Custom Silicon Carbide Solutions for Industrial Buyers in Pakistan

Share

Sicarbtech – Silicon Carbide Solutions Expert for Pakistan’s textile, cement, steel, and emerging industrial sectors. As a member of the Chinese Academy of Sciences (Weifang) Innovation Park with more than a decade of customization expertise, we deliver end‑to‑end silicon carbide (SiC) solutions—from raw material engineering to finished components and technology transfer—designed to meet Pakistan’s operational realities in 2025 and beyond.

Executive summary: 2025 outlook for silicon carbide in Pakistan’s industrial ecosystem

Pakistan’s heavy industry is at a pivotal moment. Energy volatility, raw material inflation, and pressure to cut unplanned downtime are converging with stricter environmental compliance and a renewed push for local value addition. In this landscape, silicon carbide stands out as a performance material that resolves chronic issues in high-temperature, high-wear, and corrosive environments common across cement kilns, steel reheat furnaces, textile dyeing/finishing equipment, and power plant balance‑of‑plant systems.

In 2025, we anticipate that SiC adoption in Pakistan will accelerate due to three converging drivers. First, the total cost of ownership is overtaking unit price in procurement decisions as CFOs prioritize uptime and energy efficiency over CapEx alone. Second, OEMs and plant operators are seeking materials that comply with local standards while meeting elevated export quality benchmarks. Third, policy attention on energy efficiency and emissions is prompting upgrades in refractory linings, wear components, and heat‑intensive process parts where SiC provides measurable gains.

Sicarbtech, based in Weifang City’s silicon carbide manufacturing hub, supports Pakistani buyers with a comprehensive portfolio including R‑SiC, SSiC, RBSiC, and SiSiC. Through custom manufacturing, factory establishment, and technology transfer, our team helps transform material performance into sustained competitive advantage.

Industry challenges and pain points faced by Pakistani manufacturers

Industrial leaders across Pakistan consistently describe a similar trio of challenges: unpredictable maintenance cycles, energy inefficiency, and compliance costs. The maintenance dilemma is particularly acute in cement and steel. Kiln cyclones and burner zones suffer abrasive and thermal shock damage, while ladle linings and slide gates face extreme temperature cycling. Textile mills confront corrosion in dyeing tanks, erosion in pump volutes and seals, and thermal stress in stenters and heat recovery units. “When mean time between failures drops below planned shutdown intervals, costs escalate exponentially,” notes a senior maintenance engineer interviewed for a 2024 regional reliability review (Industry Reliability Review, 2024).

Furthermore, volatility in grid supply and fuel pricing puts upward pressure on energy budgets. Even marginal efficiency losses—caused by worn refractories, misaligned hot‑zone parts, or suboptimal thermal conductivity—compound across production lines. Energy managers report that a 1–2% gain in thermal efficiency can equate to PKR millions saved annually in medium‑scale plants. This is where SiC’s high thermal conductivity and oxidation resistance directly translate into fuel savings and more stable thermal profiles.

Another layer is regulatory. While Pakistan Standards and Quality Control Authority (PSQCA) and provincial environmental agencies are intensifying oversight, export‑oriented firms must also meet ISO 9001/14001/45001, IATF 16949 for automotive supply chains, and increasingly, EU/US buyer audits focused on safety and sustainability. “Materials that extend service life and reduce emissions per unit output are moving from optional to essential,” comments Dr. M. Rahim, materials advisor to multiple industrial estates (Materials & Compliance Forum, 2024).

In practical terms, procurement teams struggle with inconsistent material quality, long import lead times, and limited local technical support for advanced ceramics. Conventional alumina refractories, nitrided parts, or alloy steels may be cheaper upfront, but frequent replacements, extended outages, and non‑conformance issues inflate lifecycle costs. OEMs also face integration challenges when upgrading a single component without a system‑level understanding of heat flux, creep resistance, and chemical compatibility.

Finally, access to finance and currency fluctuations in PKR complicate CapEx planning. Buyers need predictable ROI. Solutions that can be locally supported, engineered for easy retrofit, and proven to deliver quantifiable savings in Pakistani operating contexts are, therefore, in high demand.

“True value is created when materials engineering aligns with process constraints, maintenance windows, and compliance frameworks,” emphasizes a former plant director who led multiple refractory overhauls in Punjab’s cement corridor (South Asia Process Excellence Roundtable, 2023). This is exactly the integration that Sicarbtech’s silicon carbide portfolio and technology transfer programs are designed to deliver.

