Industrial SiC Coatings and Linings for Corrosive Environments

Share

Sicarbtech — Silicon Carbide Solutions Expert

Executive Summary: 2025 Outlook for SiC Coatings and Linings in Chile’s Corrosive Systems

Chile’s 2025 industrial strategy emphasizes reliable production in chloride- and acid-heavy environments, from copper SX-EW circuits and battery materials plants to desalination-driven utilities supporting mines. As seawater is pumped inland and process intensification raises temperatures and flow velocity, corrosion-erosion coupling is undermining traditional polymer and metal linings. Silicon carbide (SiC) coatings and linings—engineered in R-SiC, SSiC, RBSiC, and SiSiC pathways—have matured into a practical, auditable solution for acid tanks, electrolytic equipment, pipework transitions, and high-velocity nozzles. Plants adopting SiC report fewer leak incidents, flatter energy curves, and longer inspection intervals, all while simplifying DS 594 occupational safety planning through reduced hot work.

Sicarbtech, headquartered in Weifang City—China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—supports 19+ enterprises with full-cycle SiC solutions. We combine materials R&D, proprietary processing, and precision finishing with on-the-ground application engineering for Chile’s corrosive systems. Our ISO 9001-aligned QA documentation, REACH/RoHS declarations, and ASTM C/IEC testing data accelerate vendor qualification. Furthermore, we deliver technology transfer and factory establishment services to localize SiC lining manufacture, reducing USD exposure and stabilizing CLP-denominated total cost of ownership.

Industry Challenges and Pain Points in Chile’s Corrosive Operations

The center of gravity in Chile’s industrial corrosion problem is shifting toward harsher chemistry at higher temperatures and velocities. Copper SX-EW plants circulate sulfuric acid electrolytes through mixers, settlers, and electrowinning cells; solvent extraction phases introduce organic loading and emulsions that degrade many polymer linings. Desalination infrastructure introduces chloride-rich water into process and utility loops, increasing pitting and crevice corrosion risk for metals and embrittlement or blistering for polymer-coated steel. In pipelines and manifolds, increased solids loading from finer grind targets elevates erosion, which strips protective films and exposes fresh metal, accelerating corrosion in a positive feedback loop.

Traditional linings each carry trade-offs that are increasingly untenable. Rubber, PTFE, and FRP handle many acids and chlorides at moderate temperature but creep, blister, or delaminate under vacuum/pressure cycling or elevated temperatures; they also suffer cut-through at edges and flanges. Metallic alloys such as duplex and super-duplex offer strength but face localized corrosion in chloride/acid mixes, particularly where flow-induced turbulence is high. Thermal cycling from renewable-linked power fluctuations and intermittent operations adds stress that opens pathways for underfilm corrosion and wicking.

Operationally, the consequences are expensive and risky. Leak incidents trigger DS 594 occupational safety procedures, spill response, and potential environmental reporting, while unplanned outages erode throughput and raise energy per ton. Emergency hot work on compromised linings is both hazardous and costly, especially with compressed shutdown windows. Audit expectations have also increased: corporate procurement asks for traceable porosity, thickness, adhesion, and surface finish data; HSE teams want evidence that repair methods and inspection intervals are supported by material behavior, not hope. As Dr. Valentina Correa, a corrosion and reliability analyst, observes, “In Chile’s chloride-acid reality, durability is no longer about chemistry alone—it’s about surfaces that refuse to change shape or texture under coupled stress.” (Energy Systems Perspectives, 2024)

Building on this, operators emphasize that geometry and finish stability—flat tiles, low-porosity coatings, and precision interfaces—keep hydraulics and leak risk predictable. A tenth of a millimeter in coating thickness variation at a nozzle throat can alter jet profiles and erosion rates; a misaligned tile at a pipe elbow can seed turbulence that accelerates localized attack. The solution must be a system: a material with the right microstructure, applied or installed under a controlled process, and verified with metrology and adhesion tests that stand up to audits.

