barium level is controlled to influence inclusion chemistry without upsetting slag basicity or viscosity; coordination with your flux plan ensures balance.

Can Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability reduce aluminum wire usage?

Yes. Because the composite handles primary deoxidation and inclusion modification early, aluminum wire can be trimmed and reserved for final corrections, which reduces alumina formation risk.

How does Sicarbtech assure batch consistency for Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability?

Every batch is verified with Sicarbtech’s in-situ quality monitoring and traceability system—SiC %, free carbon/silicon, barium content, PSD, moisture, coating performance, and flowability—then sealed to shipment IDs for Level 2 integration.

Why Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability works for your operations

Because it tackles the problem where it starts: inclusion chemistry and dissolution kinetics, not emergency fixes at the strand. Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability delivers the silicon you need, the carbon synergy you rely on, and the inclusion modification you wish you had during long sequences. In Pakistan’s mills—where every minute of steady casting lifts throughput and confidence—this composite is a practical, data-backed route to cleaner steel and calmer operations.

Connect with specialists for custom solutions

Sicarbtech stands behind Silicon-Carbide–Barium Composite Deoxidation Modifier for Improved Nozzle Openness and Casting Sequence Stability with more than ten years of silicon carbide manufacturing expertise and Chinese Academy of Sciences–backed innovation. We develop custom materials across R-SiC, SSiC, RBSiC, and SiSiC; provide technology transfer and factory establishment services to localize powder synthesis, classification, granulation, and coating; and integrate enclosed storage with online feeding and in-situ QC for closed-loop control. With turnkey solutions proven across nineteen-plus enterprises, we will structure a no-cost pilot for your plant with clear KPIs—lower alloy cost per ton, reduced total oxygen, longer sequence stability, and fewer nozzle interventions—so you can scale with confidence and urgency.

For a free consultation and a fast, data-backed proposal, contact:

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article metadata

Last updated: 2025-09-15

Next review scheduled: 2025-12-15

Author: Sicarbtech Applications Engineering Team

Region focus: Pakistan (EAF and converter routes; billets, bars, wire rod, flats)

Timeliness note: Content aligned to 2025 cleanliness targets, PEQS-aligned dust control, and inclusion-management strategies for sequence stability

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.