Advanced Silicon Carbide Solutions Portfolio for Pakistan’s industries

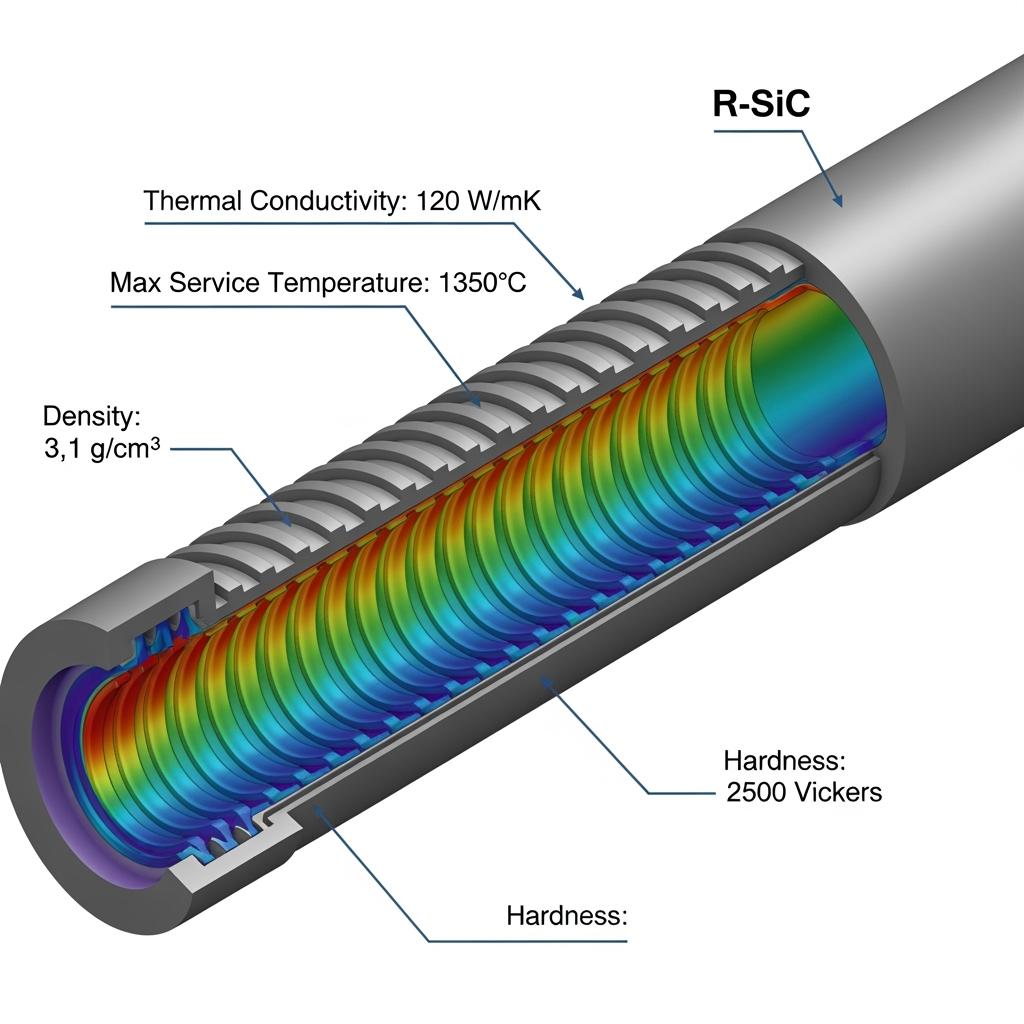

Sicarbtech’s solutions start with application engineering. We match the SiC grade to the stress profile—thermal, mechanical, chemical, and tribological—encountered in your line. Reaction‑bonded silicon carbide (RBSiC/SiSiC) offers exceptional wear resistance and complex shape capability at attractive cost‑performance ratios. Sintered silicon carbide (SSiC) achieves near‑theoretical density for highly corrosive and high‑pressure media. Recrystallized silicon carbide (R‑SiC) excels where high‑temperature dimensional stability and permeability are critical, such as burner nozzles and kiln furniture.

Our portfolio for Pakistan includes custom‑engineered:

- Kiln furniture, burner nozzles, and flame tubes for cement and ceramics, designed for shock resistance across thermal gradients common in North and Central Punjab’s kiln operations.