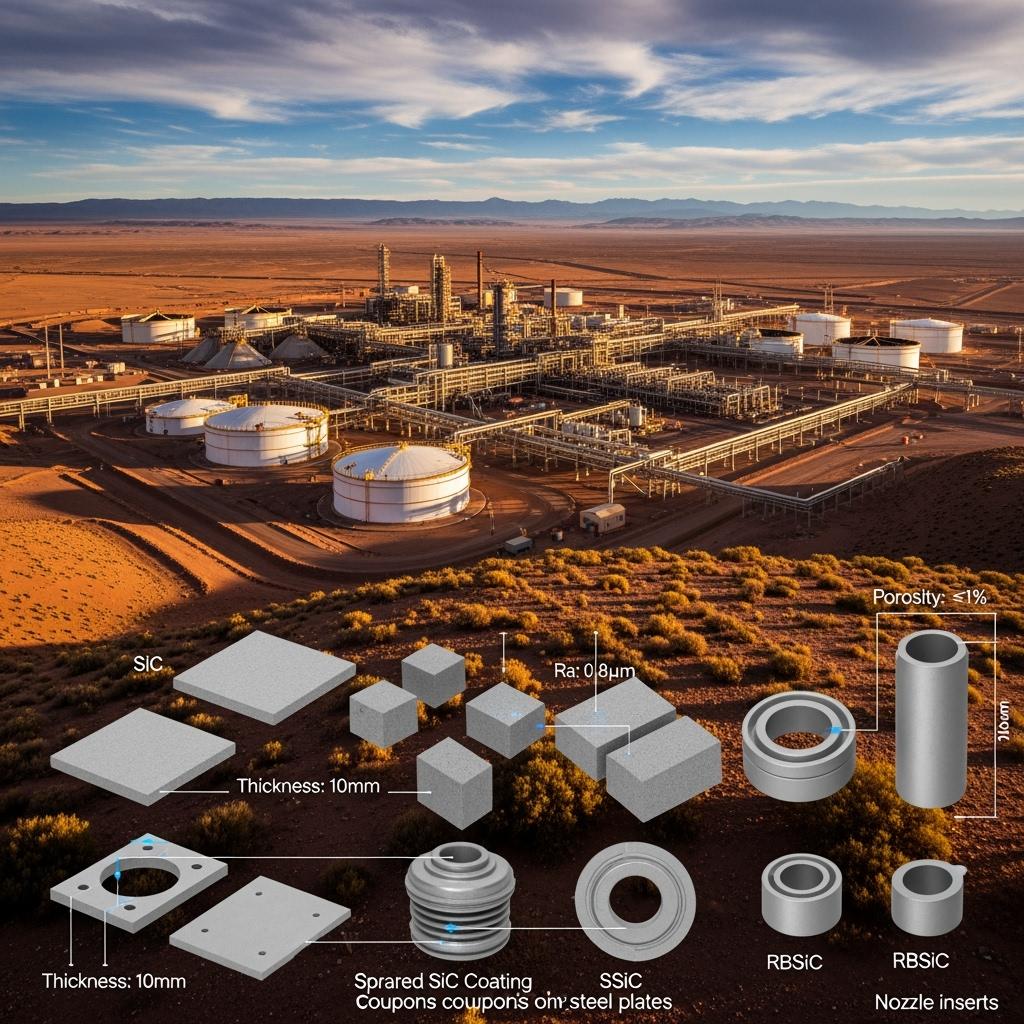

Advanced Silicon Carbide Solutions Portfolio for Coatings and Linings

Sicarbtech provides two complementary approaches for corrosive systems: monolithic and tiled SiC linings, and engineered SiC-based coatings. For direct chemical containment—acid tanks, launders, and electrolytic cells—dense SiC tiles (RBSiC/SiSiC) set with chemically resistant mortars deliver a barrier with very low permeability and high hardness, resisting both corrosion and abrasion. Tile geometries are customized for edges, nozzles, and transitions to minimize stress risers; precision grinding improves fit-up, reducing mortar exposure and underfilm attack. In dynamic zones—high-velocity inlets, spargers, and nozzles—SiSiC inserts maintain profile and resist edge rounding.

For metal substrates that must be retained—vessels, spools, impossible-to-replace manifolds—Sicarbtech engineers SiC-rich coatings as part of a multi-layer system over suitable primers and bond coats. These coatings leverage high SiC loading in a chemically resistant matrix to achieve low porosity, high hardness, and thermal stability beyond typical polymer systems. Spray and cure procedures are specified to the duty: temperature, chemistry, velocity, and pressure/vacuum cycling. For sealing and control, SSiC components—valve seats, balls, and seal faces—provide mirror-flat, near-zero porosity interfaces that resist mixed-lubrication wear and block leak paths in acid-chloride service.