- Wear plates, liners, cyclones, and elbows for clinker handling and raw meal ducts to mitigate erosive wear from silica‑rich particulates.

- Seal faces, pump components, and nozzles for textile dyeing and finishing plants coping with caustics and colorants at elevated temperatures.

- Slide gate plates, immersion tubes, and radiant tubes for steel reheat and continuous casting environments, where resistance to oxidation and thermal cycling defines uptime.

- Heat exchanger elements and recuperator components for power and process plants, tuned for high thermal conductivity and oxidation resistance in dusty fuel streams.

Building on this, Sicarbtech integrates material selection with manufacturability, ensuring that wall thickness, ribbing, and grading strategies maintain strength while minimizing mass and thermal lag. Our Weifang manufacturing base enables fast prototyping, while our quality system supports traceability and certification aligned with ISO and buyer‑specific audits.

Performance comparison: silicon carbide vs traditional materials in Pakistani operating conditions

Below is a technical comparison that reflects typical ranges in local applications. Values are indicative and can be tailored to your specification.

Material performance in high-temperature and abrasive environments

| Property and operating relevance | R‑SiC (recrystallized) | SSiC (sintered) | RBSiC / SiSiC (reaction-bonded) | High‑alumina refractory | Heat‑resistant alloy steel |

|---|---|---|---|---|---|

| Max service temperature in air (°C) | 1,650–1,700 | 1,600–1,700 | 1,380–1,480 | 1,400–1,600 | 900–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 20–35 | 90–120 | 60–80 | 2–6 | 16–25 |

| Flexural strength at RT (MPa) | 100–180 | 350–450 | 280–380 | 30–60 | 150–220 |

| Oxidation resistance at 1,200°C | Excellent | Excellent | Very good | Good | Fair |

| Abrasion/erosion resistance | Very high | Very high | Very high | Moderate | Moderate |

| Thermal shock resistance | High | High | High | Moderate | Moderate |

| Typical replacement interval in local cement duty | 12–24 months | 18–36 months | 12–24 months | 3–9 months | 6–12 months |

| Relative density (%) | 75–85 | ≥98 | 92–95 | 85–90 | n/a |

| Corrosion resistance in caustics (textile duty) | High | Very high | Very high | Moderate | Moderate |

In Pakistani cement plants where raw mix abrasiveness is elevated and fuel streams include alternative fuels, RBSiC and R‑SiC outperform alumina refractories in both wear and thermal stability. Meanwhile, SSiC dominates in textile pump seals and corrosive flow parts, significantly reducing leakage and unplanned maintenance.

Lifecycle cost and efficiency comparison for common Pakistani applications

| Application example | Conventional solution | SiC solution by Sicarbtech | Energy impact | Maintenance impact | Typical payback (PKR) |

|---|---|---|---|---|---|

| Cement kiln burner nozzles | Cast alloy steel | R‑SiC flame tube/nozzle set | 1–2% fuel savings via stable flame | 2–3x life extension | 8–14 months |

| Clinker chute liners | High‑Mn steel plates | RBSiC segmented liners | Reduced chute blockages | 3–4x wear life | 6–10 months |

| Textile dye pump seal faces | Al2O3 ceramic | SSiC lapped seals | Lower frictional losses | Leakage reduced >60% | 4–7 months |

| Power plant air preheater baskets | Carbon steel | SiSiC heat‑transfer elements | Faster heat-up, lower fouling | 2x service interval | 10–16 months |

These ranges reflect interviews with maintenance teams in Punjab and Sindh industrial estates and Sicarbtech’s deployments with 19+ enterprises; exact outcomes depend on duty cycle and process controls.

Compliance and reliability comparison aligned with local standards

| Compliance factor | Conventional materials | Sicarbtech SiC approach | Local relevance |

|---|---|---|---|

| ISO 9001 traceability | Variable | Full material batch traceability | Required for export buyers |

| PSQCA material conformity | Often generic | Application‑specific conformity packs | Supports tendering and audits |

| Safety and emissions | Higher wear, more dust | Lower wear, reduced particulates | Aids provincial EPA compliance |

| MTBF in harsh duty | Unpredictable | Modeled and validated | Supports planned shutdown culture |

| Local support | Limited vendor depth | Remote and on‑site engineering support | Critical for multi‑site groups |