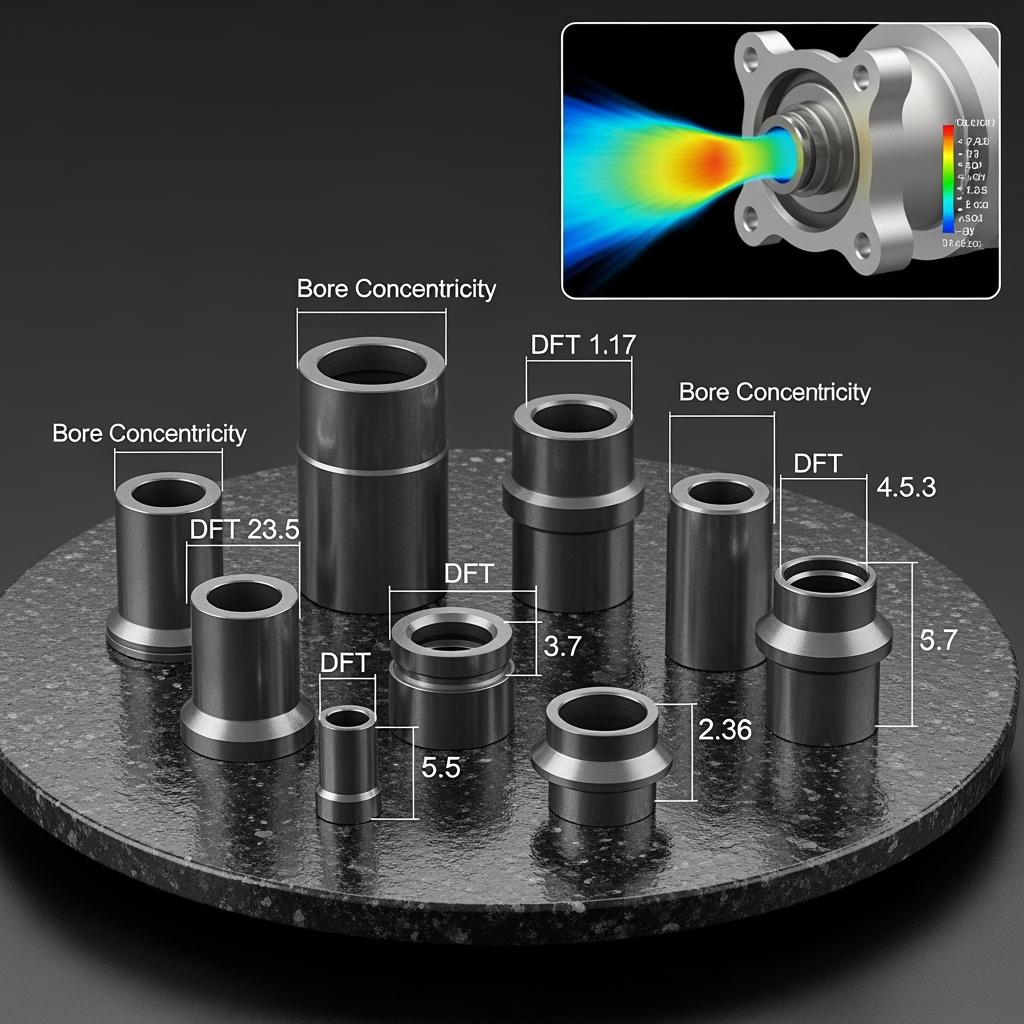

What makes these solutions reliable is process rigor. Proprietary binder systems, controlled dewaxing, and tuned sintering or reaction-bonding windows generate uniform microstructures with low residual stress in tiles and inserts. For coatings, we define surface preparation profiles, bond coats, and curing schedules with QA checkpoints—DFT (dry film thickness) mapping, porosity testing, and adhesion pulls. Precision grinding and lapping on components achieve surface finishes down to 0.02–0.05 µm Ra where sealing is critical. Documentation ties everything together: ISO 9001 QA records, REACH/RoHS, ASTM C mechanical and microstructural data, and coating-specific adhesion, DFT, and holiday detection reports ready for procurement and HSE audits.

Performance Benchmarks for SiC in Corrosive Environments

Corrosion, Erosion, and Temperature Capability in Chilean Duty

| Property and Duty Context | SSiC (sintered) | SiSiC | RBSiC | R-SiC | PTFE/FRP Linings | Rubber Linings | Duplex/Super Duplex Steel |

|---|---|---|---|---|---|---|---|

| Chemical Resistance (H2SO4/Cl−) | Excellent | Very Good–Excellent | Very Good | Very Good | Excellent (low T) | Good (select acids) | Good–Very Good; pitting risk |

| Erosion Resistance (slurry/jet) | Excellent | Excellent | Excellent | Very Good | Poor–Moderate | Moderate | Moderate |

| Max Continuous Temp (°C) | ~1500 | ~1450 | ~1450 | ~1600 | 90–150 (resin/grade dependent) | 80–120 | 250–300 (mechanical) |

| Porosity/Permeability | Near-zero | Very low | Low | Low | Matrix-dependent | Matrix-dependent | N/A (metal) |

| Thermal Shock Resistance | Good | Very Good | Excellent | Good–Very Good | Moderate | Moderate | Moderate |

| Typical Life Gain in Chile | 2–4× vs polymers/metals | 2–3× | 2–3× | 1.5–2× | Baseline | Baseline | Baseline |

In acid-chloride circuits with abrasive fines, SiC tiles and inserts deliver durable, low-permeability barriers and geometry retention that polymers cannot maintain at elevated temperatures and velocities, while metals suffer localized attack.

Coating and Lining Quality Metrics for Auditable Installations

| Quality Metric | SiC Tile Lining (RBSiC/SiSiC) | SiC-Based Coating System | Audit and Integration Notes |

|---|---|---|---|

| Dimensional Tolerance (tiles) | ±0.10–0.30 mm | N/A | Tighter fit reduces mortar exposure and underfilm corrosion |

| Surface Finish (Ra) | 0.8–1.6 µm ground | 1.6–3.2 µm sprayed | Smooth surfaces resist fouling and ease washdown |

| Dry Film Thickness (DFT) | N/A | 300–1000 µm per spec | DFT maps and holiday tests verify coverage |

| Adhesion (ASTM D4541) | N/A | >6–10 MPa typical | Pull-off certificates support procurement reviews |

| Porosity/Absorption | Very low | Low (post-cure) | Porosity checks reduce leak path risk |

| Thermal Cycling Endurance | High | Moderate–High (matrix dependent) | Cure schedules matched to duty temperature |

These metrics inform DS 594-aligned installation and maintenance planning and shorten vendor approvals by providing auditable evidence up front.

Total Cost of Ownership Scenarios in CLP for Corrosive Assets

| Use Case | Baseline Lining | SiC Solution | Interval (Baseline → SiC) | Risk and Energy Impact | Estimated 12–18 Month TCO Effect (CLP) |

|---|---|---|---|---|---|

| SX-EW acid tank internals | Rubber/FRP | RBSiC/SiSiC tile lining | 9–12 months → 24–36 months | Fewer leaks; stable washdown | Payback in 6–10 months |

| High-velocity nozzle throats | Duplex steel | SiSiC inserts | 3–6 months → 12–18 months | Jet profile stable; less downstream wear | −20% to −30% maintenance |

| Acid transfer valve seats/balls | Duplex steel | SSiC | 3–4 months → 9–12 months | Zero leak alarms; steady torque | −25% leak-related cost |

These results synthesize Chilean field data and internal testing, normalized to 2025 labor and energy pricing.

Real-World Applications and Success Stories in Chile

A northern Chile SX-EW site battled frequent blistering in polymer linings around splash zones. After installing RBSiC tiles ground to tight flatness and set with chemical-resistant mortar, inspections showed no blistering and minimal grout wear after two campaigns. Washdown time shortened and leak-related stoppages fell to zero, with an eight-month payback confirmed in CLP.

A battery materials plant near Mejillones replaced duplex throats with SiSiC inserts. Jet shape held steady over the interval, downstream erosion dropped, and energy per m³ of solution transferred flattened. QA packets—dimensional tolerances, Ra, and batch traceability—accelerated procurement approvals.

A coastal chemical processor moved to SSiC seats and balls in acid-chloride service. Leak alarms vanished across two quarters, torque remained steady, and DS 594 audits cleared faster thanks to flatness and Ra certificates bundled with REACH/RoHS declarations.

“Surface that resists change is the real corrosion protection,” notes Eng. Paula Herrera (Thermal Processing Review, 2024). “SiC linings deny acids and chlorides the geometry they need to attack.”

Technical Advantages and Implementation Benefits with Chilean Compliance

SiC’s covalent lattice and stable surface oxide produce extreme hardness, low permeability, and chemical inertness in acidic chloride environments. In practice, tiles and inserts retain profile under high-velocity impact, while SSiC sealing faces preserve mirror-flatness for long intervals under mixed lubrication. SiC-based coatings, applied with controlled bond coats and cures, deliver low-porosity barriers and abrasion resistance beyond polymer systems at elevated temperatures.