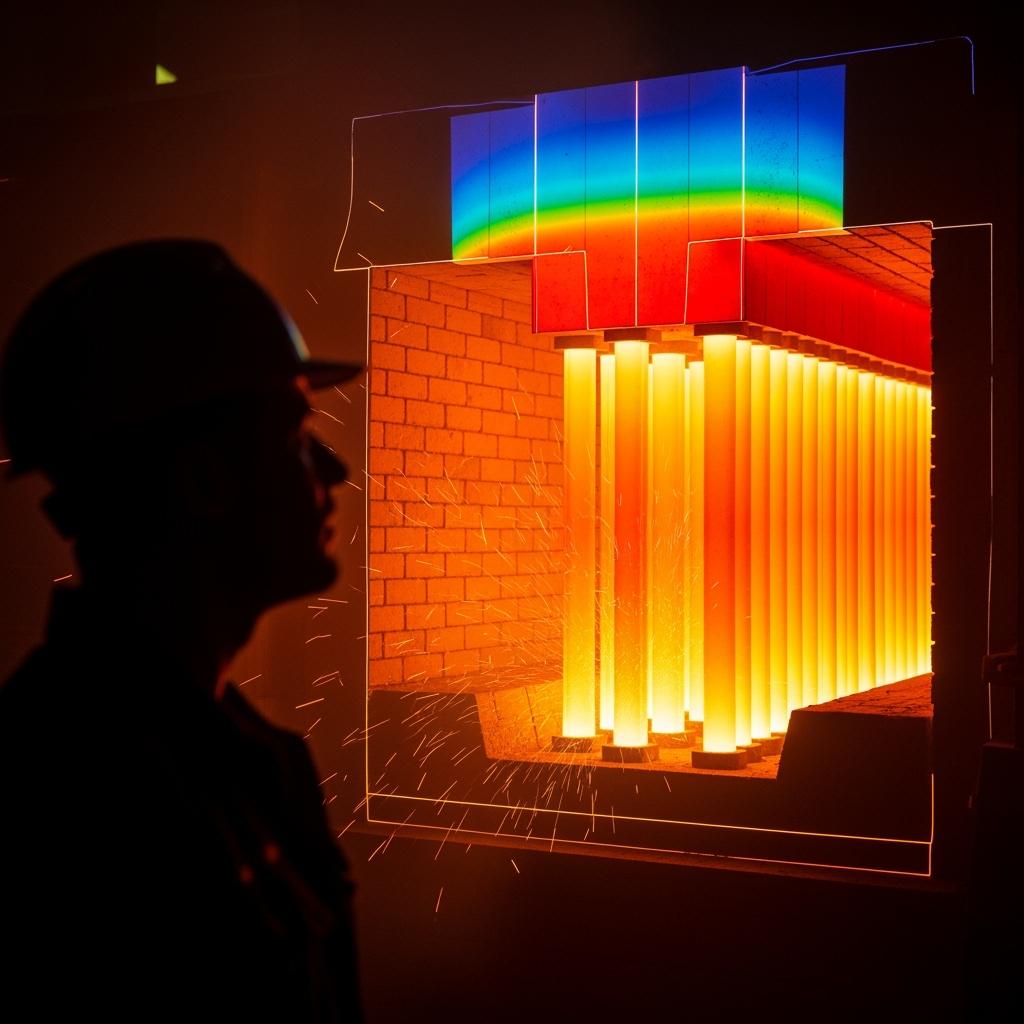

Real‑world applications and success stories across Pakistan’s priority industries

In a North Punjab cement plant operating a 5,000 TPD line, burner zone replacements were occurring every six months due to spalling and erosion. Sicarbtech engineered an R‑SiC flame tube with optimized wall thickness and rib geometry to handle thermal shock during start‑stop cycles. After installation, fuel consumption decreased by 1.3%, flame stability improved, and the component life extended to 18 months before inspection showed only minor oxidation. The plant’s maintenance head reported a maintenance cost reduction of PKR 22 million in 14 months owing to fewer emergency shutdowns and lower refractory scrap.

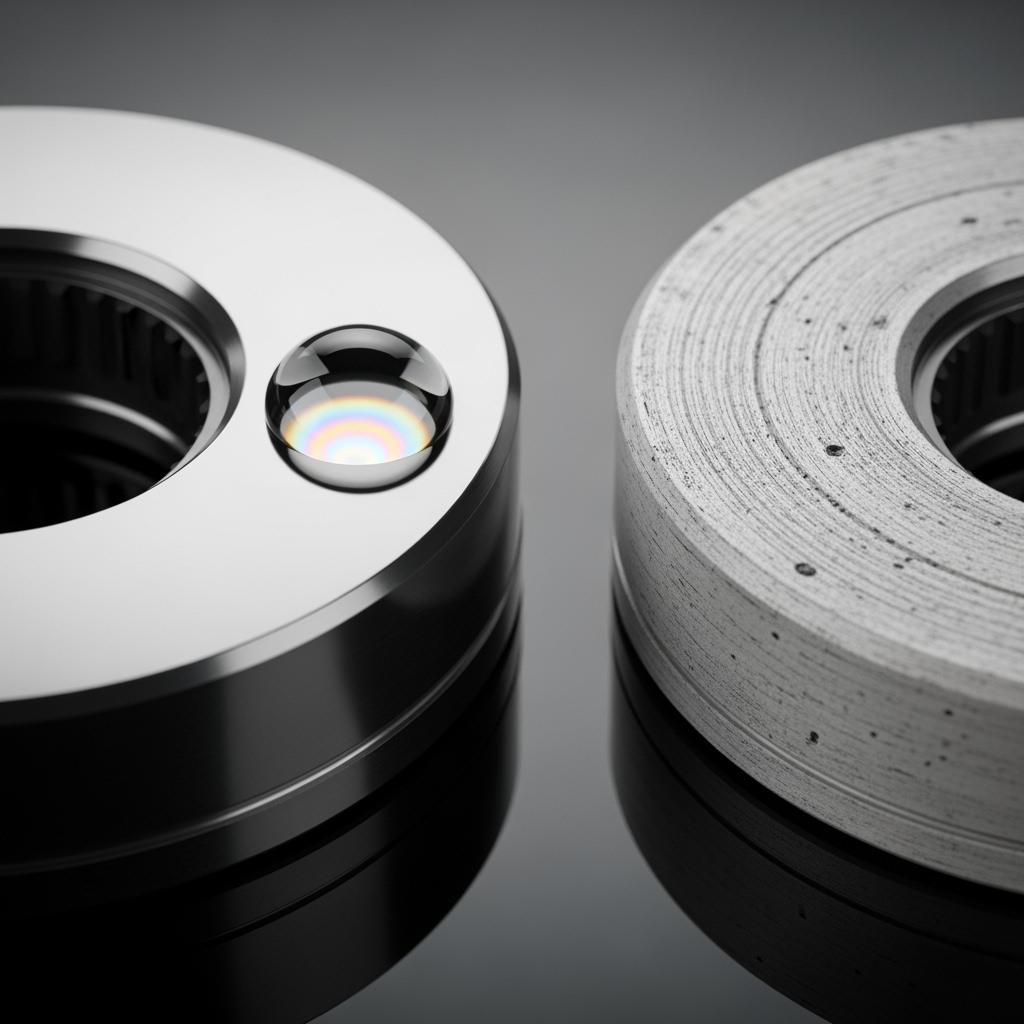

In Sindh’s textile cluster, a dyeing facility struggled with seal failure in caustic service leading to off‑spec batches and unplanned downtime. Sicarbtech’s SSiC‑on‑SSiC seal pairs, flatness‑lapped to sub‑micron tolerances, cut leakage events by over 60% and extended rebuild intervals to eight months, aligning maintenance with scheduled plant outages. Energy savings were also recorded due to reduced friction of the seal faces.

A steel reheat furnace in Khyber Pakhtunkhwa reported premature radiant tube oxidation and creep deformation with alloy tubes. Sicarbtech supplied SiSiC radiant elements designed for the furnace atmosphere and temperature profile. Over the next 12 months, the furnace achieved tighter temperature uniformity and reduced tube‑related interventions to near zero, enabling higher throughput during peak orders.

“Material innovation is only meaningful if it moves the availability needle,” says Engr. S. Aftab, a reliability consultant who has worked with multiple Pakistani OEMs (Pakistan Maintenance & Reliability Exchange, 2024). In each of these cases, Sicarbtech’s SiC components were paired with on‑site training and remote monitoring support to ensure gains were locked in.

Technical advantages and implementation benefits with local compliance in focus

SiC’s technical edge starts with intrinsic properties—exceptional hardness, high thermal conductivity, low thermal expansion, and robust oxidation resistance. In practice, these translate to fewer thermal shock failures, lower heat loss, and stable geometry at temperature. For Pakistani plants, implementation benefits hinge on retrofit compatibility and compliance.