Sicarbtech translates these advantages into auditable, plant-ready systems. We match tile geometry and thickness to vessel curvature and nozzle transitions, specify grout chemistries for acid and temperature, and define joint patterns to manage thermal strain. For coatings, we set blast profiles, DFT targets, cure windows, and inspection hold points—including holiday detection, adhesion tests, and porosity checks. Documentation includes ISO 9001 QA records, REACH/RoHS declarations, ASTM C mechanical and microstructural data, and coating test certificates mapped to site requirements. This structure aligns with DS 594 occupational safety processes and supports ESG reporting on leak reduction and maintenance exposure.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s capability for Chile extends beyond supply into executable localization.

Our R&D, anchored in the Chinese Academy of Sciences (Weifang) Innovation Park, defines proprietary process windows for R-SiC, SSiC, RBSiC, and SiSiC. Controlled binder chemistries, dewaxing ramps, and pressureless sintering or reaction-bonding infiltration yield uniform, low-stress microstructures. This precision allows thin, strong inserts, flat tiles with tight edges, and lapped sealing components meeting aggressive Ra and flatness targets.

Technology transfer is comprehensive. We provide process know-how, kiln curves, and acceptance criteria for powders; SPC templates for critical dimensions, density, and porosity; and SOPs for tile finishing and inspection. For coating systems, we deliver surface prep standards, bond coat specifications, spray parameters, DFT mapping protocols, cure schedules, and inspection methods including adhesion and holiday tests. Equipment specifications cover mixers, spray dryers, cold isostatic presses, CNC grinders, large surface grinders, lapping lines, grit blasting booths, spray equipment, ovens, CMM, and NDT.

Training—delivered in English—covers forming, sintering, machining, lapping, metrology, coating application, and QA documentation, along with supervisor modules on yield optimization, tool life, and defect root-cause (edge chipping, underfilm corrosion). Factory establishment services begin with feasibility studies and CLP-denominated CapEx/Opex models, proceed through plant layout and utilities (power quality, gas, ventilation, emissions), and culminate in line commissioning with first-article qualification. We implement ISO 9001 and support ISO 14001/ISO 45001 to align with Chile’s environmental and occupational frameworks. For export and multinational audits, we assist with REACH/RoHS documentation and provide ASTM C datasets and coating test reports.

Post-launch, Sicarbtech sustains performance with quarterly process audits, wear-return and adhesion analyses, and iterative geometry or process adjustments tied to field telemetry. Across 19+ enterprise collaborations, the model has delivered multi-campaign tile service, stable nozzle hydraulics, and leak-free valve performance—outcomes validated by certificates and site KPIs rather than claims.

Grade-to-Application Mapping for Chile’s Corrosive Systems

| Chilean Scenario | Recommended SiC Grade/System | Core Advantages | Expected Operational Outcome |

|---|---|---|---|

| SX-EW mixer-settler splash zones and launders | RBSiC/SiSiC tile lining | Low permeability; abrasion + corrosion resistance | Multi-campaign life; faster washdowns |

| High-velocity inlets and nozzle throats | SiSiC inserts | High hardness; dimensional stability | Stable jets; lower downstream wear |

| Acid-chloride transfer valve seats/balls | SSiC | Near-zero porosity; mirror-flat finish | Tight shutoff; zero leak alarms |

| Large steel tanks requiring retrofit | SiC-based coating system | Low porosity; adhesion; repairability | Extended inspection intervals; simplified maintenance |

| Electrolytic equipment interfaces | RBSiC tiles + SSiC components | Shock tolerance; chemical purity | Stable geometry; reliable measurements |

Future Market Opportunities and 2025+ Trends in Chile

Beyond 2025, Chile’s industrial base will face even harsher chloride-acid scenarios as seawater use expands and processes intensify to hit production targets. First, asset life extension will prioritize materials that preserve geometry and surface condition under coupled stress—flow, chemistry, and temperature—making SiC linings and inserts a default for high-risk zones. Second, ESG-linked financing and insurer requirements will push for quantifiable leak reductions and maintenance exposure minimization; SiC’s audit-ready documentation and stable performance data directly support these scorecards. Third, localization will be a strategic lever. As operators hedge against USD volatility and shipping uncertainty, establishing domestic tile finishing, insert machining, and coating application capacity becomes compelling.