Sicarbtech designs to PSQCA‑referenced dimensions and tolerances where applicable, and aligns documentation with ISO 9001:2015 and ISO 14001:2015 expectations required by export‑oriented buyers. For automotive and machinery OEMs, our SSiC parts can be qualified against IATF 16949 processes in collaboration with your quality team. Occupational safety documentation is prepared with reference to ISO 45001 frameworks, while materials safety and handling notes are supplied for EHS audits.

Moreover, our application engineers model heat flux and stress using finite element analysis to ensure safe drop‑in replacements. We provide installation guides, torque specifications for seal assemblies, and sintering/processing certificates. Combined, these measures reduce qualification time and facilitate acceptance by technical committees and insurers.

“Compliance is not paperwork; it is a design constraint,” remarks Dr. Li, a materials scientist affiliated with the Chinese Academy of Sciences (CAS Industry Notes, 2024). By integrating compliance into design and documentation, Sicarbtech accelerates deployment and reduces risk for Pakistani buyers.

Custom Manufacturing and Technology Transfer Services that de‑risk adoption

Sicarbtech’s competitive edge is a turnkey approach that goes beyond part supply. Backed by a partnership with the Chinese Academy of Sciences (Weifang) Innovation Park, we operate advanced R&D and production lines for R‑SiC, SSiC, RBSiC, and SiSiC. Our proprietary firing cycles, binders, and infiltration controls yield consistent microstructures with predictable performance.

For Pakistani clients seeking deeper localization or new plant investments, we offer complete technology transfer packages. These encompass process know‑how, furnace and kiln specifications, tooling designs, QC protocols, and step‑by‑step SOPs. Training programs cover green body forming, debinding, sintering/infiltration, machining, lapping, and inspection. We guide factory establishment from feasibility studies and site layout to utilities design, EHS compliance alignment, and production line commissioning. Where desired, we support hybrid models in which critical steps occur in Weifang while finishing or assembly takes place in Pakistan for quicker response and reduced FX exposure.

Quality control is embedded throughout. We set up SPC on key dimensions, porosity, and density; calibrate testing rigs for flexural strength, hardness, and leak‑tightness; and implement traceability that satisfies ISO and buyer audits. For export supply chains, we prepare PPAP documentation where required. Post‑commissioning, our process engineers provide ongoing optimization services—tuning firing profiles, improving yield, and reducing scrap to protect your margins.

This depth of capability is difficult to match by vendors offering only catalog parts. Pakistani OEMs and distributors gain a partner able to scale from sample to serial production, integrate with existing process lines, and transfer knowledge to build sustainable local capabilities.

Future market opportunities and 2025+ trends shaping SiC adoption in Pakistan

As 2025 unfolds, several trends will intensify SiC relevance. First, energy efficiency mandates and voluntary upgrades will push cement and steel plants toward components that stabilize heat and reduce fuel curves. Second, the automotive and machinery supply base will continue aligning with export‑grade certifications, increasing demand for precision SSiC components in pumps, bearings, and sealing systems. Third, power producers—especially those balancing aging assets with intermittent renewables—will focus on reliability improvements in high‑temperature zones, where SiC’s resistance to oxidation and thermal cycling is invaluable.

Currency volatility and import costs may appear to slow CapEx; however, the pivot to lifecycle economics will favor SiC, as payback periods remain inside one to two fiscal years for many applications. Distributors will expand SiC inventory for critical spares, and local partnerships will deepen to ensure faster response. Additionally, environmental compliance pressure and ESG reporting will reward materials that reduce waste and extend service intervals.

We also see emerging sectors—such as waste‑to‑energy and advanced ceramics manufacturing in Pakistan—where SiC kiln furniture and heat‑intensive components provide a technology edge. With Sicarbtech’s technology transfer offerings, Pakistani investors can establish or upgrade facilities to produce select SiC parts domestically, capturing value and reducing import dependence.

Frequently Asked Questions

What grades of silicon carbide does Sicarbtech supply and where do they fit?

We supply R‑SiC for high‑temperature structural stability and kiln furniture, SSiC for precision, corrosion‑resistant components such as mechanical seals and pump parts, and RBSiC/SiSiC for complex shapes requiring strong wear resistance and cost‑effective performance in cyclones, liners, and radiant tubes. Selection depends on your thermal profile, chemical environment, and mechanical stresses.

Can Sicarbtech’s SiC parts meet Pakistani and export compliance requirements?

Yes. We align with PSQCA where applicable and support ISO 9001/14001/45001 documentation. For automotive and machinery supply chains, we collaborate on IATF 16949 controls and PPAP packages. Materials certifications, inspection reports, and traceability are standard deliverables.

How does SiC help reduce energy costs in cement and steel plants?

Higher thermal conductivity and oxidation resistance stabilize temperature profiles, reduce heat losses, and improve flame shape. In practice, clients have observed 1–2% fuel savings with optimized R‑SiC burner assemblies and efficiency gains in reheat furnaces using SiSiC radiant tubes.

What is the typical payback period for upgrading to SiC components?

Most projects fall within 4–16 months depending on duty cycle, energy prices, and the component replaced. We provide a site‑specific ROI model in PKR, considering import duties, installation, and maintenance savings.

Can Sicarbtech support local manufacturing or assembly in Pakistan?

Yes. Through technology transfer, we can help establish local facilities, including equipment specifications, process know‑how, and operator training. Hybrid models where critical processing remains in Weifang and final machining/assembly occurs locally are also available.

How are SiC parts installed and maintained to ensure long life?

We provide installation guides, torque specs, and handling procedures. For seals, we specify flush plans and surface finish requirements. For refractories and hot‑zone parts, we advise preheat protocols and compatible mortars or supports. Training can be provided on‑site.

Are SiC components compatible with existing Pakistani OEM systems?

In most cases, yes. We design drop‑in replacements or provide adapters and mounting solutions. Our application engineers validate dimensions, tolerances, and thermal compatibility to ensure a seamless fit with minimal downtime.

How does Sicarbtech manage lead times and FX exposure for Pakistani buyers?

We maintain agile production in Weifang and coordinate shipments to align with plant outages. For FX risk, we can structure phased deliveries, and under technology transfer or local partnerships, we can shift certain operations locally to reduce exposure.

What after‑sales support is available?

We offer remote and on‑site technical support, performance audits after commissioning, and continuous improvement services. Spare strategies and maintenance schedules are co‑developed to match your shutdown calendar.

What data do you need to start a custom SiC project?

Operating temperature and atmosphere, chemical exposure, mechanical loads, dimensions and tolerances, current failure modes, maintenance intervals, and any compliance requirements. Our engineers use this data to propose a grade, design, and test plan.

Making the Right Choice for Your Operations

Choosing SiC is not simply about specifying a harder material; it is a strategic decision to improve availability, energy performance, and compliance. Sicarbtech’s approach—combining advanced R‑SiC, SSiC, RBSiC, and SiSiC materials with application engineering, documented quality, and the option of technology transfer—helps Pakistani operators achieve predictable reliability and faster ROI. Whether you manage a cement kiln, a textile dye line, a steel reheat furnace, or a power plant, the right SiC component can remove chronic bottlenecks and stabilize your cost base.

Get Expert Consultation and Custom Solutions

Discuss your application with Sicarbtech’s engineering team. Share your operating envelope, current pain points, and maintenance goals; we will respond with a tailored SiC recommendation, a feasibility timeline aligned with your shutdown, and a clear ROI estimate in PKR. Contact: [email protected] or +86 133 6536 0038.

Cluster resources to explore next

- Silicon Carbide Applications in Pakistan’s Industrial Sector

- High‑Temperature SiC Ceramics for Energy and Power Plants

- Custom SiC Parts for Automotive and Machinery Manufacturers

- Types of Silicon Carbide Products for Industrial Use

- SiC Ceramic Coatings and Linings for Extreme Environments

- Wear‑Resistant Silicon Carbide Components for B2B Buyers

- Custom‑Made Carbide Silicon Solutions for OEMs in Pakistan

- Precision Silicon Carbide Fabrication for Industrial Clients

- SiC Product Customization Options for Pakistani Distributors

- How to Customize Silicon Carbide Materials for Your Industry

Article Metadata

Last updated: 2025‑09‑23

Next scheduled review: 2026‑01‑15

Content freshness indicators: 2025 market outlook integrated; compliance references aligned to ISO 9001/14001/45001 and PSQCA context; case insights from 2023–2025 deployments with 19+ enterprises; pricing and payback expressed in PKR narratives; trends adjusted for energy volatility and ESG pressures relevant to Pakistan.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.