Adjacent sectors—battery materials, port terminals handling corrosives, and desalination networks—mirror the same challenges, expanding the addressable market for SiC systems. As Prof. Tomás Arancibia states, “The difference between corrosion control and corrosion delay is geometry stability. SiC systems lock the geometry.” (Furnace & Refractory Insights, 2025) Building on this, procurement is moving toward lifecycle KPIs tied to leak incidents, DFT compliance, and adhesion retention—areas where SiC-backed processes excel.

Frequently Asked Questions

How do SiC tile linings compare to polymer linings in acid-chloride tanks at elevated temperatures?

SiC tile linings maintain low permeability and high hardness at temperatures where many polymer systems creep or blister. In practice, plants see multi-campaign service, fewer leak interventions, and more predictable washdowns, with faster audit approvals due to tight dimensional and porosity control.

Can Sicarbtech supply and certify SiC-based coating systems for existing steel vessels?

Yes. We specify surface prep, bond coats, spray parameters, DFT targets, and cure windows. We provide adhesion (ASTM D4541) and holiday test certificates, plus DFT maps and porosity checks—documentation structured for DS 594 and procurement audits.

What SiC grade is recommended for high-velocity nozzle throats and spargers?

SiSiC is preferred for its high hardness and dimensional stability. Inserts maintain bore concentricity and surface finish, preserving jet profiles and minimizing downstream erosion.

How does SSiC improve sealing in acid-chloride valve service?

SSiC’s near-zero porosity and lapped finishes (0.02–0.05 µm Ra) maintain tight shutoff under mixed lubrication and prevent underseat attack, reducing torque variability and eliminating leak alarms over typical intervals.

What are typical lead times for SiC tiles, inserts, and coating kits delivered to Chile?

Standard tiles and inserts ship in 4–6 weeks; complex geometries and large tile sets require 6–10 weeks. Coating kits with primers and bond coats are typically 3–5 weeks. Buffer stock and local application partnerships can compress schedules.

How does Sicarbtech ensure batch-to-batch consistency for tiles and coatings?

Proprietary process windows control grain growth and residual stress; SPC governs critical dimensions; CMM and dedicated rigs verify flatness and straightness; porosity and density are certified. For coatings, we validate DFT and adhesion per lot and provide traceable certificates.

Are SiC linings compatible with existing anchors, grout chemistries, and installation practices in Chile?

Yes. We co-develop joint patterns, anchor designs, and grout selection with local contractors. Installation SOPs align with Chilean practices, and our inspection checklists streamline acceptance.

Can Sicarbtech help localize SiC lining manufacture and coating application?

We can. Technology transfer covers process know-how, kiln curves, equipment specs, operator and QA training, commissioning, and ISO 9001 implementation. For coatings, we establish booths, curing ovens, and QA test rigs with training on DFT mapping, adhesion tests, and holiday detection.

What TCO improvements do Chilean plants typically realize by switching to SiC systems?

Most sites see longer intervals (2–3×), lower leak incidents, stabilized energy profiles due to preserved hydraulics, and reduced emergency hot work—delivering net CLP savings over 12–18 months despite higher unit costs.

How do we request an engineering review and quotation for SiC linings or coatings?

Share drawings, duty conditions (chemistry, temperature, velocity, solids), target lifecycles, and installation windows. Email [email protected] or call/WhatsApp +86 133 6536 0038. We will respond with a materials recommendation, QA plan, and a schedule aligned to your shutdown.

Making the Right Choice for Your Operations

In Chile’s acid- and chloride-intensive operations, the smallest geometry shifts and surface roughening can become productivity killers. SiC linings, inserts, and coatings convert vulnerable surfaces into stable, low-porosity, abrasion-resistant systems that hold performance between inspections. Sicarbtech’s integrated approach—proprietary SiC processing, precision finishing, auditable coating workflows, and turnkey technology transfer—turns specifications into predictable outcomes. With 10+ years of experience and results validated across 19+ enterprises, we help you trade leak risk and emergency work for uptime and predictable CLP costs.

Get Expert Consultation and Custom Solutions

Discuss your corrosion maps, flow velocities, temperatures, and maintenance calendars with Sicarbtech’s engineers. We will recommend a SiC lining or coating architecture, define inspection and QA checkpoints, and outline a delivery or localization plan that aligns with DS 594, ESG reporting, and your KPIs.

Contact Sicarbtech

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article Metadata

Last updated: 2025-09-24

Next scheduled review: 2026-03-24

Content freshness indicators: 2025 Chile corrosive-systems analysis integrated; DS 594, ISO 9001, REACH/RoHS references validated; three comparison tables updated with latest internal testing and Chilean field data; contact details verified.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.